Spis treści

Essential Guide to Training 5S for Effective Workplace Organization

Would you be interested in implementing training 5S in your workplace? This guide covers the essentials you need to know. The 5S methodology was initially developed in Japan to enhance efficiency in manufacturing by adopting principles of orderliness and waste reduction. The term ‘5S’ comes from five Japanese words representing the methodology’s core principles. 5S helps you organize, clean, and maintain your workspace efficiently. From understanding the method of practical implementation tips, we’ve got you covered.

Key Takeaways

- The 5S methodology enhances workplace organization, boosts productivity, and promotes continuous improvement through systematic processes like Sort, Set in Order, Shine, Standardize, and Sustain.

- Adequate preparation and training for 5S implementation are essential. They should focus on establishing clear objectives, adhering to established standards, training leaders, and utilizing practical and engaging workshops to foster employee ownership.

- Regular audits and leadership involvement are critical for sustaining 5S efforts, addressing common challenges, and recognizing employee contributions to maintain motivation and drive continuous improvement.

Understanding 5S Methodology

The 5S methodology, a cornerstone of the Toyota Production System, is designed to organize workspaces, enhance efficiency, and maintain continuous improvement. It represents five Japanese words and embodies a Japanese concept:

- Seiri (Sort)

- Seiton (Set in Order)

- Seiso (Shine)

- Seiketsu (Standardize)

- Shitsuke (Sustain). This approach aligns with the kaizen philosophy and reflects the principles of Japanese management philosophy. The 5S methodology was influenced by Japan’s cultural emphasis on organization and efficiency, particularly in the post-World War II era.

This structured approach is not just about cleaning up but about creating a systematic approach to workplace organization that leads to an organized workspace and an improvement process that drives operational excellence through visual management.

Adopting the 5S methodology is a crucial step toward operational excellence. The focus is on organizing the workplace to enhance productivity, safety, and employee satisfaction. By eliminating waste, including non-value-added activities, 5S optimizes productivity, reduces waste, and improves employee morale through process improvements.

The scope of 5S implementation can range from small areas, such as desks or PCs, to larger spaces, including warehouses or production lines. This flexibility is significant for modern factories and other complex environments where maintaining order is critical. The methodology aims to foster an organized work environment, encourage employee ownership, and boost productivity.

5S improves productivity, quality, and safety, and significantly enhances team motivation. Achieving operational excellence is vital for creating a more efficient and effective work environment. Focusing on continuous improvement and improving efficiency, 5S helps organizations remain competitive in today’s rapidly changing business landscape, resulting in increased productivity, improved quality, and overall productivity. The success of 5S is also tied to fostering a strong company culture that values continuous improvement and employee involvement.

Benefits of 5S Implementation

Implementing the 5S methodology offers numerous benefits to organizations, including improved workplace efficiency, enhanced employee morale, and increased productivity. By creating a well-organized and clutter-free work environment, companies can reduce waste, improve quality, and promote a culture of continuous improvement. The 5S methodology is a key component of Lean manufacturing and the Toyota Production System, and its benefits are evident in various industries, ranging from manufacturing to software development.

One of the primary benefits of 5S implementation is the improvement of workplace productivity. By eliminating unnecessary items and organizing essential ones in a logical and accessible manner, employees can focus on their tasks without distractions, resulting in increased efficiency and productivity. Additionally, a well-organized work environment can improve employee morale, reduce stress, and promote a sense of pride and ownership among employees.

The 5S methodology also promotes a culture of continuous improvement, encouraging employees to contribute ideas and suggestions for further improvements. This leads to a culture of employee engagement, where employees are motivated to continually identify and solve problems, as well as improve processes and procedures. Regular audits and assessments are crucial for maintaining the benefits of 5S implementation and for identifying areas for further improvement.

Furthermore, the 5S methodology can help organizations reduce waste, improve quality, and enhance efficiency. By identifying and eliminating unnecessary items and processes, companies can streamline operations, reduce costs, and improve productivity. The 5S methodology is a valuable tool for organizations seeking to enhance their operations, improve their work environment, and foster a culture of continuous improvement.

Preparing for 5S Training

Preparing for 5S training begins with establishing the program’s scope and objectives. This foundational step sets the direction for the entire initiative. Clear goals ensure that everyone in the organization understands the purpose of 5S and its benefits for daily operations. This step involves identifying the necessary resources, planning equipment maintenance, and removing unnecessary items.

Training leaders is another key aspect of preparing for 5S implementation. Leaders manage the change within their teams, making their training integral to the success of the 5S initiative. Their buy-in is essential for fostering a culture of continuous improvement and ensuring that the 5S principles are consistently upheld throughout the organization. Leaders should motivate employees to engage with the 5S methodology. Team leaders play a crucial role in motivating employees and ensuring the successful implementation of 5S principles.

🎓 Curious how 5S tools work in practice? Explore our online course and discover real-world strategies that drive results.

Conducting Effective 5S Workshops

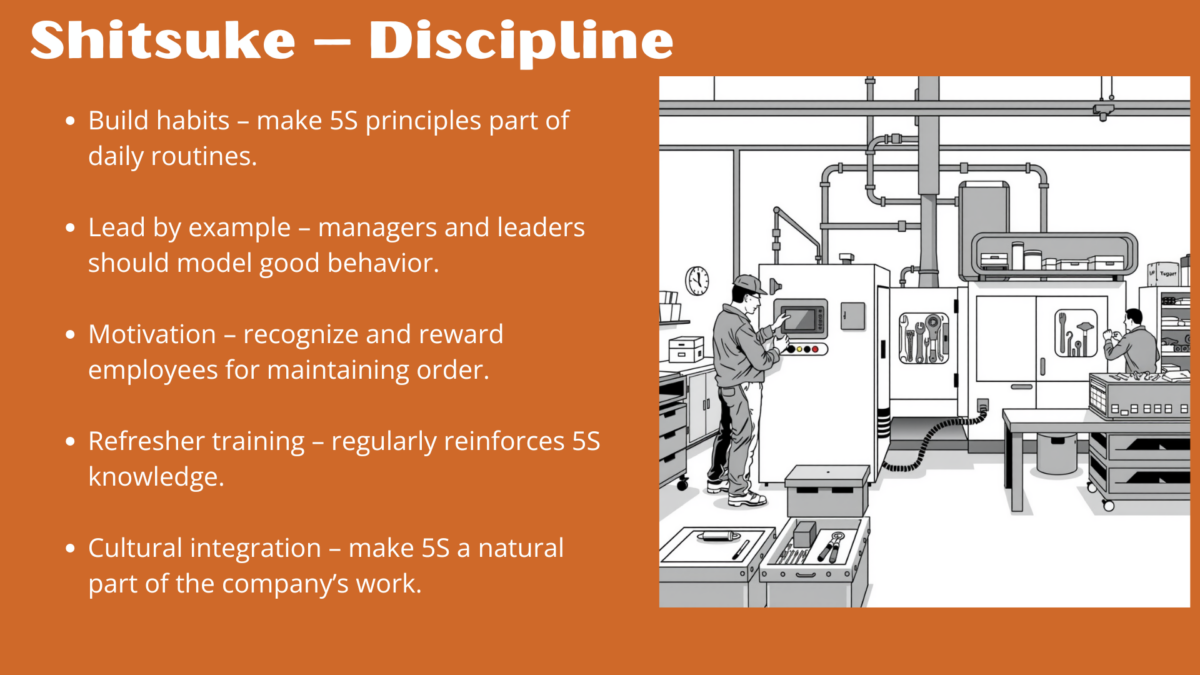

Sustainable improvement begins with discipline — Shitsuke is key to embedding training 5S practices into daily routines.

Practical 5S workshops ensure employees understand and can apply the 5S methodology in their daily tasks. These workshops should incorporate practical examples relevant to the industry’s operational context. Real-world scenarios connect content with practical applications, making the training more relevant and engaging for employees. Workshops should encourage employees to participate actively and take ownership of the 5S process.

Interactive elements, such as group discussions and hands-on activities, significantly enhance participant and employee engagement. Workshops can benefit from flexibility by incorporating various formats, such as virtual or self-paced, to cater to different learning styles and allow participants to contribute ideas. This approach ensures that all employees benefit from the training regardless of their preferred learning method. Additionally, kaizen events can be integrated into workshops to facilitate focused improvements and engage employees in continuous improvement activities.

Workshops should conclude with actionable takeaways to ensure employees can apply what they’ve learned immediately. This might include creating a checklist of tasks to implement the 5S principles in their work environment. Clear, actionable steps make employees more likely to adopt and sustain the 5S methodology, improving workplace productivity and organization.

Key Components of 5S Training Programs

The 5S methodology consists of five key components:

- Sort: This principle aims to eliminate clutter and optimize efficiency by separating necessary from unnecessary items. Effective sorting involves distinguishing between necessary and unnecessary items using visual markers, such as labeling or color-coding systems. The sorting process is crucial for maintaining organizational efficiency.

- Set in Order: This involves arranging items based on their frequency of use, ensuring everything has a specific location. Organizing remaining items for easy access helps reduce waste from excess motion, contributing to an efficient work environment.

- Shine: Promoting safety and responsibility, this principle requires operators to conduct thorough cleaning and inspection of tools and equipment. Regular cleaning and inspection help identify and address maintenance issues, which are crucial for improving quality and safety. A clean work environment improves safety and enhances productivity by reducing the time spent searching for tools.

- Standardize: This principle captures best practices for 5S and ensures consistent processes for maintaining the organization. Standardizing procedures helps improve quality by providing consistent practices and reducing variability. It also helps create a visual workplace where everyone knows their responsibilities and how to maintain the standards.

- Sustain: Sustaining the 5S methodology requires fostering a culture of continuous improvement and personal accountability. Regular training and reinforcement ensure that the 5S principles are upheld over time, leading to sustained improvements in workplace efficiency.

Implementing 5S in Different Industries

The 5S methodology is highly adaptable and can be implemented across various industries to improve efficiency and organization. In sectors such as IT and finance, implementing 5S emphasizes the organization of data and digital infrastructures. This minimizes wasted time and motion, creating a more efficient work environment. Implementing 5S helps streamline processes by organizing data and digital infrastructures, improving productivity.

In the apparel manufacturing industry, 5S enhances organization, facilitates the location of elements, creates a work space, and minimizes unnecessary motion, fatigue, and injuries. Adapting 5S across different sectors promotes efficiency, increased organization, and benefits both digital and physical environments. Implementing 5S in various sectors leads to improved productivity and operational efficiency.

This versatility makes 5S a valuable insights tool for any industry seeking to enhance operational efficiency.

Monitoring and Auditing 5S Performance

Regular audits and reviews are essential to ensure that the principles of 5S are consistently upheld and continually improved. These audits identify areas of strength and those that need improvement, providing a roadmap for further enhancing workplace efficiency. Sharing best practices discovered during audits helps maintain momentum in 5S initiatives. Regular audits ensure adherence to established standards, which is crucial for maintaining productivity and avoiding practices that hinder it.

Periodic audits, both internal and external, monitor 5S performance. Scheduled audits, such as quarterly or semiannually, ensure adherence to 5S practices. Involving both internal and external auditors enhances the effectiveness of these evaluations. Deviations from established standards can hinder productivity and should be addressed promptly.

Utilizing audit technology, such as digital checklists and the Kamishibai method, streamlines data collection and analysis. Detailed audit reports identify strengths and areas needing improvement within the 5S framework. This constant search for improvement ensures the organization remains committed to the 5S methodology, leading to long-term success.

Overcoming Common Challenges in 5S Training

Implementing 5S is not without its challenges. Here are some common challenges faced during 5S implementation:

- Insufficient training and education on 5S principles can hinder employees’ ability to implement and sustain the methodology effectively.

- Employee resistance to change can impede progress.

- A poor understanding of the 5S purpose can lead to ineffective application.

- Difficulties in maintaining new standards can arise over time.

Bad habits in the workplace can hinder productivity and need to be addressed through practical training and communication.

By addressing these challenges, organizations can enhance their chances of successfully implementing 5S and identify opportunities for improvement.

Clear communication channels are crucial for conveying the importance and objectives of 5S to employees. Organizations must adapt their 5S practices to changing business needs to avoid obsolescence. Effective communication, sufficient resources, and support all significantly contribute to the successful implementation of 5S initiatives. It is essential to encourage employees to embrace the 5S principles and overcome resistance to change.

🎓 Discover how 5S works in real companies. Enroll in our practical course and start transforming your workplace today: 👉 Start learning

Role of Leadership in 5S Training Success

Effective leadership is vital for embedding 5S into daily routines and ensuring long-term success. A lack of leadership support is a significant barrier to successful 5S implementation, as employees may not fully engage without management’s backing. Leaders should actively participate in 5S activities to reinforce their commitment and engage employees. Leaders should organize kaizen events to facilitate continuous improvement and engage employees in the 5S process.

Leaders should provide the necessary resources to support 5S implementation and work to remove any barriers that may hinder the process. Integrating 5S training with broader team development programs fosters a culture of continuous improvement initiatives.

Regular training and coaching on 5S principles play a crucial role as a key component in developing visual control leadership skills in team leaders, fostering self-discipline, and addressing essential items.

Using Technology to Enhance 5S Training

Technology significantly enhances 5S training. Mobile apps, digital signage, and production floor scoreboards support 5S training efforts. Mobile applications offer quick reminders, training resources, and interactive content to support 5S practices. Technology can also help in improving quality by providing real-time data and insights for better decision-making.

5S audit apps streamline the audit process by providing editable templates, saving time on report generation. Analytical features in these apps visualize inspection results over time, allowing organizations to identify trends and address recurring issues. Integrations with business intelligence tools, such as Tableau, enable comprehensive performance tracking and data analysis in 5S audits, helping to streamline processes and improve overall efficiency.

Recognizing and Rewarding 5S Achievements

Recognizing and rewarding employees for their contributions to 5S practices is crucial for maintaining motivation. Acknowledging achievements fosters a culture of excellence and motivates teams to maintain momentum in 5S implementation. Recognizing achievements helps encourage employees to maintain high standards and stay committed to the 5S principles.

Various methods recognize and reward employees, including digital signage on production floors displaying motivational messages and essential tips related to 5S. Non-monetary rewards, such as badges or certificates, effectively recognize outstanding contributions to the 5S initiative. Publicly celebrating successes reinforces positive behaviors and motivates employees to continue contributing to the 5S process.

Integrating 5S with Lean Manufacturing Principles

The 5S methodology supports Lean principles by ensuring a clean and organized environment, which is crucial for continuous improvement. Integrating 5S with Lean principles helps improve quality by eliminating waste and standardizing processes. The successful application of 5S leads to a culture of constant improvement, aligning with Lean manufacturing goals.

Integrating safety as the sixth S in 5S emphasizes the importance of a safe working environment, which is crucial for Lean manufacturing. By eliminating waste and optimizing processes, 5S promotes the systematic organization of workspaces, improved safety, and reduced downtime. Additionally, 5S helps streamline processes and enhance overall operational efficiency.

Real-Life Examples of Successful 5S Implementation

Real-life examples of successful 5S implementation highlight significant and incremental improvements. Two companies applied the 5S principles of kaizen to enhance their workplace efficiency and create a more organized environment. Kaizen events played a crucial role in the success of these companies by facilitating focused improvements and engaging employees in the 5S process.

These examples illustrate the practical benefits of 5S, including improved productivity, reduced waste, and increased employee morale. Adopting the 5S methodology enables organizations to achieve numerous benefits, including a more efficient work environment and a competitive edge in their respective industries.

Summary

The 5S methodology is a powerful tool for achieving operational excellence and maintaining an organized workplace. By understanding its principles, preparing effectively, and overcoming common challenges, organizations can successfully implement 5S and enjoy its many benefits. A strong company culture that values continuous improvement and employee involvement is essential for successfully implementing 5S.

Leadership plays a crucial role in the success of 5S training, and leveraging technology can enhance the effectiveness of training programs. Recognizing and rewarding achievements fosters a culture of continuous improvement, aligning perfectly with the principles of Lean manufacturing. Real-life examples demonstrate the significant improvements that 5S can bring to workplace efficiency and productivity.

🎓 Learn 5S the Way It Was Meant to Be Used – Practical, Powerful, Proven

Are you ready to stop reading about 5S and finally put it into practice to transform your organization?

With over 25 years of experience implementing Lean and 5S across leading manufacturing companies, I’ve designed a course that skips the fluff and delivers what truly works:

👉 The Fundamentals of 5S – Boosting Efficiency and Safety Throughout the Organization

This training is ideal for professionals seeking a comprehensive approach that combines theory with practical application. It’s built to help you apply 5S effectively—from day one.

What’s inside:

🎥 Watch on your schedule – On-demand video lessons available anytime

♾️ Never lose access – Lifetime entry to all content

🧰 Ready-made materials – Templates, checklists, and red tags you can use right away

📘 True understanding – Go beyond surface-level tips and discover the cultural roots of 5S in Japanese industry

👉 Start by previewing a free lesson and see how this course delivers practical, results-driven knowledge.

If you’re serious about making 5S work—not just learning about it—this course is your next step.

Frequently Asked Questions

What is the 5S methodology?

The 5S methodology is a structured approach to workplace organization that emphasizes five key steps: Sort, Set in Order, Shine, Standardize, and Sustain. This method is essential for enhancing efficiency and maintaining a tidy work environment.

Why is leadership important in 5S training?

Leadership is essential in 5S training. It ensures the integration of 5S principles into daily practices and facilitates long-term success by providing resources and overcoming obstacles.

How can technology enhance 5S training?

Technology can significantly enhance 5S training by utilizing mobile apps and digital signage to provide quick access to reminders and interactive training resources, thereby improving engagement and retention. Implementing these tools ensures a more effective and dynamic learning experience.

What are the common challenges in 5S implementation?

A successful 5S implementation often encounters challenges such as insufficient training, employee resistance to change, and difficulty maintaining new standards. Addressing these issues proactively is crucial for sustainable results.

How does 5S integrate with Lean manufacturing principles?

5S integrates with Lean manufacturing principles by fostering a clean and organized work environment, which helps eliminate waste and enhances continuous improvement initiatives. This alignment is crucial for achieving optimal operational efficiency.