Spis treści

Introduction to 5 S Lean and Its Origins

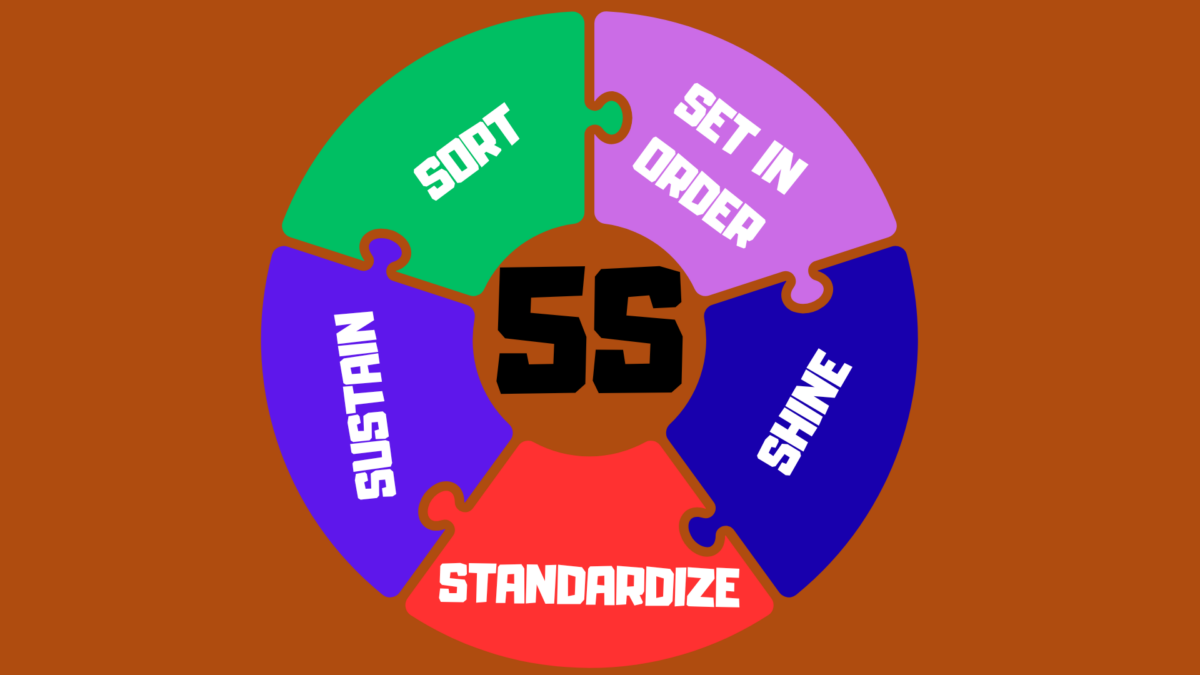

In the manufacturing industry, achieving continuous improvement and waste reduction is imperative. The 5 S Lean approach—derived from the Toyota Production System, pioneered by the Toyota Motor Company—provides a five-step process to create a highly organized and efficient visual workplace. This structured methodology focuses on eliminating waste as a core objective and is essential for organizing workplaces to achieve maximum efficiency and productivity. The importance of 5S lies in its ability to improve efficiency, safety, and organizational culture, making it a foundational tool in lean manufacturing. By systematically applying the five Japanese words—Seiri (Sort), Seiton (Set in Order), Seiso (Shine), Seiketsu (Standardize), and Shitsuke (Sustain)—organizations eliminate unnecessary items, reduce unnecessary motion, and optimize production processes. These Japanese terms have English counterparts (Sort, Set in Order, Shine, Standardize, Sustain), which make the methodology accessible globally.

Accelerate your transformation with hands-on tools and templates in our 5S Lean Training Course.

Sort: Clearing Clutter to Reduce Waste

The first Japanese word, Seiri (Sort), is the first step of the 5S methodology, targeting the removal of all unnecessary items, broken tools, and hazardous materials from the shop floor. A rigorous Sort phase:

- Frees up valuable space and necessary resources

- Cuts the wasted time spent locating tools and materials

- Exposes hidden inefficiencies in workflows

Best practice: Host a cross-functional Red Tag event to categorize items for retention, relocation, or disposal, and document the findings for future inventory decisions.

Set in Order & Shine: Building a Visual, Safe Workspace

Set in Order (Seiton)

Once clutter is cleared, Set in Order arranges the remaining items so every tool and component is easily accessible:

- Mount shadow boards for visual tool storage

- Apply visual cues and color-coded bins to designate fixed locations

- Map workstations to align with process flow, minimizing unnecessary motion

Shine (Seiso)

During Shine, teams perform regular maintenance and cleaning to maintain a clean and safe workplace environment:

- Daily wipe-downs, sweeps, and equipment checks

- Quick inspection logs to catch leaks or wear early

- Improved patient safety in healthcare-adapted 5S

Explore real-world Shine techniques in our 5S Lean Training Course.

Standardize: Embedding Consistency Across the Floor

Seiketsu (Standardize) codifies the processes of Sort, Set in Order, and Shine into a stable system, playing a crucial role in maintaining order across the workplace:

- Develop clear standardized work procedures and visual checklists

- Post SOPs and visual management boards at each station

- Conduct regular audits to track adherence and highlight improvement opportunities

Standardization is essential for sustaining the improvements made in previous steps by maintaining the standards and practices established through the 5S methodology. This phase helps ensure consistent working conditions for all employees, supporting ongoing efforts in maintaining order and discipline.

This phase transforms visual cues into a standard that all employees follow, ensuring a consistent visual approach across the organization.

Sustain: Fostering Self-Discipline and Engagement

The final step, Shitsuke (Sustain), focuses on fostering participation and self-discipline. Sustained effort is essential to keep 5S practices alive and effective over time:

- Celebrate 5S champions to boost employee engagement

- Schedule periodic 5S reviews integrated with daily huddles, and ensure that specific tasks are regularly completed to maintain organization and cleanliness.

- Integrate 5S performance into management reviews and KPIs

Sustain ensures that the gains from 5S are not one-time events but a core element of your organization’s culture. By embedding 5S into daily routines, workers benefit from easier, safer, and more efficient tasks, which support ongoing improvement and enhance workplace safety.

Applications of 5S: Beyond the Manufacturing Floor

While the 5S methodology was first developed as a key component of the Toyota Production System to revolutionize the manufacturing industry, its impact now reaches far beyond the traditional production floor. Organizations across healthcare, education, and government have adopted the 5S methodology to enhance workplace organization, eliminate waste, and foster continuous improvement in their respective environments.

In healthcare, for example, 5S is used to organize medical tools and supplies, ensuring that critical equipment is always easily accessible and that hazardous materials are properly managed, directly contributing to patient safety and operational efficiency. Educational institutions apply 5S principles to classrooms and administrative offices, reducing clutter and wasted time so that both teachers and students can focus on value-added activities. Even government agencies are adopting the 5S system to streamline processes, reduce unnecessary paperwork, and create a more productive work environment for employees and the public they serve.

Regardless of the sector, the 5S methodology offers a proven framework for reducing waste, enhancing organization, and fostering a culture of continuous improvement. By applying these principles beyond the manufacturing floor, organizations can unlock new levels of efficiency, safety, and quality in every aspect of their operations.

Integrating 5S Lean with Lean Manufacturing Principles

To maximize benefits, combine 5 S Lean with other lean manufacturing tools to help workers work efficiently and identify and reduce wastes:

- Value Stream Mapping: Pinpoint high-waste zones for targeted 5S application and save time by streamlining processes.

- Pull Systems: Use organized 5S cells as natural pull points.

- Kaizen Events: Leverage tidy, standardized areas for rapid improvement workshops that save time and reduce waste.

This integrated approach drives manufacturing excellence and optimizes productivity across production lines.

Measuring Success: Key Metrics

Track these indicators to quantify the impact of 5 S Lean:

- Search Time reductions for tools and components

- Audit Compliance rates on regular 5S checks

- Decrease in waste and excess inventory

- Improvements in production floor throughput

- Enhanced workplace safety and reduced incidents

Example Implementation Roadmap

- Leadership Alignment: Secure sponsorship and set clear objectives.

- Pilot Area: Run a Sort & Set in Order blitz in one cell.

- Shine Launch: Introduce daily cleaning and inspection routines.

- Standardize Rollout: Publish SOPs and dashboards across shifts.

- Sustainment Plan: Schedule audits, reward champions, and embed in PDCA cycles.

Get detailed guidance: Sign up for our 5S Lean Training Course and secure your template library and expert coaching.

Conclusion: Your Path to a Lean Future

Adopting the 5S Lean system is the first step toward a culture of continuous improvement and waste elimination. By following the five Japanese words—Seiri, Seiton, Seiso, Seiketsu, and Shitsuke—you will cultivate a productive work environment, elevate workplace efficiency, and set your organization on a trajectory of operational excellence.

Start transforming today with our 5S Lean Manufacturing Course!