5S Checklists: Your Complete Guide to Sustaining Workplace Excellence

Implementing the 5S methodology in any organization brings visible improvements: cleaner workspaces, better efficiency, and improved safety. However, maintaining these standards over time requires a consistent, structured approach. This is where a comprehensive guide like the 5S audit checklist becomes indispensable.

In this guide, you’ll learn:

- What are 5S checklists, and why do they matter?

- How to create an effective 5S checklist audit.

- What a professional 5S audit format should look like.

- How to effectively use a 5S audit sheet, 5S audit form, and 5S audit worksheet.

- Where to find and how to use free 5S checklist templates.

🎓 Want ready-made, practical 5S audit templates? Access our professional 5S training course and boost your workplace organization today!

Introduction to 5S

The 5S methodology is a systematic approach to creating an orderly environment that lays the foundation for enhanced operational efficiency and safety. Derived from five Japanese principles—Sort, Set in Order, Shine, Standardize, and Sustain—5S encourages employees to take ownership of their workspace and actively participate in maintaining a clean and organized environment. Implementing the 5S system may appear small and trivial initially, but it leads to significant results over time. The audit process instills a sense of discipline and accountability, improving employee morale and productivity. By adhering to the principles of 5S, organizations can ensure that their work areas remain organized, safe, and efficient.

What Are 5S Checklists?

5S checklists are structured evaluation tools used to systematically assess whether a workplace adheres to the standards of the 5S methodology:

- Sort

- Set in Order

- Shine

- Standardize

- Sustain

These checklists help evaluate specific workplace areas to ensure they meet the 5S standards.

Simple ‘pass/fail’ questions are a best practice for creating practical 5S checklists.

A good checklist:

- Breaks down expectations for each step.

- Provides a scoring or rating system.

- Encourages continuous improvement.

5S checklists help organizations sustain their 5S efforts by making assessments easy, regular, and objective.

Benefits of 5S

Conducting a 5S audit offers numerous benefits for organizations of all sizes. A 5S audit helps to ensure workplace cleanliness, which is fundamental for enhancing productivity and safety. A 5S audit helps identify areas for improvement and reduce waste, promoting a culture of continuous improvement and employee engagement. By standardizing processes and procedures, 5S audits improve workplace safety and reduce the risk of accidents. Additionally, they help to reduce costs and enhance productivity, fostering a sense of ownership and accountability among employees. Regular 5S audits are essential for maintaining a well-organized and efficient workspace and tracking progress. By consistently applying the 5S principles, organizations can achieve a safe, productive, and efficient work environment.

Understanding the 5S Principles

The 5S principles are the foundation of a well-organized and efficient workspace. These principles—sort, Set in Order, Shine, Standardize, and sustain—promote continuous improvement and employee engagement. By understanding and implementing these principles, organizations can identify areas for improvement, reduce waste, and optimize productivity.

- Sort: This principle involves removing unnecessary items from the workspace, ensuring that only essential tools and materials are easily accessible. By doing so, organizations can minimize waste and create a more efficient workspace.

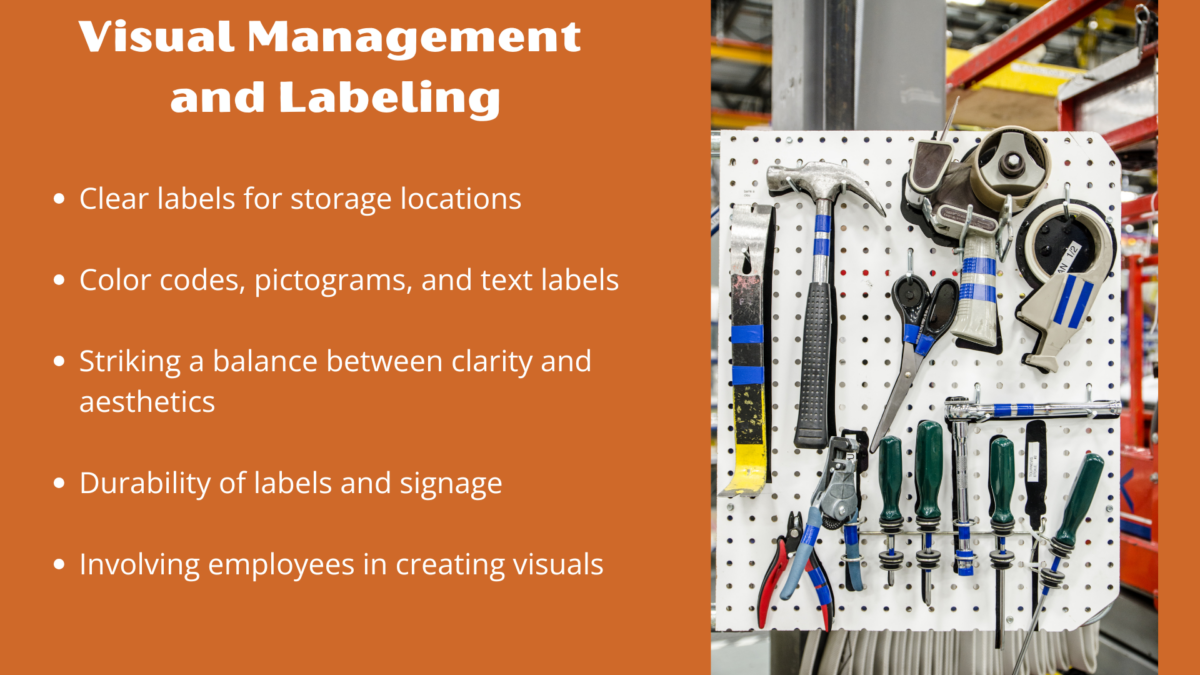

- Set in Order: This step organizes tools and materials to enhance the workflow. Visual cues and labeling help employees quickly locate their needs, saving time and reducing frustration.

- Shine: Regular cleaning and maintenance are crucial for a safe and efficient work environment. Establishing cleaning schedules ensures that work areas remain clutter-free and equipment is in good working condition.

- Standardize: Developing standard operating procedures (SOPs) and visual controls helps maintain consistency across the organization. This principle ensures that best practices are followed and the workspace remains organized.

- Sustain: The final principle emphasizes the importance of maintaining the improvements achieved through the first four steps. Regular audits and continuous training help sustain the 5S efforts and foster a culture of constant improvement.

Organizations can create a safe, productive, and efficient work environment by integrating these principles into daily operations.

Why Use a 5S Checklist Audit?

Performing a 5S checklist audit ensures:

- Accountability: Each area and team maintains agreed-upon standards.

- Visibility: Gaps and improvement opportunities become apparent.

- Consistency: Different areas apply the same high standards.

- Continuous improvement: Audits reveal minor issues before they become bigger problems.

Regular audits help monitor progress and maintain the results of a 5S audit.

Regular auditing using 5S checklists is a key strategy for embedding discipline and driving cultural change in Lean environments.

✅ Ready to systematize your workplace audits? Our 5S course includes customizable audit sheets and templates.

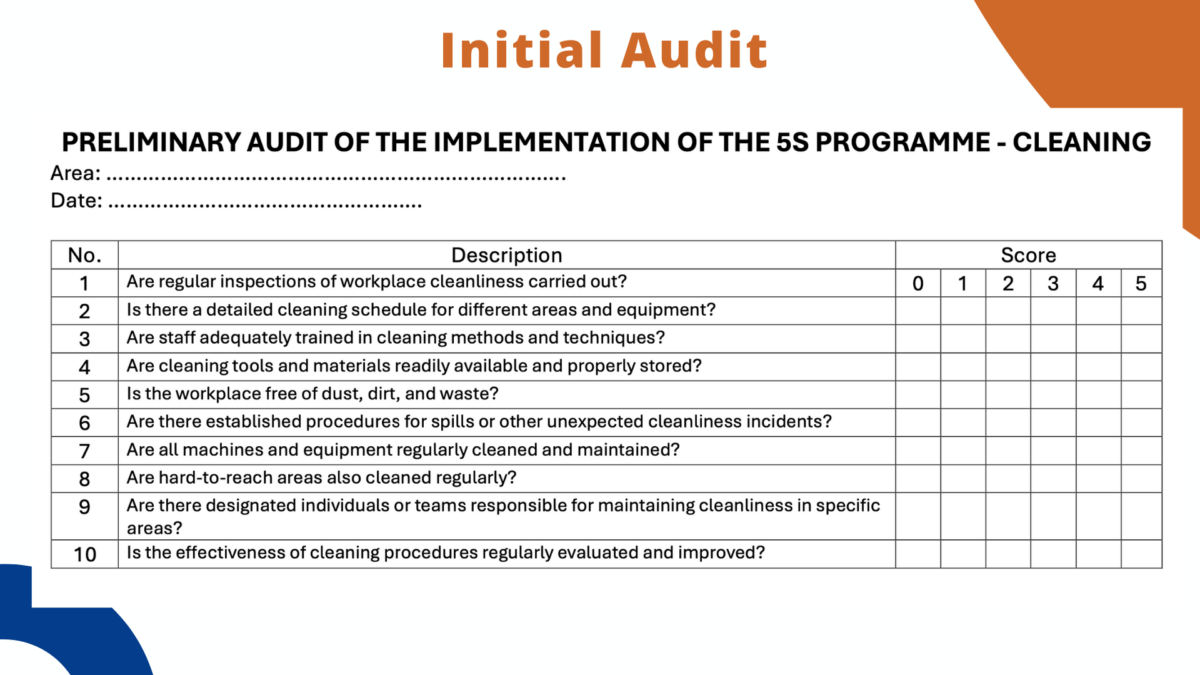

The Audit Process

The audit process is a critical component of the 5S methodology. It involves a systematic approach to assessing compliance with the 5S principles and identifying potential safety hazards. Regular audits using a comprehensive guide, such as a 5S audit checklist, ensure the workspace is organized and efficient.

A well-structured audit process includes:

- Specific Criteria: The checklist should include detailed criteria for evaluating each of the 5S principles. This ensures that all aspects of the workspace are thoroughly assessed.

- Documenting Findings: Auditors should report their findings, noting any areas that need improvement. This documentation provides valuable insights into the workspace’s current state.

- Identifying Areas for Improvement: Regular audits help identify areas for improvement. This proactive approach prevents minor issues from becoming larger problems.

- Tracking and Monitoring Progress: Organizations can conduct regular audits to track progress over time and assess the effectiveness of their 5S efforts.

Regular audits are essential for maintaining a safe and efficient workspace. They help organizations stay on track with their 5S goals and promptly address issues.

Components of an Effective 5S Audit Format

A good 5S audit format typically includes:

| Section | Details |

|---|---|

| Area to Audit | Specify the location (e.g., Assembly Line A). |

| Date and Time | For scheduling and tracking trends. |

| Auditor’s Name | Accountability and follow-up. |

| Audit Criteria | Questions tied to each of the 5S principles. |

| Scoring System | Numeric (e.g., 1–5) or qualitative (Good/Fair/Poor). |

| Comments | Room for observations and improvement ideas. This section is crucial for auditors to document findings effectively. |

| Action Plan | Take immediate corrective actions if needed. |

This standard format ensures clear documentation and easy comparison across teams and periods.

Using a 5S Audit Sheet or 5S Audit Form

A 5S audit sheet or 5S audit form is a physical or digital document containing the checklist items for inspection.

When conducting a 5S audit:

- Conduct a systematic walk-through of the area.

- Score each item based on defined criteria.

- Make notes for improvement opportunities.

- Discuss results with the team immediately after.

Consistency is key. That’s why using a standard 5S audit worksheet makes each audit fair and comparable.

Sample 5S Checklist Template

A 5S checklist template should be organized clearly by each “S”. Here’s an example:

Sort

- Are only the necessary items present, and have unnecessary items been identified?

- Are obsolete items red-tagged or removed?

Set in Order

- Does the frequency of use of tools and materials?

- Are locations visually labeled?

Shine

- Are work areas clean and free from dust and debris? Regular cleaning schedules are essential to keep the workspace clean and free from dust and debris.

- Are cleaning supplies accessible?

- Are cleaning schedules established and followed consistently?

Standardize

- Are standard operating procedures (SOPs) visibly posted?

- Are visual controls (e.g., floor markings, labels) in place?

Sustain

- Are 5S audits conducted regularly?

- Are actions from previous audits closed?

- Are audit results communicated to employees for effective corrective action and ongoing training?

📝 Need a plug-and-play 5S checklist sample? Download our free templates inside the 5S course.

Manufacturing 5S Audit Checklist

In a manufacturing environment, 5S audit formats must emphasize:

- Machine cleanliness and maintenance.

- Proper storage of tools and dies.

- Clear labeling of materials.

- Quick visibility of production status.

- Safety compliance in hazardous zones.

- Designated storage areas for essential tools and materials.

A manufacturing 5S audit checklist typically includes additional categories like machine uptime records, lubrication standards, and emergency equipment accessibility.

How to Build a 5S Audit Template for Your Organization

When creating a 5S audit template, follow these steps:

- Customize for your environment: Add questions relevant to the office, shop floor, warehouse, or healthcare.

- Use simple language: Avoid jargon.

- Add space for comments: Observations help drive improvements. Including visual evidence, such as photos or videos, can enhance the documentation and clarity of audit findings.

- Keep it concise: 1–2 pages maximum.

- Pilot before rollout: Test the form with a few audits and refine.

- Ensure proper implementation: Systematically identify opportunities for improvement by observing how effectively 5S and Kaizen principles are applied.

An excellent 5S audit worksheet scores performance and promotes conversations about continuous improvement.

Analyzing Results and Identifying Improvement Opportunities

Analyzing the results of a 5S audit is essential for identifying improvement opportunities and implementing changes. The audit results should be reviewed carefully to pinpoint recurring issues and areas that need attention.

Key steps in this process include:

- Reviewing Audit Results: Carefully analyze the audit findings to identify patterns and recurring issues. This helps you understand the root causes of problems.

- Addressing Recurring Issues: Any recurring issues should be addressed promptly to prevent them from affecting productivity and safety. This may involve implementing new processes or procedures.

- Implementing Changes: Based on the audit results, make targeted changes to the workspace. This could include reorganizing storage locations, providing additional employee training, or physically changing the workspace.

- Monitoring Improvements: After implementing changes, monitor the workspace to ensure practical improvements. Regular follow-up audits can help track progress and ensure the changes are sustained.

By analyzing audit results and identifying areas for improvement, organizations can make targeted changes that positively impact their operations.

Implementing Changes and Integrating with Other Systems

Implementing changes and integrating the 5S methodology with other systems is critical for sustaining improvements. This involves developing standard operating procedures, establishing cleaning schedules, and creating visual controls to remind employees of their responsibilities.

Steps to ensure successful implementation include:

- Developing SOPs: Standard operating procedures provide clear guidelines for employees, ensuring task performance consistency. This helps maintain the improvements achieved through the 5S process.

- Establishing Cleaning Schedules: Regular cleaning schedules ensure the workspace remains clean and organized. This helps prevent the buildup of clutter and maintains a safe work environment.

- Creating Visual Controls: Visual controls, such as labels and floor markings, help employees quickly identify where items belong. This reinforces the principles of 5S and makes it easier to maintain an organized workspace.

- Integrating with Other Systems: The 5S methodology can be integrated with other management systems, such as quality or environmental management systems. This comprehensive approach ensures that all aspects of the organization are aligned and working towards common goals.

By systematically implementing changes, organizations can ensure their workspace remains organized, efficient, and safe.

Best Practices for 5S Implementation

Best practices for 5S implementation include creating a comprehensive 5S audit checklist, conducting regular audits, and using digital tools to automate reporting. The 5S audit checklist should consist of essential items such as sorting, setting in order, shining, standardizing, and sustaining. Tailor the checklist to the organization’s specific needs and use it to assess compliance with 5S standards. By following best practices for 5S implementation, organizations can optimize productivity, reduce waste, and maintain a clutter-free and efficient workspace. Regular audits and automated reporting help to track progress and identify areas for improvement, ensuring that the workplace remains clean, organized, and safe.

Common Challenges and Solutions

Despite the many benefits of the 5S methodology, organizations may face several common challenges when implementing it. One of the most significant challenges is ensuring employees are engaged and committed to the process.

Solutions to common challenges include:

- Providing Training and Education: Educate employees on the 5S principles and the benefits of the methodology. This helps build understanding and commitment to the process.

- Recognizing and Rewarding Contributions: Recognize and reward employees who contribute significantly to the improvement process. This fosters a sense of ownership and encourages continued engagement.

- Maintaining Momentum: Sustaining improvements over time can be challenging. To maintain momentum, conduct regular audits, track progress, and adjust the process as needed.

- Addressing Resistance to Change: Some employees may resist changes to their routine. Address this by involving them in the process and demonstrating the benefits of the 5S methodology.

By being aware of these common challenges and having solutions in place, organizations can overcome obstacles and achieve the full benefits of the 5S methodology. Regular audits and continuous improvement efforts help maintain a clean, organized, efficient workspace.

By following these guidelines, the new sections will seamlessly integrate into the existing article, providing a comprehensive and reader-friendly guide to sustaining workplace excellence through the 5S methodology.

Where to Find Free 5S Checklist Templates

You can find free 5S checklist templates from:

- Lean manufacturing websites.

- Educational institutions offering Lean resources.

- Professional organizations like SME and ASQ.

- Some consultants’ blogs and toolkits.

However, beware—many free templates are overly generic.

Use free templates as a base for best results, then customize to your organization’s processes, standards, and layout.

🎯 Want editable, expert-level templates for immediate use? Our 5S course provides real-world examples and custom formats.

How to Implement a Successful 5S Checklist Audit Program

- Train auditors: Ensure they understand 5S principles, not just scoring.

- Schedule audits consistently: Weekly, bi-weekly, or monthly.

- Publish results: Celebrate improvements, address low scores constructively.

- Involve employees: Everyone should understand the purpose of the audits.

- Review and adjust: Continually refine your audit sheets based on experience.

- Audit new processes: When new methods, equipment, or workstations are introduced, ensure they align with 5S principles to maintain workplace efficiency.

Consistency is more important than perfection. The goal is a steady cycle of checking and improving.

Frequently Asked Questions

What is a 5S checklist?

A checklist is a structured tool for systematically assessing adherence to the five key principles of 5S workplace organization.

How often should 5S audits be conducted?

Ideally, short audits should be conducted weekly or bi-weekly, with more detailed audits monthly or quarterly.

Can I create my 5S checklist?

Absolutely! You can start with a 5S checklist sample or free 5S checklist templates and customize them for your workplace.

Final Thoughts: 5S Checklists Are the Backbone of Sustainable 5S Programs

A clean and organized workplace doesn’t happen accidentally—it requires discipline, visibility, and continuous follow-up. 5S checklists make this possible.

By using a well-designed 5S audit form, 5S audit worksheet, or manufacturing 5S audit checklist, you create a structured pathway to workplace excellence. Analyzing the results of these audits can provide valuable insights into the workplace’s current condition, guiding proactive improvements.

Start simple. Audit regularly. Improve continuously.

🎓 Want Ready-to-Use 5S Checklists and Audit Templates?

If you’re serious about applying 5S in your organization and sustaining it for the long term, I invite you to join my online course:

👉 The Fundamentals of 5S – Boosting Efficiency and Safety Throughout the Organization

In the course, you’ll get:

- 🎥 VoD format – Access anytime, anywhere.

- ♾️ Lifetime access – Perfect for refreshing knowledge when needed.

- 📄 Downloadable 5S audit forms, checklist templates, and worksheets.

- ⏳ Self-paced learning – Learn at your speed, individually or in teams.

👉 Plus, you can preview a free lesson and see firsthand how actionable and practical our approach is!

Master 5S audits, build discipline, and drive continuous improvement—starting today.