What is the 5S Methodology and 5S examples?

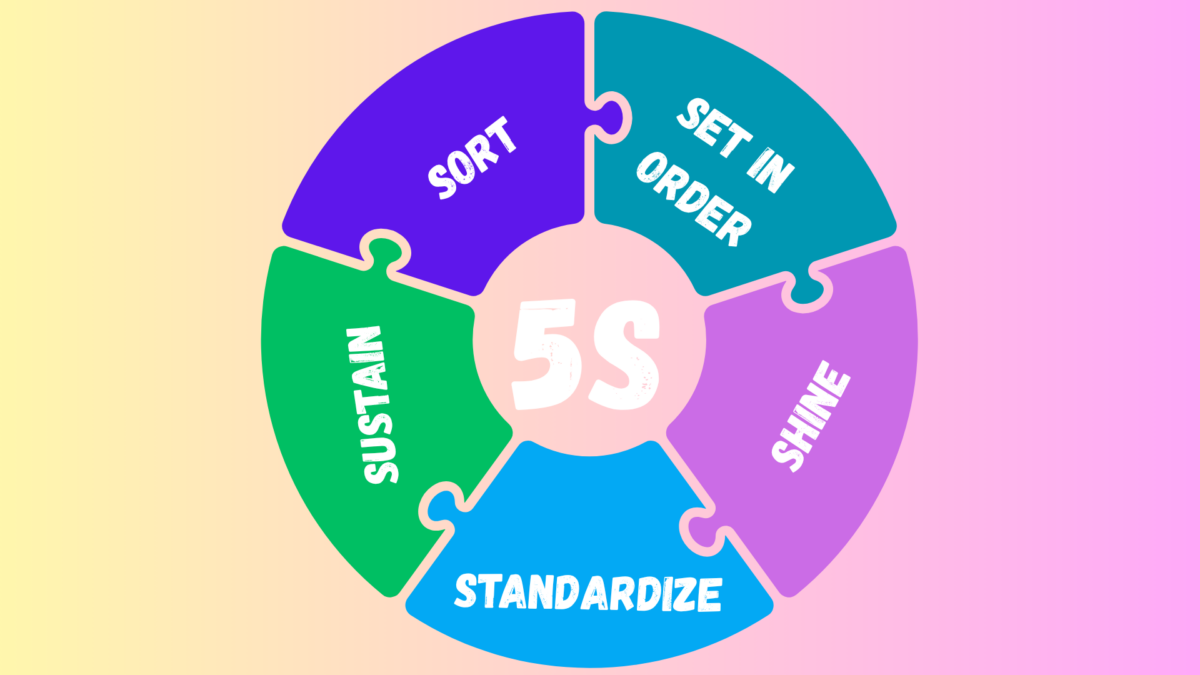

The 5S methodology is a foundational tool of Lean Manufacturing, derived from five Japanese words: Seiri (Sort), Seiton (Set in order), Seiso (Shine), Seiketsu (Standardize), and Shitsuke (Sustain). It focuses on workplace organization, eliminating waste, and promoting continuous improvement through a clean, efficient, and well-structured environment. It is not just about cleanliness, but about building a culture that enhances workplace safety, boosts employee engagement, and drives manufacturing excellence.

Real-World 5S Examples in the Manufacturing Industry

Example 1: Automotive Plant – Visual Controls and Shadow Boards

A leading car manufacturer adopted the 5S methodology as part of its implementation of the Toyota Production System. One immediate success was the introduction of shadow boards for tools on the shop floor. This allowed workers to instantly identify unnecessary items and ensure essential items were always easily accessible. The visual controls reduced time searching for tools, improving productivity by over 20% in just three months.

Example 2: Electronics Company – Red Tags and Initial Implementation

During the initial implementation, an electronics manufacturer conducted a comprehensive assessment of its workplace, identifying non-essential items and tagging them using the red tag method. This helped remove unnecessary materials, streamline daily operations, and ultimately improve employee morale.

Office 5S Example – Organizing Office Equipment

The 5S methodology isn’t limited to factories. One multinational organization applied 5S principles to its back office. Teams sorted through office equipment, removed broken or outdated items, and reorganized storage spaces using color coding. This organized working environment led to improved focus, fewer distractions, and measurable increases in efficiency and employee well-being.

Cross-Departmental Success Through Project Management

With the help of project management principles, a 5S implementation team in a food processing company involved key stakeholders from operations, maintenance, and quality assurance. By fostering open communication, they created clear 5S standards that ensured sustained improvements across the business. Regular cleaning materials checklists and daily red tag reviews were introduced to maintain consistency.

Benefits of 5S Across Different Industries

- In the manufacturing industry, the 5S methodology enhances safety, productivity, and quality.

- In healthcare, it helps reduce fluid leaks and boosts patient safety.

- In offices, it minimizes time spent searching for files and enhances company culture.

Regardless of the industry, 5S examples demonstrate that a structured workplace promotes continuous improvement, reduces waste, and enhances employee buy-in.

From Examples to Implementation

To effectively implement 5S in your organization, it’s essential to learn from others’ successes. Our comprehensive course “👉 The Fundamentals of 5S – Boosting Efficiency and Safety Throughout the Organization” includes real-life 5S examples from different industries. You’ll gain a deeper understanding of:

- Red tagging and identifying remaining items

- Creating easily accessible storage zones

- Applying color-coded visual tools

- Structuring a sustain phase with audits and leadership support

🎯 Want hands-on experience? Try our Lean Simulation Game, where your team can practice 5S in a dynamic, interactive format: 👉 GET LEAN Simulation Game

Conclusion

5S methodology is not just a theory—it’s a proven system with measurable results. Whether you’re managing a manufacturing floor, organizing office equipment, or leading a project management initiative, 5S can bring numerous benefits. These 5S examples are just a glimpse into what’s possible when an organization commits to structured workplace practices, ongoing employee engagement, and a culture of continuous improvement.

Start your journey with the tools and training that have helped others achieve real results: 👉 Enroll in our 5S Course Now