Introduction: The Power of the 5S System in Lean Manufacturing

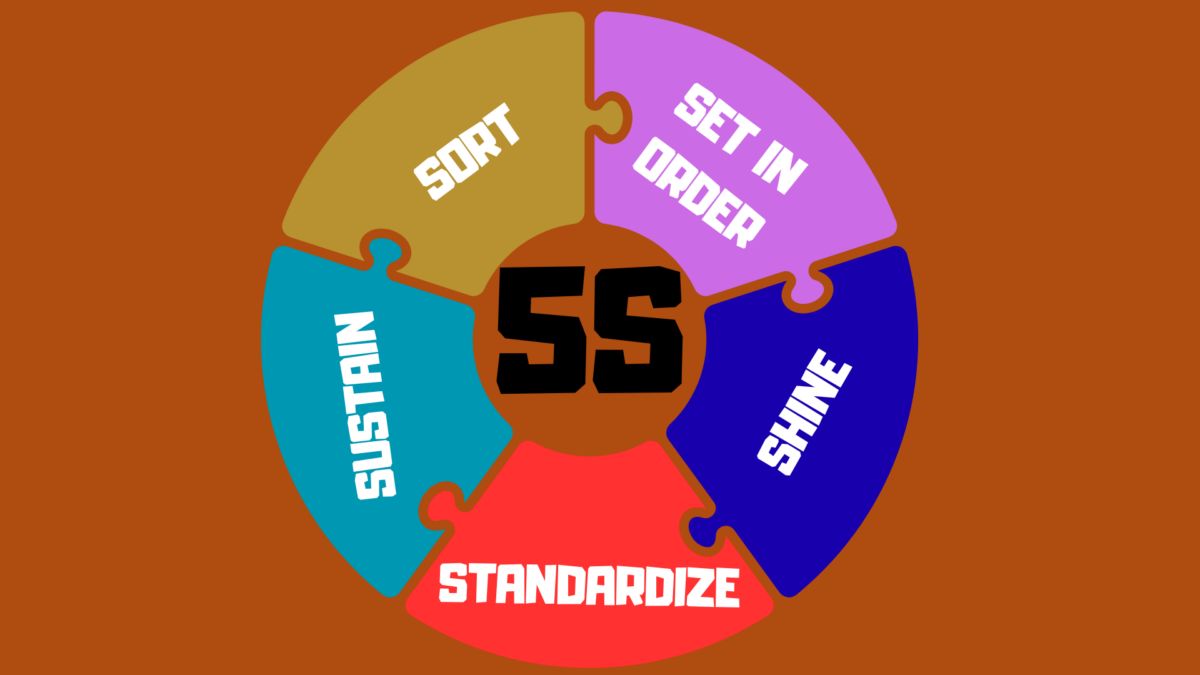

In the manufacturing industry, embracing the 5S system lean manufacturing methodology is indispensable for achieving continuous improvement, eliminating waste, and building a truly visual workplace. Originating from the Toyota Production System, which was pioneered by Toyota Motor Company, the 5S System—Seiri (Sort), Seiton (Set in Order), Seiso (Shine), Seiketsu (Standardize), and Shitsuke (Sustain)—provides a comprehensive approach to workplace organization and efficiency that transforms chaotic shop floors into highly efficient workplaces.

While 5S began in manufacturing, it has since been adopted by many organizations beyond this sector. Its successful application in other industries, such as healthcare, offices, and government, demonstrates its broad versatility. 5S supports overall productivity, safety, and efficiency in any work environment.

Begin your transformation with our hands-on Fundamentals of 5S Course, complete with templates, real-world case studies, and expert coaching.

Origins of 5S: From Japanese Roots to Global Best Practice

The 5S methodology originated in Japan, where it was developed as a foundational element of the Toyota Production System—a pioneering approach to lean manufacturing. The name “5S” is derived from five Japanese words: seiri (sort), seiton (set in order), seisō (shine), seiketsu (standardize), and shitsuke (sustain). These principles were designed to create a workplace organization method that would streamline the manufacturing process, reduce waste, and foster a culture of continuous improvement.

Initially, 5S was implemented on the manufacturing floor to optimize productivity and eliminate waste by ensuring that only what is needed is kept in the workspace and everything has its proper place. Over time, the effectiveness of the 5S methodology in improving process performance and work environment led to its adoption beyond manufacturing, spreading to industries such as healthcare, education, and government. Today, 5S is recognized globally as a best practice for workplace organizations, supporting lean manufacturing practices and driving process improvement in diverse settings. The enduring power of the five Japanese words lies in their universal focus on creating a clean, efficient, and safe environment that supports both people and processes.

Sort: Clearing Clutter to Reduce Waste

The first Japanese word, Seiri (Sort), tackles all unnecessary items and broken tools on the manufacturing floor:

- Action: Conduct a cross-functional red tag event, using red tags to identify and tag items of uncertain value or infrequent use, and then segregate items into “keep,” “store,” or “discard.”

- Impact: Frees up valuable space, eliminates wasted time searching for tools, and lays the foundation for a lean workflow.

- Lean Principle: Eliminating waste in production processes by removing excess motion and obsolete materials.

Set in Order: Crafting a Visual Factory

Next, Seiton (Set in Order) arranges the remaining items so that every tool, part, and material has a fixed, easily accessible location:

- Visual Communication Tools: Use shadow boards, floor markings, and visual cues to designate storage and pathways. A properly organized workspace ensures tools and materials are arranged to maximize workflow and safety.

- Efficiency Gains: Reduces unnecessary motion, speeds up cycle times, and ensures the right tools are always at hand.

- Building Participation: Involves frontline employees in layout design to boost employee engagement and adoption.

Optimize your layout with advanced techniques in our 5S Lean Manufacturing Course.

Shine: Maintaining Cleanliness and Quality

Seiso (Shine) combines regular cleaning tasks with equipment inspections to maintain a workplace clean and safe:

- Routine Maintenance: Basic cleaning activities such as dusting, sweeping, and mopping are essential to the Shine phase, helping to keep the workspace organized and clean. Develop daily checklists to wipe, sweep, and inspect machines for wear or leaks.

- Safety Benefits: Regular maintenance is crucial for preventing equipment breakdowns and reducing downtime while also identifying hazardous materials or spills that could cause injury, thereby enhancing workplace safety.

- Quality Uplift: Early detection of defects prevents downstream quality issues, improving overall quality.

Standardize: Embedding Best Practices

The fourth step, Seiketsu (Standardize), codifies your Sort–Set–Shine gains into uniform procedures:

- Visual Management: Post audit checklists and SOPs at each station, use visual controls to track compliance, and establish regular tasks and scheduled responsibilities to ensure ongoing adherence to 5S standards.

- Training: Integrate 5S into onboarding for new employees, ensuring the core elements of the 5S System are consistently applied.

- Change Management: Update standards as processes evolve, supporting process development and further improvements.

Sustain: Cultivating Self-Discipline and Culture

Finally, Shitsuke (Sustain) makes 5S an ingrained habit:

- Regular Audits: Conduct weekly or monthly reviews against standardized checklists. Sustaining 5S is a team effort that requires active participation from managers and employees across all departments.

- Recognition & Rewards: Celebrate teams and individuals who consistently maintain high 5S scores to foster positive employee morale.

- Continuous Improvement: Link audit results to Kaizen events and drive lean manufacturing practices across shifts.

5S and Safety: Building a Safer Workplace

Safety is an integral part of the 5S methodology, often referred to as the “sixth S” due to its critical role in creating a secure work environment. By systematically organizing tools and equipment and maintaining regular cleaning routines, 5S helps to identify and eliminate potential hazards before they can cause harm. Visual communication tools—such as floor markings, color-coded signs, and clear labels—play a vital role in alerting employees to safety zones, walkways, and danger areas, ensuring that everyone on the production floor is aware of their surroundings.

Regular cleaning and inspection, as emphasized in the “shine” step, not only keeps the workplace clean but also helps prevent accidents related to slips, trips, and equipment malfunctions. Employees are encouraged to take responsibility for their workspaces and report any safety concerns or issues with tools and equipment promptly. This proactive approach to safety, embedded within the 5S methodology, leads to fewer incidents, improved morale, and a more productive and efficient workplace overall.

Integrating 5S with Broader Lean Principles

Lean manufacturing utilizes many tools, including 5S, kaizen, kanban, jidoka, heijunka, and poka-yoke, to drive efficiency, reduce waste, and maintain organized, safe work environments.

The 5S System is most powerful when combined with complementary lean tools:

- Value Stream Mapping pinpoints waste hotspots for targeted 5S applications.

- Pull Systems (Kanban) leverage organized work cells to signal demand.

- Six Sigma Collaboration uses a 5S foundation to support process capability and quality control.

- AI-driven analytics powered by artificial intelligence can monitor 5S compliance metrics—such as tool availability and cleaning frequencies—to prompt real-time alerts and drive innovation in process improvement.

Real-World Example: Automotive Industry Application

At a leading automotive industry plant, 5S was applied to optimize the production process on one production line and achieved:

- 40% reduction in wasted time locating parts

- 25% decrease in workplace incidents via early hazard detection

- 15% increase in overall output after three months

This classic example demonstrates the transformative power of 5S when aligned with lean principles and robust visual management.

Measuring Success: Key Performance Indicators

To quantify your 5S System impact, track:

- Search Time: Average minutes employees spend locating tools

- Audit Compliance: Percentage of work areas meeting 5S standards

- Safety Incidents: Reduction in near-misses related to clutter

- Throughput: Improvement in units produced per labor hour

- Employee Engagement: Survey scores on engagement and well-being

Common Challenges and Solutions in 5S Implementation

While the benefits of 5S are clear, organizations often encounter challenges during the implementation process. Common obstacles include limited employee engagement, inadequate training, and insufficient management support. To address these issues, it’s essential to foster a culture of continuous improvement and lean manufacturing from the top down. Management should actively participate in 5S activities, demonstrating commitment and setting expectations for the entire team.

Providing thorough training on the 5S methodology, including the use of visual management tools and audit checklists, helps employees understand both the “why” and the “how” of 5S. Stream mapping can be used to visualize current processes and identify areas where further improvements are needed. Regular feedback sessions and audits encourage employee engagement, allowing team members to contribute ideas and take ownership of the process. By addressing challenges directly and equipping employees with the necessary tools and resources, organizations can overcome resistance and achieve lasting improvements in safety, productivity, and process performance.

5S Training and Resources: Empowering Your Team for Success

Empowering your team with practical 5S training is a critical step toward building a culture of lean manufacturing and continuous improvement. Comprehensive training programs can include classroom sessions, online courses, and hands-on workshops that cover the five Japanese words and their practical application in the workplace. These programs should also highlight the benefits of waste reduction, process improvement, and safety, ensuring that every employee understands the value of the 5S methodology.

To support ongoing learning, organizations can provide access to books, articles, videos, and other resources that reinforce key concepts and best practices. Recognizing and rewarding employee contributions to 5S implementation further boosts engagement and motivation. Regular refresher courses and workshops help maintain momentum, ensuring that 5S principles remain embedded in daily routines and organizational culture. By investing in training and resources, companies can equip their teams to drive process improvements, reduce waste, and create a safer, more efficient workplace for everyone.

5S Beyond Manufacturing: Adapting to Any Industry

The systematic approach of 5S, which originated on the shop floor in manufacturing environments, now extends to many other industries:

- Healthcare: Enhance patient safety by organizing medical supplies.

- Offices: Create a clutter-free digital and physical workspace for knowledge workers, improving work processes by organizing workflows and reducing inefficiencies.

- Food & Beverage: Ensure hygiene and maintain traceability in kitchens and storage areas.

- Logistics: Optimize warehouse flows with clear visual factory zones.

It is essential to note that the original concept of seiketsu in 5S emphasizes maintaining hygiene and cleanliness, rather than merely standardization.

Conclusion: Your Pathway to a Lean, Visual Workplace

The 5S System of Lean Manufacturing is your blueprint for a safe, efficient, and visually organized workplace. By systematically applying Sort, Set in Order, Shine, Standardize, and Sustain—and integrating lean tools—you will unlock significant benefits: reduced waste, improved productivity, and a culture of continuous improvement.

👉 Take action now: Enroll in the Fundamentals of 5S Course to access complete training, templates, and expert support.