Understanding 5S Training and Its Role in Lean Manufacturing

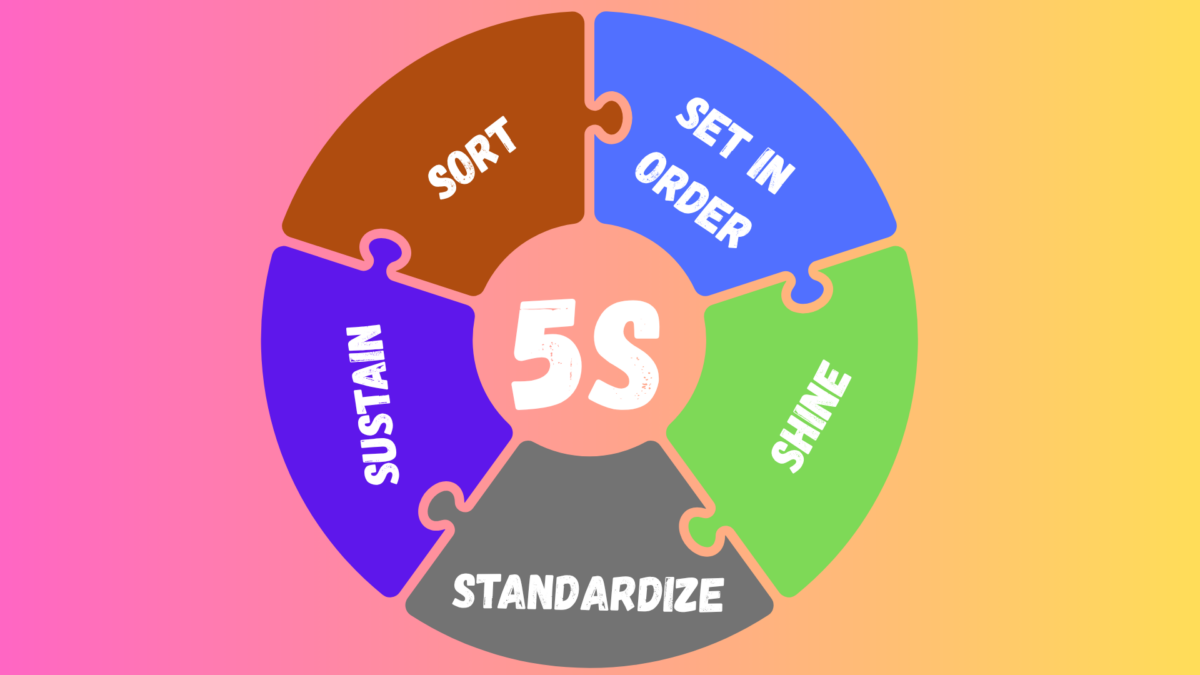

5S training is the backbone of successful lean manufacturing systems and serves as a starting point for implementing continuous improvement in organizations across industries. Originally developed as part of the Toyota Production System, the 5S methodology was created to improve organization and efficiency in manufacturing. This method is part of a family of methodologies used in workplace organization. These principles—Sort, Set in Order, Shine, Standardize, and Sustain—are not just steps but a cultural shift that transforms the way teams operate and solve problems. The 5S concept is rooted in Japanese continuous improvement philosophies, and understanding these core concepts is essential for effective implementation. The foundations of 5S provide the basic structural elements necessary for establishing stability and consistency in lean manufacturing.

By teaching employees how to identify and eliminate unnecessary items, establish visual management standards, and maintain consistent routines, 5S training promotes operational excellence, employee engagement, and long-term workplace efficiency. Through 5S training, employees develop the knowledge and skills needed to support continuous improvement. Companies that provide structured 5S training often experience gains in productivity, quality, and safety.

Why Is 5S Training Critical for Organizational Success?

Modern businesses, especially in the manufacturing industry, rely on efficient workflows and minimal waste. Here’s how 5S training delivers key results:

- Supports a continuous improvement culture across departments

- Reduces downtime caused by disorganization or missing tools. Providing necessary resources, such as cleaning utensils and standardization tools, is essential for successful 5S implementation.

- Enhances employee morale by fostering a safer and more organized environment. An organized workspace is crucial for efficiency, waste reduction, and helping employees stay focused.

- Encourages accountability and teamwork. Leaders must actively manage the 5S process to ensure its sustainability and ongoing improvement.

- Aligns with broader lean strategies like value stream mapping and standard work

These benefits are significant in production lines, warehouses, healthcare environments, and offices where inefficiency can be costly.

Step-by-Step Breakdown of 5S Training

To ensure effective implementation, organizations should develop a tailored 5S training program that addresses their specific needs and requirements. 5S training is broken down into simple steps, making it easy for teams to follow and implement. Before starting 5S training, it is essential to prepare teams and resources to maximize success.

A comprehensive 5S training course typically includes the following modules:

The first step in 5S is crucial for setting the foundation for the rest of the process.

[…module breakdown remains unchanged…]

The last step in 5S focuses on sustaining improvements and standardizing practices.

Sort (Seiri)

Employees learn how to:

- Separate necessary and unnecessary items

- Use red tags to mark items for review

- Create space and reduce clutter

- Organize the work area to ensure efficiency and maintain a safe, orderly environment

Workers play a crucial role in organizing and sorting items, which helps maintain a productive and efficient work area.

Set in Order (Seiton)

This phase focuses on:

- Arranging tools and materials for easy access and organizing the work area for optimal workflow

- Creating visual cues and shadow boards

- Labeling equipment to streamline tasks

Organizing tools and materials in the work area supports efficiency and safety by reducing search time and minimizing hazards.

Shine (Seiso)

Cleaning isn’t just for aesthetics—it helps:

- Identify early signs of fluid leaks, broken tools, or wear and tear by regularly cleaning the work area to improve hygiene and equipment performance

- Improve visibility and reduce accidents

- Instill pride in maintaining a clean environment

Workers play a key role in maintaining a clean and safe work area, ensuring operational efficiency and quality control.

Standardize (Seiketsu)

Here, employees:

- Learn how to create standard operating procedures

- Use checklists, color coding, and floor marking tape

- Implement regular tasks and cleaning schedules

Sustain (Shitsuke)

As the last step in the 5S process, Sustain is crucial for embedding 5S into the company’s DNA. Coaching and ongoing support play a vital role in empowering leaders and teams to maintain 5S practices over time. Preparing teams for the sustain phase—by organizing resources, planning activities, and aligning members—ensures long-term success and continuous improvement.

This crucial step ensures that:

- 5S becomes part of the company’s DNA

- Teams perform regular audits and engage in refresher training

- All employees remain aligned with the continuous improvement culture

The Impact of 5S Training in Different Industries

Manufacturing Sector

- Reduces tool search time

- Prevents machine downtime

- Supports Toyota Production System principles

Healthcare

- Promotes patient safety by ensuring supplies are properly labeled

- Organizes surgical kits and emergency equipment for rapid access

Offices and Service Environments

- Improves office equipment layout

- Reduces delays in administrative processes

Warehousing and Logistics

- Streamlines material handling

- Facilitates accurate stock rotation and inventory management

Why Organizations Need a Structured 5S Training Program

Simply reading about 5S isn’t enough. Companies need to develop a structured 5S training program tailored to their organizational needs. Structured methodologies, such as Lean and Kaizen, support the consistent and effective implementation of 5S. Companies need:

- Expert-led training sessions

- Hands-on activities and case studies

- Downloadable tools like audit checklists and templates

- Ongoing support to monitor and improve implementation

Our training ensures every team member understands the principles, practices, and expectations of a successful 5S initiative.

Recommended Course: The Fundamentals of 5S – Boosting Efficiency and Safety Throughout the Organization

This in-depth course provides everything you need to implement 5S effectively:

- 🎓 On-demand video lessons

- 🧰 Ready-to-use templates and red tag tools

- 🧠 Deep insight into the Japanese origins of 5S

- 📈 Real-life case studies from the manufacturing industry

You’ll also receive lifetime access, allowing your team to revisit key materials as needed.

Practice Makes Perfect: The GET LEAN Simulation Game

Want to understand how 5S works in the real world, honestly? Try the interactive GET LEAN Simulation Game.

This hands-on simulation allows teams to:

- Practice applying each of the five S’s in a simulated production environment

- Identify waste and improve process efficiency

- Experience the power of visual cues, standardization, and continuous flow

It’s a dynamic way to reinforce training while building engagement and teamwork.

Best Practices for Long-Term 5S Success

- Conduct regular audits to maintain standards

- Ensure leadership involvement from the beginning

- Share wins and challenges to build buy-in

- Include 5S in onboarding for new employees

- Celebrate successes to reinforce good habits

Overcoming Common Challenges in 5S Implementation

Implementing the 5S methodology is a transformative journey, but it’s not without its hurdles. One of the most common challenges organizations face is employee resistance to change. This can stem from uncertainty or a lack of understanding about how 5S will benefit both the individual and the workplace. Overcoming this requires clear communication and engaging training sessions that highlight the tangible improvements in workplace efficiency, safety, and overall work environment that 5S brings.

Another frequent obstacle is sustaining the momentum of 5S practices after the initial implementation. To maintain high standards, organizations should conduct regular audits using audit checklists, ensuring that the 5S methodology becomes a consistent part of daily routines. Leadership commitment is also a key component—when leaders actively support and participate in 5S activities, it reinforces the importance of continuous improvement. It helps embed a culture aligned with lean manufacturing and the Toyota Production System.

By proactively addressing these challenges through ongoing training, regular audits, and strong leadership, organizations can successfully implement 5S, driving lasting improvements in efficiency and fostering a culture of continuous improvement.

Measuring Success: Key Metrics and Continuous Improvement

To ensure that 5S implementation delivers real value, organizations must measure progress using clear and actionable metrics. Tracking reductions in waste, improvements in production lines’ throughput, and enhancements in the overall work environment provide a concrete picture of workplace efficiency gains. Visual management tools, such as color-coded labels and organized workspaces, facilitate the identification of areas for improvement and the monitoring of ongoing performance.

Regular audits play a crucial role in maintaining standards and identifying opportunities for further improvement. Involving employees in the feedback process not only boosts engagement but also uncovers practical insights that can drive continuous improvement. By focusing on these key metrics and fostering a culture of operational excellence, organizations can ensure that their 5S efforts yield sustained benefits, increased employee engagement, and a more efficient, high-performing workplace.

The Future of 5S: Trends and Innovations

The 5S methodology continues to evolve, with new trends and innovations enhancing its impact across industries. Digital tools—such as downloadable templates, mobile apps, and cloud-based audit checklists—are making it easier than ever to implement and sustain 5S practices, supporting workplace organization and efficiency. These resources help teams quickly identify problems, standardize processes, and maintain an organized workspace.

Beyond the shop floor, 5S principles are increasingly being applied in administrative and service environments, where a focus on efficiency, quality, and employee engagement can drive significant improvements. The use of visual management techniques, like red tags and shadow boards, is also expanding, enabling organizations to prioritize improvements and maintain high standards.

By embracing these innovations, organizations can create more efficient, safe, and productive workplaces. Staying ahead of these trends ensures that 5S remains a key driver of operational excellence, providing the ultimate guide for organizations committed to continuous improvement and world-class quality.

Final Thoughts

5S training is the foundation of workplace excellence. When implemented effectively, it reduces waste, improves safety, and transforms company culture from the inside out. Whether you’re a lean beginner or looking to refresh your team’s practices, quality training makes all the difference.

🎓 Ready to build a culture of continuous improvement?

Enroll in The Fundamentals of 5S Training Course

🎮 Want to experience 5S in action?

Play the GET LEAN Simulation Game and take your team’s understanding to the next level.