The question often arises in workplaces: to implement 5S or not? Implementing 5S is more than just tidying up a workspace—it’s about embedding a systematic approach that fosters continuous improvement, enhances workplace efficiency, and drives operational excellence. The 5S methodology, a five-step methodology for workplace organization and improvement, was initially developed as part of the Toyota Production System, which established 5S as a foundational element of lean production. It focuses on organizing the workplace, minimizing waste, and ensuring that work areas are clean, standardized, and continuously improving. This article serves as a comprehensive guide to implementing the 5S methodology in your organization.

Understanding the 5S Methodology

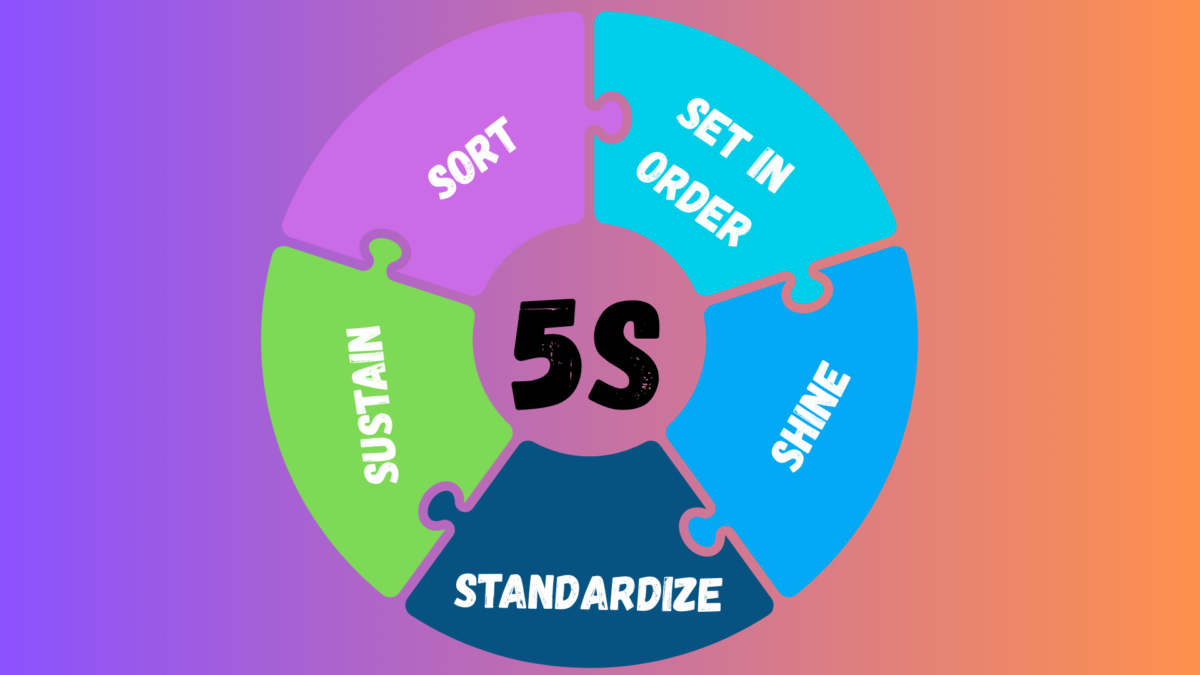

At its core, 5S stands for five Japanese words: Seiri (Sort), Seiton (Set in order), Seiso (Shine), Seiketsu (Standardize), and Shitsuke (Sustain). These principles aim to create an organized environment that supports efficient workplace operations. A successful implementation of 5S begins with a comprehensive assessment of current conditions and identification of unnecessary items and workplace hazards. The initial step emphasizes eliminating unnecessary items as a key process to streamline and organize the workplace.

Preparing for 5S Implementation

A successful 5S implementation begins long before the first red tag is placed or the first tool is organized. Preparation is a key component that sets the stage for lasting results and operational excellence. Start by developing a comprehensive plan that outlines the goals of the 5S methodology and the steps needed to achieve them. Providing training to all affected departments ensures that everyone understands the principles of 5S and the benefits it brings, including improved workplace efficiency, reduced wasted time, and increased employee morale.

Bringing every team member onto the same page is essential for building a culture of continuous improvement. Utilize practical tools, such as shadow boards and floor marking tape, during the set-in-order phase of 5S to facilitate easy access to necessary items, thereby minimizing search time and promoting an efficient workplace. Anticipate potential challenges, such as resistance to change or difficulty maintaining new standards, and develop strategies to address them early. By emphasizing the role of 5S in driving continuous improvement and operational excellence, organizations can lay a strong foundation for a smooth and successful implementation.

The Five Steps of 5S Implementation

1. Sort (Seiri)

Remove all unnecessary items from the workspace. Use red tags to label and eliminate clutter that does not contribute to productivity.

2. Set in Order (Seiton)

Arrange the necessary resources and tools so that they are easily accessible, and label items for clear identification. Organize raw materials efficiently to minimize waste and improve workflow. Use floor marking tape, visual cues, shadow boards, and storage locations to ensure everything has a correct location. For manufacturing environments, provide tools and materials that are systematically arranged along production lines to optimize output and quality.

3. Shine (Seiso)

Ensure regular cleaning of the workplace. The shine aspect goes beyond aesthetics—it is about identifying early signs of malfunction, such as machine downtime, fluid leaks, or damaged tools. Introduce cleaning checklists to streamline this step.

4. Standardize (Seiketsu)

Create standardized work procedures that all team members follow, ensuring adherence to established standards during audits and daily operations. Establishing standards ensures everyone is on the same page, which reduces confusion and improves employee morale.

5. Sustain (Shitsuke)

The final step ensures that the other four steps are maintained regularly. Sustain focuses on maintaining improvements through consistent procedures and regular audits. Regular audits, employee training, and positive reinforcement help embed the 5S principles into the organizational culture, making them part of everyday behavior.

Why Companies Should Implement 5S

1. Boosting Workplace Efficiency

A structured approach to 5S implementation significantly enhances overall workplace efficiency. Employees spend less time searching for tools and documents, resulting in increased productivity.

2. Reducing Waste and Hazards

5S aligns with lean principles by focusing on eliminating waste, including wasted time, excess inventory, and unnecessary motion. It also enhances workplace safety by reducing clutter and making visual controls, such as signage and floor marking tape, highly visible.

3. Enhancing Employee Engagement

When employees are involved in the initial implementation and ongoing upkeep of 5S, it fosters employee engagement, reduces employee frustration, and improves well-being. Workers take pride in a productive workspace and feel a sense of ownership over their environment.

4. Achieving Manufacturing Excellence

In the manufacturing industry, companies that implement the 5S methodology experience fewer errors, fewer defects, and shorter lead times. The method helps streamline processes on the shop floor and contributes to manufacturing excellence.

How to Ensure a Successful 5S Implementation

- Provide training across affected departments.

- Involving every team member in the process is essential.

- Utilize visual communication tools, such as visual cues and shadow boards.

- Conduct regular audits to track progress.

- Set clear, standardized procedures and assign responsibility.

Overcoming Challenges to 5S Implementation

Even with careful planning, organizations may encounter obstacles during the implementation of 5S. Common challenges include employee resistance to change, difficulty in maintaining consistent procedures, and sustaining new habits across the entire organization. To overcome these hurdles, it’s essential to focus on building participation and engagement at every level. Encourage employees to take ownership of their workspace and recognize their contributions to the process.

Incorporating visual controls, such as clear signage and shadow boards, helps reinforce lean principles and facilitates the maintenance of an organized environment. The use of red tags to identify and remove unnecessary items, combined with regular audits, supports the ongoing effort to eliminate waste and maintain an efficient workplace. By aligning 5S implementation with broader lean manufacturing initiatives and emphasizing the connection to manufacturing excellence, organizations can foster a culture of continuous improvement. Addressing challenges proactively ensures that consistent procedures are maintained and that the benefits of 5S are realized throughout the entire organization.

Measuring the Success of 5S Implementation

To ensure continuous improvement and maximize the impact of 5S, it’s essential to measure the success of your implementation. Begin by tracking key metrics, including productivity, quality, employee morale, and machine downtime. Regular audits and the use of cleaning checklists help maintain an organized environment and provide tangible evidence of progress. Visual management tools facilitate the easy monitoring of standards and enable the prompt identification of areas that require attention.

Compare these metrics to data collected before the initial implementation of 5S to quantify improvements in efficiency and workplace organization. Gathering feedback from employees and customers adds valuable insight into the human and operational impact of 5S, highlighting opportunities for further growth. By consistently measuring results and acting on findings, organizations reinforce a culture of lean thinking, ensuring that 5S remains a driving force for increased efficiency, productivity, and competitiveness.

5S Implementation as Part of Lean Thinking

Implementing 5S is often the key component to successfully adopting lean thinking and the lean methodology. It lays the groundwork for continuous improvement and helps organizations establish a culture of constant improvement.

When done correctly, 5S helps companies reduce waste, promote employee engagement, and maintain consistent procedures that support long-term success.

Learn More and Get Started

🎓 Ready to put 5S into action in your organization?

👉 The Fundamentals of 5S – Boosting Efficiency and Safety Throughout the Organization – This practical course offers real-world examples, downloadable tools, and a structured framework to help your team successfully implement 5S.

🎯 Want a hands-on experience? Try the interactive GET LEAN Simulation Game to see how 5S and Lean principles work in a realistic setting. Ideal for teams seeking to apply Lean concepts through hands-on practice.

Implement 5S and watch your organization’s performance transform through improved work environments, enhanced safety, increased efficiency, and a stronger organizational culture, while optimizing processes and laying a stronger foundation for continuous improvement.