Sort in 5S: Master the First Step to an Organized Workspace

How do I kickstart the 5S methodology? The ‘Sort’ step is essential. It involves removing unnecessary items from your workspace to boost efficiency. The 5S methodology consists of five steps designed to improve workplace organization and productivity systematically. This article will show you how to sort effectively in 5S, ensuring you keep only what’s essential.

Key Takeaways:

- The ‘Sort’ step in the 5S methodology focuses on decluttering workspaces by removing unnecessary items to enhance operational efficiency.

- Effective sorting, rooted in lean manufacturing principles, creates a more functional and efficient workspace by reducing waste and improving organization. This leads to better employee engagement and productivity.

- Key strategies for successful sorting include employee involvement, regular feedback, and visual management tools to sustain an organized workspace.

Introduction to 5S Methodology

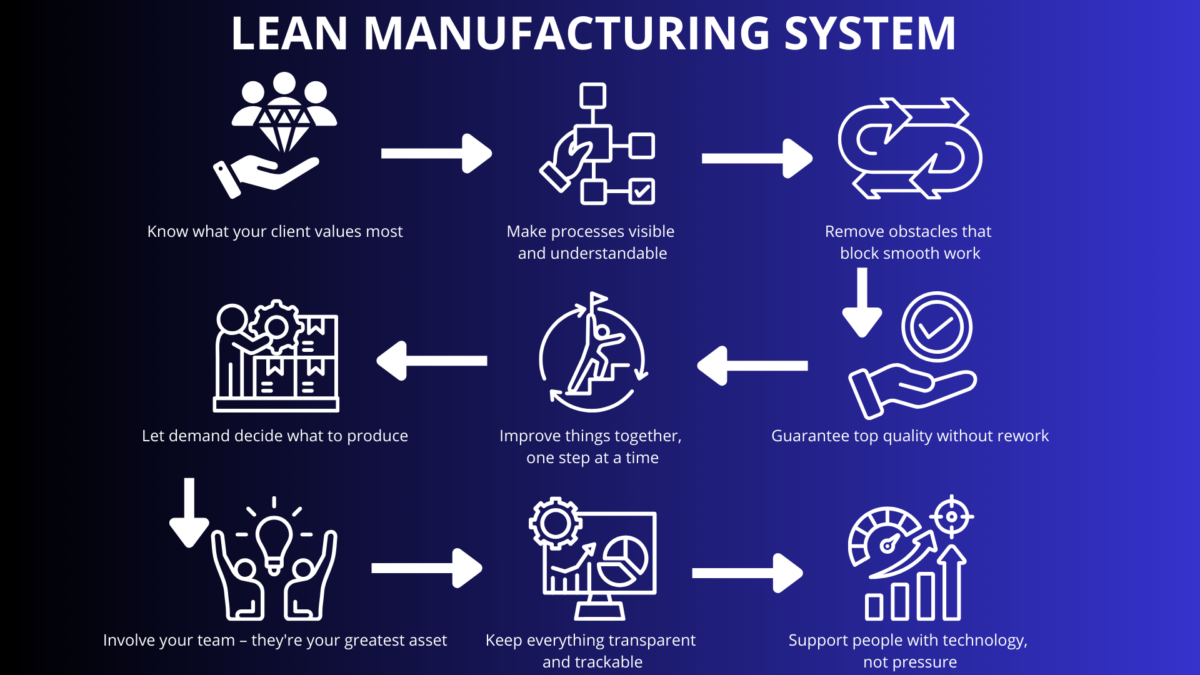

The 5S methodology is a foundational system in lean manufacturing, designed to create an organized, efficient, and safe workspace by systematically eliminating unnecessary items and reducing workplace hazards. The five words—Sort, Set, Shine, Standardize, and Sustain—form the backbone of this approach, guiding organizations through a step-by-step process to improve their work environment. By removing unnecessary items and streamlining processes, the 5S methodology helps organizations reduce waste, boost efficiency, and foster a culture of continuous improvement. This visual workplace strategy makes identifying what belongs in each area easier, ensuring that only essential items are kept and everything has its place. As a result, organizations can create a more productive, organized, and sustainable workspace that supports ongoing improvement and operational excellence.

Understanding “Sort” in the 5S Methodology

The journey to an organized workspace begins with the “Sort” step, the foundation of the 5S methodology. The term ‘Sort’ comes from the Japanese word ‘Seiri.’ This word means to determine what is needed. This step involves removing unnecessary items from the workspace to streamline operations, standardize processes, and improve efficiency. The Sort step helps organize the workspace by ensuring only essential items are present and systematically arranged. For a deeper understanding of 5S principles, explore the 5S Workplace Organization course.

The primary goal of the sort step is to declutter workspaces by eliminating items that aren’t needed for current processes. This involves identifying and organizing items into needed and unneeded groups and using a red tag system for items requiring further assessment. Focusing on essential items during the sorting phase, as a second step, sets the stage for a more organized and efficient work environment. The primary task is to ensure that only necessary items remain.

Decisions made during the sorting process involve determining items’ current and future value. The result is a workspace free of clutter, with optimized storage areas and organized tools and materials for ease of use. Workers play a crucial role in maintaining the organized workspace by actively participating in the sorting and sustaining processes. This methodical approach enhances productivity and lays the groundwork for the remaining steps in the 5S process.

The Importance of Sorting in Lean Manufacturing

Sorting is a key component of lean manufacturing, emphasizing eliminating waste and optimizing resources. Reducing various forms of waste, such as time spent searching for tools or unnecessary motion, aligns perfectly with lean production principles. An effective sorting process can significantly free up floor space and enhance the organization of tools and materials. By improving the arrangement of work areas and workplaces, sorting creates more efficient, safer, and easier-to-manage environments.

On the shop floor, sorting helps categorize items strategically, reducing unplanned downtime and lowering in-process inventory levels. This improves operational efficiency and ensures that employees can focus on value-added tasks rather than getting bogged down by clutter in their daily operations.

Achieving employee buy-in is crucial for the success of the sort step. When employees see the tangible benefits of a well-organized workspace, such as improved workflow and reduced waste, they are more likely to engage fully with the process. This collective effort fosters a culture of continuous improvement, ensuring that the benefits of sorting are sustained over time. Regular maintenance of these practices is essential to uphold ongoing organization and efficiency.

Preparing for the Sort Step

Before diving into the Sort step, teams must lay the groundwork for success. Start by thoroughly assessing the work area to identify unnecessary items, unused equipment, and cluttered spaces that may be hindering productivity. The sorting process should involve everyone on the team, encouraging open discussion about what is necessary for daily operations. By focusing on removing items that do not directly support current tasks or processes, teams can create a more organized and efficient workspace. This preparation helps reduce waste and sets the stage for a safer and more productive work environment, making it easier to maintain improvements as you move through the rest of the 5S methodology.

Step-by-Step Guide to Sorting

Embarking on the sorting process requires a systematic approach. Before you begin, developing a structured plan for sorting is vital, as it helps ensure clear communication and successful implementation.

Here’s an ultimate guide to help you through the first step of the 5S methodology:

- Assess Your Workspace: Evaluate your work area to identify necessary items and equipment that are unused frequently. After assessment, an initial cleaning creates a tidy and hygienic environment.

- Group Items into Categories: Establish criteria to determine which items are non-essential. Common types of clutter include empty boxes, rejected parts, and obsolete machinery or tools.

- Use a Red Tag System: For items that require further assessment, employ a red tag system, relocate items, and plan for reassessment.

- Dispose of Unneeded Items: Involve frontline staff and 5S leaders in decision-making, ensuring a clutter-free workspace. Where appropriate, recycle materials to promote sustainability and proper waste management.

Ongoing cleaning is essential to maintaining the sorting benefits and supporting workplace safety, hygiene, and efficiency.

Creating a Red Tag Area

A Red Tag Area is an essential element of the 5S methodology, serving as a dedicated space for items that are no longer needed, broken, or awaiting further evaluation. This area should be easily accessible and clearly marked, making it simple for employees to identify and temporarily store unneeded items during the sorting process. Using a red tag system, teams can systematically remove unnecessary items from the work area, review their status, and decide on appropriate disposal, recycling, or relocation. Establishing a Red Tag Area helps maintain an organized workspace and encourages continuous improvement by involving employees in keeping their environment clean and efficient. This practice supports a culture where everyone takes responsibility for maintaining order and identifying opportunities for improvement.

Using Visual Cues

Visual cues are a powerful tool in the 5S methodology, transforming the workspace into an actual visual workplace. By implementing clear signs, labels, and floor markings, organizations can make it easy for employees to identify storage areas, tools, equipment, and supplies at a glance. These visual cues help reduce waste by minimizing the time spent searching for materials and ensuring everything is stored in its designated place. They also support a safer and more efficient work environment, as employees can quickly locate what they need and return items after use. Visual cues empower employees to take an active role in maintaining order and efficiency daily by making the workspace more intuitive and organized.

Common Mistakes to Avoid

Successfully implementing the 5S methodology requires careful planning and ongoing commitment. One common mistake is failing to involve employees in the sorting process, which can lead to low employee buy-in and missed opportunities for improvement. Another pitfall is neglecting adequate training and support, resulting in confusion and inconsistent application of 5S practices. Rushing through the steps or trying to implement changes too quickly can also undermine long-term success, leading to burnout and difficulty sustaining improvements. Organizations should use regular audit checklists to avoid these issues and foster open communication, ensuring that employees are engaged and any challenges are promptly addressed. By removing these common mistakes, organizations can create a sustainable 5S system that improves productivity, waste reduction, and workplace safety.

Benefits of Effective Sorting

Effective sorting brings a myriad of benefits to the workplace. It speeds up activities, minimizes waste, and fosters a safer environment. For example, in the automotive industry, sorting has significantly reduced search time for tools and materials, directly improving production efficiency. Organizations can improve efficiency and focus on value-added tasks by decluttering the workspace.

The concept of a visual factory further supports the goals of the 5S methodology by using visual tools and displays to standardize processes, enhance safety, and optimize workflow.

For a practical guide to applying 5S, check out the 5S Workplace Organization course.

Summary

The first step of the 5S methodology, sorting, is a powerful tool for transforming chaotic workspaces into efficient models. By removing unnecessary items, organizing essential tools, and fostering a culture of continuous improvement, sorting lays the foundation for a productive and safe work environment. The first three steps are essential, as they establish consistent standards and ensure lasting adherence to new procedures, which are crucial for sustaining long-term change.

Embracing the sort step not only enhances operational efficiency but also promotes employee engagement and reduces waste. As you implement these practices, remember that every minute spent sorting earns an hour of productivity. Start your journey today and experience the transformative power of sorting in creating an organized and efficient workspace.