What Are The Five S’s? Best Practices and Tips

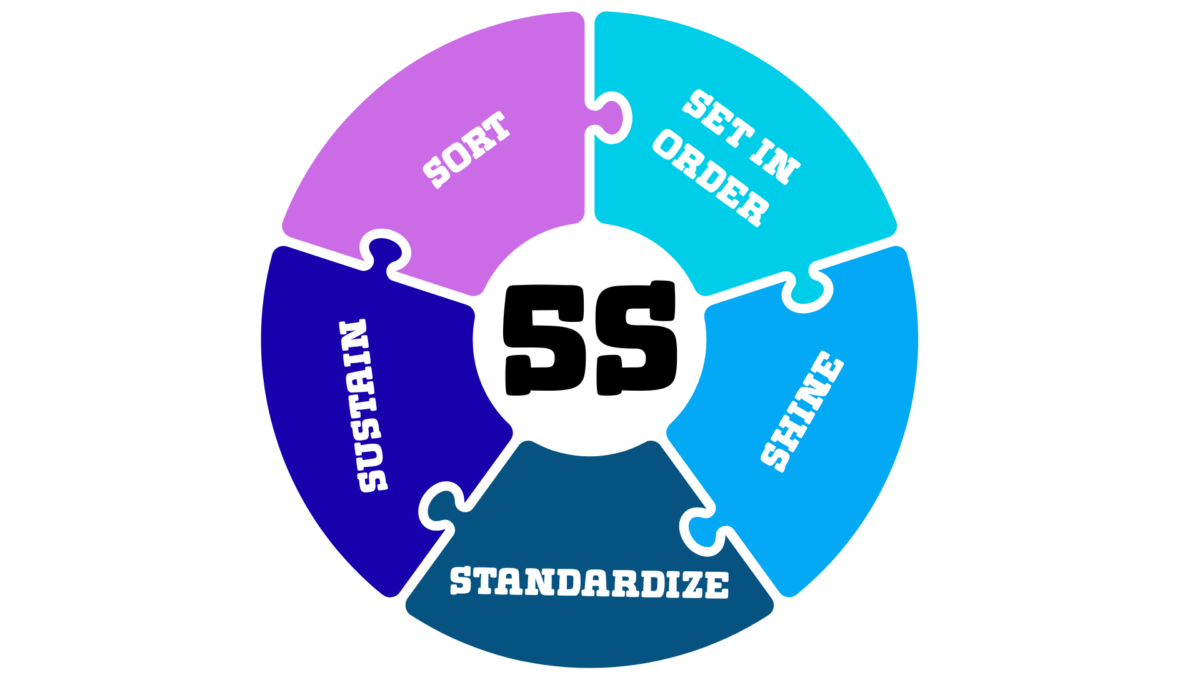

What are the five S’s? They are Sort, Set in Order, Shine, Standardize, and Sustain. This structured approach, known as “what are the five S’s,” helps organizations improve efficiency and create organized workspaces across various sectors, not just manufacturing. The 5S methodology is widely used in other industries such as healthcare, education, and government, demonstrating its versatility and impact. Read on to discover how each step contributes to a more productive environment. This article will guide you on how to implement 5S in your organization. Adopting 5S also creates an opportunity for process improvement and a stronger workplace culture. For practical guidance, check out the 5S Workplace Organization course.

Key Takeaways

- The 5S methodology consists of five steps: sort, Set in Order, Shine, Standardize, and sustain. It aims to improve organization and efficiency in workspaces.

- Originating from the Toyota Production System, 5S is a cost-effective way to enhance workplace productivity and safety across various sectors, not just manufacturing.

- Successful implementation of 5S requires employee engagement, clear communication, and the adoption of visual management tools to maintain order and promote continuous improvement. 5S practices should be reviewed and maintained frequently to ensure lasting results.

Understanding the Five S’s

The 5S methodology is a robust, five-step process designed to organize and optimize workspaces. Its main goal is to enhance productivity and safety. Additionally, it focuses on improving cleanliness, output quality, and team morale. The methodology is particularly critical in modern factories, where maintaining order in complex environments can significantly impact overall efficiency. However, its benefits are not confined to manufacturing alone; 5S can be equally effective in logistics, offices, and other sectors.

One of the key elements of the 5S methodology is its cost-effectiveness. Implementing 5S does not require a significant financial investment. Instead, it leverages existing resources to enhance work environments, making it an attractive option for organizations looking to optimize their operations without incurring high costs. Signs that your workplace might benefit from 5S include messy workstations and frequent worker inquiries about the location of items. Each item should have a designated place to improve efficiency. 5S also supports workplace health by promoting hygiene and safety standards, helping to protect employees and ensure product integrity.

The primary purpose of 5S activities is to build discipline for continuous improvement. Regular practice of the five S’s fosters a culture of sustained excellence and efficiency. It may take several months to implement and fully see the benefits of 5S. This continuous improvement mindset ensures that workspaces are continually optimized, leading to long-term benefits for the organization. Learn how to start implementing these principles with the 5S Workplace Organization course.

The Origins of the Five S’s

The 5S methodology originated in Japan as a straightforward method for enhancing efficiency and minimizing waste. Its roots can be traced back to the Toyota Production System, where it was initially developed to improve workplace organization. The need for a systematic approach to streamline operations led to the creation of 5S, which has since become a fundamental aspect of lean manufacturing.

Key figures such as Taiichi Ohno and Shigeo Shingo played essential roles in refining the principles of 5S within the Toyota Production System. Shigeo Shingo, in particular, contributed significantly by training Toyota engineers and extensively writing on the subject. Their efforts helped solidify 5S as a core component of Toyota’s innovative manufacturing practices.

The Five S’s Explained

The five S methodology consists of five Japanese words that stand for:

- Sort (Seiri)

- Set in Order (Seiton)

- Shine (Seiso)

- Standardize (Seiketsu)

- Sustain (Shitsuke)

Each step is crucial in improving a business’s overall function by promoting workplace participation and systematic organization. Setting clear standards and procedures for each step is essential to ensure consistency and maintain organization. To deepen your understanding, explore the 5S Workplace Organization course.

At the end, the goal of the 5S process is to achieve a fully organized and efficient workspace.

Sort (Seiri)

The first step in the 5S methodology is Sort, which involves:

- Separating and categorizing items based on their usefulness.

- Identifying and removing unnecessary items from the workspace.

- Eliminating clutter and distractions to make the workspace more productive and efficient.

An effective technique used during the Sort phase is the red tag method. Items of uncertain value, including unneeded items, are tagged and placed in a red tag area. If these items are not used within a specific timeframe, they are removed. Items that are not needed are discarded according to clear guidelines. This approach ensures that only essential remaining items are kept, reducing the risk of damaged or misplaced materials.

The Sort phase is most effective when:

- The people working in the space assess which items should be kept or removed.

- Workers sort items based on established guidance, ensuring the workspace is clutter-free.

- A specific timeframe for sorting activities is established to ensure the process is efficient and thorough.

Set in Order (Seiton)

After sorting, the next step is to set it in order. This phase involves:

- Designating specific storage locations to facilitate easy access and minimize unnecessary movements, optimizing the work area for better workflow.

- Logically arranging work areas to maximize efficiency.

- Ensuring tools and materials are readily accessible.

Setting things in order often opens up more space within the work area, making the environment more productive.

Learn how to create an organized workspace with the 5S Workplace Organization course.

Shine (Seiso)

The Shine phase focuses on maintaining a clean and tidy workplace, including removing dirty surfaces and materials. Like keeping a house clean, the Shine step emphasizes the importance of regular cleaning and maintenance, such as identifying and cleaning up spills to maintain safety and efficiency. Thorough cleaning and regular equipment maintenance create a safe and efficient work environment.

Standardize (Seiketsu)

Standardization ensures that the 5S practices become habits and are consistently applied. The Standardize phase aims to establish routines that support ongoing organization and efficiency. Codifying standards for 5S practices establishes a consistent and easy-to-follow process.

Sustain (Shitsuke)

The final step in the 5S methodology is Sustain, which focuses on:

- Maintaining developed processes with a focus on continuous improvement.

- Emphasizing the importance of self-discipline among workers to ensure adherence to 5S practices without external prompting.

- Ensuring that 5S processes are sustained over time through self-discipline.

Find more practical tips in the 5S Workplace Organization course.

Implementation Strategies

Successfully implementing the 5S methodology starts with a clear strategy focused on sorting and removing unnecessary items from the workplace. Organizations can reduce clutter and create a more efficient environment by discarding unnecessary items. The next step is standardizing processes—establishing clear procedures for storing and accessing supplies and equipment. Conducting a thorough review of current work areas helps identify obstacles hindering productivity. Observing the side or stomach position of equipment and supplies can reveal opportunities to optimize their placement, making it easier for workers to complete tasks without unnecessary movement. By implementing these strategies, businesses can maintain order, streamline workflows, and set the stage for long-term success with the 5S methodology.

Overcoming Challenges

Implementing the 5S methodology isn’t without its challenges; one of the most important is overcoming employee resistance. To address this, providing comprehensive training and ongoing support is essential, helping workers understand how the methodology benefits them and the organization. Giving employees ownership of their work areas and turning the process into a collaborative effort encourages active participation and pride in maintaining order. Supplying the right tools and resources further supports this transition. It’s important to note that adapting to a new system takes time. Still, with clear expectations and consistent encouragement, employees will see positive results as the workplace becomes more organized and efficient.

Role of Leadership

Leadership is essential to the success of any 5S initiative. Leaders set the tone by demonstrating a commitment to maintaining order and supporting the adoption of the methodology throughout the workplace. By providing training, resources, and ongoing support, leaders empower employees to take ownership of their work areas. Giving workers the autonomy to manage their spaces creates a sense of responsibility and accountability, which helps sustain improvements over time. Just as the happiest baby thrives in a secure and comfortable environment, employees are more productive and engaged when they feel supported and valued. Effective leadership sets the foundation for 5S success and fosters a culture of continuous improvement and order.

Employee Engagement and Participation

Employee engagement and participation are key elements in successfully adopting the 5S methodology. Businesses can create a more motivated and productive workforce by giving employees ownership of the process and involving them in decision-making. Training and support ensure everyone understands their role and feels confident in maintaining order. Leveraging technology, such as productivity press tools, makes it easier for employees to find supplies and information, streamlining daily tasks. Swaddling, or securely wrapping items, can keep tools and materials organized, much like swaddling a baby provides comfort and security. These strategies help create a supportive environment where employees feel empowered to contribute to continuous improvement.

Measuring Success

Measuring the success of a 5S implementation is essential for ensuring ongoing effectiveness and continuous improvement. Tracking key metrics—such as productivity, quality, and waste reduction—provides valuable insights into the impact of the methodology. Businesses can identify areas for further improvement and make informed adjustments to their processes using data and analytics. Regularly reviewing and refining the 5S system helps maintain high standards and reduces risk. By adopting the 5S methodology, organizations lay a strong foundation for other lean techniques, supporting a culture of excellence and long-term success. 5S is designed to create a more efficient, organized, and productive workplace.

Benefits of Implementing the Five S’s

Implementing the 5S methodology offers numerous benefits, enhancing workplace efficiency and effectiveness through systematic organization and maintenance. One of the most significant advantages is improving visual management, which promotes proper labeling and organization of tools and materials. This visual clarity helps reduce waste and ensures a safer, more efficient workplace.

Operational results of implementing the 5S methodology include:

- Increased efficiency

- Reduced waste

- Faster cycle times

- Lower error rates

- Improved safety

- Better data collection

By reducing clutter and improving organization, 5S makes it easier to complete each task efficiently, ensuring that employees can focus on their work without unnecessary obstacles.

These benefits are achievable with structured training, such as the 5S Workplace Organization course.

Summary

The 5S methodology is robust for enhancing workplace efficiency, safety, and organization. By embracing the five key elements—sort, Set in Order, Shine, Standardize, and sustain—organizations can create a culture of continuous improvement that fosters productivity and employee engagement.

Take a moment to think about how you might begin implementing the five S’s in your organization. Let yourself wonder about the potential improvements 5S could bring to your workspace.

Ready to transform your workspace? Start learning with the 5S Workplace Organization course. Embrace the 5S methodology today and experience the transformative power of systematic organization and maintenance.