Understanding the 5S Methodology in Production

In the world of lean manufacturing, one critical yet often underestimated tool is the 5S methodology. Originally developed by the Toyota Motor Company as part of the Toyota Production System, the 5S method is a systematic approach designed to enhance the production process by organizing the workplace, minimizing waste, and promoting continuous improvement. But what is 5S in production, and why is it considered a critical step toward achieving operational excellence?

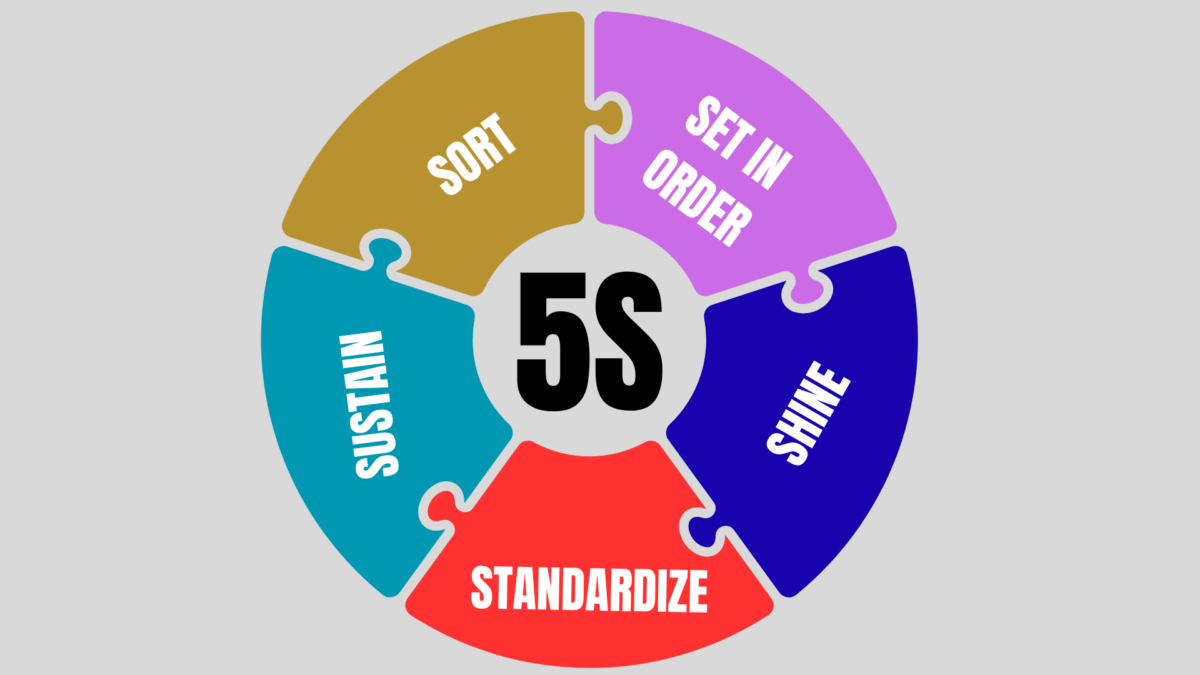

The 5S system stands for five Japanese words—Seiri, Seiton, Seiso, Seiketsu, and Shitsuke—translated into English as Sort, Set in Order, Shine, Standardize, and Sustain. Each of these steps plays a key role in shaping a productive work environment and boosting overall productivity on the manufacturing floor.

The Core Elements of 5S Lean Manufacturing

Sort (Seiri)

This step focuses on removing unnecessary items from the workplace. By clearing out clutter and excess inventory, teams can make room for essential tools and materials, improving employee morale and safety while freeing up valuable space in production lines.

Set in Order (Seiton)

Known as the organization phase, this step ensures all necessary tools are placed in their correct locations for easy access. The use of visual cues, such as labels, shadow boards, and color coding, makes it much easier to identify the remaining items. It lays the foundation for a more efficient workplace.

Shine (Seiso)

This phase involves basic cleaning and maintenance of the work environment. Beyond just tidying up, Shine helps catch problems early, such as equipment leaks or signs of wear. Routine maintenance leads to safer, more productive work conditions.

Standardize (Seiketsu)

Here, companies create standards for cleanliness and workplace organization. Standardized procedures, checklists, and visual communication tools help maintain organization across shifts, ensuring consistent implementation of practices across the manufacturing industry.

Sustain (Shitsuke)

The final stage focuses on developing the discipline to follow established standards. It often involves employee training, employee engagement, and regular evaluations to ensure the 5S system becomes an ingrained part of the organizational culture.

Benefits of Implementing 5S in the Production Process

When organizations implement 5S correctly, they unlock a variety of benefits that contribute to streamlined operations and lean manufacturing practices:

- Reduced waste and unnecessary motion.

- Better time efficiency by minimizing wasted time searching for tools.

- Improved workplace safety reduces the risk of workplace accidents.

- Enhanced product quality through clean, properly organized workstations.

- Increased employee buy-in and morale thanks to clear expectations and a well-being-oriented work environment.

- Standardized procedures that support repeatable processes across the production process.

Real-World Impact and Visual Management

The implementation of 5S introduces powerful visual management techniques, transforming facilities into visual workplaces. Using visual controls, such as signage, floor markings, and color-coded zones, employees can easily navigate production areas, follow standardized procedures, and maintain established standards.

This comprehensive approach enhances communication, ensures accountability, and keeps everyone aligned with the organization’s lean manufacturing goals. A classic example of the success of visual management can be found on the shop floor of the Toyota Production System, where visual cues help eliminate inefficiencies and ensure a continuous flow.

From Manufacturing to Other Industries

While 5S was initially developed for the manufacturing floor, it has found success in many industries, including healthcare, logistics, and software development. Its adaptable structure and focus on workplace efficiency make it valuable beyond traditional manufacturing practices.

Companies that apply 5S across various sectors report improved product quality, enhanced team dynamics, and better customer satisfaction. The methodology’s simplicity and repeatability make it a key element of successful lean manufacturing and continuous improvement strategies.

Take the Next Step: Master 5S Implementation.

To experience these benefits and learn how to implement 5S with real-world case studies and industry best practices, consider enrolling in our course: The Fundamentals of 5S – Boosting Efficiency and Safety Throughout the Organization.

This course offers:

- Actionable tools for organizing your work environment.

- Step-by-step guidance on implementing the 5S methodology.

- Insight into how the Toyota Production System built world-class efficiency using 5S.

- Examples from real manufacturing organizations across multiple sectors.

👉 Learn more and start transforming your operations: Master the 5S Method Now

Bonus: Train Your Team with a Simulation Game

Looking for an interactive way to reinforce 5S and Lean concepts? Try the GET LEAN Simulation Game – a powerful tool for engaging your team and practicing lean manufacturing and continuous improvement in a fun, hands-on way.

From understanding production processes to applying visual management, this simulation game allows employees to identify problems, apply 5S principles, and experience operational excellence firsthand.

Summary:

So, what is 5S in production? It’s not just a method—it’s a mindset. A systematic approach that aligns your production process with lean manufacturing goals through visual management, eliminating waste, and engaging your workforce. Start implementing 5S today and move your company closer to operational excellence and continuous improvement.