Spis treści

5S Defined: A Complete Guide to the 5S Methodology

In pursuit of operational excellence, organizations across various industries utilize proven frameworks that simplify processes, minimize waste, and enhance workplace safety. One such timeless and practical system is the 5S methodology. If you’ve ever wondered what exactly 5S means, you’re in the right place. This article provides a detailed look at 5S, explores the definition of the 5S methodology, and demonstrates how understanding these concepts can significantly transform a company’s operations.

Introduction to 5S

The 5S methodology is a powerful tool for organizations seeking to improve their workplace efficiency and productivity. Initially developed by the Toyota Motor Company as part of the Toyota Production System (TPS), the 5S methodology has been widely adopted across various industries, including manufacturing, as a key element of lean manufacturing. The core principle of 5S is to create an organized work environment by eliminating waste, reducing clutter, and optimizing productivity. This is achieved by implementing five sequential steps: Sort, Set in Order, Shine, Standardize, and Sustain. By consistently applying these steps, organizations can create a visual workplace that promotes efficiency, quality, and safety.

What is 5S Defined?

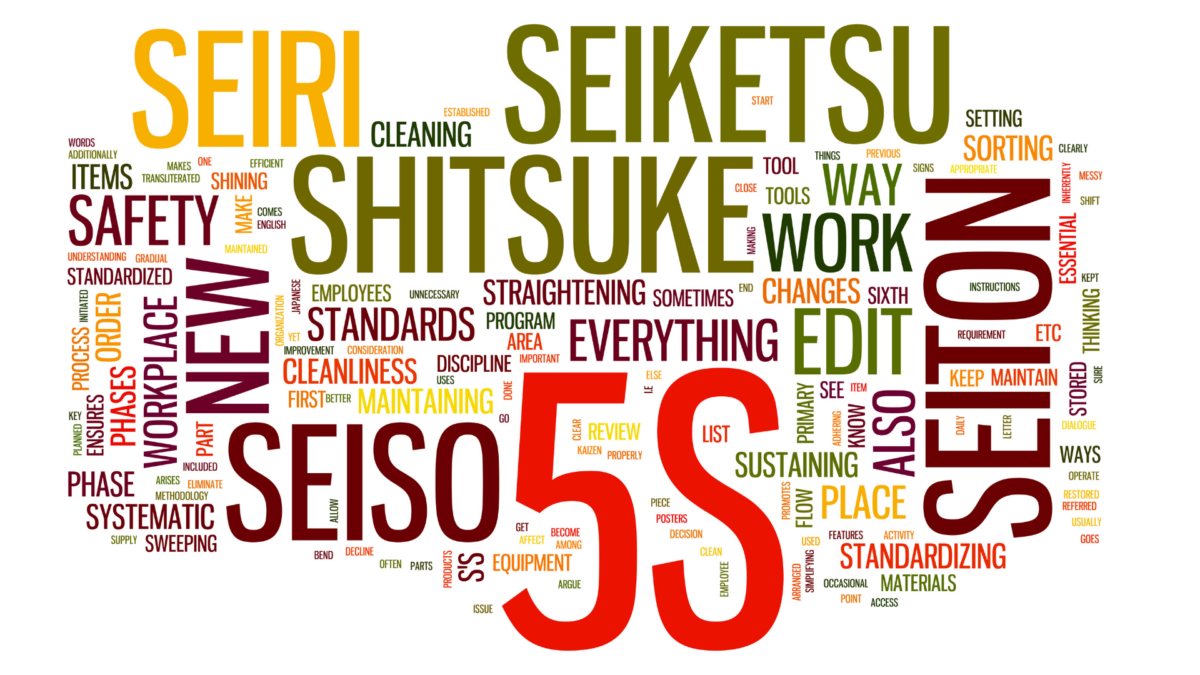

When we discuss 5S, we refer to a systematic approach developed in Japan, designed to organize and manage the workspace efficiently and effectively. The 5S methodology is built on five Japanese words that all start with the letter “S”:

- Seiri (Sort): Through a thorough sorting process, distinguish between necessary and unnecessary items and remove those that are not needed. Red tagging is used here to identify and temporarily set aside items whose necessity is uncertain.

- Seiton (Set in Order): Arrange necessary items for easy and efficient access.

- Seiso (Shine): Clean the workplace regularly to maintain standards and identify defects.

- Seiketsu (Standardize): Establish norms and procedures to maintain the first three steps.

- Shitsuke (Sustain): Build a culture of discipline and continuous improvement.

5S is defined this way, which shows that it is much more than just cleaning or organizing — it is about creating an environment that fosters efficiency, quality, and safety.

Want to master the principles of 5S and apply them effectively? Enroll in our practical 5S training course here!

5S Methodology Definition

The 5S methodology definition emphasizes a visual management system that supports lean principles, Lean Manufacturing, and other operational excellence initiatives. It is based on the belief that a well-organized workplace is a productive and safe one. Specifically, 5S helps to:

- Increase efficiency by minimizing wasted motion and time

- Improve safety through clean and precise work areas

- Enhance employee morale by fostering pride in their environment

- Support continuous improvement efforts

The 5S methodology provides a structured framework for workplace organization, cleanliness, and discipline. Maintaining a clean and organized work area as part of the Shine step is crucial for operational efficiency and safety, as it empowers employees to take ownership of their spaces and identify potential issues early.

The History of 5S

Understanding 5S requires an examination of its origins. The methodology was first developed in post-World War II Japan, primarily within the manufacturing industry. Toyota Motor Corporation played a significant role in formalizing and promoting 5S as part of its broader Toyota Production System (TPS). Since then, the principles of 5S have spread across industries worldwide, becoming a fundamental aspect of lean production. They emphasize foundational principles and methodologies to enhance productivity and eliminate waste.

Why 5S Matters Today

In today’s business world, where agility, efficiency, and quality are paramount, the many benefits of implementing 5S cannot be overstated. Organizations that implement the 5S experience:

- Reduced workplace accidents

- Improved workflow and faster production cycles

- Lower inventory levels and space optimization

- Better customer satisfaction

Reducing waste is a central element of Lean Manufacturing and 5S methodology. It effectively optimizes workflow and increases productivity while aligning to maximize customer value and minimize resource usage.

Moreover, 5S provides a foundation for other continuous improvement initiatives, such as Kaizen, Six Sigma, and Total Productive Maintenance (TPM).

Would you be ready to build a safer and more efficient workspace? Take your first step with our comprehensive 5S training course here!

Step-by-Step Guide to Implementing 5S

Successfully implementing 5S requires a structured approach. Here’s a step-by-step guide:

Step 1: Sort (Seiri)

Begin by removing all unnecessary items from the workspace. This step involves evaluating each item to determine its necessity. Use ‘red tags’ to label items uncertain in value. This allows the team to categorize and assess whether these items should remain in the workspace or be removed after a designated period.

Step 2: Set in Order (Seiton)

Organize the items so that they are easily accessible and returned to their designated places. This step focuses on creating an efficient layout that minimizes wasted time and effort.

Step 3: Shine (Seiso)

Clean the workspace thoroughly to ensure it is free of dirt and clutter. Maintaining a ‘workplace clean’ environment is crucial for efficiency and safety, as it facilitates job performance, reduces time wastage, and minimizes the risk of injuries.

Step 4: Standardize (Seiketsu)

Could you establish standards and procedures to ensure the first three steps are maintained? This would involve creating schedules, charts, and checklists to ensure consistency.

Step 5: Sustain (Shitsuke)

Please foster a culture of continuous improvement so that the 5S methodology becomes a habit. Regular audits and training can help sustain the changes that have been made.

Step 1: Sort (Seiri)

- Eliminate clutter

- Remove broken, obsolete, or unnecessary items

- Categorize essential tools and materials

- Use the red tag method to identify items that are uncertain. Mark them with a red tag and place them in a designated area for further evaluation before deciding whether to keep or discard them.

Step 2: Set in Order (Seiton)

- Designate specific locations for all items

- Label storage areas and tools. A shadow board for hand tools helps identify missing equipment, enhances efficiency, and reduces the time wasted searching for misplaced tools.

- Implement visual management systems.

Step 3: Shine (Seiso)

- Schedule regular cleaning activities

- Empower employees to take ownership of their workspace

- Identify potential hazards and maintenance needs during the cleaning process. Routine maintenance, which includes cleaning and inspecting tools and equipment, as well as performing regular maintenance, is crucial to ensure optimal performance and prevent potential issues.

Step 4: Standardize (Seiketsu)

- Develop standardized procedures for daily tasks

- Create checklists and visual controls

- Ensure consistency across departments. Visual cues, such as labels, signs, and floor markings, play a crucial role in visual management systems by enhancing navigation and structure, making processes more efficient, and preventing clutter.

Step 5: Sustain (Shitsuke)

- Conduct regular audits

- Recognize and reward compliance

- Embed 5S principles into the organizational culture. Self-discipline is essential in this context, as it ensures that employees consistently follow the 5S process without needing constant reminders, thereby maintaining efficiency and safety.

Want a proven roadmap for implementing 5S in your workplace? Our practical course offers detailed strategies and tools — enroll now here!

This image depicts a surgical team working in a clean and organized operating room. The overlaid text emphasizes the contrast between tolerance for disorganization in general and critical situations, underscoring how personal risk sharpens our focus on order. It serves as a metaphor for the necessity of organization in all professional settings, especially when outcomes are crucial.

Implementation Strategies

Implementing the 5S methodology requires a well-planned approach to ensure its success. Here are some strategies to guide your organization through a successful 5S implementation:

- Start with a Clear Understanding of the 5S Methodology: Before diving into implementation, it’s crucial to grasp the principles and steps involved in the 5S methodology. This includes understanding the Toyota Production System, which emphasizes the elimination of waste and fosters continuous improvement.

- Build a Strong Management Team: A dedicated management team is crucial for leading the 5S implementation process. This team should include representatives from various departments and levels to ensure a comprehensive approach.

- Identify Areas for Improvement: Conduct a thorough workplace analysis to pinpoint areas that need enhancement. Look for excess inventory, unnecessary items, and inefficiencies in production processes that can be streamlined.

- Develop a Plan for Implementation: Create a detailed plan outlining the steps for implementing 5S. This plan should include timelines, budgets, and the required resources. It should also include strategies for building participation and engagement among employees.

- Provide Training and Education: Educate employees on the 5S methodology and its benefits. Training should cover identifying waste, reducing clutter, and creating a visual workplace. This knowledge empowers employees to contribute effectively to the 5S process.

- Utilize Visual Management Tools: Implement visual management tools, including floor marking tape, shadow boards, and visual controls. These tools help create a visual workplace that optimizes productivity and ensures everything is located correctly.

- Establish Key Performance Indicators (KPIs): Set KPIs to measure the success of the 5S implementation. Track key metrics, including productivity, quality, and employee morale, to gauge progress and identify areas for further improvement.

- Conduct Regular Audits: Regular audits are essential to ensure that the 5S methodology is consistently applied. These audits help identify areas for improvement and ensure that the gains made are sustained over time.

- Encourage Employee Participation: Cultivate a culture of employee engagement and participation. Provide opportunities for them to suggest improvements and be involved in decision-making processes. This not only enhances the implementation process but also boosts employee morale.

- Sustain the Gains: Continuously monitor and refine processes to maintain the gains achieved through 5S implementation. Review KPIs regularly and make necessary adjustments to ensure ongoing improvement and efficiency.

By following these strategies, organizations can successfully implement the 5S methodology and reap its many benefits, including improved workplace efficiency, reduced waste, and increased productivity.

Benefits of 5S Implementation

Understanding 5S helps reveal why so many organizations adopt it. Key benefits include:

- Improved Productivity: Streamlined workflows and reduced motion waste to optimize productivity

- Enhanced Quality: Fewer defects due to organized, error-proofed environments

- Greater Employee Involvement: Teams take pride and responsibility for their workspaces

- Cost Savings: Efficient use of space, materials, and time reduces operational costs

Additionally, creating a safe environment is crucial for employee well-being and productivity, making safety an essential component of 5S implementation.

Organizations that consistently practice 5S see a significant impact on their bottom line.

Quality and Safety

Quality and safety are critical aspects of any organization, and the 5S methodology significantly enhances both. Organizations can reduce the risk of accidents and errors by creating a well-organized environment and improving workplace safety. The 5S methodology also helps identify and eliminate unnecessary items, excess inventory, and wasted time, improving quality management. The Shine stage of the 5S method, in particular, emphasizes regular cleaning and maintenance, which helps prevent equipment failures and reduce downtime. Additionally, the Standardize step involves creating standards and procedures that help ensure consistency and quality in production processes. By implementing the 5S methodology, organizations can create a safe and productive workspace that supports continuous improvement and lean thinking. The ‘sixth S’ concept emphasizes the importance of Safety in workplace organization, highlighting its role in preventing workplace hazards and maintaining employee well-being. Regular audits and assessments are also crucial for sustaining the benefits of 5S and ensuring the workplace remains organized, clean, and safe.

Common Challenges and How to Overcome Them

While 5S offers tremendous benefits, implementation can come with challenges:

- Resistance to Change: Some employees may view 5S as unnecessary “busy work.”

- Inconsistent Practices: Without standardized procedures, improvements may not stick.

- Management Commitment: A lack of leadership support can undermine efforts.

To overcome these obstacles:

- Communicate the value of 5S clearly

- Involve employees in the process

- Demonstrate management’s commitment through active participation

5S Beyond Manufacturing

Although developed for manufacturing, the principles of 5S methodology are highly versatile and applicable to various workplaces:

- Healthcare: Organized patient care areas and faster access to critical supplies

- Offices: Reduced paperwork clutter and improved document management

- Retail: Neat, well-organized store layouts and backrooms

- Education: Streamlined classroom setups and administrative areas

On the manufacturing floor, the involvement of employees and managers in maintaining organizational procedures is crucial for sustaining practices that enhance productivity, engagement, and overall efficiency within the workplace.

5S delivers benefits wherever efficiency, safety, and organization are valued.

5S Audits and Continuous Improvement

A critical component of sustained 5S is the regular use of audits. These audits:

- Ensure compliance with established standards

- Identify new areas for improvement

- Maintain employee accountability

Audit results should be shared openly, and action plans should be developed to address deficiencies.

Want to learn how to conduct effective 5S audits? Our training provides step-by-step guidance — sign up today here!

Final Thoughts on 5S Defined

When you genuinely understand what 5S is defined as, it becomes clear that 5S is much more than a tidy-up campaign; it is a mindset and a structured system that creates sustainable change. Implementing the 5S methodology builds a strong foundation for ongoing operational excellence, employee engagement, and customer satisfaction.

A classic example is using a shadow board for tools to emphasize the importance of organizing the workspace in the ‘Set in Order’ step.

For years to come, organizations that incorporate 5S into their culture will reap the benefits of a streamlined, safer, and more productive workplace.

Final Invitation

🎓 Stop Treating 5S Like a Buzzword. Start Using It as a Strategy.

If your goal is to bring real structure, clarity, and safety to your work environment—not just talk about it—then it’s time to approach 5S correctly.

Based on over 25 years of experience in Lean implementation across leading companies, this course gives you the tools and know-how to apply 5S where it matters most: on the ground.

👉 The Fundamentals of 5S – Boosting Efficiency and Safety Throughout the Organization

Inside, you’ll discover:

🎥 Clear, on-demand video lessons – Learn at your own pace, from anywhere

♾️ Lifetime access – Use the course whenever you need it

🧰 Practical resources – Templates, red tags, and checklists ready to implement

📘 Cultural insights – Understand what 5S really means in a Japanese context

👉 Preview a free lesson and see how this course delivers real-world value.

Whether you’re just starting out or struggling to sustain 5S in your organization, this course is your roadmap to achieving lasting results.