Spis treści

Discovering the 5S Meaning: Practical Steps for Effective Workplace Organization

5S is a method used to create an organized and efficient workplace. It helps reduce clutter, minimizing the risk of accidents and exposure to hazardous materials. Originating from Japan’s Toyota Production System, the five steps—Sort, Set in Order, Shine, Standardize, and Sustain—help eliminate waste and streamline workflow. In this article, you’ll learn what 5S means, its benefits, and how to apply it in your workspace.

Introduction to 5S

The 5S methodology is a powerful tool for improving workplace organization, efficiency, and productivity. Developed by the Toyota Motor Company as part of the Toyota Production System (TPS), 5S is a key component of Lean manufacturing and has been widely adopted in the manufacturing industry. The 5S methodology is based on five core principles: Sort, Set in Order, Shine, Standardize, and Sustain. By implementing these principles, organizations can eliminate waste, reduce clutter, and create a more organized and productive work environment. The 5S methodology is a key element of Lean thinking and essential for continuous improvement and long-term success.

Key Takeaways

- The 5S methodology, derived from the Toyota Production System, focuses on workplace organization and waste elimination to enhance productivity and safety.

- The five essential steps of 5S—sort, Set in Order, Shine, Standardize, and sustain—create a systematic approach to establishing an organized and efficient work environment.

- Implementing 5S provides numerous benefits, including improved operational efficiency, enhanced employee morale, and significant cost savings through waste reduction.

- Self-discipline is crucial for maintaining the 5S methodology and ensuring consistency. It helps prevent waste and enables individuals to identify when standards are not met.

Understanding the 5S Methodology

The 5S methodology is a cornerstone of lean manufacturing, designed to create a more efficient workplace by focusing on organization and waste elimination. At its core, 5S aims to maintain order and eliminate waste through a systematic approach that involves assessing and removing unnecessary items, logically organizing the remaining items, and maintaining cleanliness. This methodology is not just about cleanliness—it’s about creating a work environment where everything has its place, making it easier to perform tasks efficiently.

Originating from the Toyota Production System, 5S has evolved to become a global standard for workplace organization, supporting the philosophy of continuous improvement (Kaizen). Implementing the 5S methodology can significantly enhance productivity by minimizing waste and improving workflow efficiency. The outcomes include a more organized workspace, improved output quality, employee pride, and safety.

Understanding 5S is foundational to Six Sigma methodologies, as professionals, such as Black Belts, utilize these methodologies together to drive continuous improvement and enhance productivity within enterprises.

The name “5S” is derived from five Japanese words representing the methodology’s steps: Sort, Set in Order, Shine, Standardize, and Sustain. These steps work together to foster a culture of continuous improvement and mutual respect. 5S helps establish a sustainable system with clear rules and processes, encouraging employees to take ownership of their workspace.

🎓 See 5S in action! Join our online training and learn how to apply the tools effectively: 👉 Enroll now

The Origins of 5S

The 5S methodology has deep roots in Japan’s automotive industry, specifically within the Toyota Production System, which was developed in the 1950s. Created by Hiroyuki Hirano in the 1960s, 5S was designed to enhance production line efficiency and has since played a significant role in Toyota’s success as a leading producer of high-quality motor vehicles. The principles of 5S were pioneered by the Toyota Motor Company, establishing a reputation for high-quality production.

Initially utilized in manufacturing, the 5S method has evolved into a core element of the lean production philosophy and continuous improvement. Taiichi Ohno and Shigeo Shingo were pivotal in popularizing the 5S methodology within Toyota and beyond. The productivity gains associated with 5S are achieved through effective organization and waste reduction, as exemplified in the Toyota Production System.

Today, the 5S lean system is a widely adopted paradigm used across various industries to enhance efficiency and organization. Its evolution from a manufacturing tool to a universal methodology underscores its effectiveness in improving productivity and fostering a culture of continuous improvement.

The Five Essential Steps of 5S

The heart of the 5S methodology lies in its five essential steps: sort, Set in Order, Shine, Standardize, and sustain. Each step is crucial in creating an organized, efficient, and productive workplace. The five-step methodology advocates having materials, information, and equipment only where and when needed, ultimately keeping work and organization simple.

Analyzing organization and workflow through the lens of 5S helps businesses reduce waste and optimize processes, significantly improving productivity. Let’s delve into these steps to understand their contributions to the overall goal of workplace organization.

In addition to the traditional five steps, some experts advocate including a sixth ‘S’—Safety. This additional step emphasizes the importance of workplace organization and employee well-being. Incorporating Safety can involve ergonomic workstation arrangements and precise labeling to eliminate risks. While there are differing opinions on the necessity of this additional step, many believe that it enhances the overall effectiveness of the 5S system by prioritizing a safe working environment.

Sort

The first step in the 5S methodology is Sort, which focuses on identifying necessary items and eliminating unnecessary ones. Employees who work in the space are best suited to assess which items are essential for daily operations. This step is crucial as clutter can lead to worker injuries and wasted time searching for items.

Identifying and tagging broken tools is also crucial for enhancing safety and maintaining quality in the workplace.

One effective technique in the Sort step is the Red Tag method, which helps categorize and handle unnecessary items. Tagging items of uncertain value enables employees to make informed decisions about what should be retained and what should be removed, ensuring a safer and more efficient workspace.

Set in Order

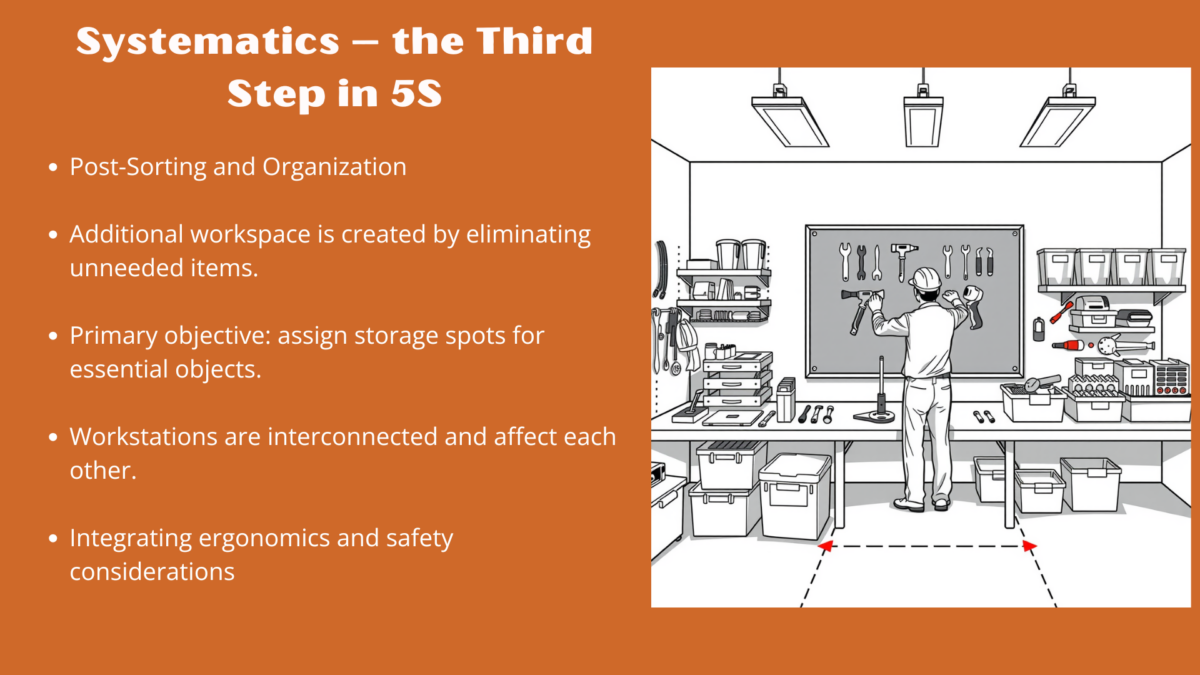

Following the Sort step, the Set in Order phase aims to organize items for optimal locations and easy access. This involves arranging items logically and systematically to minimize waste from unnecessary motion and enhance accessibility.

Practical strategies in this phase include labeling storage locations, outlining work areas, and considering ergonomic placements. Placing a trash can under each workstation can significantly reduce wasted time and improve efficiency while reducing waste. The layout should align with the workflow to enhance production goals.

Shine

The Shine step involves cleaning and maintaining the workspace to ensure a hygienic environment, which is crucial for a safe and healthy work environment that promotes overall well-being.

Maintaining a clean and organized shop floor is crucial to enhancing efficiency and reducing waste by minimizing the time spent searching for tools and materials.

Regular cleaning tasks include:

- Sweeping

- Mopping

- Dusting

- Wiping down surfaces

These tasks can prevent dust and grime build-up, making it easier to identify potential issues. A clean, productive workspace boosts employee morale, making the workplace cleaner, safer, and more visually appealing, which in turn helps improve productivity.

Shadow boards for tool storage ensure that tools are properly stored and easily accessible, saving time and reducing the risk of accidents. A shadow board can further enhance this organization.

Standardize

Standardization creates consistent procedures and schedules to ensure tasks are uniform across the workspace. This step involves organizing cleaning schedules, defining roles and responsibilities, and preparing written procedures or diagrams to create standards and standardized work.

Tools like daily checklists, schedules, and visual cues can help maintain these standards. Regular audits and peer reviews help ensure compliance with 5S principles and support the improvements achieved in the earlier steps.

Sustain

The final step, Sustain, emphasizes embedding lean principles into the organizational culture to ensure lasting improvements. This involves sustaining developed processes and fostering a culture of continuous improvement through lean thinking.

Training new employees on 5S procedures and keeping the process engaging for all staff is crucial for long-term success. Peer reviews and regular check-ins help ensure that the workspace remains organized and procedures are followed.

Benefits of Implementing 5S

Implementing the 5S methodology provides numerous benefits, including enhanced operational efficiency and reduced waste. One of the core advantages of 5S is its ability to minimize various types of waste, such as unnecessary movement and waiting times. A well-organized workspace enables staff to focus solely on essential tasks, thereby improving productivity and helping organizations optimize their operations. Effective organization reduces the time spent searching for items, allowing organizations to focus more on value-creating activities.

5S also fosters a safer work environment by minimizing hazards and reducing the likelihood of accidents. Employees engaged in the 5S process often exhibit higher morale and job satisfaction, as they take pride in maintaining a well-organized workspace. The structured nature of 5S encourages continuous improvement and ongoing evaluation of processes.

Financially, 5S can lead to substantial savings by optimizing inventory and minimizing unnecessary costs. The methodology aims to eliminate various forms of waste, including time, materials, and excess inventory, contributing to a more efficient and cost-effective operation.

🎓 Ready to implement 5S in your organization? Learn how it’s done in real settings through our hands-on online course: 👉 View course

Practical Tips for Getting Started with 5S

Careful planning and successful execution are crucial for implementing the 5S methodology effectively. Organizations should introduce the methodology weeks to months in advance of formal implementation to ensure a smooth transition. Identifying involved departments and personnel is crucial as an initial step for launching a 5S program.

Staff training is vital for the success of 5S. Training programs should consist of both individual and team-oriented activities that focus on the five principles. Utilizing posters and handouts can serve as effective reminders for employees about the importance of the 5S principles. Integrating 5S tasks into daily routines makes maintaining organization a natural part of operations.

Follow-up training sessions tailored to individual employees or teams can help reinforce the principles of 5S after the initial training. Utilizing existing resources can make implementing 5S both efficient and budget-friendly.

Best Practices for 5S Implementation

Implementing 5S requires a structured approach and a commitment to continuous improvement. Best practices for 5S implementation include building employee participation and engagement, providing regular training and coaching, and establishing clear goals and objectives. Organizations should also utilize visual controls, such as floor marking tape and shadow boards, to create a visual workplace and facilitate the identification and elimination of waste. Regular audits and assessments should be conducted to ensure that the 5S methodology is implemented effectively and to identify areas for improvement. By following these best practices, organizations can create a well-organized and productive workspace that supports Lean production and continuous improvement.

5S Beyond Manufacturing

This visual represents the third step of the 5S methodology — systematics, also known as “Set in Order.” It shows a workplace where every tool has a designated place, illustrating how post-sorting organization enhances efficiency, safety, and ergonomics.

The 5S methodology has proven successful beyond the Japanese manufacturing industry in various global sectors. In healthcare, 5S promotes order, proper labeling, and improves patient safety. Education helps create a pleasant learning environment by removing unnecessary items.

Implementing 5S principles in hospitality enhances operational efficiency and improves the customer experience. In retail, 5S promotes sorting and organization, which enhances worker efficiency and the customer experience. The methodology’s universal benefits apply to any organization that handles work processes and spaces.

Building Participation and Engagement

Building participation and engagement in 5S initiatives is crucial for sustained success. Top management’s involvement signals the importance of 5S and encourages the workforce to engage. Effective leadership drives employee commitment to the methodology.

Recognizing and rewarding employee contributions can boost morale and motivation towards maintaining an organized workplace. Involving employees in 5S decision-making helps reinforce their engagement and commitment to workplace organization.

Clear communication is essential to convey the significance of 5S and foster a better understanding among staff.

Visual Management Tools for 5S

Visual management tools play a significant role in implementing the 5S methodology. Tools like floor marking tape, labels, and visual cues help create a visual workplace that is easy to navigate and maintain. Floor tape can outline work areas, indicate equipment locations, and mark hazardous zones.

Shadow boards visually indicate where tools belong and highlight when a tool is missing, saving time and reducing the risk of accidents. Implementing visual control tools makes spaces cleaner and easier to navigate.

Ensuring that all employees understand color-coded visual cues is crucial for easy identification, and posting a color chart can help achieve this goal.

Key Performance Indicators for 5S Success

Key Performance Indicators (KPIs) are essential for evaluating the effectiveness of 5S implementation. Measuring success through relevant KPIs allows organizations to track progress, identify areas for improvement, and align with strategic goals. A key component of process KPIs, such as cycle time and first-pass yield, measures the efficiency of production and service delivery under the 5S framework.

Dashboards visually display information about production processes, making abnormalities and waste apparent. Effective measurement through KPIs ensures that the 5S methodology contributes to overall workplace efficiency and productivity.

Common Challenges and Solutions in 5S Implementation

Implementing the 5S methodology can present several challenges, but these can be overcome with the right strategies and approach. A preliminary assessment can help ascertain whether 5S will benefit the organization. Tailoring training to specific business needs ensures employees understand how 5S applies to their roles.

Regular audits help maintain 5S momentum and identify areas for improvement to ensure continued success. Consistently applying 5S practices across all departments enhances overall efficiency and productivity. Flexibility in adapting 5S practices to changing business needs ensures the methodology’s relevance and effectiveness.

Continuous Improvement in 5S

Continuous improvement is a key principle of the 5S methodology, essential for achieving long-term success. Organizations should regularly review and assess their 5S implementation to identify areas for improvement and make necessary adjustments. This can include conducting regular audits, soliciting employee feedback, and analyzing key performance indicators (KPIs) such as productivity, efficiency, and waste reduction. By continuously improving and refining their 5S implementation, organizations can create a culture of continuous improvement and maintain a competitive edge in the manufacturing industry. The 5S methodology is robust for eliminating waste, reducing clutter, and creating a more organized and productive work environment. It is an essential component of lean manufacturing and lean thinking.

Summary

The 5S methodology offers a systematic approach to workplace organization that can significantly enhance productivity, safety, and employee morale. From its origins in the Toyota Production System to its widespread application across various industries, 5S has proven to be a powerful tool for continuous improvement and waste reduction.

Organizations can create a more efficient and enjoyable work environment by understanding and implementing the five essential steps of 5S—Sort, Set in Order, Shine, Standardize, and Sustain. The commitment to 5S principles fosters a culture of continuous improvement, ensuring long-term success and operational excellence.

🎓 Turn 5S Into Real Results—Not Just Another Theory

Most 5S trainings stop at definitions. This one takes you further, into real implementation, tools, and change.

Suppose you’re looking for a way to organize your workspace, increase safety, and improve efficiency with proven Lean strategies. In that case, this is your opportunity to learn directly from over 25 years of hands-on industry experience.

👉 Explore the course: The Fundamentals of 5S – Boosting Efficiency and Safety Throughout the Organization

Inside, you’ll find:

🎥 Bite-sized video lessons – Learn at your own pace, on your schedule

♾️ Unlimited lifetime access – Revisit content anytime

🧰 Plug-and-play resources – Templates, red tag tools, checklists

📘 Rooted in the real 5S – Discover how each “S” connects to Japanese industrial culture and continuous improvement

👉 Want to see what it’s like? You can preview a lesson for free.

If you’re ready to stop guessing and start applying 5S as intended, this course will guide you every step of the way.

Frequently Asked Questions

What is the primary goal of the 5S methodology?

The primary goal of the 5S methodology is to enhance workplace efficiency and organization by systematically eliminating waste and maintaining order through the five steps: Sort, Set in Order, Shine, Standardize, and Sustain.

How does 5S contribute to lean manufacturing?

5S significantly contributes to lean manufacturing by fostering an organized workplace that enhances efficiency and reduces waste, aligned with the continuous improvement principles of Kaizen. By implementing the 5S methodology, companies can streamline their workflows and establish a foundation for sustained operational excellence.

What are some practical tips for getting started with the 5S methodology?

To effectively implement 5S, it is essential to thoroughly train employees, make 5S a regular part of daily tasks, and utilize visual aids to reinforce the methodology. These steps will help ensure a smooth transition and successful adoption of the 5S principles.

Can 5S be applied outside of manufacturing?

Indeed, 5S can be effectively applied outside of manufacturing in various sectors, including healthcare, education, hospitality, and retail, as it enhances order, efficiency, and the overall customer experience.

What are the key performance indicators (KPIs) for measuring 5S success?

To effectively measure 5S success, key performance indicators should include process metrics such as cycle time and first-pass yield, as well as visual dashboards that provide insights into production efficiency. These indicators collectively highlight improvements in operational performance.