Spis treści

Introduction: 5S Method in the Lean Manufacturing Landscape

In the relentless pursuit of continuous improvement, the 5S method stands as a key component of lean manufacturing and the foundational Toyota Production System. Initially developed by the Toyota Motor Company, 5S creates a visual workplace that empowers teams to eliminate waste, enhance workplace efficiency, and optimize production processes for peak performance.

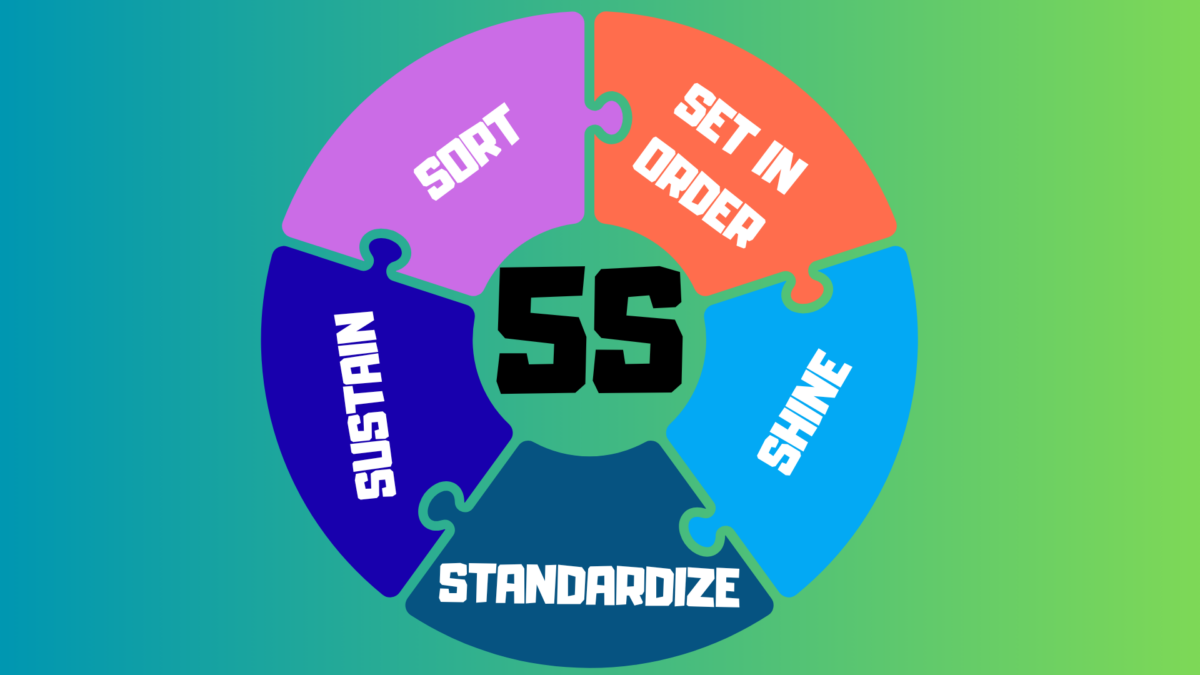

This five-step methodology—known by the Japanese words Seiri (Sort), Seiton (Set in Order), Seiso (Shine), Seiketsu (Standardize), Shitsuke (Sustain)—extends beyond shop floors to entire organizations, from manufacturing industry plants to healthcare environments focused on patient safety.

The Benefits of 5S: Why It Matters for Your Organization

Adopting the 5S methodology delivers far-reaching advantages that extend well beyond a tidy workspace. By systematically applying Sort, Set in Order, Shine, Standardize, and Sustain, organizations unlock a host of benefits that drive continuous improvement and support lean manufacturing goals.

- Improved Quality: A well-organized work environment reduces errors and defects, leading to consistently higher product and service quality.

- Increased Productivity: Streamlined processes and clearly labeled tools minimize wasted time and unnecessary motion, allowing teams to focus on value-added activities.

- Reduced Waste: The 5S methodology targets all forms of waste—whether it’s excess inventory, inefficient workflows, or redundant steps—helping companies reduce costs and optimize resources.

- Enhanced Employee Engagement: Involving staff in 5S activities fosters ownership and pride, building a culture where everyone contributes to workplace efficiency and improvement.

- Sustained Results: By embedding shine, standardizing, and sustaining practices into daily routines, organizations ensure that gains are maintained and built upon over time.

Ultimately, 5S is more than just a tool for organizing workplaces—it’s a catalyst for transforming the entire organization into a high-performing, waste-free environment.

Sort: Clearing the Foundation for Improvement

The first step, Sort, removes all unnecessary items, broken tools, and hazardous materials from your work environment. Conduct a red tag event to identify and categorize items for retention, relocation, or disposal. Red tagging is the process of marking items that need further evaluation during sorting, ensuring nothing valuable is accidentally discarded. Red tags are used to temporarily identify items that may be required in the future, allowing for tracking and review before a final decision is made.

By clearing clutter, teams:

- Reduce wasted time searching for equipment

- Free up necessary resources for productive use

- Expose hidden process bottlenecks and safety risks

Properly managing the remaining items after sorting is crucial for maintaining efficiency and reducing waste in the workspace.

Set in Order & Shine: Building a Visual, Safe Workspace

After sorting, combine the Set in Order and Shine to create an organized, clean space that fosters both workplace safety and productivity.

Set in Order

- Assign fixed locations for tools and materials using visual cues, shadow boards, and clear labels to ensure efficient organization. A shadow board is a classic example of tool organization and visual management, making tools easily visible and accessible.

- Arrange workstation layouts to optimize flow and minimize unnecessary motion.

- Ensure all items are easily accessible, eliminating waiting time and delays.

Shine

- The shine stage of 5S focuses on cleaning and maintenance to ensure workplace cleanliness, equipment upkeep, and safety.

- Implement routine maintenance and daily cleaning to spot wear, leaks, or quality issues before they disrupt production.

- Empower team leaders and operators to perform quick inspections, capture shine, standardize, and sustain feedback.

- Enhance employee morale by maintaining a workplace clean and hazard-free.

The Sixth S: Safety as a Core Principle

Many organizations are now embracing a sixth S—Safety—to further strengthen the 5S methodology. Originally developed as part of the Toyota Production System, this addition underscores the critical role of safety in every work environment. By making safety a core principle, companies ensure that efficiency and productivity never come at the expense of employee well-being.

Integrating safety into 5S involves:

Standardize: Embedding Best Practices Throughout the Organization

Standardize codifies Sort, Set in Order, and Shine into formal processes:

- Develop clear standardized work procedures and SOPs for every cell.

- Use visual management boards to display key metrics and daily tasks.

- Integrate 5S steps into digital 5S training modules, ensuring the management team actively supports, enforces, and models standardization so that both new hires and existing staff consistently apply the method.

Sustain: Cultivating a Culture of Discipline and Continuous Improvement

The final step, Sustain, ensures the 5S method becomes ingrained in your organization’s DNA. Key tactics include:

- Implementing a structured audit process with regular audits and simple scorecards to track compliance, monitor ongoing progress, and drive accountability as part of continuous improvement.

- Celebrate 5S champions and share success stories to build employee engagement.

- Empower teams to catch problems early and propose process improvements.

Consider adding a “Sixth S” for Safety to explicitly integrate hazard identification and risk reduction.

Best Practices for 5S Implementation

Integrating 5S with Lean and Change Management

While 5S stands alone, its true power emerges when integrated with broader lean methodology and change management practices:

- Value Stream Mapping pinpoints high-waste zones for targeted 5S application. Identifying and reducing waste, as well as optimizing work processes, are central to integrating Lean and 5S.

- Pull Systems leverage well-organized cells as visual signals in just-in-time flow.

- PDCA Cycles embed the 5S steps within continuous Plan-Do-Check-Act loops, helping to reduce waste and improve efficiency on the shop floor.

Integrating 5S with Lean helps optimize productivity across all work processes.

Measuring Success: Key Performance Indicators

To quantify the impact of your 5S method, track metrics like:

- Search Time: Reduction in average time to find tools.

- Audit Compliance: Percentage of areas meeting 5S standards.

- Safety Incidents: Decrease in near-misses tied to clutter or equipment hazards.

- Productivity Gains: Improved output per labor hour on production lines, clearly demonstrating increasing productivity as a direct result of 5S implementation.

Conclusion: Your Roadmap to 5S-Driven Excellence

Implementing the 5S method offers many benefits and is just a matter of following the five Japanese words with discipline and energy. By embedding Sort, Set in Order, Shine, Standardize, and Sustain into daily routines and integrating them with lean practices, organizations unlock significant benefits, including reduced waste, optimized workflows, enhanced workplace safety, increased employee engagement, and a more organized environment that supports efficiency and safety.

Ready to transform your operations? Dive into our 5S Lean Manufacturing Course for a complete toolkit and expert coaching to guide your journey.