Spis treści

Introduction: What Is the 5S Methodology Definition?

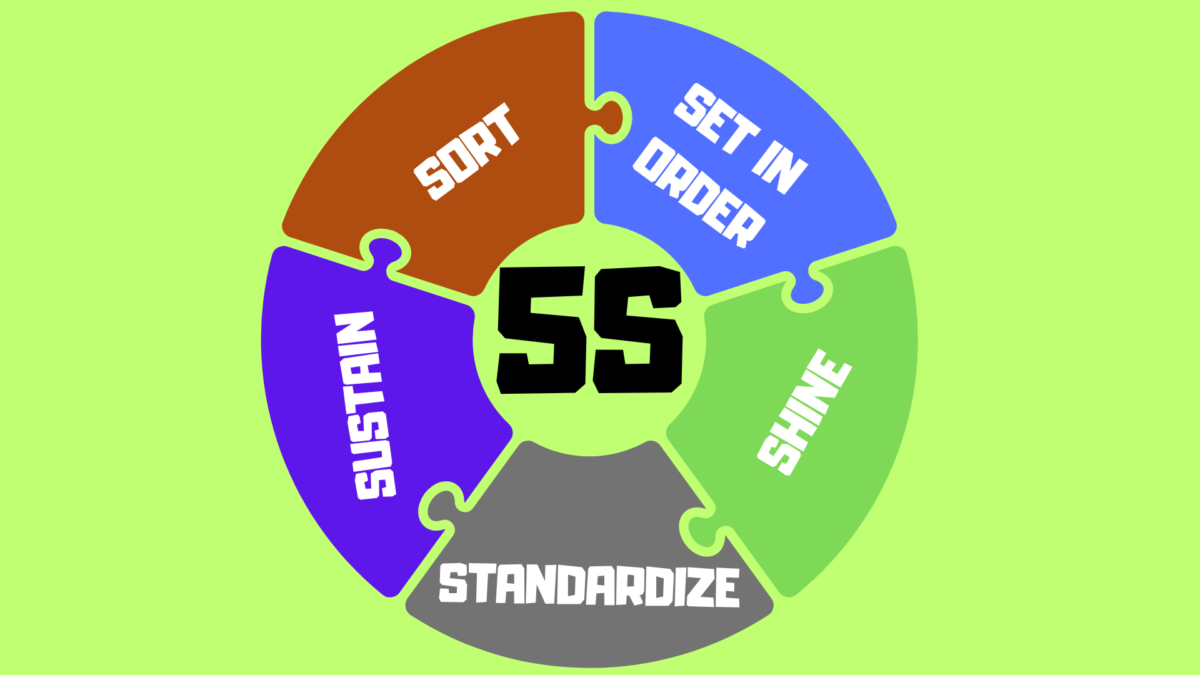

The 5S methodology is a structured method for workplace organization, originating from the Toyota Production System and the Toyota Motor Company. Built on five Japanese words—Seiri (Sort), Seiton (Set in Order), Seiso (Shine), Seiketsu (Standardize), and Shitsuke (Sustain)—each is a Japanese word, reflecting the cultural significance of orderliness and efficiency in Japanese tradition and the roots of 5S in the Toyota Production System. The 5S methodology, also known as the 5S system, plays a key role in creating an organized work environment. It provides a simple yet powerful framework for eliminating waste, boosting workplace efficiency, and driving continuous improvement across production processes in the manufacturing industry and beyond. As a practical tool, 5S supports workplace organization and efficiency. As a foundational system within lean manufacturing, 5S underpins key lean principles, including waste elimination and continuous improvement. Key benefits of the 5S system include improving productivity and reducing waste.

Explore the fundamentals: Jumpstart your 5S journey with our Fundamentals of 5S Course and master each step with practical templates and real-world case studies.

Principles of 5S: The Foundation of Workplace Organization

The 5S methodology stands as a cornerstone of workplace organization, especially within the manufacturing industry. Rooted in Japan, this workplace organization method is built on five foundational Japanese words: Seiri (Sort), Seiton (Set in Order), Seisō (Shine), Seiketsu (Standardize), and Shitsuke (Sustain). Each principle represents a critical step toward creating a more efficient, organized, and productive workspace.

These five principles are not just steps—they are the guiding philosophy behind the 5S methodology. By systematically applying each concept, organizations implement a culture of lean manufacturing and continuous improvement. The focus on sorting out unnecessary items, organizing equipment for easy access, maintaining a clean environment, establishing standards, and promoting self-discipline helps reduce waste at every level of the production process.

Adopting the 5S principles transforms the workplace into a well-ordered environment where efficiency thrives and waste is minimized. This approach not only streamlines daily operations but also lays the groundwork for ongoing improvement, making it an essential strategy for any organization aiming to improve efficiency and maintain a competitive edge in the manufacturing industry.

1. Sort: Clearing Clutter and Unnecessary Objects

The first step, Sort, removes unnecessary items and objects from the shop floor or office to reduce clutter and organize spaces:

- Objective: Identify and remove unnecessary items to reduce clutter and enhance space organization.

- Actions: Conduct a sorting process using red tags to mark items for retention, storage, or disposal. After identifying unnecessary items, consider the following options: remove them, tag uncertain items with a red tag, or set reminders to follow up on items that require further review.

- Benefits: Reduces excess inventory, frees up space, and cuts wasted time searching for required tools.

2. Set in Order: Organizing for Easy Access

The second step, Set in Order, is crucial because this step involves organizing the remaining items logically for efficient retrieval and inventory management, ensuring that everything has a correct location:

- Objective: Create an organized workspace where supplies and tools are easily accessible.

- Actions: Utilize visual management tools, such as labels, color codes, floor marking tape, shadow boards, and color-coded bins, to designate fixed areas and enhance organization and workflow.

- Benefits: Minimizes unnecessary motion and accelerates workflows on the manufacturing floor.

Optimize your layout: Learn advanced set-in-order techniques in our Advanced 5S Workshop.

3. Shine: Maintaining a Clean, Safe Environment

The third step, Shine, combines regular cleaning tasks with inspections to sustain a clean and safe workplace environment:

- Objective: Maintain spotless equipment and floors, and promptly identify hazards.

- Actions: Implement daily Shine routines, documented checklists, and quick operator inspections.

- Benefits: Enhances workplace safety, prevents quality defects, and boosts employee engagement and well-being.

Practice Shine drills in our interactive 5S Simulation Game.

4. Standardize: Creating Visual Controls and SOPs

The fourth step, Standardize, embeds the first three steps into stable procedures:

- Objective: Establish visual controls, standard work instructions, and floor marking tape guidelines.

- Actions: Develop SOPs, post checklists at point-of-use, and integrate digital 5S audits.

- Benefits: Delivers long-term benefits by ensuring consistent application and supporting lean thinking.

5. Sustain: Building a Culture of Self-Discipline

The final step, Sustain, makes 5S a daily habit:

- Objective: Drive ownership and self-discipline throughout the organization.

- Actions: Conduct regular audits, recognize 5S champions, and integrate metrics into leadership reviews.

- Benefits: Maintains organization, prevents backsliding, and fuels ongoing continuous improvement.

Why 5S Is a Key Component of Lean Production

By defining and applying the 5S methodology, organizations transform their work environment into an actual visual workplace and visual factory, benefiting workplaces by improving organization and safety:

- Reduce waste in materials, time, and motion—reducing waste is a core objective and benefit of 5S

- Optimize productivity on production lines

- Improve overall quality and safety

- Foster team participation and higher employee morale

Employees play a crucial role in implementing, maintaining, and participating in 5S practices, including training, standardizing procedures, and fostering a safety culture within workplaces.

Conclusion and Call to Action

A clear definition of the 5S methodology equips you to eliminate waste, streamline operations, and cultivate a culture of operational excellence. Ready to implement world-class 5S in your facility?

👉 Enroll now in the Fundamentals of 5S Course and transform your shop floor into a visual, waste-free powerhouse!