Spis treści

5S Program: How to Effectively Implement 5S in the Workplace

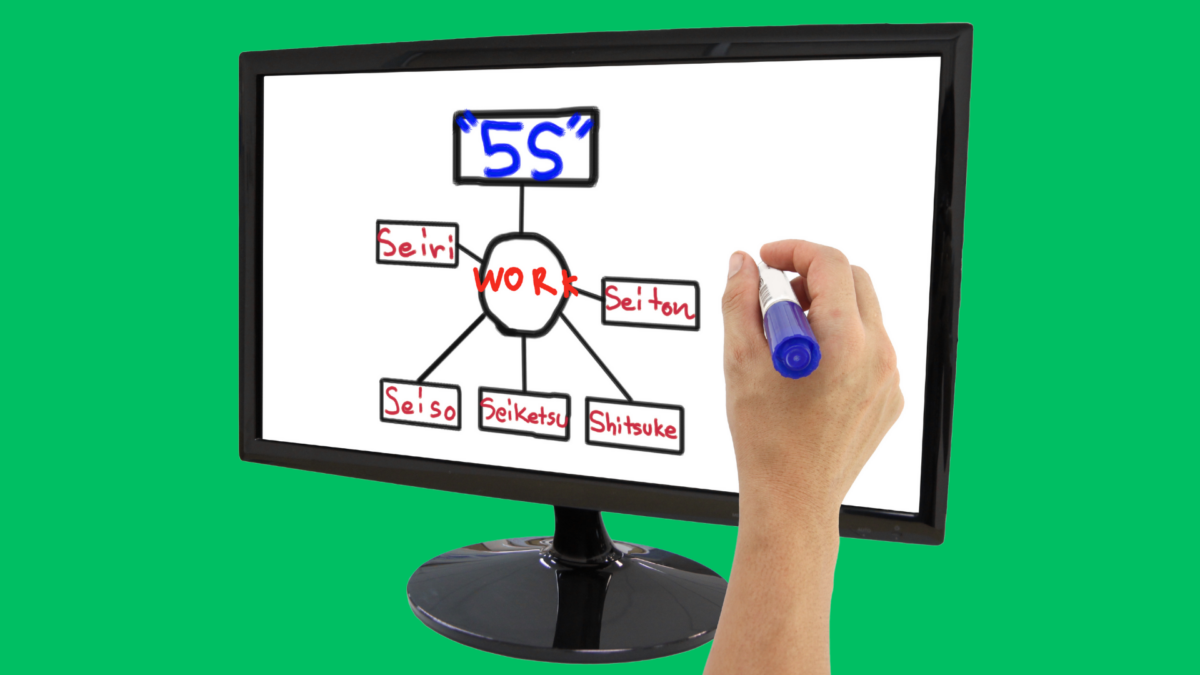

In today’s competitive business environment, companies strive to optimize processes, reduce waste, and enhance workplace efficiency. One of the most powerful methodologies that supports these objectives is the 5S program. Derived from five Japanese terms (Seiri, Seiton, Seiso, Seiketsu, and Shitsuke), the 5S methodology provides a structured approach to workplace organization that enhances productivity, safety, and morale. This article will explore the fundamentals of implementing 5S, recommended books on 5S, essential procedures, and best practices for a successful 5S methodology implementation.

What is the 5S Program?

The 5S program is a workplace organization method that uses a five-step methodology to create and maintain an efficient, clean, and safe work environment. Each “S” represents a stage:

- Sort (Seiri): Remove unnecessary items from the workspace.

- Set in Order (Seiton): Logically organize tools and equipment.

- Shine (Seiso): Keep the workplace clean and tidy by regularly maintaining it.

- Standardize (Seiketsu): Establish standards and procedures for consistency.

- Sustain (Shitsuke): Maintain and review standards through regular audits.

Organizing raw materials within various work environments is crucial, particularly when implementing a 5S program to enhance safety and efficiency. Disorganized raw materials can pose significant hazards, leading to accidents and inefficiencies in processes, especially on construction sites.

The 5S methodology is a foundational tool that integrates lean principles into organizational processes, fostering a culture of continuous improvement and waste elimination.

The 5S methodology originated at Toyota Motor Company and is foundational in total productive maintenance and lean manufacturing.

Understanding these stages is the first step toward successfully implementing 5S in your workplace.

Want to turn theory into practice? Sign up for our hands-on 5S fundamentals course here!

Introduction to 5S

Historical Background of 5S

The 5S methodology has its roots in Japan, where the Toyota Motor Company first implemented it as part of the Toyota Production System (TPS). The TPS is a lean manufacturing philosophy aiming to eliminate waste and maximize customer value. The 5S methodology was developed to support this philosophy by creating a clean and organized work environment that fosters continuous improvement and efficiency. The term “5S” comes from the Japanese words Seiri, Seiton, Seiso, Seiketsu, and Shitsuke, which translate to Sort, Set in Order, Shine, Standardize, and Sustain in English. Over time, the 5S methodology has been adopted by organizations worldwide as a key component of lean manufacturing and continuous improvement initiatives.

Why Implementing 5S Matters

Implementing 5S is about cleanliness and instilling discipline, efficiency, and safety into the organizational culture. Companies that have successfully embraced 5S have reported:

- Reduction in waste and non-value-adding activities

- Improved workplace safety

- Higher employee morale and involvement

- Enhanced product quality

- Better space utilization

Organizing raw materials is crucial for improving workplace safety and efficiency, as disorganized raw materials can pose significant hazards.

These benefits contribute to fostering a culture of continuous improvement within the organization, ultimately enhancing productivity.

Employees who operate in an organized, clutter-free environment are naturally more productive, resulting in an efficient workplace. This also enhances employee engagement by fostering a sense of involvement, recognition, and communication.

Benefits of 5S

The benefits of implementing the 5S methodology are numerous. One of the key advantages is that it helps to reduce waste by streamlining processes and organizing workspaces. Additionally, organizing raw materials is one of the key benefits of the 5S methodology, as it enhances safety and efficiency. Key benefits include improved productivity, reduced waste, increased efficiency, enhanced safety, and improved morale. The 5S methodology also fosters a culture of continuous improvement, where employees are encouraged to identify areas for improvement and implement necessary changes. Additionally, the 5S method helps to reduce employee frustration and stress by creating a clean and organized work environment. Organizations can reduce costs and enhance workplace efficiency by eliminating unnecessary items and streamlining processes, ultimately creating a more productive workspace.

This 5S improvement example demonstrates the effectiveness of tool organization and labeling in streamlining processes and saving time.

How to Implement 5S in the Workplace

For many organizations, the biggest question remains: How can 5S be implemented effectively in workplace settings during the initial implementation phase? Here is a practical roadmap:

- Initial Assessment: Evaluate the current workplace organization and identify areas for improvement, including the organization of raw materials to enhance safety and efficiency.

- Training and Communication: Educate all employees on the 5S principles and their importance. Please identify the affected departments, such as production, safety, maintenance, and quality, to make sure they’re aware of their involvement.

- Pilot Implementation: Start with a small, manageable area to demonstrate quick wins.

- Full Rollout: Systematically expand the 5S program across the organization.

- Monitoring and Sustaining: Use regular audits and feedback loops to maintain standards.

A well-structured business case is critical for securing the necessary budget allocation to ensure the successful implementation of the 5S program.

To ensure success, follow these practical steps: identify involved departments, provide necessary training, and establish an auditing schedule.

The key is persistence and commitment from all organizational levels.

Want practical guidance from experienced professionals? Join our comprehensive 5S training program here!

5S Methodology: Step-by-Step Guide

The 5S methodology is a step-by-step approach to workplace organization. The first step, Sort, involves identifying and removing unnecessary items from the workplace. This helps reduce excess inventory by ensuring that only necessary items are retained, resulting in improved inventory efficiency. The second step, Set in Order, involves organizing the remaining items in a logical and efficient manner. This includes organizing raw materials to enhance safety and efficiency, particularly in construction sites where disorganized raw materials can pose significant hazards. The third step, Shine, involves cleaning and maintaining the work environment. The fourth step, Standardize, consists in creating standardized work procedures and visual controls to support the new organization. The final step, Sustain, involves maintaining and continuously improving the new organization over time. By following these steps, organizations can create a productive and efficient work environment that is safe and clean.

Key Components of 5S

The key components of the 5S methodology include visual controls, such as floor marking tape and shadow boards, to help maintain the new organization. Organizing raw materials is a key component of the 5S methodology, as it helps to maintain a safe and efficient work environment. Additionally, the 5S method involves training employees on the new procedures and standards. The 5S methodology also consists in establishing a system for continuous improvement, where employees are encouraged to identify areas for improvement and implement necessary changes. By using visual cues, such as signs and labels, organizations can also help to maintain the new organization and reduce errors. Maintaining a clean workplace environment is crucial in the ‘Shine’ step, allowing employees to perform their tasks more effectively while minimizing risks. Overall, the 5S methodology is a comprehensive approach to workplace organization that systematically eliminates waste, reduces unnecessary items, and creates a clean and organized work environment.

Essential 5S Procedure for a Smooth Implementation

A structured approach to 5S procedures can distinguish between success and failure. A typical procedure might include:

- Forming a 5S implementation team

- Conducting 5S audits and gap analysis on the manufacturing floor

- Defining KPIs related to cleanliness, organization, and safety

- Documenting procedures and creating visual management aids

- Scheduling regular reviews and refresher training

- Organizing raw materials to enhance safety and efficiency

A comprehensive assessment is crucial for evaluating the effectiveness of these procedures and ensuring continuous improvement.

A clear and actionable 5S procedure ensures consistency, accountability, and sustainable results.

Best Practices for 5S

Implementing a 5S program requires careful planning, execution, and maintenance to ensure continuous improvement and overall workplace efficiency. Here are some best practices to consider:

- Start with a Thorough Sorting Process: Begin by identifying and eliminating unnecessary items in the workplace. This step is crucial for reducing waste, improving productivity, and creating a more efficient work environment. By removing clutter, you can focus on what truly adds value to your operations.

- Organize raw materials to reduce hazards and improve efficiency. Disorganized raw materials can pose significant risks, particularly on construction sites, leading to accidents and inefficiencies.

- Use Visual Controls: Implement visual controls, such as floor marking tape, shadow boards, and signs, to create a visually organized workplace. These tools help employees quickly locate the correct tools and materials, reducing wasted time and unnecessary movement. Visual cues help maintain organization and streamline processes.

- Establish Consistent Procedures: Develop standardized work procedures and provide training to ensure all employees are on the same page. Consistent procedures help maintain a clean and organized workplace, reducing variability and enhancing overall efficiency.

- Focus on Employee Engagement: Encourage employees to participate and engage in the 5S process. Building a culture of continuous improvement requires the involvement of all team members. Employees who feel valued and included are more likely to take ownership of the 5S program and contribute to its success.

- Conduct Regular Audits: Regularly conduct audits to ensure the 5S program is being followed and identify areas for improvement. Utilize key performance indicators (KPIs) to track progress and make adjustments to the program. Audits help maintain standards and ensure continuous improvement.

- Ongoing Training: Offer continuing training and support to employees to ensure they possess the necessary skills and knowledge to maintain a clean and organized workplace. Continuous learning helps reinforce the importance of 5S and keeps everyone aligned with the program’s goals.

- Make It a Part of Daily Work: Integrate 5S into daily tasks and responsibilities. This approach ensures that the program is sustainable and that employees continuously improve their work processes. Making 5S a routine part of work helps embed it into the organizational culture.

- Use a Systematic Approach: Implement the 5S method systematically, starting with sorting and proceeding through the remaining steps logically and methodically. A structured approach ensures that each step is thoroughly executed and the program builds on a solid foundation.

- Involve All Affected Departments: Involve all affected departments in the 5S implementation process. This comprehensive involvement ensures that everyone is on the same page and the program addresses the organization’s needs effectively. Collaboration across departments enhances the program’s effectiveness.

- Celebrate Successes: Recognize employees who contribute to the 5S program and celebrate their successes. Acknowledging achievements helps build momentum and reinforces the importance of maintaining a clean and organized workplace. Celebrations also boost employee morale and engagement.

By following these best practices, organizations can establish a successful 5S program that enhances workplace efficiency, minimizes waste, and fosters a culture of continuous improvement. The 5S methodology is a key component of lean manufacturing and the Toyota Production System, and it has been proven effective in a wide range of industries and workplaces.

Best Books on 5S and Related Resources

Reading materials are an excellent way to deepen your understanding of the 5S methodology. Here are some recommended books on 5S and books about 5S that offer practical insights:

- “5S for Operators: 5 Pillars of the Visual Workplace” by Hiroyuki Hirano — A practical guide for frontline workers.

- “The 5S Playbook: A Step-by-Step Guide to Implementing Lean 5S in Manufacturing” by Chris A. Ortiz — Offers a straightforward approach to applying 5S in production environments.

- “5S Made Easy: A Step-by-Step Guide to Implementing and Sustaining Your 5S Program” by David Visco is ideal for beginners and seasoned practitioners.

These resources provide different perspectives on implementing and sustaining 5S initiatives. Understanding lean thinking is crucial for maximizing the benefits of these methodologies.

Ready to supplement your reading with real-world practice? Enroll in our practical 5S fundamentals course here!

Overcoming Challenges in 5S Methodology Implementation and Eliminating Waste

Even with a solid understanding of the principles, 5S methodology implementation can face several challenges, including:

- Resistance to Change: Employees might be reluctant to adopt new habits. Emphasizing that maintaining cleanliness helps reduce workplace hazards can highlight the importance of 5S in preventing injuries and equipment failures.

- Inconsistent Application: Without regular audits, 5S can gradually erode.

- Disorganized raw materials can lead to inefficiencies and hazards, underscoring the importance of regular audits.

- Management Apathy: If leadership is not fully committed, employees will not prioritize the 5S approach.

Moving forward, it is crucial to have processes in place to support sustained organizational change.

To overcome these hurdles, companies should:

- Communicate the benefits clearly

- Involve employees in decision-making

- Celebrate small wins and improvements

- Provide ongoing training and reinforcement

Implementing 5S audits and unique KPIs to measure the effectiveness of the 5S process is essential to ensuring continuous improvement. This approach helps motivate teams and track performance, driving ongoing enhancements as part of a larger continuous improvement strategy aligned with lean methodology.

Practical Tips for How to Implement 5S in the Workplace

Here are some actionable tips:

- Use Visual Management: Implement visual cues, such as labels, color coding, and floor markings. Consider conducting one-day sessions to train employees on effectively using these visual tools.

- Organize Raw Materials: Utilize visual cues to organize raw materials, thereby enhancing safety and efficiency effectively. Disorganized raw materials can pose significant hazards, especially on construction sites.

- Create a 5S Calendar: Schedule regular cleaning, organizing, and audit activities. Ensure that the right cleaning materials are readily available and provide guidance on their effective use to maintain a clean and organized workspace.

- Involve Everyone: From managers to frontline staff, engagement at all levels is essential for success.

- Measure Progress: Utilize key performance indicators (KPIs) to track and monitor improvements.

- Promote Ownership: Assign responsibilities for maintaining 5S areas.

Implementing 5S Beyond Manufacturing with Visual Controls

Although 5S originated in manufacturing, it is equally applicable across industries. The manufacturing industry, particularly at Toyota, has demonstrated how 5S enhances efficiency and organization in manufacturing environments. As a component of lean production, 5S principles can be applied to streamline operations and reduce waste in various sectors:

- Healthcare: Streamlining hospital operations for better patient care.

- Offices: Organizing desks, digital files, and workflows.

- Retail: Maintaining neat and accessible inventory areas and sales floors.

- Manufacturing: Organizing raw materials to enhance efficiency and reduce hazards, particularly in construction sites where disorganized materials pose significant risks.

Effective shop floor management, within the framework of 5S, contributes to reducing waste and improving efficiency in production processes by maintaining an orderly environment and minimizing the time spent searching for tools and materials.

The principles are universal: wherever there is work, 5S can add value.

Want to see how 5S can work in your industry? Get practical insights through our exclusive training here!

5S in Service Industries

While the 5S methodology originated in the manufacturing industry, its principles can be applied to any workplace, including those in the service industry. Many service industries, such as healthcare and finance, have successfully implemented the 5S methodology to enhance workplace efficiency and minimize waste. For example, a hospital might utilize 5S to organize its supply closet, thereby reducing wasted time and improving patient care. A financial institution may utilize 5S to streamline its paperwork processes, thereby reducing errors and improving customer satisfaction. By applying the 5S methodology, service industries can create a more efficient and productive work environment that supports continuous improvement and excellent customer service.

Cultural Impact of 5S

The 5S methodology has a significant cultural impact on organizations that implement it. By creating a clean and organized work environment, 5S promotes a culture of continuous improvement and efficiency. Employees are empowered to take ownership of their workspace and contribute to improving processes and procedures. This increases employee engagement, morale, and a sense of pride and responsibility among team members. Additionally, 5S helps establish a visual management culture, where problems are visible and can be addressed quickly. This leads to a more transparent and accountable work environment, where everyone works together to achieve common goals. Organizations that adopt the 5S methodology can create a cultural shift that supports lean manufacturing and continuous improvement principles.

Case Studies of Successful 5S Implementation

There are many case studies of successful 5S implementation in various industries. For example, a manufacturing company might implement 5S to reduce waste and improve productivity on the shop floor. By sorting and eliminating unnecessary items, setting in order and organizing necessary items, shining and cleaning the workspace, standardizing procedures, and sustaining the improvements, the company can achieve significant gains in efficiency and productivity. Another example might be a hospital implementing 5S to improve patient care and reduce medical errors. By applying the 5S methodology to its processes and procedures, the hospital can create a safer and more efficient work environment that supports excellent patient care. These case studies demonstrate the effectiveness of the 5S methodology in achieving continuous improvement and operational excellence in various industries.

Conclusion: Building a Culture Around 5S and Continuous Improvement

Implementing 5S successfully means embedding it into the company culture. Achieving and maintaining a clean and efficient workplace directly contributes to a broader cultural change, which promotes continuous improvement and enhances both productivity and employee morale. It’s not a one-time event but a constant journey of improvement and learning. The benefits — from reduced waste to improved morale — are worth the effort. Organizations that sustain their 5S initiatives are often better positioned to pursue broader Lean Manufacturing goals. This commitment to 5S fosters operational excellence, enhances safety, and creates a culture of continuous improvement within organizations.

Ready to turn theory into action? Sign up for our in-depth, practical 5S course and see the difference real experience makes!

Final Note

If you are serious about implementing 5S principles effectively, I highly recommend joining our practical course: The Fundamentals of 5S – Boosting Efficiency and Safety Throughout the Organization. Understanding and applying lean methodology is crucial for achieving continuous improvement and efficiency. This course consolidates 25 years of real-world experience in Lean Manufacturing and 5S into an actionable guide. It offers practical, field-tested advice on applying 5S across different types of organizations. Join us and learn from a professional who has successfully led 5S implementations across numerous industries!

👉 Preview a free lesson and see how this course delivers real-world value.