Spis treści

5S Training Courses: Your Guide to Mastering Workplace Organization

In the ever-evolving business world, efficiency, organization, and safety are more critical than ever. Organizations across all industries are turning to 5S training courses and lean manufacturing to foster a culture of continuous improvement and operational excellence. These courses are accessible for beginners, with each module making it easy for those new to 5S to get started and understand its function in enhancing workplace organization and efficiency. Additionally, professionals teach the courses, ensuring learners receive expert guidance and valuable insights. Whether you’re new to 5S or looking to deepen your knowledge, understanding the value of comprehensive training is crucial. In this article, we will explore the benefits of 5S training, the differences between in-person and 5S online courses, what you can expect from 5S classes, and why investing in your 5S education is a game-changer for individuals and organizations.

Introduction to 5S

The 5S methodology is a systematic approach to workplace organization and management, focusing on creating a clean, safe, and efficient work environment. Rooted in lean principles, 5S is designed to promote operational excellence across various industries. Understanding how 5S relates to lean principles is crucial for employees to effectively apply the methodology and improve organizational performance. The system is based on five Japanese words: Seiri (Sort), Seiton (Set in Order), Seiso (Shine), Seiketsu (Standardize), and Shitsuke (Sustain). These words provide a step-by-step guide to implementing continuous improvement in any workplace. Visual management is also a key component of 5S, helping to create a more organized and efficient work environment.

By implementing the 5S methodology, organizations can reduce waste, improve productivity, and enhance employee morale. The 5S training course is designed to provide learners with a comprehensive understanding of the 5S methodology and its application in the workplace. The course covers the fundamentals of 5S, including the five Japanese words and their significance in creating a well-organized work environment.

Through practical examples and case studies, learners will gain a deeper understanding of how to implement 5S in their workplace. The 5S methodology is a self-paced learning experience, allowing learners to complete the course at their convenience. By the end of the course, learners will be able to apply the 5S methodology to their work environment, leading to improved efficiency and productivity.

Benefits of 5S

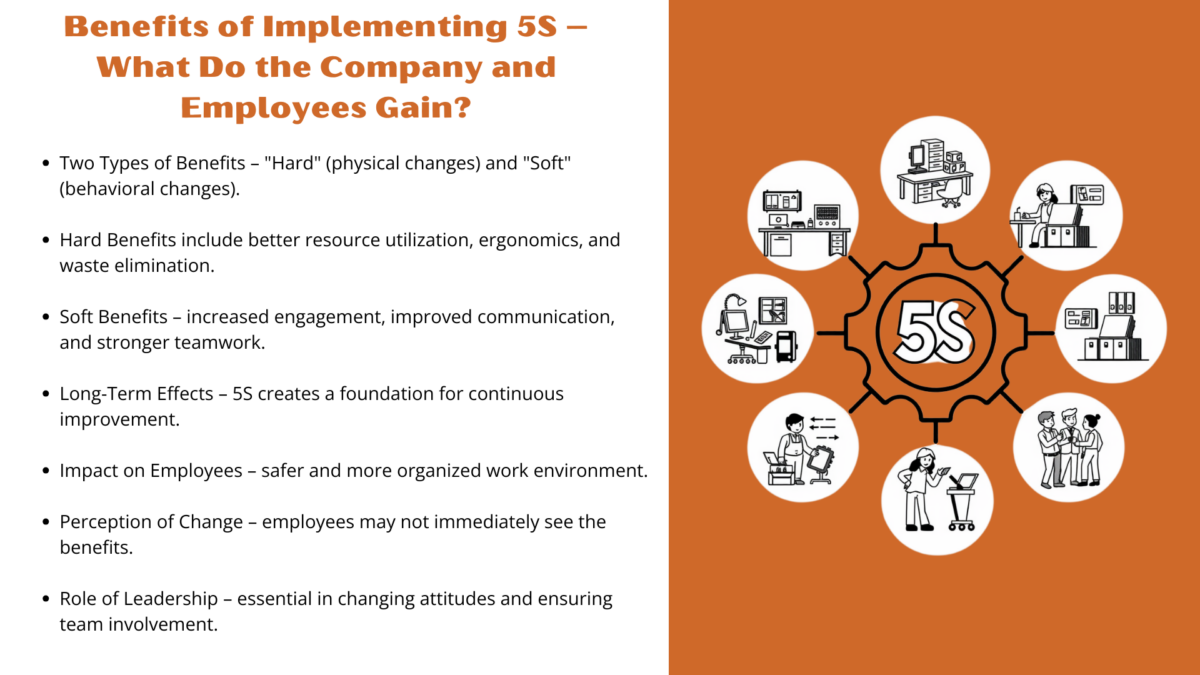

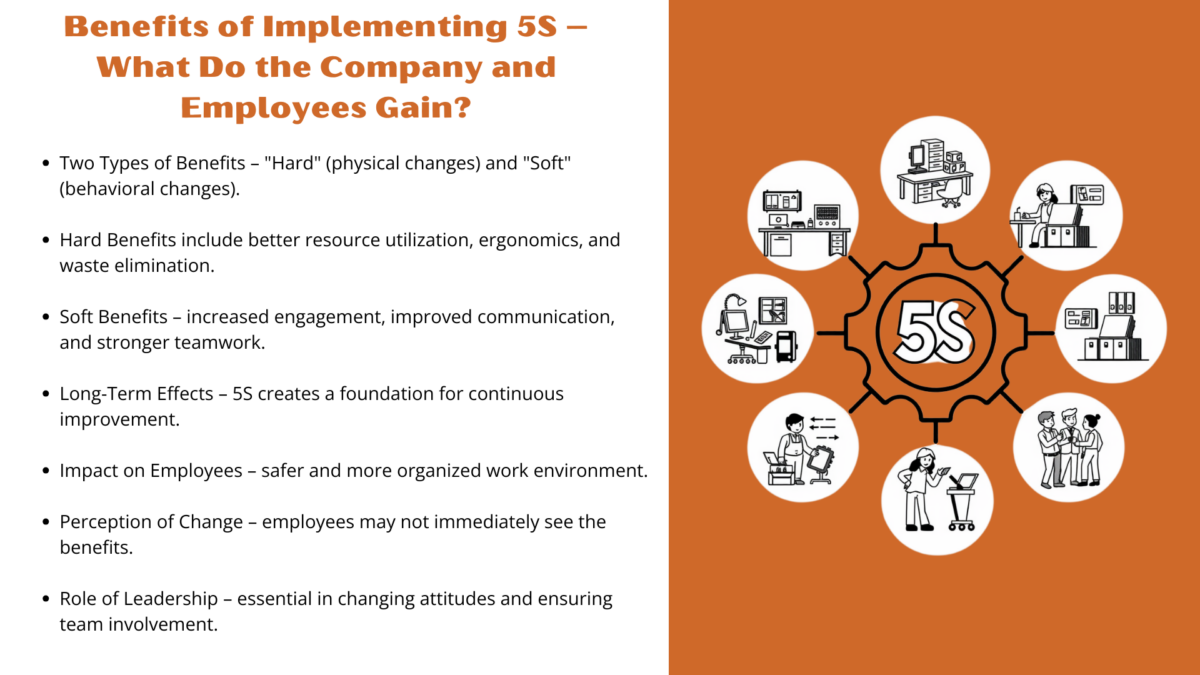

The 5S methodology offers numerous benefits that can transform any workplace into a model of efficiency and productivity. By implementing the 5S method, organizations can significantly reduce waste and optimize their work environment, thereby fostering a culture of continuous improvement and operational excellence.

One of 5S’s primary benefits is creating a clean, safe, and orderly work environment, which enhances workplace safety. This improves productivity and boosts employee morale, as workers take pride in maintaining an organized space. The methodology’s focus on standardizing processes and procedures helps eliminate inconsistencies and variations, improving quality and efficiency.

Moreover, 5S is a cornerstone of lean principles, providing a step-by-step roadmap for implementation that is easy to understand and apply. This structured approach ensures that improvements are sustainable over the long term, helping organizations stay competitive in ever-changing market conditions. The benefits of 5S are not limited to a single industry; they can be realized in manufacturing, healthcare, service sectors, and beyond.

By laying a solid foundation for continuous improvement, 5S enables organizations to enhance productivity, improve safety, and reduce errors. This methodology is a powerful tool for any organization seeking to optimize operations and achieve operational excellence.

What Are 5S Training Courses?

5S training courses are structured programs, with each module designed to teach the principles and practical applications of the 5S methodology: Sort, Set in Order, Shine, Standardize, and Sustain. The primary objectives of these courses are to enhance the efficiency and quality of work through the 5S principles. Standard work is also emphasized to ensure consistency and reliability in processes. These courses help manage workplace organizations by providing step-by-step methods for achieving these objectives effectively. Participants will:

- Understand the philosophy behind 5S.

- Learn best practices for implementing 5S

- Develop skills for sustaining 5S initiatives

- Build a safer and more efficient work environment

Enrolling in 5S training will equip you with the tools necessary to transform cluttered and disorganized spaces into models of efficiency and safety.

Ready to put 5S theory into action? Enroll now in our practical 5S fundamentals course here!

Why Choose 5S Training Courses?

Comprehensive 5S training courses provide:

- Hands-on Learning: Practical exercises that reinforce theoretical knowledge.

- Expert Insights: Lessons drawn from real-world experience.

- Immediate Application: You can apply tools and techniques immediately, demonstrating how 5S can be effectively implemented in various scenarios.

- Certification: Many courses offer certifications that enhance your professional credibility.

These benefits make 5S training a vital investment for individuals seeking to drive significant organizational improvements. Additionally, understanding the value stream is crucial for identifying and eliminating waste, further enhancing the efficiency and effectiveness of 5S practices.

🎓 5S isn’t just theory—see how it works in real life. Start our practical course today: 👉 Enroll now

Course Content

A comprehensive 5S training course covers the fundamentals of the 5S methodology. Each module focuses on one of the five Japanese words: Seiri (Sort), Seiton (Set in Order), Seiso (Shine), Seiketsu (Standardize), and Shitsuke (Sustain). The course begins with an introduction to the 5S methodology, its history, and its application across various industries.

Learners are guided through the step-by-step process of implementing 5S, using practical examples and case studies to illustrate each concept. The course also explores how to standardize and sustain 5S practices, ensuring that improvements are sustained over time. It includes developing and using standard operating procedures to support these practices. Participants learn how to measure and evaluate the effectiveness of 5S implementation, using metrics such as productivity, quality, and employee engagement.

The course includes quizzes, videos, and discussions to make the learning experience engaging and interactive. These elements help learners understand and apply the 5S methodology in real-world scenarios. The course objectives are clearly defined, and learners must demonstrate their understanding and application of 5S upon completion.

The course content is relevant to various industries, including manufacturing, healthcare, and service sectors. It is designed to be flexible, with options for self-paced learning or instructor-led training. Upon completing the course, learners receive a certificate of completion, which can be used to demonstrate their knowledge and skills in the 5S methodology.

Target Audience

The 5S training course is designed for individuals who want to learn about the 5S methodology and its application in the workplace. Whether you are an employee, manager, or leader, this course is suitable for anyone seeking to enhance their organization’s efficiency and productivity. It is ideal for individuals new to the 5S methodology who want to refresh their knowledge and skills.

The course is designed for individuals across various industries, including manufacturing, healthcare, and the service sector. It suits teams and organizations that want to create a culture of continuous improvement and operational excellence. Participants can develop their skills and knowledge in workplace organization and management by learning about the benefits of 5S, such as improved productivity, reduced waste, and enhanced employee morale. Additionally, the course emphasizes process improvement as a key outcome of implementing 5S principles.

The course covers the five Japanese words of 5S and their significance in creating a well-organized work environment. Participants will learn about the tools and techniques used in 5S, including downloadable templates and quizzes, to enhance their understanding. By the end of the course, individuals will be equipped to foster a culture of continuous improvement within their organization, ultimately leading to long-term success and competitiveness.

🎓 Want to know how 5S is used on the shop floor? Our online course shows you step by step: 👉 Learn more

Choosing a Course

When selecting a 5S training course, it’s essential to consider its alignment with your organization’s goals and objectives, focusing on continuous improvement and operational excellence. Look for courses that provide practical examples and case studies to illustrate the application of lean principles in real-world scenarios. A comprehensive 5S training course should cover the five Japanese words —Seiri, Seiton, Seiso, Seiketsu, and Shitsuke —and their significance in creating a well-organized work environment.

Consider a self-paced course that offers downloadable templates and quizzes to reinforce learning and provide a structured approach to 5S training. The course aims to help learners understand the fundamentals of 5S and its benefits in enhancing workplace efficiency and productivity. A good course should provide a step-by-step guide to implementing 5S, including tools and techniques for optimizing workflows and reducing waste. Additionally, it should introduce various lean tools that can be integrated into the 5S methodology. The course should also cover the importance of standardizing and sustaining 5S practices to ensure long-term success.

Look for courses that offer a certificate of completion and are certified by a reputable organization. Consider the convenience of the course, including its accessibility on devices such as smartphones and tablets, as well as the option to learn at your own pace. Finally, read reviews and ask for referrals to ensure the course effectively teaches 5S methodology and provides a solid foundation for implementation.

Enrollment

Enrolling in the 5S training course is straightforward and convenient, designed to fit seamlessly into your busy schedule. This self-paced learning experience allows you to start at any time and progress at your own pace, making it ideal for individuals and teams aiming to enhance their work environment through lean principles.

Upon registration, you will gain immediate access to a comprehensive curriculum that covers the fundamentals of 5S and its application across various industries. The course is inclusive, catering to beginners new to 5S and experienced professionals seeking a refresher. Whether you want to improve your knowledge or implement 5S in your organization, this course provides the necessary tools and insights.

The course fee includes access to all learning materials, interactive quizzes, and downloadable templates, ensuring you have everything you need to succeed. You can enroll at any time, and the self-paced nature of the program allows you to complete it at your own pace.

Upon completing the course, you will receive a certificate of completion with a recognized credential in 5S methodology. This certification enhances your professional credibility and equips you with the knowledge and skills necessary to drive continuous improvement and operational excellence in your workplace.

Enrolling in the 5S training course is crucial to creating a culture of continuous improvement and operational excellence. You will gain the knowledge and skills to implement 5S in your organization, improve overall efficiency and productivity, and foster a more organized and productive work environment.

Exploring 5S Online Options

With the rise of digital learning, 5S online courses have become increasingly popular. These courses are often delivered through a virtual learning platform, with each module offering several advantages: Virtual training provides a comprehensive and flexible learning experience.

- Flexibility: Learn at your own pace, anytime, anywhere.

- Affordability: Online courses are often more cost-effective than in-person training.

- Accessibility: Great for remote teams and global organizations.

- Interactive content, including videos, quizzes, and case studies, enhances engagement.

However, when choosing a 5S online course, ensure it provides practical, real-world examples rather than just theory.

Want a flexible, hands-on approach to learning 5S? Discover our expertly crafted online 5S course here!

Technical Requirements

The 5S training course is an online, self-paced learning experience that requires an internet connection. It is designed to be completed on various devices, including desktops, laptops, and mobile devices. To ensure a smooth learning experience, we recommend using a supported browser, such as Google Chrome or Mozilla Firefox.

The course is accessible on various platforms, including Windows and macOS, and requires a minimum internet speed of 1 Mbps to ensure smooth video playback. Learners can complete the course at their convenience, with the ability to log in and out as needed. A valid email address is required to receive course materials and notifications.

The course is compatible with various devices, including tablets and smartphones, and requires a PDF viewer to access downloadable templates and resources. Designed to be free from spam and viruses, it ensures a safe and secure learning experience for all participants.

What to Expect from 5S Classes

Whether online or in-person, practical 5S classes cover a range of crucial topics:

- Introduction to 5S: Origins and philosophy

- Deep Dive into Each S: Practical applications of Sort, Set in Order, Shine, Standardize, and Sustain

- Visual Management Tools: How to use signage, labels, and color coding

- 5S Auditing: Conducting and evaluating audits

- Common Challenges: How to overcome resistance and maintain momentum

Some classes also incorporate simulations and case studies, allowing participants to apply their knowledge in controlled environments. These activities are essential for understanding workplace organization.

Key Features of a Quality 5S Training Program

When selecting a 5S training course, look for these features:

- Experienced Instructors: Trainers with real-world 5S implementation experience.

- Comprehensive Curriculum: Coverage from basics to advanced strategies.

- Practical Application: Real-life examples and assignments.

- Interactive Learning: Opportunities for discussion, Q&A, and problem-solving.

- Certification: Formal recognition of your knowledge and skills.

A training program that ticks all these boxes prepares you for successful 5S deployment in any workplace. Additionally, it should incorporate lean thinking to ensure a holistic approach to efficiency and waste reduction.

Looking for a 5S training course that combines theory with practical tools? Check out our fundamentals training here!

Benefits of Completing 5S Training

Completing a 5S training course delivers both personal and organizational benefits:

- Increased Efficiency: Organized workplaces reduce time spent searching for tools and materials.

- Enhanced Safety: Clear pathways and clean environments lower accident risks.

- Employee Engagement: Workers take pride in maintaining organized spaces.

- Cost Savings: Reduced waste translates into lower operating costs.

- Foundation for Lean Initiatives: 5S is often the first step in broader Lean transformations.

These gains make 5S training a wise investment for companies aiming to thrive in competitive markets. Visual controls enhance these benefits by providing clear indicators and guidelines for maintaining organization and efficiency.

How to Maximize Your 5S Training Experience

To get the most out of your 5S classes:

- Stay Engaged: Participate actively in discussions and exercises.

- Apply Quickly: Start implementing the 5S principles in your workplace immediately after training.

- Seek Feedback: Encourage colleagues to provide feedback on your 5S practices.

- Stay Consistent: Make 5S a daily habit, not just a one-time event. Use standard work instructions to maintain consistency.

- Continue Learning: 5S is a journey. Stay curious and keep refining your skills.

Want to ensure your success with a structured and practical 5S learning journey? Our course is built for real-world application — sign up here!

Common Mistakes to Avoid During 5S Implementation

Even with training, mistakes can happen. Common pitfalls include:

- Inconsistent Follow-Through: Failing to sustain 5S efforts.

- Top-Down Mandates: Implementing 5S Without Employee Buy-In

- Neglecting Training: Assuming everyone understands 5S without proper instruction or refresher courses.

- Lack of Auditing: Not conducting regular 5S audits to maintain standards. A visual workplace can help keep these standards by making it easier to identify and correct issues.

Avoiding these mistakes ensures your 5S initiative delivers lasting results.

Getting Started with the 5S Training Course

The 5S training course begins with an introduction to the five Japanese words that form the foundation of the methodology: Seiri (Sort), Seiton (Set in Order), Seiso (Shine), Seiketsu (Standardize), and Shitsuke (Sustain). Each word represents creating a clean, organized, and efficient work environment.

Learners will explore the meaning and application of each word, understanding how they relate to eliminating waste and improving productivity. The course provides practical examples and case studies to illustrate the implementation of 5S in various industries and settings, making the concepts easy to grasp and apply.

Through a step-by-step approach, you will learn how to organize, maintain, and sustain a well-ordered workspace. This structured methodology helps systematically organize items, ensuring that everything has its place and is easily accessible. The course includes interactive quizzes and exercises to reinforce understanding and retention of the material.

You will also have access to downloadable templates and resources to support the implementation of 5S in your organization. These practical tools are designed to help you apply what you’ve learned and achieve tangible improvements in your work environment.

The course is designed to be self-paced, allowing you to progress through the material at your convenience and review topics as needed. Available online, the course is accessible to learners from anywhere in the world, providing the flexibility to learn at your own pace and on your schedule.

By starting the 5S training course, you are taking the first step towards creating a more efficient, organized, and productive work environment. The course provides a comprehensive roadmap for implementing 5S, ensuring you have the tools and knowledge necessary to succeed.

Implementation

Implementing a 5S system requires a step-by-step approach, starting with a thorough understanding of the five Japanese words and their applications in the work environment. Begin by teaching employees the basics of 5S and its benefits in improving productivity and safety. Provide training and tools to help teams organize their workspaces and standardize processes. Utilize visual aids, such as videos and PDFs, to effectively illustrate key concepts and provide a clear roadmap for implementation.

The course provides practical examples and case studies to illustrate the implementation of 5S in various industries and settings, making the concepts easy to grasp and apply. This helps in fostering a lean culture within the organization.

Establish a management system to sustain 5S practices and ensure continuous improvement. Encourage employee participation and feedback to identify areas for improvement and optimize workflows. Develop a strategy for implementing 5S in various industries and methodologies, including lean manufacturing. Provide refresher courses and workshops to reinforce learning and ensure standardization of 5S practices. Use quizzes and assessments to evaluate knowledge and understanding of the 5S methodology.

Celebrate successes and recognize employees who have learned and implemented 5S practices, promoting a culture of continuous improvement and operational excellence. By following these steps, organizations can effectively implement 5S and achieve long-term success.

Sustaining 5S

Sustaining 5S requires a long-term commitment to the methodology and its application. Establishing a culture of continuous improvement, through regular audits and evaluations, is crucial for maintaining 5S practices. Ongoing training and support for employees are essential to ensuring they understand and apply the 5S methodology correctly. Standard work procedures should also be established to maintain consistency and quality in 5S practices.

Organizations should establish a system for measuring and evaluating the effectiveness of 5S implementation, using metrics such as productivity, quality, and employee engagement. Integrating the 5S methodology into the organization’s overall strategy and objectives, with clear goals and targets, is vital for successful implementation.

A roadmap for 5S implementation, with a clear timeline and milestones, helps keep the initiative on track. Communicating the benefits and application of 5S to all employees ensures everyone understands its importance. Recognizing and rewarding employees who contribute to the success of 5S implementation can also motivate continued adherence to the methodology.

Regularly reviewing and updating the 5S methodology ensures it remains relevant and practical. Seeking feedback from employees and customers can help identify areas for improvement and opportunities for growth. By fostering a culture of continuous improvement, organizations can sustain the benefits of 5S and achieve long-term success.

Real-Life Success Stories

Organizations worldwide have leveraged 5S training courses as a roadmap to drive remarkable improvements. From manufacturing floors to hospital wards, examples abound of:

- 30% reduction in workplace accidents

- 40% improvement in workspace utilization

- 25% increase in employee productivity

- Significant cost savings through reduced material waste

These success stories underscore the power of a well-executed 5S initiative and the broader impact of lean transformation.

Conclusion: Why 5S Training is Essential for Modern Organizations

In a world where operational excellence is no longer optional, 5S training courses provide a proven path to success. By embracing the principles of 5S, companies can train their employees to create safer, more organized, and more efficient workplaces, leading to happier employees and more satisfied customers.

Whether you’re exploring 5S online options or enrolling in traditional 5S classes, the investment in your education will yield long-term dividends. This investment is a crucial step in your lean journey.

Final Invitation

🎓 Build a High-Performance Workplace with the True 5S Method

Forget surface-level explanations. If you aim for fundamental transformation in how your workspace functions, this training provides everything you need to implement 5S the way it was initially designed — with clarity, consistency, and lasting impact.

Created by a Lean expert with over 25 years of hands-on experience, this course bridges the gap between concept and execution.

👉 The Fundamentals of 5S – Boosting Efficiency and Safety Throughout the Organization

Inside the program, you’ll discover:

🎥 Flexible access – Learn through short, practical videos when it suits your schedule

♾️ No expiration – Rewatch content anytime, with unlimited availability

🧰 Ready-to-use files – Implement instantly with downloadable tools like red tag forms and 5S checklists

📘 Deep cultural insights – Understand each phase of 5S through the lens of Japanese industrial philosophy

👉 Not sure if it’s right for you? See a sample lesson and experience the teaching style firsthand.

Stop guessing. Start applying a system that’s been transforming organizations worldwide for decades.