Spis treści

Introduction to the Lean 5S Method

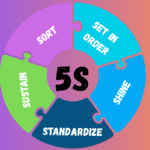

The Lean 5S method is a workplace organization method born from the Toyota Production System and perfected by the Toyota Motor Company. The 5S system was created within the manufacturing industry, specifically as part of lean production practices, to address organizational and efficiency challenges. As a key component of lean manufacturing, it offers a five-step methodology—Sort, Set in Order, Shine, Standardize, and Sustain—that transforms any work environment into a visual workplace, driving continuous improvement, waste reduction, and enhanced workplace efficiency.

5S in manufacturing is a methodology for enhancing workplace organization, efficiency, and safety, and it plays a crucial role in minimizing waste. The 5S system originated from Toyota and is now widely used in the manufacturing industry to reduce waste and improve productivity.

Begin your Lean 5S journey: Enroll in our Fundamentals of 5S Course for case studies, templates, and expert coaching.

What is 5S?

5S is a workplace organization method that forms the backbone of lean manufacturing and the visual workplace. Rooted in five Japanese words—seiri (sort), seiton (set in order), seiso (shine), seiketsu (standardize), and shitsuke (sustain)—the 5S methodology provides a systematic approach to organizing workplaces, eliminating waste, and improving efficiency. By focusing on identifying, sorting, and maintaining only necessary items, 5S helps create a work environment where quality and safety are prioritized. This key component of lean manufacturing not only streamlines processes but also ensures the system’s sustainability over time, leading to higher productivity and a culture of continuous improvement. Through the 5S methodology, organizations can create and maintain a well-organized, efficient, and high-quality workplace.

History and Evolution of 5S

The 5S methodology originated within the Toyota Production System, developed by the Toyota Motor Company in the 1950s. As a foundational element of this system, 5S was designed to eliminate waste and drive efficiency on the shop floor. Over the decades, the 5S methodology has evolved beyond its manufacturing roots, incorporating tools such as visual management and standardized work to further enhance workplace organization. Today, organizations across various industries, including manufacturing, healthcare, and education, utilize the 5S methodology to improve processes, maintain order, and facilitate ongoing improvement. The adaptability and effectiveness of 5S have made it a global standard for organizations seeking to optimize their systems and boost productivity.

Benefits of 5S

Implementing 5S delivers a wide range of benefits that extend across the entire organization. By systematically eliminating waste and optimizing productivity, 5S helps organizations improve efficiency, reduce costs, and enhance quality. The methodology fosters a culture of continuous improvement, empowering employees to take ownership of their work environment and actively participate in problem-solving. In healthcare, 5S contributes to patient safety by minimizing errors and improving communication, while in manufacturing, it reduces waste, increases productivity, and improves product quality. A well-organized workplace not only supports employee engagement but also creates the foundation for long-term success. Ultimately, 5S is a vital tool for any organization seeking to establish an efficient, safe, and high-quality work environment.

1. Sort: Eliminate Unnecessary Items

Sort (Seiri) removes all unnecessary items, broken tools, and hazardous materials from the shop floor:

- Action: Use a red tag event to categorize equipment and materials as ‘keep’, ‘store’, or ‘discard’.

- Outcome: Frees up space for necessary resources, cuts wasted time, and exposes hidden inefficiencies by eliminating wastes from the work area, making it safer and more efficient for workers.

Classic Example: An automotive line cut search time was reduced by 40% after eliminating obsolete fixtures, enabling workers to benefit from a more organized work area.

2. Set in Order: Create a Visual Factory

Set in Order (Seiton) arranges the remaining items so each tool, part, and document has a designated, easily accessible location:

- Tools: Implement shadow boards, visual cues, visual controls, and floor markings to designate fixed spots, helping workers quickly identify the right tools in their work areas.

- Benefit: Minimizes unnecessary motion, speeds up cycle times on production lines, and creates a tangible visual workplace. Organizing work areas with the right tools and visual controls reduces wasted time and motion.

Optimize layouts: Learn advanced strategies in our Advanced 5S Workshop.

3. Shine: Maintain Cleanliness and Safety

Shine (Seiso) combines basic cleaning tasks with inspections to maintain a clean and safe environment:

- Tasks: Schedule daily cleaning and equipment checks to catch wear, leaks, or quality issues.

- Impact: Improves patient safety in healthcare settings, reduces defects, and boosts employee engagement. Regular cleaning also enhances working conditions and is crucial for maintaining a tidy and orderly workplace.

Tip: Rotate Shine responsibilities among team leaders to foster self-discipline.

4. Standardize: Embed Best Practices

Standardize (Seiketsu) codifies Sort, Set in Order, and Shine into standardized work:

- Implement: Develop SOPs and audit checklists, and use visual management boards at each station. Standardize the process to ensure consistency across teams.

- Result: Ensures consistent application, simplifies training for new employees, and preserves gains from the first three steps.

5. Sustain: Drive Continuous Improvement

Sustain (Shitsuke) embeds 5S into the company culture:

- Approach: Conduct regular audits, celebrate 5S champions, and integrate metrics into performance reviews, sustaining improvements and ensuring that standards are maintained through ongoing effort.

- Outcome: Locks in a culture of continuous improvement, maintains order, supports ongoing efficiency, and creates a disciplined environment that promotes long-term success.

Practice real scenarios: Try our 5S Simulation Game to master each step in a dynamic environment.

Integrating Lean 5S with Other Tools

- Value Stream Mapping: 5S plays a key role in enabling the success of other lean tools and improvement initiatives by helping pinpoint waste hotspots for targeted 5S focus.

- Kanban Pull Systems: Use 5S-organized cells as visual pull signals.

- Kaizen Events: Leverage tidy, standardized areas for rapid improvement sprints.

Measuring Success: Key Metrics

Track these KPIs to evaluate your Lean 5S program:

- Search Time: Average time saved locating tools and materials.

- Audit Compliance: Percentage of areas meeting 5S standards.

- Safety Incidents: Reduction in workplace accidents due to clutter removal.

- Productivity Gains: Increase in output per labor hour.

Conclusion & Next Steps

Implementing the Lean 5S method is your pathway to a visual, waste-free factory where organizing workplaces and visual management drive exceptional results. From eliminating waste to boosting employee engagement, 5S lays the foundation for sustained continuous improvement.

👉 Transform your production floor: Enroll in our Fundamentals of 5S Course now and lead your organization to world-class performance!