Spis treści

Definition 5S: Understanding the Core Principles of Workplace Organization

Many organizations seek frameworks to achieve operational excellence in a world where efficiency, safety, and quality are non-negotiable. One of the most straightforward yet most powerful systems is 5S. But what exactly is the definition of 5S? How does it improve workplace performance? This article explores the full scope of 5S, including real-world examples such as a 5S sorting example, insights into the 5S definition, 5S sorting, and sorting in 5S, and answers the common question: what does 5S mean and what is 5S’s meaning in today’s industries.

Definition 5S: What Is 5S?

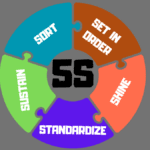

When discussing the definition of 5S, we refer to a methodology developed in Japan that creates a clean, organized, and efficient work environment. The term “5S” represents five Japanese words, each starting with “S”:

- Seiri (Sort): Remove unnecessary items.

- Seiton (Set in Order): Arrange necessary items for optimal accessibility.

- Seiso (Shine): Clean the workspace thoroughly.

- Seiketsu (Standardize): Establish uniform procedures and practices.

- Shitsuke (Sustain): Foster a culture of continuous adherence to standards.

Each step in the 5S process is sequential, building on the previous one to enhance workplace efficiency and organization.

These are the ‘five words’ that form the foundation of the 5S methodology.

Thus, the 5S definition process is more than cleaning—it is about creating and maintaining a workplace that optimizes performance and safety.

Interested in practical 5S application? Learn more through our hands-on 5S training course here!

Introduction to 5S

The 5S methodology is a fundamental component of Lean manufacturing, originating from the Toyota Production System (TPS). It is a systematic approach to workplace organization that aims to eliminate waste and improve efficiency. The five steps of 5S—Sort, Set in Order, Shine, Standardize, and Sustain—work together to create a clean, safe, and productive work environment. By implementing 5S, organizations can reduce unnecessary items, improve workplace safety, and increase productivity. Fostering open communication when introducing the 5S methodology to employees can enhance engagement and support understanding of new expectations related to lean manufacturing initiatives.

What Does 5S Mean?

What does 5S mean in modern workplaces? Simply put, it means:

- Reducing wasted time searching for tools and materials

- Improving safety through organized workspaces

- Enhancing product and service quality

- Promoting employee morale and ownership

The 5’s meaning extends beyond physical organization; it embeds a mindset of efficiency, responsibility, and continuous improvement into daily operations.

Principles of 5S

The principles of 5S are rooted in the idea of creating a visual workplace where everything has its place. Visual cues, such as labels and floor markings, are crucial in maintaining an organized and efficient workplace. This is achieved by removing unnecessary items, organizing essential items in a logical, accessible manner, and maintaining a clean, tidy environment. The 5S methodology emphasizes the importance of employee engagement and participation in maintaining a well-organized workplace. By building participation and encouraging employee buy-in, organizations can create a culture of continuous improvement, leading to improved consistency and reduced waste. Key components of 5S include using visual management tools, such as floor marking tape, and implementing audit checklists to track progress.

The Importance of 5S Sort: Removing Unnecessary Items

At the methodology’s core lies the sort step — the foundational step that sets the tone for all subsequent actions. Sort in 5S means:

- Identifying what is necessary and what is not

- Removing clutter and obsolete items

- Creating more space, leading to less clutter, and reducing distractions and hazards

A powerful 5S sorting example is a manufacturing floor audit, during which all tools are assessed. Daily tools are kept close, while rarely used ones are stored elsewhere or discarded. This approach ensures efficiency and reduces workplace hazards.

Need help organizing your workplace effectively? Our 5S course provides real-world sorting strategies — join us here!

5S Define: Each Step Explained

Understanding 5S in depth requires breaking down each “S” in turn. The first three steps are crucial, as they lay the groundwork for subsequent steps and establish a culture of continuous improvement and workplace efficiency.

Seiketsu (Standardize)

Standardizing processes is essential to maintain the improvements achieved through the first three steps. One effective method is using a shadow board, which helps organize tools and ensure they are returned to designated spots. This system uses labeled outlines to indicate where each tool belongs, allowing workers to identify tool locations quickly and reducing time spent searching through storage spaces.

Seiri (Sort)

- Remove what you don’t need. This step uses red tagging to identify items that should be removed. Items not required for a specific area are marked with a red tag, allowing for better tracking, collection, and potential reassignment within the workspace.

- Eliminate obstacles to streamline workflow.

Seiton (Set in Order)

- Organize items by frequency of use, ensuring the most frequently used items are easily accessible.

- Label everything clearly.

Seiso (Shine)

- Implement the shine step by cleaning equipment and workspaces daily.

- Identify potential issues during cleaning.

Seiketsu (Standardize)

- Create procedures for maintaining the organization by implementing the standardized steps.

- Use visual management tools like shadow boards and color codes.

Shitsuke (Sustain)

- Develop habits through training and audits. Self-discipline is crucial in this step, as it helps develop processes among workers that encourage proactive engagement and accountability.

- Foster a sense of pride and discipline. This sense of self-discipline, also known as ‘shitsuke,’ emphasizes the importance of sustaining effective practices without external prompts, fostering a culture of responsibility and continuous workplace efficiency improvement.

Curious how to establish each “S” practically? Enroll in our step-by-step 5S fundamentals training here!

Organizing the Workplace

Organizing the workplace is crucial to improving workplace efficiency and reducing waste. The 5S methodology, a key component of Lean manufacturing, is designed to create a more organized and productive workspace. Employees can work more efficiently and effectively by systematically removing unnecessary items and creating a visual workplace.

The Toyota Production System (TPS) is a well-known example of a Lean manufacturing system that uses the 5S methodology to enhance workplace efficiency. The 5S method involves five steps: Sort, Set in Order, Shine, Standardize, and Sustain. These steps work together to create a clean, organized work environment, which is essential for minimizing waste and optimizing performance.

By implementing the 5S methodology, organizations can create a work environment that supports continuous improvement and operational excellence. This approach improves workplace efficiency and fosters a culture of discipline and responsibility among employees, leading to long-term success.

Real-World 5S Sorting Example

A well-known 5S sorting example comes from the automotive industry:

At a leading auto plant, a 5S audit revealed that mechanics spent up to 20% of their time searching for tools. By applying the sort in the 5S principle:

- Unnecessary tools were removed using a red-tag system to identify items requiring evaluation.

- Essential tools were color-coded and hung at ergonomic heights. Distinguishing new equipment from old equipment is crucial for effective organization and utilization.

- Walkways were cleared, and storage areas were labeled.

The result? A 15% increase in repair efficiency and a 10% reduction in workplace injuries within a year.

Common Pitfalls in 5S Sorting

When starting with 5S sort, organizations often encounter challenges such as:

- Emotional Attachment: Employees are hesitant to discard old items.

- Poor Categorization: Confusion between “useful” and “frequently used” tools.

- Lack of Follow-Through: Inconsistent sorting sessions lead to clutter reappearing. Addressing the remaining items after decluttering is crucial to prevent clutter from reappearing and ensure a logical arrangement that aligns with Lean principles. Maintaining organized work areas is also essential to avoid clutter from reappearing and to ensure efficiency.

Solutions include:

- Clear communication of benefits

- Involving employees in decision-making

- Establishing clear sorting criteria

Sustaining 5S Efforts for Workplace Safety

Implementing 5S is just the beginning. Sustaining 5S requires:

- Regular audits

- Regular audits and training help keep the workplace clean and organized, thus enhancing safety.

- Employee training refreshers

- Leadership support

- Visual performance tracking

Incorporating new practices into regular work procedures is crucial to ensure long-term change and continuous improvement. Successful organizations embed 5S into their daily routines rather than treating it as a one-off initiative.

Want your 5S implementation to last? Learn sustainable practices in our dedicated course here!

Benefits of Mastering 5S

Mastering the definition of 5S and its practical applications leads to significant benefits:

- Time Savings: Less time wasted searching for items and a more efficient workspace.

- Reduced Costs: Lower inventory and storage expenses.

- Improved Safety: Fewer accidents and workplace hazards.

- Enhanced Quality: Better focus on core tasks with fewer distractions.

- Employee Satisfaction: Pride in a clean, organized environment.

Mastering 5S has many advantages, including improved employee engagement and easier identification of maintenance issues, which lead to enhanced productivity and safety outcomes.

Applications of 5S

The applications of 5S extend beyond the manufacturing industry, with its principles applied across sectors such as healthcare, education, and government. The 5S methodology can improve work processes by enhancing organization and reducing risks. In manufacturing, 5S improves workplace efficiency, reduces equipment failure, and enhances production processes. On the shop floor, 5S helps eliminate unnecessary motion, minimize waste, and create a more organized, productive work environment. By establishing standards and implementing regular cleaning schedules, organizations can maintain a clean, safe workplace, reduce the risk of accidents, and improve overall productivity. The 5S methodology is a key part of Lean manufacturing, and its implementation can lead to significant improvements in workplace safety, efficiency, and productivity.

5S and Lean Manufacturing: Creating a Visual Workplace

5S forms the foundation of Lean Manufacturing. The concept of a visual factory is integral to implementing 5S practices and maintaining efficiency. By ensuring a clean and organized workplace, 5S:

- Supports Just-In-Time production

- Reduces setup times

- Facilitates smooth process flows

- Minimizes waste (muda)

- Plays a crucial role in eliminating waste by improving productivity and ensuring an organized work environment

Without a strong 5S culture, achieving broader Lean goals becomes much more difficult.

How to Start Your 5S Journey

Starting with 5S doesn’t require massive investments. Here’s a simple approach:

- Begin with a pilot area.

- Involve employees in sorting and organizing. Clearing out unnecessary materials in the initial step is crucial for providing the space needed for effective organization.

- Set clear expectations and standards.

- Provide comprehensive training on 5S procedures to new employees, ensuring they become comfortable and proficient with the established practices.

- Monitor progress and celebrate wins.

Small steps, consistently applied, lead to lasting transformation.

Ready to start your 5S journey with expert guidance? Take the first step with our practical training program here!

Ultimate Guide to 5S

The ultimate guide to 5S is a comprehensive resource that provides an in-depth overview of the 5S methodology and its application in the manufacturing industry. This guide covers the five steps of the 5S method, starting with the sort phase, which involves removing unnecessary items from the workplace. Organizations can create a more efficient and productive work environment by eliminating clutter.

The set-in-order step involves organizing the remaining items in a logical, efficient manner. Tools such as floor marking tape and shadow boards ensure that everything has its place and is easily accessible. This step helps streamline workflows and reduce wasted time searching for tools and materials.

The shine step involves regular workplace cleaning and maintenance. This keeps the work environment clean and helps identify and address potential issues before they lead to equipment failure. Regular cleaning is essential for improving workplace safety and maintaining high-quality standards.

The standardization step involves creating standards and procedures for maintaining the workplace. By implementing consistent practices, organizations can ensure that the benefits of the first three steps are sustained over time. Visual management tools, such as audit checklists, track progress and ensure compliance with established standards.

The sustain step focuses on fostering a culture of continuous improvement. This involves tracking progress, making ongoing improvements, and encouraging employee engagement. Organizations can create a work environment that supports long-term success by building participation and promoting self-discipline.

By following the ultimate guide to 5S, organizations can improve workplace efficiency, reduce waste, and create a more productive and safe work environment. This guide provides a step-by-step approach to implementing the 5S methodology, including tips and best practices for building participation and using audit checklists to track progress.

The guide also covers the importance of self-discipline and the creation of standards in the 5S methodology. It provides examples of how to apply the methods in different industries and workplaces, highlighting the benefits of improved workplace safety, reduced equipment failure, and increased productivity.

By using the ultimate guide to 5S, organizations can create a more efficient, productive, and safe work environment and improve their overall competitiveness and success. This guide is a key component of any Lean manufacturing system and is essential for anyone looking to improve their workplace organization and reduce waste.

Conclusion: Why Understanding Definition 5S Matters

The definition of 5S reveals that it’s not just a set of housekeeping tasks but a strategic approach to improving workplace efficiency, safety, and culture. While janitorial staff traditionally handle cleaning tasks, the responsibility for maintaining cleanliness should extend to all employees. By grasping concepts like 5S define, 5S sort, and understanding what 5S means, organizations can build a resilient foundation for operational excellence.

This article serves as the ultimate guide to understanding and implementing 5S principles. From a simple 5S sorting example to a full-scale cultural transformation, mastering 5S can unlock new levels of performance and employee engagement.

Final Invitation

Suppose you’re serious about implementing 5S principles properly and want practical, field-tested strategies. In that case, I invite you to enroll in our specialized course: The Fundamentals of 5S—Boosting Efficiency and Safety Throughout the Organization. This training draws on 25 years of experience in Lean Manufacturing and 5S implementation, offering valuable, actionable insights. Start your journey to workplace excellence today!

🎓 Bring Lasting Order and Efficiency to Your Work Environment

Looking to elevate workplace standards with a proven system rooted in discipline and clarity? Discover a method that goes beyond surface-level fixes and delivers meaningful improvement.

With insights shaped by decades of hands-on practice in Lean transformations, this training equips you with the mindset and materials to drive change from day one.

👉 The Fundamentals of 5S – Boosting Efficiency and Safety Throughout the Organization

What’s included:

🎥 Modular content – Stream concise lessons whenever it’s convenient

♾️ Unlimited entry – Return anytime to revisit ideas and refresh knowledge

🧰 Field-ready tools – Access downloadable forms, visual aids, and labeling systems

📘 Cultural background – Explore the original intent behind each step rooted in the Japanese industry

👉 See a sample lesson before you decide – and experience the clarity and practicality this course offers:

Take this opportunity to shift from abstract concepts to actionable improvements.