Definition of 5S: Understanding the Foundation of Workplace Excellence

In today’s fast-paced and competitive environment, businesses must focus on efficiency, quality, and continuous improvement. One of the most fundamental methodologies that supports these goals is 5S. However, to successfully implement it, you must understand the 5S’s definition, purpose, and impact on organizational culture. Embedding 5S into the organization’s culture is crucial for sustaining improvements and achieving long-term success.

This article will explain:

- The precise definition of 5S.

- The meaning of 5S in various industries.

- How to properly define 5S for teams.

- Why understanding the meaning of 5S is critical for success.

🎓 Want to learn how to apply 5S practically in your organization? Join our comprehensive 5S course today and build a real culture of excellence.

Introduction to 5S

The 5S methodology is a cornerstone of lean manufacturing, designed to enhance workplace efficiency and eliminate waste. This powerful tool consists of five sequential steps: Sort, Set In Order, Shine, Standardize, and Sustain. By following these steps, organizations can create a more organized and productive workspace, significantly reducing waste and boosting overall productivity.

The 5S system helps facilities avoid the pitfalls of lost productivity due to delayed work, unplanned manufacturing downtime, and injured workers. By implementing the 5S methodology, organizations can streamline their operations, ensuring everything is in its place and easily accessible. This improves efficiency and fosters a safer and more pleasant work environment.

Origins and Elements of 5S

The 5S methodology originated in Japan and was first implemented by the Toyota Motor Company as a key component of the Toyota Production System (TPS). This system was designed to eliminate waste and improve efficiency, laying the foundation for modern lean manufacturing practices.

The term 5S comes from five Japanese words: Seiri, Seiton, Seiso, Seiketsu, and Shitsuke. Translated into English, these words mean Sort, Set in Order, Shine, Standardize, and Sustain. Each step is crucial in creating an organized, efficient, and safe workplace.

- Sort (Seiri): The first step involves removing unnecessary items from the workplace. By decluttering and keeping only what is essential, organizations can reduce waste and improve efficiency.

- Set in Order (Seiton): The second step focuses on organizing the remaining items logically and efficiently. This includes assigning specific locations for tools and materials, making them easily accessible, and reducing unnecessary motion.

- Shine (Seiso): The third step involves regularly cleaning and maintaining equipment and the workplace. This keeps the area clean and helps identify potential issues such as equipment failure and safety hazards early on.

- Standardize (Seiketsu): The fourth step is creating procedures and schedules to maintain the first three steps. Standardization ensures consistency and helps sustain the improvements made.

- Sustain (Shitsuke): The final step involves making the 5S process a part of the company culture. This requires continuous improvement and regular audits to ensure that the 5S practices are maintained and updated.

The 5S methodology is a key part of lean manufacturing and is used in many industries to improve workplace efficiency and reduce waste. By implementing 5S, organizations can improve consistency, reduce errors, and increase overall productivity, making it a vital tool for achieving operational excellence.

What Is the Definition of 5S?

The definition of 5S is simple yet powerful:

5S is a structured system for organizing, cleaning, developing standard practices, and maintaining a disciplined workplace. Understanding and consistently applying the 5S principles is vital for improving workplace organization, reducing waste, enhancing efficiency, and promoting continuous improvement in a manufacturing setting.

The term comes from five Japanese words, each starting with the letter “S”:

- Seiri (Sort) – Separate needed items from unneeded ones and remove the latter.

- Seiton (Set in Order) – Arrange necessary items for easy access and retrieval.

- Seiso (Shine) – Clean and inspect the workplace regularly.

- Seiketsu (Standardize) – Establish standards to maintain the first three S’s.

- Shitsuke (Sustain) – Build a habit of properly maintaining standards. The sustain step is crucial for ensuring the other steps are maintained over time, integrating 5S practices into the company culture through consistent audits and continuous commitment.

Understanding the meaning of 5S goes beyond memorizing these five words—it’s about realizing how they drive efficiency, quality, and employee engagement.

Define 5S: More Than Just Cleaning and Workplace Organization.

When you define 5S, it’s important to clarify that it’s not just about tidiness. Improving quality is a key aspect of 5S, as it involves applying principles and lean tools to reduce waste and enhance efficiency. Instead, 5S is a methodology designed to create organized, efficient, safe, and visually managed workplaces, focusing on eliminating waste.

Proper 5S implementation leads to:

- Reduced waste (searching, unnecessary movement, downtime).

- Improved product and service quality.

- Enhanced safety and fewer workplace accidents.

- Higher employee satisfaction.

📌 Take your 5S understanding from theory to practice! Access our practical 5S online course and discover real-world tools and templates.

What Is the Meaning of 5S in Lean Manufacturing and Industry?

In business contexts, the meaning of 5S is straightforward: Create an environment where “everything has its place, and there’s a place for everything.” The 5S methodology was initially developed for the manufacturing industry to enhance efficiency and organization within workspaces.

In manufacturing:

- 5S reduces production delays caused by missing tools or misplaced materials.

- Clean, organized production lines improve product consistency and speed.

- Addressing excess inventory during the sorting phase helps eliminate waste and enhances efficiency.

In offices:

- Employees spend less time searching for files or supplies.

- Collaboration improves when physical and digital workspaces are standardized.

In healthcare:

- Standardized storage areas ensure that medical supplies are accessible quickly, improving patient care and safety.

The meaning of 5S is universal—it enhances any environment where people and processes interact.

Breaking Down the Five Steps: The Deep Meaning Behind Each S

1. Sort (Seiri)

Focus: Remove the unnecessary.

- Red tagging is essential in this phase. Attaching obvious tags to unidentified or unowned items to track their origin and ownership.

- Get rid of obsolete tools, documents, and supplies.

- Keep only what adds value to the process.

2. Set in Order (Seiton): Visual Management

Focus: Organize what remains.

- Assign logical locations for everything. A highly effective method is using a shadow board, which involves placing labels that match the shape and size of each tool in its designated spot.

- Use labels, outlines, and color coding.

3. Shine (Seiso)

Focus: Clean and inspect.

- Regular cleaning helps identify leaks, defects, and other issues early.

- The ‘shine step’ is critical in maintaining cleanliness and order in a work area.

- Individual workers should do regular cleaning rather than relying solely on janitorial staff. This fosters a sense of ownership and personal accountability for one’s workspace, enhancing overall workplace cleanliness and efficiency.

4. Standardize (Seiketsu)

Focus: Create clear standards.

- Use checklists, visual controls, and procedures to maintain organization. The standardization step is crucial as it connects the initial steps (Sort, straighten, shine) to the final step (Sustain), ensuring that work procedures are consistently applied and improving workplace safety alongside efficiency. Additionally, incorporating other lean tools can help identify and eliminate various forms of waste, encouraging team involvement in continuous improvement and fostering a culture of efficiency.

5. Sustain (Shitsuke)

Focus: Make it a habit.

- Reinforce behaviors through training, leadership, and recognition. Securing employee buy-in is crucial for the success of implementing 5S activities.

- Integrate 5S practices into the organization’s culture to ensure long-term success.

🎯 Want ready-to-use checklists and audit templates for each step? Our 5S course includes all the tools you need. Get instant access here.

Benefits of 5S

Implementing a 5S program offers numerous benefits, including improved workplace efficiency, reduced costs, and enhanced quality. Adopting the 5S methodology has many benefits, primarily when strong management support exists. Organizations can declutter their workspaces and optimize workflow by eliminating unnecessary items and processes, increasing productivity and efficiency.

The 5S methodology also promotes a culture of continuous improvement and employee engagement. When employees are involved in organizing and maintaining their work areas, they take greater ownership and pride in their work. This can improve workplace safety and waste reduction, as employees are more likely to identify and address potential hazards and inefficiencies.

Additionally, the 5S system helps organizations improve quality by reducing defects and ensuring process consistency. By standardizing work practices and maintaining a clean and organized environment, organizations can achieve higher levels of quality and reliability in their products and services.

Why Understanding the Meaning of 5S Matters for Continuous Improvement

When companies misunderstand 5S as just “a cleaning campaign,” they miss the more profound benefits:

- Better quality control through visual management.

- Improved employee morale through ownership and empowerment.

- Faster onboarding because expectations are clearly defined visually.

Fully grasping the meaning of 5S allows organizations to create workspaces that drive productivity and pride, not just superficial tidiness. Addressing workplace hazards as part of a safety initiative within the 5S framework is crucial. Implementing a visual factory with visual controls helps maintain order and effectiveness within the workspace, enhancing operational efficiency.

Implementing 5S

Implementing 5S involves five essential steps: Sort, Straighten, Shine, Standardize, and Sustain. Each step plays a crucial role in creating an efficient and organized workspace.

- Sort: The first step involves removing unnecessary items from the workspace. Organizations can create a more streamlined work environment by decluttering and organizing essential items logically and efficiently.

- Straighten: The second step focuses on designating a place for all items in the work area. Ensuring everything is easily accessible and logically arranged helps reduce wasted time and unnecessary motion. Minimizing excess motion is crucial for efficiency, as it allows for easier access and return of items to their designated places.

- Shine: The third step involves regular cleaning and maintenance of the workspace. This keeps the area clean and helps identify potential issues such as equipment failure and safety hazards early on.

- Standardize: The fourth step is about developing and implementing standards for the 5S system. This includes creating procedures and checklists to ensure all employees know their responsibilities and the workspace remains organized and efficient.

- Sustain: The final step involves maintaining the 5S system over time. This requires ongoing commitment and continuous improvement to ensure that the benefits of 5S are sustained and that the organization continues to reduce waste and improve efficiency.

Process Development

Process development is a critical component of the 5S methodology, as it involves creating and improving processes to eliminate waste and improve efficiency. The 5S method can be used to develop new processes or enhance existing ones by identifying and removing unnecessary steps and activities.

Lean tools and techniques, such as job cycle charts and floor marking tape, play a significant role in process development. These tools help visualize workflows, identify bottlenecks, and streamline operations, reducing waste and improving efficiency.

The 5S methodology also helps identify and eliminate safety hazards, such as equipment failure and unnecessary motion. Organizations can improve workplace safety and create a more productive work environment by addressing these issues.

Visual management and visual factory techniques are essential in process development. These techniques use visual cues, such as labels and color-coded markings, to enhance navigation and organization within the workspace. This not only improves efficiency but also helps maintain order and consistency.

Building employee participation and engagement is crucial for successful process development. By involving employees in the 5S process, organizations can foster a culture of continuous improvement and ensure that processes are continuously refined and optimized.

In summary, the 5S methodology is a key component of lean manufacturing and is used in many industries to improve process development and reduce waste. Organizations can enhance their processes, improve workplace safety, and increase productivity by leveraging lean tools, visual management techniques, and employee engagement.

Practical Tips: How to Teach and Define 5S for Your Team

- Connect it to daily problems: Missing tools? Lost files? Show how 5S solves these pain points. Emphasize distinguishing between old and new equipment to prevent outdated tools from hindering efficiency.

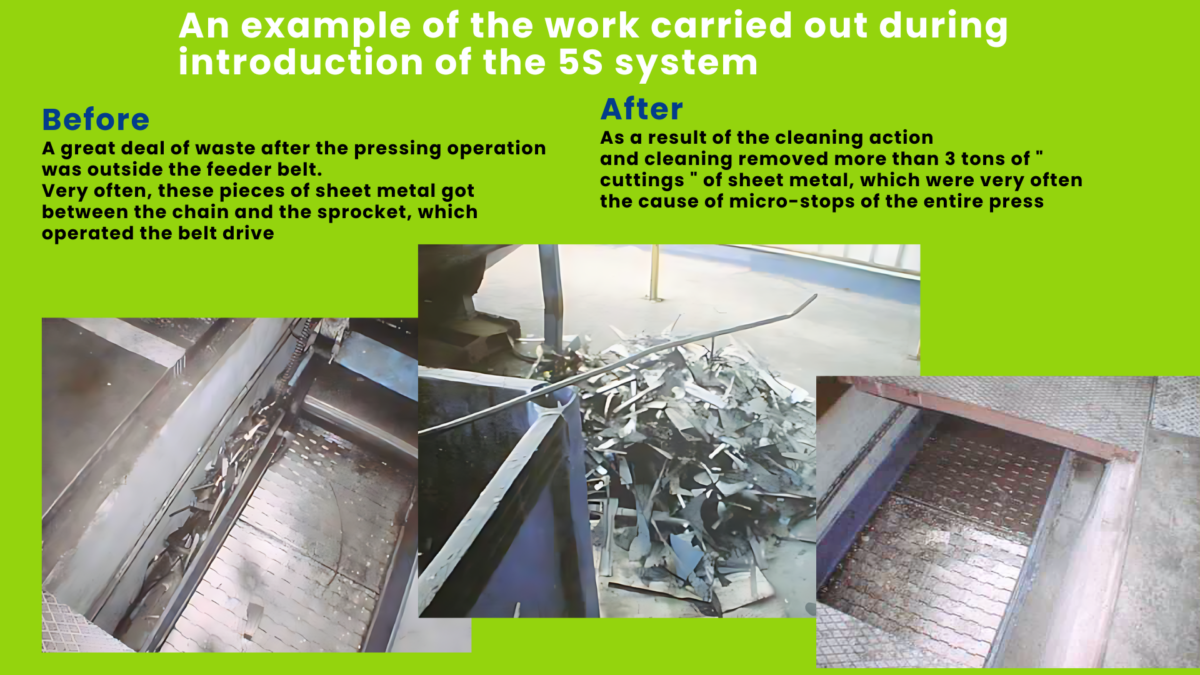

- Use visual examples: Before-and-after photos demonstrate the power of 5S better than lectures.

- Pilot in small areas: Let employees experience quick wins through practical application.

- Celebrate small successes: Recognize teams that sort, organize, and shine in their areas.

- Standardize early: Provide clear procedures and checklists to maintain progress.

- Train new employees: Ensure all new employees receive specific training about the 5S procedures in their area to maintain consistency and the program’s effectiveness.

🎥 You can even show your team real-world examples of 5S success by previewing a lesson from our course. Watch a free sample lesson here.

Overcoming Challenges

One of the biggest challenges in implementing 5S is overcoming resistance from employees who may be accustomed to traditional working methods. However, there are many advantages to successfully implementing 5S, such as enhanced employee engagement and effective maintenance. Organizations can build participation by involving employees in the 5S process from the beginning to address this. Training and education on the benefits of the methodology can also help employees understand its value.

Visual management tools such as floor marking tape and shadow boards can be highly effective in helping employees understand the 5S system and their role in maintaining it. These tools provide clear visual cues that make it easier for employees to keep the workspace organized and efficient.

Setting measurable goals and recognizing employee contributions can also encourage engagement and motivation. By celebrating small successes and providing regular feedback, organizations can foster a culture of continuous improvement and ensure that all employees embrace the 5S system.

Measuring Success

Organizations can use various metrics, including productivity, quality, and safety metrics, to measure the success of a 5S implementation. Understanding and improving production processes is also crucial, as it helps eliminate waste and achieve consistent, high-quality results in a clean and organized work environment. Regular audits are essential to ensure that the 5S system is maintained and that employees follow established procedures.

Tracking key performance indicators (KPIs) such as waste reduction, inventory turnover, and employee engagement can provide valuable insights into the effectiveness of the 5S implementation. By analyzing these metrics, organizations can identify areas for improvement and make data-driven decisions to enhance their processes.

Tools such as job cycle charts and department tours can also be used to identify opportunities for improvement. Organizations can continuously improve workplace efficiency and reduce waste by regularly reviewing work processes and involving employees in developing new practices.

By integrating these new sections, the article now provides a comprehensive overview of the 5S methodology, its benefits, implementation strategies, and ways to measure success. This ensures readers understand how to apply 5S in their organizations to achieve workplace excellence.

Common Misunderstandings About 5S

- “5S is just cleaning.” No cleaning reveals problems early and prevents deterioration.

- “5S is only for factories.” False—offices, hospitals, restaurants, and even home offices benefit from 5S.

- 5S applies to many industries beyond manufacturing, including healthcare, offices, and schools. On the manufacturing floor, 5S practices improve organization and productivity, emphasizing employee engagement and involvement.

- “We can skip steps.” Skipping standardization or sustain phases leads to rapid backsliding.

- “Once implemented, 5S is complete.” Wrong—5S is a continuous, evolving practice.

Understanding these misconceptions ensures your 5S efforts are sustainable and impactful.

Frequently Asked Questions

What is the full definition of 5S?

5S is a methodology for organizing workplaces through sorting, ordering, cleaning, standardizing, and sustaining, leading to greater efficiency, safety, and quality. Effective workplace organization, notably through implementing the 5S methodology, enhances efficiency, cleanliness, safety, and overall operational quality across various environments.

How do you define 5S in simple terms?

Everything should be in its proper place, clean, labeled, and maintained consistently. Creating the space needed is crucial in the 5S methodology, starting with the Sort step to declutter the workspace. Maintaining a clean workplace is a fundamental aspect of the 5S method, as it enhances efficiency, effectiveness, and safety.

What is the true meaning of 5S?

The true meaning of 5S lies in building structured, visual workplaces that naturally drive productivity and continuous improvement. Organizing the shop floor through the 5S methodology helps create an orderly and efficient environment. A visual workplace incorporates various visual communication tools, such as labels and floor markings, to enhance navigation and organization within the workspace.

Final Thoughts: 5S Is the Language of Efficiency

If you want smoother operations, fewer errors, faster work, and happier teams, start by deeply understanding and applying the 5S definition. By implementing the 5S system, you can avoid wasting time and reduce the risk of injury while performing tasks.

When you truly grasp the meaning of 5S, you realize it’s not just about looking organized—it’s about being efficient, ready, and world-class.

🎓 Ready to Turn the Definition of 5S into Action?

If you’re serious about moving from theory to practice and making 5S part of your organization’s DNA, I warmly invite you to join my practical online course:

👉 The Fundamentals of 5S – Boosting Efficiency and Safety Throughout the Organization

Based on my 25 years of hands-on experience implementing Lean and 5S across European industries, this course offers:

- 🎥 VoD format – watch anytime, anywhere.

- ♾️ Lifetime access – revisit lessons whenever needed.

- ⏳ Self-paced learning – learn at your speed.

- 👥 Group learning ready – ideal for training teams.

👉 Plus, you can preview one of the lessons for free and see how our approach makes 5S practical, actionable, and sustainable.

Start your journey toward a better-organized, safer, and more efficient workplace today!