Spis treści

Training on Lean Manufacturing: Building Skills for Efficiency and Excellence

In a competitive global economy, organizations need practical tools and strategies to optimize their operations. Lean manufacturing training is one of the most effective ways to develop a workforce that understands how to reduce waste, improve efficiency, and deliver value. From foundational lean principles to advanced Six Sigma methodology, this training provides essential knowledge for professionals across the manufacturing industry. Lean manufacturing training is valuable across sectors, not just manufacturing, as it equips professionals to drive efficiency and quality improvements. This training helps organizations optimize operations and positively impacts overall business performance. The benefit of such training extends to both individuals, who gain valuable skills for career advancement, and organizations, which achieve greater operational excellence.

What Is Lean Manufacturing Training?

Lean manufacturing training equips professionals with the tools and knowledge to streamline production processes, eliminate non-value-added activities, and improve product quality. These training programs typically cover topics such as:

- The core principles of lean and continuous improvement

- How to identify and eliminate waste in the manufacturing process

- Tools like value stream mapping, 5S, Kaizen, and Kanban

- Learning about different methods used in lean manufacturing, such as Lean, Six Sigma, and Kaizen

- Techniques for process improvement and quality control

- Integrating lean tools with six sigma for data-driven decision-making

Training can be delivered in various formats, including online courses, in-person workshops, and blended learning models. An online program offers flexibility and accessibility, making it ideal for busy professionals seeking convenient and cost-effective training options.

Why Training on Lean Manufacturing Matters

Manufacturers face constant pressure to reduce costs, improve output, and meet evolving customer expectations. Training empowers employees to:

- Implement lean principles to optimize operations

- Achieve operational excellence by continuously refining processes

- Improve customer satisfaction through consistent product quality

- Reduce defects and enhance efficiency using statistical tools from Six Sigma

- Support supply chain management with lean-focused planning and execution

- Increase operational efficiency across manufacturing processes

Professionals who receive lean manufacturing training often experience increased job opportunities, higher productivity, and the ability to drive organizational change. Lean manufacturing training can transform a company by fostering a culture of efficiency and continuous improvement. Training also enhances team effectiveness, enabling better collaboration and the successful implementation of lean initiatives.

Key Components of Lean Manufacturing Training

Practical training in lean manufacturing combines theory and application. Essential components include:

- Introduction to lean concepts and history

- Tools to analyze production processes and identify bottlenecks, with a focus on improving manufacturing processes

- Practical exercises in eliminating waste and improving workflow

- Problem-solving techniques and real-world case studies

- Preparation for Lean Six Sigma certification and sigma certification levels (Yellow Belt, Green Belt, Black Belt), including the requirements for successful completion to advance to higher certification levels

These elements ensure that participants gain comprehensive knowledge, not only conceptual but also applicable in day-to-day operations, with successful completion of the training and certification programs essential for advancing in lean six sigma roles.

Quality and Control in Lean Manufacturing

Quality control stands at the heart of lean manufacturing, ensuring that every product meets rigorous standards and exceeds customer expectations. By implementing lean principles and focusing on continuous improvement, organizations can systematically eliminate defects and reduce variations throughout the manufacturing process. Lean manufacturing training emphasizes integrating quality control into every stage of production, equipping employees with the knowledge and skills to identify issues before they escalate.

A robust quality control system leverages lean concepts, such as value stream mapping and value stream analysis, to pinpoint inefficiencies and sources of waste. These tools help organizations visualize their production processes, making it easier to target areas for improvement and optimize operations. Lean Six Sigma certification programs further enhance this approach by teaching employees to apply statistical tools and sigma methodology, enabling data-driven problem solving and process optimization.

Effective quality control extends beyond the shop floor. It encompasses supply chain management, ensuring that raw materials and components consistently meet quality standards and are delivered on time. By maintaining high standards across the entire supply chain, organizations can minimize defects, reduce costs, and build a reputation for manufacturing excellence.

Investing in lean manufacturing training and certification programs empowers employees to confidently apply lean principles and quality control techniques. This not only increases customer satisfaction but also positions organizations as leaders in the manufacturing industry, capable of delivering superior value while continuously improving their processes.

Certification Options and Career Impact

One of the most substantial benefits of lean training is access to certification programs. These credentials validate a professional’s expertise in lean methodologies and their ability to lead process optimization initiatives. Lean Six Sigma certification is a valuable asset for professionals seeking to advance their careers, as employers highly regard it and demonstrates a commitment to operational excellence.

Some of the most recognized certification options include:

- Lean Management Course – An in-depth introduction to lean principles, tools, and strategic implementation.

- Lean Six Sigma Course – A practical guide to combining lean with six sigma methodology and learning sigma principles as a foundation for process improvement and operational excellence.

- Continuous Improvement Training – Focused on developing a lean mindset and fostering a culture of improvement.

These certifications enhance credibility and open new doors in manufacturing, supply chain, and operations roles.

The Power of Simulation: Learn by Doing

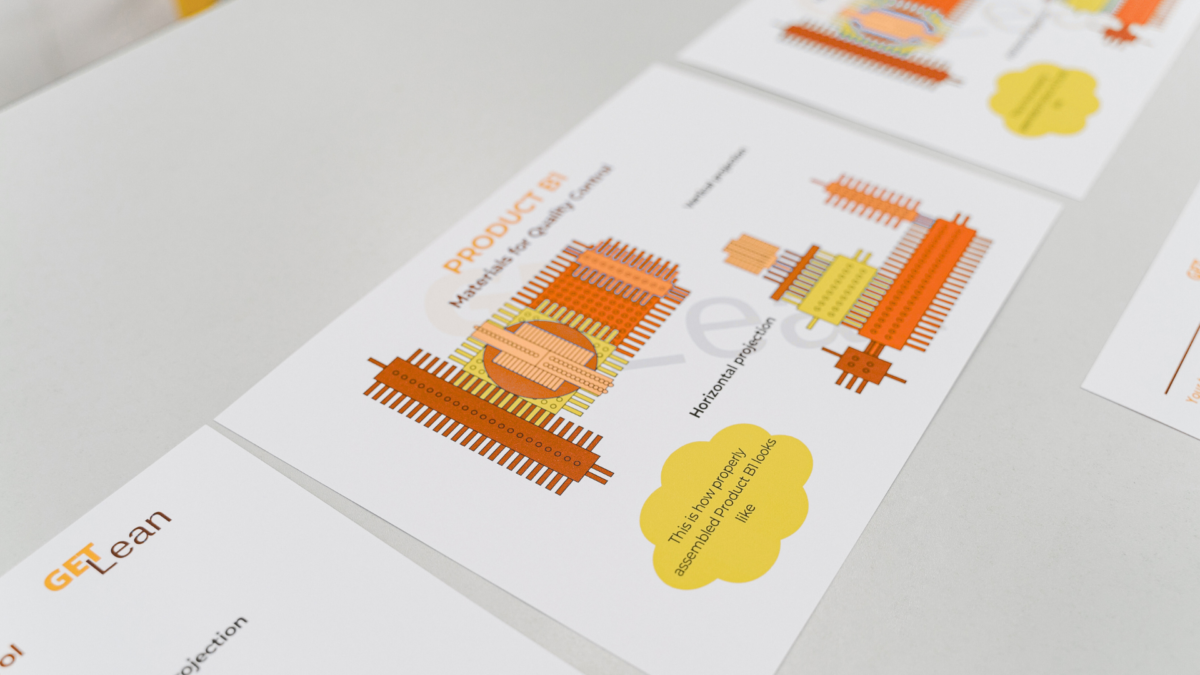

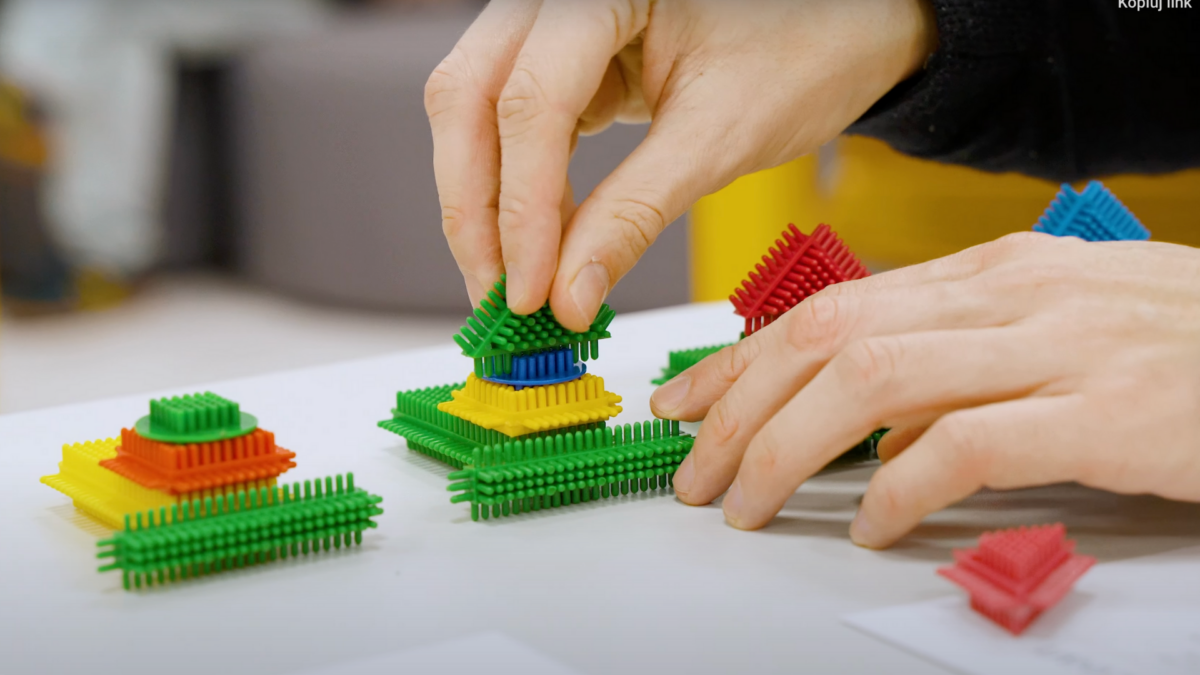

A standout example of applied lean manufacturing training is the GET LEAN Simulation Game. This interactive, team-based game replicates real production challenges using physical materials such as plastic bricks. Participants go through six rounds where they must:

- Meet varying levels of customer demand

- Adapt to evolving production processes

- Apply lean tools like one-piece flow, pull systems, and standard work

The simulation encourages hands-on learning, cross-functional collaboration, and critical thinking. It also helps participants understand the cost impact of process changes and improvements, highlighting how reducing defects and inefficiencies can yield significant savings. It’s an engaging and effective way to teach and apply lean principles while building leadership and communication skills.

Implementation and Best Practices

Successfully implementing lean principles in manufacturing requires a structured and strategic approach. The journey begins with a thorough analysis of current processes, using lean tools to identify bottlenecks, inefficiencies, and opportunities for improvement. Techniques such as Kanban and Total Productive Maintenance are essential for optimizing production processes and eliminating waste.

A key best practice in lean manufacturing is fostering a culture of continuous improvement. This means engaging employees at every level—from shop floor operators to senior management—in the lean journey. When everyone is committed to applying lean principles, organizations can embed process improvement and problem-solving into their daily routines.

Lean Six Sigma certification provides a proven framework for implementation, combining process improvement, statistical analysis, and hands-on problem solving. Regular training and coaching ensure that employees have the skills and knowledge to use lean tools effectively, while ongoing support helps sustain momentum.

Benchmarking against industry leaders and visiting organizations that have successfully implemented lean manufacturing can offer valuable insights and inspire new ideas. By learning from others and sharing best practices, companies can accelerate their own lean transformation.

Ultimately, the most successful lean implementations prioritize employee involvement, continuous learning, and a relentless focus on customer satisfaction. By following these best practices and investing in lean manufacturing training, organizations can achieve lasting improvements in efficiency, productivity, and operational excellence.

Performance and Metrics: Measuring Lean Success

Measuring the impact of lean manufacturing initiatives is essential for sustaining progress and demonstrating value. Organizations rely on key performance indicators (KPIs) and metrics—such as lead time, throughput, and defect rate—to track the effectiveness of their lean efforts and guide informed decisions.

Establishing a clear set of metrics aligned with strategic objectives allows organizations to monitor production processes, identify trends, and uncover areas for further improvement. Lean Six Sigma certification emphasizes the use of statistical tools and data-driven analysis, empowering employees to make objective decisions that drive continuous improvement.

Regularly reviewing and analyzing performance metrics helps organizations optimize their production processes and maintain a competitive edge. Benchmarking against industry standards and best practices provides additional context, enabling companies to set realistic goals and measure their progress against peers.

Advanced certifications, such as master black belt, equip professionals with the expertise to develop comprehensive metrics frameworks and lead complex improvement initiatives. By focusing on data-driven decision-making and continuous measurement, organizations can ensure their lean manufacturing implementation delivers tangible results—such as increased customer satisfaction, reduced costs, and improved productivity.

In the end, a commitment to measuring and analyzing performance is what transforms lean manufacturing from a set of tools into a sustainable strategy for operational excellence.

Who Should Take Lean Manufacturing Training?

This type of training is suitable for professionals at every level and from a wide range of industries:

- Operators and technicians seeking to improve their daily workflows

- Team leaders and supervisors aiming to boost team performance

- Engineers focused on process improvement and quality control

- Managers looking to lead lean initiatives and align strategy with execution

Whether you’re early in your lean journey or pursuing a master black belt, continuous education ensures you’re ready for modern manufacturing challenges.

Final Thoughts: Investing in Operational Excellence

Training on lean manufacturing is more than professional development; it’s an investment in your organization’s future. With the right lean tools, certification program, and commitment to continuous improvement, your team will:

- Drive down costs and reduce inefficiencies

- Elevate product quality and meet customer expectations

- Foster a culture where problem-solving and data-driven decision-making thrive

To explore these benefits for yourself or your organization, start with a Lean Management course or test your skills in the GET LEAN Simulation Game and experience the power of lean manufacturing training firsthand.