Spis treści

Mastering Lean and Manufacturing: Strategies for Efficiency and Growth

Why Lean Manufacturing Matters in the Modern World

Lean manufacturing remains a cornerstone of operational excellence in today’s fast-paced industrial environment. With increasing global competition, demand for customization, and rising pressure to reduce costs, lean operations principles offer a proven approach to achieving efficiency and quality. By minimizing waste and focusing on value from the customer’s perspective, lean manufacturing helps organizations adapt and thrive.

This article explores the philosophy, implementation, benefits, and challenges of lean manufacturing. It outlines the foundational lean operations principles and how to apply them across various industries. Additionally, you’ll discover how technology, employee engagement, and strategic planning are essential for building a sustainable lean culture.

Learn more in our Lean Management course to implement lean in your organization.

What Is Lean Manufacturing?

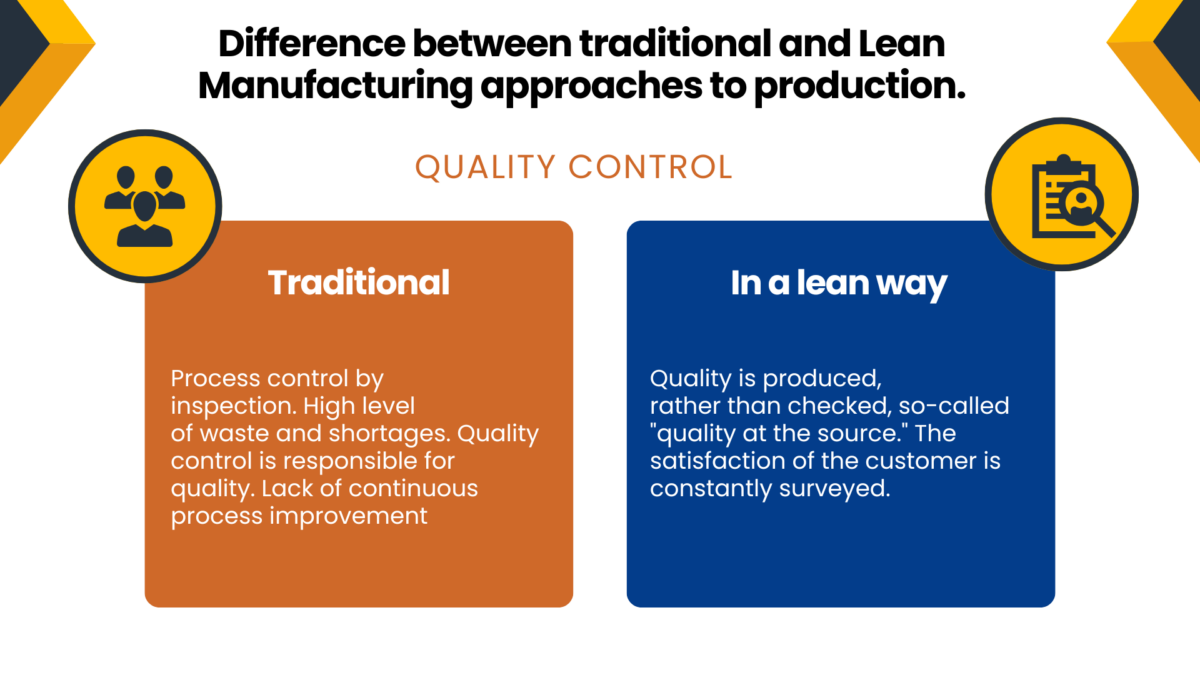

Lean manufacturing is a systematic approach to identifying and eliminating waste (non-value-added activities) through continuous improvement. It originated from the Toyota Production System but has since evolved into a universal methodology applicable across manufacturing and service sectors.

At its core, lean manufacturing aims to optimize every aspect of the production process. It aligns operations with customer demand and expectations by reducing excess inventory and improving delivery times.

The term “lean” signifies maximizing value with fewer resources. Instead of producing based on forecasts, lean uses a pull system where production is driven by actual customer demand.

The Five Lean Operations Principles Explained

The five key principles of lean manufacturing form a framework for building efficient, customer-focused processes:

Define Value

Value is defined by the customer as what they are willing to pay for. Everything else that doesn’t contribute to that value is considered waste.

Map the Value Stream

Use value stream mapping to analyze every manufacturing process step—from handling raw materials to delivery. This highlights inefficiencies and helps organizations eliminate non-value-adding steps.

Create Flow

Achieve smooth flow by restructuring processes so that operations flow smoothly from one stage to the next without bottlenecks or delays.

Establish a Pull System

The pull system ensures that production only happens in response to actual demand. This reduces overproduction, minimizes excess inventory, and aligns production with customer needs.

Seek Perfection

Continuous improvement, or Kaizen, is about consistently eliminating waste and optimizing performance. This includes involving employees in identifying problems and generating solutions.

Our Effective Problem Solving course, which teaches how to improve processes from root cause to implementation, dives into each principle.

Implementing Lean Manufacturing in Practice

Implementing lean requires more than just applying tools. It demands a mindset shift throughout the organization. Here are key strategies for putting lean into action:

- Assess current state: Use value stream mapping to understand existing workflows.

- Engage employees: Involve workers in identifying waste and proposing solutions.

- Prioritize improvement areas: Focus on critical bottlenecks first.

- Establish feedback loops: Use metrics and visual tools to track progress.

- Standardize best practices: Implement standard work to sustain improvements.

Lean Culture and Organizational Alignment

Building a lean culture is crucial to the long-term success of any lean transformation. This involves promoting open communication, empowering teams, and aligning leadership around lean goals.

Lean is not just a toolbox. It’s a philosophy—a way of thinking that values continuous improvement, customer satisfaction, and the elimination of unnecessary processes. Organizations that embrace lean as a cultural commitment enjoy greater innovation, resilience, and performance.

Explore our Teamwork and Leadership course to build strong leadership that supports lean thinking.

Managing Inventory the Lean Way

One of the hallmarks of lean manufacturing is efficient inventory management. The goal is to reduce raw materials, work-in-progress, and finished goods inventory without compromising customer service.

Just-in-time (JIT) production is a core component that enables organizations to produce precisely what is needed, when it’s needed. This minimizes waste and frees up resources for more value-added activities.

Learn how to organize your workplace for flow with our 5S Workplace Organization course.

Role of Technology in Lean Manufacturing

While lean is often viewed as low-tech, technology is increasingly playing a role in lean transformations. Tools like ERP systems and IoT sensors provide real-time visibility, improve production line control, and support data-driven decision-making.

Technological solutions make it easier to map the value stream, implement a pull system, and monitor key principles in real time. However, technology must align with lean goals—it should enhance rather than complicate operations.

The Eight Wastes: What to Eliminate

Lean identifies eight types of waste (muda):

- Overproduction – Making more than is needed.

- Waiting – Time delays for people, machines, or materials.

- Transport – Unnecessary movement of items.

- Overprocessing – Doing more than required.

- Inventory – Holding excess stock.

- Motion – Unnecessary movement by workers.

- Defects – Rework or scrap due to errors.

- Underutilized talent – Not leveraging employees’ skills.

Understanding these wastes is fundamental to applying lean operations principles effectively.

Measuring Lean Success: Metrics That Matter

Metrics are essential for tracking progress in lean initiatives. Common lean performance indicators include:

- Lead time reduction

- First-pass yield

- Inventory turnover

- Customer satisfaction

- Overall equipment effectiveness (OEE)

These metrics help you align improvements with strategic goals.

Lean Manufacturing Across Industries

While lean was born in the automotive industry, it’s now widely used across sectors:

- Healthcare: Improving patient flow and reducing errors

- Construction: Enhancing scheduling and waste management

- Logistics: Streamlining the entire supply chain

- Service industries: Improving response times and customer experience

The lean mindset is flexible and scalable, offering benefits wherever waste and inefficiency exist.

Simulating Lean with Practical Training

One of the best ways to teach and reinforce lean concepts is through interactive simulations. Our GET LEAN Simulation Game is a hands-on training tool that:

- Demonstrates the impact of waste

- Builds understanding of lean tools

- Trains teams in applying lean methods

- Supports team collaboration

Simulations bridge the gap between theory and practice, making lean more accessible and engaging.

Common Challenges in Lean Implementation

Even with the best intentions, companies face challenges when adopting lean. These include:

- Resistance to change

- Misunderstanding lean as a cost-cutting initiative

- Short-term thinking

- Poor cross-functional collaboration

- Inconsistent leadership support

Organizations must focus on training, leadership development, and sustained communication to overcome these.

Benefits of Lean Manufacturing: Long-Term Gains

Applying lean principles leads to transformative benefits:

- Improved productivity and manufacturing efficiency

- Reduced operating costs

- Better product quality

- Enhanced customer satisfaction

- Agile response to market shifts

- Environmentally sustainable operations

Organizations that fully integrate lean see significant returns on investment through operational excellence.

Final Thoughts: Your Lean Journey Starts Now

Lean manufacturing is more than a methodology—it’s a long-term commitment to excellence. It offers a structured yet flexible approach to process optimization, customer focus, and employee empowerment.

🎓 Start building your strategy with the Lean Management course

🧰 Reinforce practical skills with the GET LEAN Simulation Game

📘 Improve workplace organization with the 5S Course

With lean operations principles as your foundation, you can unlock new levels of productivity, quality, and competitiveness across your organization.