Spis treści

Lean for Managers: A Strategic Guide to Driving Lean Success

Introduction

Managers are constantly pressured to improve productivity, reduce costs, and deliver better customer value in the modern business landscape. One of the most effective strategies to achieve these goals is Lean Management, which is built on lean management principles. These principles serve as the foundation for Lean for managers, promoting continuous improvement, waste reduction, and customer value. Companies across various industries apply lean management principles to improve performance, achieve excellence, and build sustainable, value-driven organizations.

Looking to become a more effective Lean Manager? Discover our hands-on Lean Management course designed for real-world application across industries.

Lean management helps a company become more adaptable and high-performing by increasing flexibility and improving customer responsiveness.

What Is Lean and Why Should Managers Care?

Lean is a methodology that systematically seeks to eliminate waste, streamline processes, and deliver greater value to customers. Originally derived from the Toyota Production System, Lean thinking has evolved into a universal framework for achieving operational excellence. Lean manufacturing originated in the Toyota Production System and has significantly improved processes and efficiency across industries.

For managers, a lean approach is not just a set of tools but also a mindset and leadership approach. Lean Managers are responsible for embedding Lean principles into everyday work, aligning operations with strategic goals, and nurturing a culture of continuous improvement. Lean management principles are a universal philosophy that promotes continuous improvement, reduces waste, and enhances customer value across industries.

Key Benefits of Lean for Managers

- Improved process efficiency

- Enhanced customer satisfaction

- Greater team engagement and collaboration

- Reduced operational costs

- Waste reduction as a key performance indicator

- Long-term performance gains

Our Lean Management course provides the exact tools and frameworks successful managers use to lead Lean transformations.

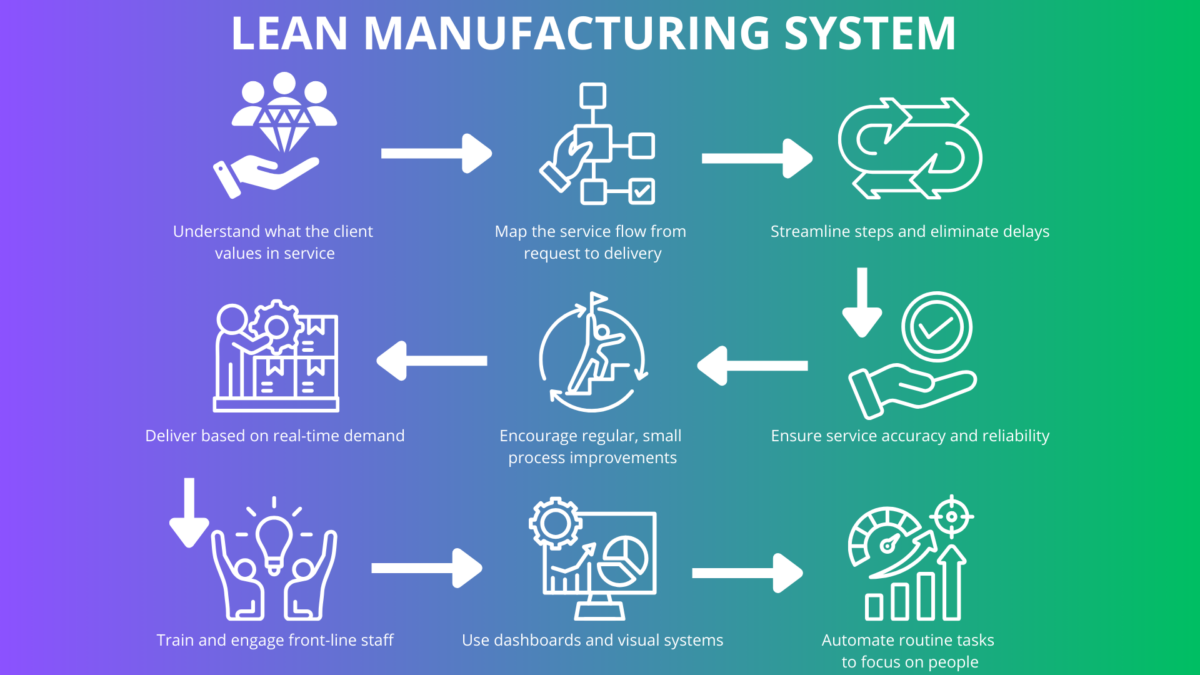

Core Lean Principles Every Manager Should Know

The five Lean principles, outlined by Womack and Jones, are the foundation of Lean methodology and are essential for any manager implementing Lean practices:

- Define Value: Understand what the customer truly values and focus efforts on delivering that.

- Map the Value Streams: Map the value streams to identify all activities involved in delivering a product or service, and eliminate anything that does not add value, as these activities are considered waste.

- Create Flow: Ensure that processes move smoothly without delays or bottlenecks.

- Establish a Pull System: Respond to customer demand by implementing a pull system that produces only what is needed when required.

- Pursue Perfection: Continuously improve processes by pursuing perfection in all operations to achieve operational excellence.

These principles guide managers in making strategic decisions, improving work processes, and aligning teams with organizational goals.

Responsibilities of a Lean Manager

A Lean Manager plays a vital role in translating Lean philosophy into daily operations. As a lean leader, they guide teams through continuous improvement, foster a culture of efficiency, and embody Lean principles. Their key responsibilities include:

- Identifying inefficiencies and root causes of waste

- Facilitating value stream mapping workshops

- Leading Kaizen events and improvement initiatives

- Promoting employee engagement in Lean activities

- Monitoring performance metrics and aligning them with Lean objectives

- Championing a Lean culture that emphasizes problem-solving and customer focus

- Applying Lean techniques to drive improvement and eliminate waste

- Optimizing resources to enhance efficiency and value creation

Want to improve your team’s problem-solving skills? Enroll in our Problem-Solving course.

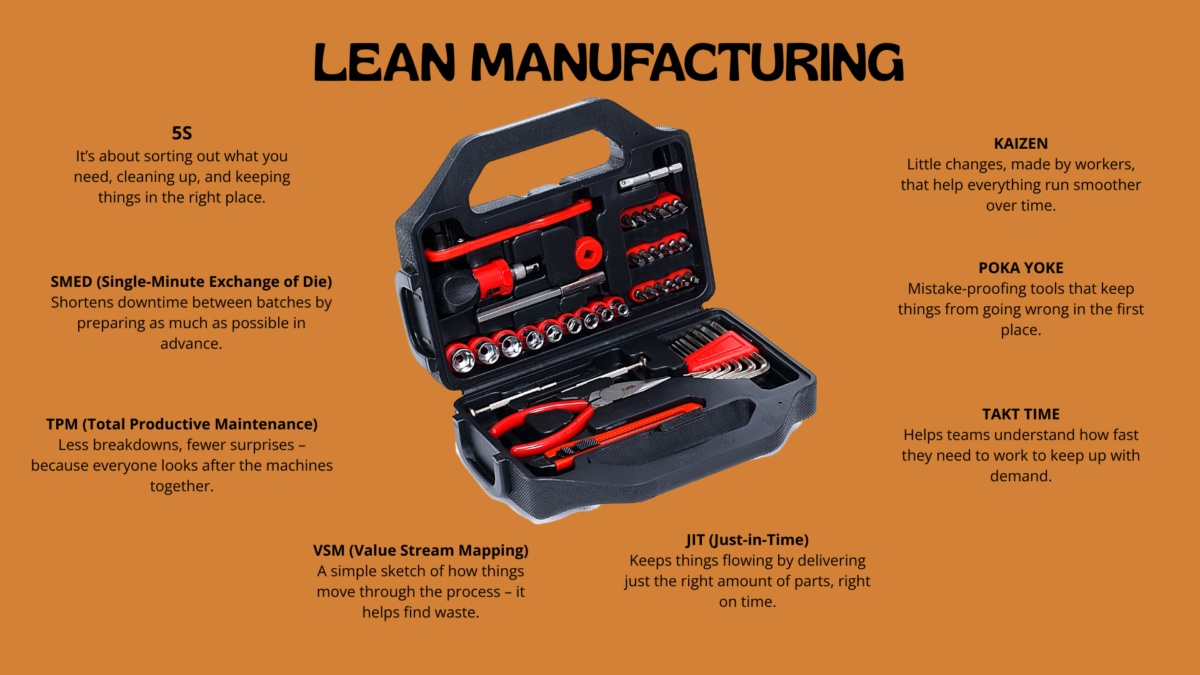

Essential Lean Tools for Managers

Managers must be proficient in several Lean tools and techniques to lead Lean initiatives effectively. Many of these tools and techniques originated in lean manufacturing, developed to improve processes, reduce waste, and increase efficiency. These Lean tools and techniques are essential for effective Lean management:

- 5S Methodology: Organize the workplace for efficiency and standardization.

- Kanban and Pull Systems: Control workflow and inventory based on actual demand.

- A3 Thinking: Structured approach to solving problems and documenting decisions.

- Value Stream Mapping: Analyze and improve entire processes.

- Standard Work: Documenting best practices to ensure consistency.

Learn how to apply these tools practically through our 5S Workplace Organization course.

Creating a Customer Focus: Putting the Customer at the Heart of Lean

A true Lean transformation begins and ends with the customer. In Lean management, creating a customer focus means ensuring that every business process is designed to deliver maximum value to the end customer. Lean leaders and managers must prioritize customer satisfaction and deeply understand customer requirements and expectations.

By focusing on the customer, Lean managers can drive process improvement and eliminate waste, ensuring that every step adds value and nothing is considered pure waste. This customer-centric approach is a core principle of Lean, guiding organizations to develop processes that are efficient and aligned with customers’ true needs.

To put the customer at the heart of Lean, managers should:

- Regularly gather and analyze customer feedback to identify opportunities for improvement.

- Map business processes from the customer’s perspective, ensuring each activity contributes to customer value.

- Streamline processes to reduce waste and respond quickly to changing customer requirements.

- Foster a culture where every employee understands their role in delivering value to the end customer.

By embedding customer focus into Lean management, organizations can improve customer satisfaction, reduce waste, and boost overall efficiency, creating a sustainable competitive advantage.

Implementing Lean: Step-by-Step Guide for Managers

1. Assess Current State

Begin by clearly understanding your current business processes. Conduct value stream mapping to identify bottlenecks and pure waste.

2. Define Vision and Goals

Align Lean initiatives with long-term goals and define success.

3. Train Your Team

Empower employees with training on Lean methodology and tools. Incorporate team collaboration and leadership workshops.

4. Pilot Lean Projects

Start small—implement Lean in one area before scaling. Focus on streamlining processes and measurable improvements.

5. Measure and Sustain

Use KPIs to track progress. Continuously revisit and refine processes. Encourage employee feedback and maintain momentum.

Dive deeper into sustaining continuous improvements with our Continuous Improvement course.

Lean Leadership: How Managers Inspire Change

Lean leaders do more than manage—they inspire. They lead by example, ask the right questions, and foster a culture where everyone is responsible for identifying waste and solving problems.

Characteristics of effective Lean Leaders:

- Servant leadership mindset

- Strong communication and coaching abilities

- Focus on developing employees

- Long-term thinking and systematic decision-making

Learn how to become a transformational leader in Lean environments through our Teamwork and Leadership course.

Lean in Action: Examples from Various Industries

Manufacturing

Lean has its roots in manufacturing, where reducing inventory and improving flow has led to significant cost savings.

Services

Banks and hospitals use Lean to streamline administrative tasks, reducing scope creep and improving service quality.

IT & Software

Agile methodologies draw heavily on Lean thinking, particularly the concepts of pull systems and continuous improvement.

Want to experience Lean in action? Explore our interactive Lean Simulation Game that applies Lean principles in a dynamic environment.

Overcoming Common Challenges in Lean Implementation

Managers may face resistance, a lack of clarity, or poor engagement during Lean transformations. Key strategies to overcome these include:

- Effective communication of the Lean vision

- Aligning Lean goals with individual and departmental objectives

- Continuous training and mentoring

- Recognizing small wins to build momentum

Best Practices for Lean Managers

Successful Lean managers live and breathe its principles every day. They understand that continuous improvement, respect for people, and a relentless focus on customer value are essential to achieving operational excellence.

Here are some best practices for Lean managers:

- Adopt a long-term approach: Focus on sustainable improvement rather than quick fixes. Set long-term goals that align with the organization’s Lean vision.

- Systematically seek improvement: Use Lean tools, such as value stream mapping, to identify inefficiencies and streamline processes. Regularly review and refine work processes to eliminate waste.

- Empower employees: Recognize that employees are essential to the improvement process. Encourage involvement, provide training, and create an environment where everyone feels responsible for process improvement.

- Lead by example: Demonstrate commitment to Lean principles through your actions. Foster a Lean culture by promoting open communication, collaboration, and respect for every team member.

- Prioritize leadership development: Invest in developing your team’s Lean leadership skills. Strong leadership is essential for driving the Lean culture and achieving operational excellence.

By following these best practices, Lean managers can create a culture of continuous improvement, deliver greater customer value, and ensure that Lean principles are deeply embedded in every aspect of the organization.

Common Mistakes to Avoid in Lean Management

While Lean management offers powerful tools for improvement, common pitfalls can undermine even the best-intentioned Lean transformations. Awareness of these mistakes can help Lean managers avoid obstacles and achieve lasting success.

- Neglecting customer focus: Failing to prioritize the customer can lead to processes that don’t meet customer needs or requirements. Always keep customer value at the center of every improvement effort.

- Overlooking Lean principles: Not fully embracing Lean’s core principles—such as continuous improvement and respect for people—can stall progress and limit results.

- Allowing scope creep and pure waste: Expanding projects beyond their original intent or tolerating unnecessary steps can introduce waste and reduce efficiency. Stay disciplined in eliminating waste and reducing unnecessary activities.

- Ignoring Lean culture and employee involvement: Lean transformations falter when managers don’t engage employees or fail to build a culture of empowerment and accountability.

- Underutilizing Lean tools and neglecting long-term goals: Skipping essential Lean practices like value stream mapping or focusing only on short-term gains can prevent organizations from achieving operational excellence.

By avoiding these common mistakes, Lean managers can ensure their Lean management efforts lead to meaningful, sustainable improvement and a culture of excellence.

Metrics That Matter: Measuring Lean Success

To ensure Lean practices are making an impact, managers should monitor:

- Cycle time reduction

- Employee engagement scores

- Customer satisfaction metrics

- Reduction in defects and rework

- Achievement of performance improvement targets

Final Thoughts: Why Lean Matters for Managers

Lean offers more than just tools—it provides a strategic approach to process improvement, customer focus, and value creation. Managers who understand and apply Lean principles improve efficiency and foster a resilient, agile organization.

🎓 Ready to master Lean practically? Join our Lean Management course today. It’s a rich collection of real-world strategies, tools, and examples based on 25 years of experience implementing Lean and 5S principles across industries.

👉 You can even preview a lesson for free to see how actionable and insightful the course is.

And don’t miss out on our engaging Lean Simulation Game—a hands-on training that turns Lean theory into practice through immersive gameplay.

Start your Lean journey today, and lead your organization toward excellence.