Spis treści

Lean Management Principle: The Path to Streamlined Success and Sustainable Growth

The Lean Management Principle is more than a framework—a mindset. It guides organizations in eliminating waste, optimizing processes, and delivering outstanding customer value. With roots in the Toyota Production System, it has become a global benchmark for companies aiming to achieve operational excellence, improve quality, and respond effectively to dynamic market demands.

This comprehensive guide explores how applying the Lean Management Principle empowers businesses to remain competitive, drive continuous improvement, and build an efficient, effective organization. Whether you’re new to lean or seeking to refine your approach, this article offers practical strategies, real-world examples, and expert insights to elevate your operations.

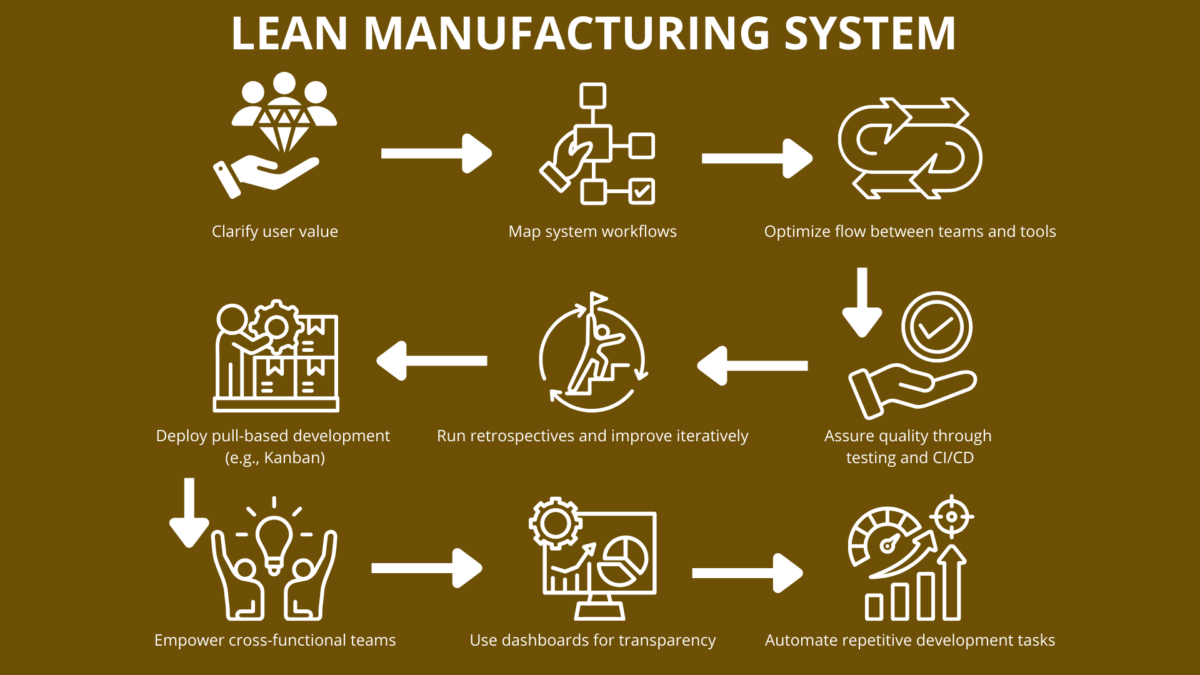

What Is the Lean Management Principle?

The Lean Management Principle focuses on maximizing customer value while minimizing waste. This means doing more with less—less time, less effort, less space—without compromising quality or customer satisfaction.

It promotes a culture of continuous improvement, encourages cross-functional collaboration, and drives value-adding activities across the value stream. By understanding and applying the Lean Management Principle, organizations can become more agile, reduce operating costs, and boost productivity.

Core Concepts

- Customer Value: The starting point of lean—understanding what customers truly need.

- Value Stream: The complete flow of materials and information needed to bring a product or service to the customer.

- Pull System: Producing based on actual demand, not forecasts.

- Creating Flow: Ensuring work processes move smoothly without bottlenecks.

- Continuous Improvement: Constantly seeking better ways to operate.

📘 Want to explore the fundamentals? Start with our Lean Management Course to gain practical insights into applying lean principles.

Mapping the Value Stream: The Second Lean Management Principle

Once the value is defined, the next step is mapping the value stream. This principle requires identifying all value-adding and non-value-adding steps to eliminate waste and improve efficiency.

Through value stream mapping, organizations gain visibility into their workflows and identify opportunities to streamline. It’s a vital tool for effectively implementing lean and as a reference point for continuous improvement initiatives.

➡️ To dive deeper into process diagnosis and waste elimination, visit our Effective Problem Solving Course.

Creating Flow: Achieving a Smooth, Continuous Workflow

Flow refers to the seamless movement of materials and information throughout the production system. In an ideal lean environment, tasks move smoothly from one team member or workstation to the next without delays or interruptions.

Benefits of creating flow include:

- Shorter lead times

- Lower inventory levels

- Faster time-to-market

- Greater responsiveness to customer needs

Lean organizations redesign layouts, cross-train staff, and standardize work processes to facilitate flow. This is particularly effective when supported by visual management and daily performance monitoring.

🧰 Get hands-on experience with these concepts in our GET LEAN Simulation Game.

Pull System: Producing Only What’s Needed

The pull-based system is one of the most critical Lean Management Principles. Instead of pushing products into the market based on forecasts, lean organizations produce according to customers’ actual or latent needs.

By aligning production with real-time demand:

- Inventory levels are reduced

- Waste is minimized

- Customer satisfaction improves

Kanban systems, demand signals, and flexible scheduling help establish pull inventory systems that support operational agility.

Pursuing Perfection: Continuous Improvement as a Lifestyle

The Lean Management Principle culminates in striving for perfection through continuous improvement, or Kaizen. This philosophy encourages organizations never to settle and to continually look for ways to refine work processes, cut waste, and deliver more value.

Strategies for driving continuous improvement:

- Daily team huddles

- Employee-led Kaizen events

- Root cause analysis

- Tracking KPIs and performance trends

🎯 Discover how to build a culture of ongoing improvement with our Continuous Improvement Course.

Encouraging a Lean Mindset Across All Departments

To be effectively implemented, the Lean Management Principle must be adopted across all levels and departments. It’s not limited to manufacturing—it extends to customer service, logistics, administration, and leadership.

Fostering a lean mindset involves:

- Empowering employees

- Creating cross-functional departments

- Eliminating unnecessary processes

- Encouraging ownership and accountability

Organizations that foster a learning culture can adapt more quickly, improve workplace efficiency, and stay ahead in competitive markets.

🧠 For guidance on developing team synergy, check out our Teamwork and Leadership Course.

Leveraging Value Stream Mapping and Just-in-Time Delivery

Advanced lean systems apply value stream mapping and just-in-time delivery to identify bottlenecks and align production timing with customer demand. These approaches are integral to an efficient and effective organization.

Key benefits:

- Real-time visibility into production

- Better inventory management

- Faster delivery cycles

- More responsive customer service

These tools support qualitative and quantitative techniques to monitor performance and identify gaps.

Integrating Technology in Lean Management Systems

Digital technologies like ERP, IoT, and automation enhance lean management systems. These systems collect data, optimize operations, and ensure accountability at every stage.

Technology supports the Lean Management Principle by:

- Enabling data-driven decision-making

- Ensuring transparency in the value stream

- Facilitating continuous workflow and process improvement

By combining the Lean Management Principle with digital transformation, organizations gain a competitive edge through scalability, speed, and precision.

Benefits of Applying the Lean Management Principle

Organizations that embrace lean principles and create a lean management system report significant improvements across the board:

- Higher efficiency in production processes

- Reduced costs through waste elimination

- Faster response to customer needs

- Improved quality and fewer defects

- Better resource utilization

- Increased employee engagement

- Stronger supply chain performance

Implementing lean can transform not just your operations, but your entire business.

Conclusion: Building a Future-Proof Organization with Lean Principles

The Lean Management Principle is a powerful guide for any company striving for excellence. Lean principles provide a structured, proven path to sustainable success from defining customer value to creating flow and pursuing perfection.

By embedding these principles into your culture, training employees, and leveraging technology, your organization can achieve continuous improvement, reduce waste, and deliver greater customer value.

🎓 Ready to master lean principles and apply them in real operations? Enroll in the Lean Management Course.

📘 Want to implement workplace improvements? Learn how with the 5S Workplace Organization Course.

🧩 Looking for interactive learning? Experience lean in action with the GET LEAN Simulation Game.

With the Lean Management Principle as your foundation, you can lead your team to a more efficient, agile, and customer-focused future.