Business Improvement Techniques: Strategies for Enhancing Organizational Efficiency

In today’s dynamic business environment, implementing business improvement techniques is essential for staying competitive, boosting customer satisfaction, and fostering a culture of continuous improvement. This includes adopting continuous business improvement as an ongoing, systematic approach to enhancing operations. These strategies help organizations streamline business processes, focusing on business process analysis and process improvement, to eliminate inefficiencies and drive operational excellence.

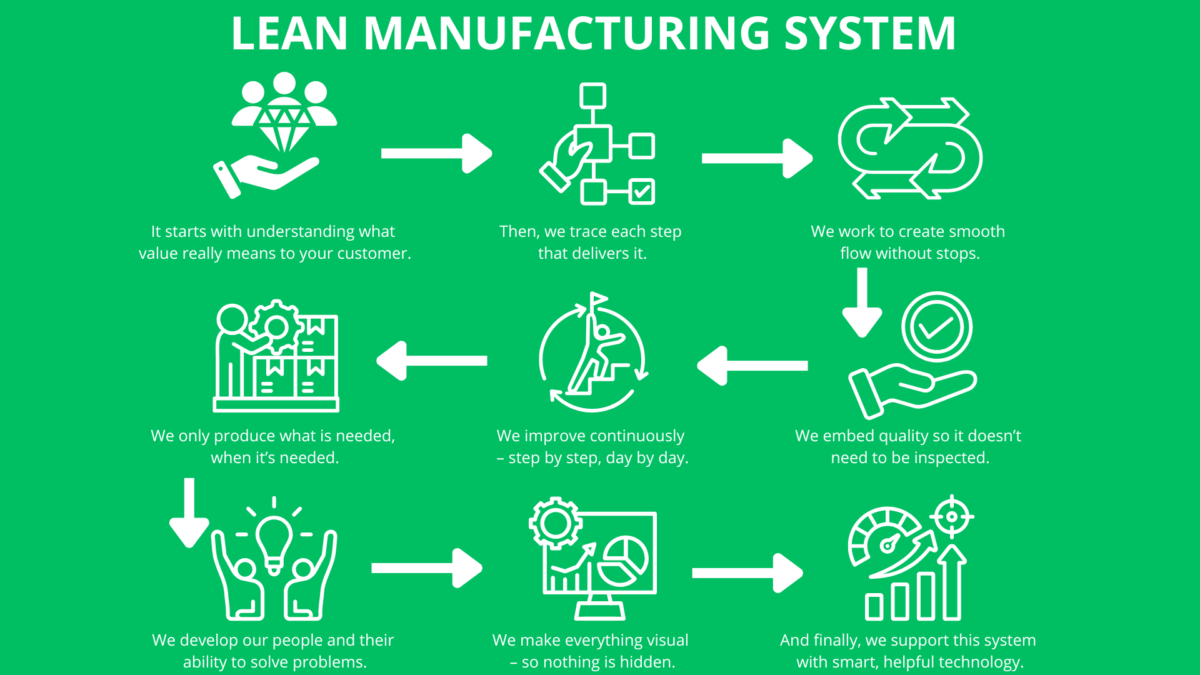

One core approach to business improvement is lean management, which focuses on eliminating waste and achieving operational efficiency by optimizing workflows. The Lean Management course equips professionals with the tools to lead transformation efforts and achieve meaningful outcomes, allowing teams to learn how to effectively apply lean methods and foster a mindset of problem-solving.

Introduction to Business Improvement

Business improvement is a systematic approach focused on identifying, analyzing, and enhancing various aspects of a company’s operations to drive greater efficiency, productivity, and customer satisfaction. At its core, business improvement relies on continuous improvement and a data-driven approach to process improvement, ensuring organizations constantly seek ways to optimize their performance. By implementing process improvements, companies can eliminate waste, reduce unnecessary costs, and elevate the quality of their products and services. The ultimate goal is to achieve operational excellence by streamlining workflows, optimizing processes, and delivering an outstanding customer experience. This ongoing commitment to business improvement increases efficiency and positions organizations to meet evolving customer needs better and remain competitive in their industries.

Understanding Business Improvement Techniques

Business improvement techniques encompass a range of process improvement methodologies that enhance efficiency, quality, and customer satisfaction. These include adopting a process improvement methodology or an improvement methodology as a structured approach to process mapping, value stream analysis, and identifying bottlenecks within business processes. By using a structured, data-driven approach like root cause analysis or by applying a continuous improvement methodology as an overarching framework, teams can uncover hidden issues and design effective solutions.

For example, in a typical continuous improvement cycle, it’s crucial to involve cross-functional teams in identifying areas for optimization. Leadership is key in facilitating workshops and aligning efforts with broader organizational goals. Standard process improvement methodologies are essential in guiding teams to ensure consistent and practical improvements. For those looking to strengthen leadership capabilities, the Effective Teamwork and Leadership course offers practical techniques for guiding teams through change.

Process Analysis and Mapping

Process analysis and mapping are foundational tools in the journey toward business improvement. By creating process maps—visual representations of existing processes—organizations gain a clear understanding of how work flows across different functions. This visibility allows teams to pinpoint repetitive tasks, bottlenecks, and inefficiencies hindering process efficiency. Through process mapping, businesses can develop targeted strategies to eliminate waste and implement solutions that drive improvement. Techniques such as value stream mapping and stream mapping are especially effective for analyzing manufacturing, service delivery, and software development business processes. These tools help organizations document their current processes and identify improvement opportunities, enabling them to increase efficiency and productivity across all areas of operation.

Tools for Driving Process Improvement

Commonly used business improvement techniques include Lean Manufacturing practices (with origins in the manufacturing industry, focusing on manufacturing processes, the production process, lean production, and the Toyota Production System), Six Sigma methodologies (including the six sigma methodology and sigma methodology as structured, data-driven approaches to process improvement), and Total Quality Management (TQM) (which emphasizes quality control, quality improvement, improving quality, improve quality, and product and service quality as key outcomes). Each method has its unique strengths, but they all aim to improve process efficiency and deliver value to the customer.

Tools like process mapping and value stream mapping (a stream map for visualizing process flows) help teams visualize current processes, identify redundancies, and develop a future state that eliminates unnecessary steps. These methods align closely with the 5S methodology, a core component of workplace organization. The 5S approach helps organizations standardize processes, improve productivity, optimize processes, and streamline workflows by creating efficient, organized workspaces. To learn more about how 5S can improve efficiency, safety, and team collaboration, explore the Fundamentals of 5S course.

Additionally, business process and project management tools are crucial in supporting and sustaining process improvement initiatives.

Root Cause Analysis and Problem-Solving

Root cause analysis is a powerful problem-solving technique that enables organizations to uncover the underlying reasons behind issues affecting process performance. Rather than simply addressing surface-level symptoms, root cause analysis digs deeper to identify the most critical limiting factor causing a problem. This approach involves gathering and analyzing data, brainstorming possible causes, and systematically determining the root cause. By focusing on root causes, businesses can develop effective strategies that lead to lasting solutions, reduce defects, and enhance customer satisfaction. Incorporating root cause analysis into the continuous improvement process ensures that improvement efforts are targeted and impactful, driving meaningful change and supporting ongoing business success.

Implementing and Sustaining Business Improvement Initiatives

Implementing business improvement techniques requires tools, team engagement, and ongoing evaluation. Key steps include implementing improvements and launching a process improvement initiative to drive change. Successful organizations establish key performance indicators to measure the impact of initiatives, incorporating a process improvement method and tracking progress toward desired outcomes as part of the measurement process. They use feedback loops to refine practices and apply root cause analysis when challenges arise. The commitment to continuous improvement must become part of the organizational DNA to sustain progress. Ongoing business improvement efforts require organizations to develop strategies for increased efficiency and focus on improving business processes as continuous priorities.

For those seeking to embed a continuous improvement culture in their organization, the Continuous Improvement course provides actionable frameworks and templates for sustaining long-term gains.

Common Challenges and Best Practices

While business improvement benefits are clear, organizations often encounter challenges when implementing process improvements. Common obstacles include resistance to change, limited resources, and gaps in employee training. To overcome these hurdles, adopting a systematic approach that emphasizes continuous improvement, employee engagement, and a strong commitment to excellence is essential. Best practices for successful improvement initiatives include leveraging data-driven decision making, aligning process improvements with overall business strategy, and applying lean principles to streamline operations. Monitoring progress through key performance indicators and metrics allows organizations to measure the impact of their improvement efforts and identify new growth opportunities. By consistently applying these best practices, businesses can achieve sustainable improvements, increase efficiency, and deliver higher customer satisfaction.

Conclusion

Adopting business improvement techniques is not a one-time effort—it’s a commitment to an ongoing journey of optimization, learning, and innovation. By understanding tools like process mapping and value stream analysis, fostering continuous improvement, and building leadership capabilities, organizations can transform how they work, deliver higher-quality products and services, and improve the overall customer experience.

For professionals ready to sharpen their problem-solving skills, the Problem-Solving Process course offers hands-on strategies for tackling challenges and implementing lasting solutions. When leaders and teams embrace structured improvement techniques, they unlock the potential for true operational excellence.