Courses on Lean Manufacturing: Elevate Skills and Transform Production Efficiency

In today’s competitive and rapidly evolving manufacturing industry, efficiency, adaptability, and continuous innovation are non-negotiable. Manufacturers face rising costs, shifting market demands, and the constant need to improve quality and reduce waste. For businesses striving to remain competitive, investing in courses on lean manufacturing is a proven strategy to transform operations and unlock lasting value.

Lean manufacturing is more than a collection of tools—it’s a mindset and philosophy grounded in eliminating waste, improving processes, and delivering maximum value to customers. Whether a production manager, engineer, team leader, or executive, these courses are your gateway to mastering lean principles and achieving measurable results. They help learners develop a deep understanding of Lean concepts and the skills needed to implement them effectively in real-world settings.

What Are Courses on Lean Manufacturing?

Lean manufacturing courses are structured training programs designed to teach individuals and teams how to apply lean methodologies to real-world operational challenges. These programs cover various topics, from foundational concepts to advanced applications in process analysis, lean tools, and strategic transformation initiatives.

Offered in various formats—including in-person, hybrid, and online—these courses enable learners to:

- Understand and apply the five core lean principles

- Identify and remove waste in any manufacturing process

- Improve workflows across production processes

- Use standardized methods for process improvements

- Drive a continuous improvement culture throughout the organization

Many online courses also include discussion forums to facilitate peer interaction, engagement, and industry-specific discussions.

🎓 Want to start applying Lean in your workplace? Discover our Lean Management – Practical Course and access lifetime content, templates, and real-world strategies.

Why Lean Manufacturing Training Is Crucial Today

The need for skilled professionals in lean manufacturing is higher than ever. The importance of quality training and certification cannot be overstated, as it significantly enhances employability and career prospects in the manufacturing industry. As organizations grapple with global supply chain challenges, digital transformation, and the demand for higher quality at lower cost, Lean offers a proven framework to adapt and thrive.

Benefits of Lean Training:

- Reduce operational waste and inefficiencies

- Improve customer satisfaction and delivery reliability by reducing defects and improving product quality, which increases customer satisfaction.

- Enhance employee engagement and problem-solving abilities.

- Foster cross-functional collaboration and ownership

- Build capabilities to lead lean transformation initiatives

From shop floor operators to executive leaders, Lean courses help organizations align strategy with daily execution.

What You’ll Learn in Lean Manufacturing Courses

1. Core Lean Principles

All successful Lean courses start by exploring the foundational principles:

- Value – Define what the customer truly values.

- Value Stream – Map every step in the process to identify waste.

- Flow – Eliminate interruptions in the manufacturing process.

- Pull – Produce only what’s needed when it’s needed.

- Perfection – Strive for continuous refinement through process improvements.

These principles are then contextualized through case studies and simulations.

2. Lean Tools in Practice

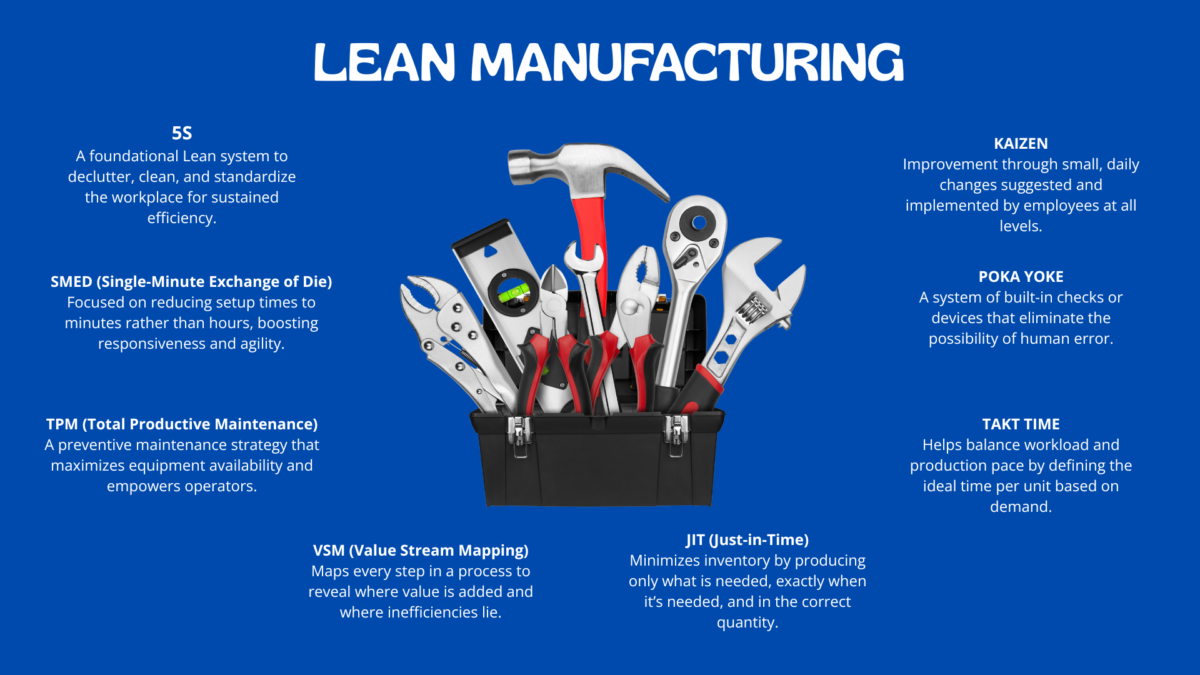

Participants gain hands-on experience using tools such as:

- 5S for workplace organization

- Kanban for visual inventory control

- Poka-Yoke (mistake-proofing)

- Value Stream Mapping

- Standard Work

These tools are key to implementing lean principles and sustaining daily excellence.

3. Process Analysis and Standardization

Courses teach participants how to analyze existing workflows, including every stage of the production process, to identify inefficiencies, standardize best practices, eliminate waste, and create new standards for consistent output and quality.

4. Problem Solving and Continuous Improvement

Attendees learn to drive small, incremental changes and structured problem-solving using the PDCA cycle (Plan-Do-Check-Act), A3 thinking, and root cause analysis.

💡 Ready to go deeper into systematic improvement? Explore our Continuous Improvement course.

Lean Six Sigma: Integrating Lean and Six Sigma Methodologies

Lean Six Sigma is a powerful approach that merges the strengths of Lean manufacturing and Six Sigma to deliver exceptional results in process optimization and quality control. By combining Lean principles—focused on eliminating waste and streamlining production processes—with the data-driven rigor of Six Sigma methodology, organizations can achieve both efficiency and precision in their operations.

Integrating Lean and Six Sigma methodologies enables companies to drive continuous improvement, minimize defects, and increase customer satisfaction. Lean Six Sigma certification programs equip professionals with the skills and knowledge to lead Lean transformation initiatives, conduct thorough process analysis, and implement process improvements that optimize operations and reduce waste.

Lean Six Sigma experts utilize tools and techniques like process mapping, root cause analysis, and statistical methods to identify inefficiencies and implement sustainable changes. This methodology is widely adopted in manufacturing to enhance quality control, reduce costs, and boost productivity. By implementing Lean principles alongside Six Sigma methodologies, organizations can expect significant improvements in their production processes, leading to higher efficiency and increased customer satisfaction.

Earning a Lean Six Sigma certification is a valuable asset for anyone seeking to advance their career in the manufacturing industry. It demonstrates a deep understanding of Lean management, process optimization, and the ability to drive continuous improvement across an organization. As a key component of modern Lean management, Lean Six Sigma empowers professionals to lead successful Lean transformations and deliver measurable business results.

Formats: Online, On-Site, and Hybrid Courses

Today’s learners need flexibility. That’s why courses on lean manufacturing are available in multiple formats to suit individual and organizational needs:

- Online courses: Self-paced, accessible anytime, anywhere

- Virtual instructor-led: Real-time training with expert feedback

- On-site workshops: Hands-on learning in your facility

- Hybrid programs: Combine digital and in-person experiences

Each format offers unique benefits, with online courses beneficial for organizations that need to train across locations or shifts.

📦 Our Lean Management – Practical Course is 100% online, includes on-demand videos, real templates, and lifetime access—perfect for busy professionals.

Who Should Take a Lean Manufacturing Course?

Lean courses are valuable for professionals across the manufacturing industry, regardless of their role or experience level.

| Role | Value of Training |

|---|---|

| Line Operators | Learn how to improve work areas using 5S and standard work |

| Supervisors | Use Lean to manage daily operations and eliminate barriers |

| Engineers | Optimize the design and layout of production processes |

| Quality Professionals | Strengthen process analysis and defect prevention |

| Supply Chain Managers | Align inventory and logistics using Lean thinking |

| Executives | Champion and sustain Lean culture organization-wide |

Industry Applications: Where Lean Manufacturing Makes a Difference

Lean manufacturing is not limited to a single sector—it’s a versatile approach that delivers measurable improvements across a wide range of industries, from automotive and aerospace to healthcare and beyond. By implementing Lean principles and methodologies, organizations can transform their production processes, reduce waste, and optimize operations at every stage of the supply chain.

In the automotive industry, Lean manufacturing has revolutionized assembly lines through the use of Just-In-Time (JIT) production, ensuring that parts arrive exactly when needed to minimize inventory and reduce costs. Aerospace companies rely on Lean tools like Total Productive Maintenance (TPM) to maximize equipment reliability and maintain high-quality control standards. Lean methodologies streamline patient flow, reduce wait times, and improve patient satisfaction in healthcare.

Lean manufacturing is also essential for optimizing supply chain management. It enables organizations to respond quickly to changing customer demands while minimizing excess inventory and operational waste. Lean tools such as process mapping and statistical analysis help teams identify bottlenecks, eliminate inefficiencies, and drive continuous organizational improvement.

By focusing on Lean management principles, companies across industries achieve significant cost reductions, increased productivity, and enhanced customer satisfaction. Whether improving quality control in manufacturing, optimizing logistics in supply chain operations, or enhancing service delivery in healthcare, Lean manufacturing provides the framework and tools needed to deliver lasting improvements and maintain a competitive edge.

Certification and Recognition

Many courses provide formal recognition upon successful completion, ranging from certificates of participation to professional Lean certifications (e.g., Lean Bronze, Silver, or Gold).

Earning Lean or Six Sigma certification can open up new job opportunities in the manufacturing industry and increase employability with major companies.

Certifications help professionals stand out in a competitive job market and provide validation of real capability in lean management and execution.

📈 Want to become a Lean-certified professional? Our program supports both learning and application, making it ideal for preparing for Lean or Six Sigma credentials.

Learning Outcomes: What You’ll Gain

After completing a Lean manufacturing course, you will:

- Understand the complete Lean system and mindset

- Be able to identify waste and improvement opportunities

- Apply tools and techniques to real problems

- Lead or contribute to team-based improvement initiatives

- Build confidence to take part in or lead Lean transformations

Lean knowledge is not just theoretical—it’s immediately actionable.

How to Choose the Right Course

When evaluating courses on lean manufacturing, consider the following:

- ✅ Practicality – Does it include real examples and tools?

- ✅ Flexibility – Can it be completed on your own time?

- ✅ Resources – Are templates, checklists, or simulations provided?

- ✅ Instructor experience – Is the course built on factual industry background?

- ✅ Scalability – Can teams or departments learn together?

✅ Our Lean Management – Practical Course checks every box—plus, you can preview a lesson for free before committing.

From Course to Culture: Embedding Lean Across the Organization

Completing a course is only the beginning. True transformation comes when Lean becomes part of daily decision-making. This requires leadership, reinforcement, and continuous development.

Supporting efforts like lean manufacturing training, process analysis, and daily kaizen builds a culture of improvement that can survive market changes and operational shocks.

🚀 Want to enhance leadership capability? Our Teamwork and Leadership Course helps align behaviors and vision.

Final Thoughts: Lean Learning That Drives Results

In a world driven by efficiency, adaptability, and agility, courses on lean manufacturing offer the skills and tools that professionals need to succeed. From mastering lean tools to building systems for continuous improvement, these programs serve as the launchpad for long-term excellence.

If you’re serious about removing waste, empowering people, and building a competitive edge, the right Lean course can change everything.

🎓 Ready to Get Started?

The Lean Management – Practical Course includes:

🎥 On-demand video format – Train at your pace, on your schedule

♾️ Permanent access – Perfect for onboarding new hires and revisiting concepts

🧰 Tools included – Downloadable templates, checklists, red tags

📘 Real-world insights – Based on 25+ years of Lean consulting experience

👉 Preview a full lesson for free and see how practical the training is.