Introduction to Lean Thinking

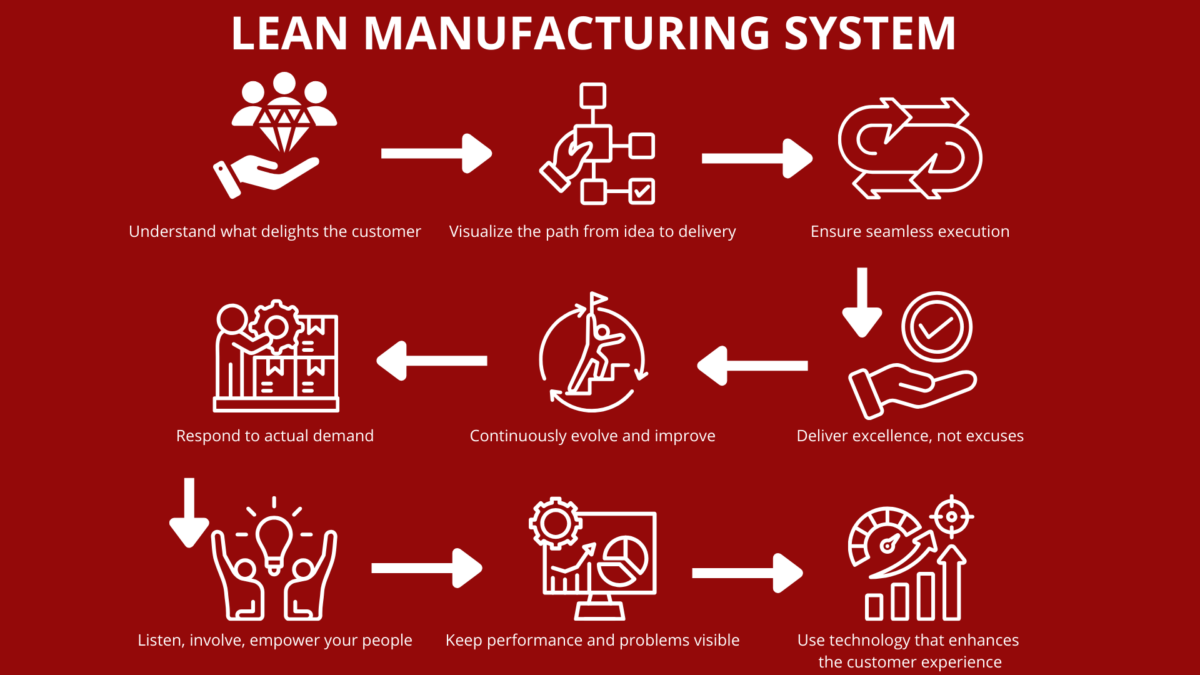

Lean thinking is a powerful philosophy rooted in the Toyota Production System, designed to eliminate waste and maximize value throughout production processes. At its core, lean thinking challenges organizations to focus on what truly matters to the end customer, while systematically reducing or eliminating anything that does not add value. This approach is not limited to manufacturing companies—any organization can benefit from applying lean principles to streamline processes, reduce costs, and enhance customer satisfaction.

The core principle of lean thinking is to identify and remove the eight wastes of lean manufacturing: transportation waste, inventory waste, motion waste, waiting waste, overproduction, overprocessing, defects, and non-utilized talent. By targeting these wastes, organizations can simplify workflows, eliminate unnecessary steps, and create more efficient processes that deliver better results for both the business and its customers. Ultimately, lean thinking empowers teams to continuously improve, adapt, and thrive in a competitive environment.

What Are the Eight Wastes of Lean Manufacturing?

In lean thinking, the core lean principles are based on identifying and eliminating waste across production processes by applying the lean method as a systematic approach.

While initially focusing on seven wastes, many modern implementations—rooted in the Toyota Production System—highlight eight specific forms of waste:

- Overproduction – making more than demanded by the end customer

- Waiting waste – idle time between process steps

- Transportation waste – unnecessary movement of materials

- Excess inventory/inventory waste – storing more than what’s needed

- Motion waste – extra movement by workers (wasted motion)

- Over-processing / extra processing – adding unneeded features or complexity

- Defects – producing defective parts needing rework

- Non-utilized talent – failing to involve employees’ ideas and skills

These are categories of manufacturing waste and non-value-adding activities that can be found in various work processes. The eighth waste, non-utilized talent, was added when lean was adopted in the Western world.

These forms of pure waste drain resources, inflate costs, and prolong cycle time. They incur costs and can lead to additional expenses, such as rework, scrap, or lost opportunities. Identifying and removing them is the heart of every lean manufacturing initiative, making it essential to locate wastes as the first step in lean initiatives.

Why Waste Occurs in Production and Business Processes

Wastes arise in both manufacturing companies and business processes due to:

- Unclear value stream mapping that misses hidden inefficiencies

- Pressure to overproduce, leading to extra raw materials consuming storage and increasing costs and inefficiencies

- Complex layouts cause unnecessary movement, excessive motion, and unnecessary transportation as forms of waste

- Poor scheduling results in wasted waste, idle equipment, and lost time

- Over-engineering solutions that don’t address actual customer needs

Efforts to meet the needs of external customers can sometimes drive overproduction or overprocessing.

These primary wastes often lead to other wastes, compounding inefficiencies.

Unaddressed, these wastes escalate into errors, delays, and poor customer satisfaction, driving up overall costs. It is essential to improve processes to prevent these wastes.

Types of Waste: A Closer Look

Understanding the different types of waste is essential for any organization committed to lean manufacturing. The eight wastes of lean are generally divided into two categories: visible wastes and hidden wastes. Visible wastes—such as transportation waste, inventory waste, motion waste, and waiting waste—are often easy to spot during the production process. These can include excess movement of materials, unnecessary storage of products, inefficient worker motions, and delays between process steps.

Hidden wastes, on the other hand, are less obvious but can have a significant impact on efficiency and customer satisfaction. These include overproduction, overprocessing, defects, and non-utilized talent. Hidden wastes may not be immediately apparent, but they can lead to increased costs, longer lead times, and missed opportunities for process improvement. By recognizing both visible and hidden wastes, organizations can develop targeted strategies to eliminate waste, create more efficient processes, and deliver greater value to their customers.

How to Tackle the Eight Wastes in Lean Manufacturing

Use Value Stream Mapping to Visualize Waste

Begin by process mapping the entire production line. Highlight where inventory piles up, including work in progress, where delays occur, and where over-processing happens. Visual maps uncover misaligned flow and areas for improvement.

Conduct a Waste Walk

Observe actual work in real-time: walk through the line, systematically identify waste, look for overproduction, note unclear steps, and talk to frontline workers. A waste walk helps identify transportation and waiting waste that may not be apparent on paper.

Engage in Kaizen and Continuous Improvement

Empower teams to apply lean methodology daily. Utilize root-cause analysis to address defective parts, reduce over-processing, and eliminate non-utilized talent by soliciting ideas from employees, with a Sigma Green Belt facilitating these improvement projects.

Standardize and Simplify

Develop standard work procedures to ensure consistent flow and eliminate wasted time. This simplifies processes, reducing errors and delays.

Align Production to Actual Demand

Move to a pull system where each process step signals the need for the next. This removes excess inventory and unnecessary production, preventing overproduction and minimizing holding costs.

Optimize Layout for Motion Efficiency

Redesign workstations to minimize travel distances and repetitive motions, while also reducing excessive and unnecessary movements. Minor tweaks—such as ergonomic tools and rearranged supply locations—can reduce motion waste and boost productivity.

Reducing Excess Inventory: Strategies for Lean Success

Excess inventory is a common challenge that can drain resources and add unnecessary costs to any production process. When organizations hold more inventory than needed, they face increased storage expenses, risk of obsolescence, and wasted capital that could be better used elsewhere. To eliminate waste caused by excess inventory, companies can adopt several proven strategies.

Implementing just-in-time (JIT) production ensures that products are made and delivered only as needed to meet actual demand, reducing the risk of overstocking. A pull system, where real customer orders trigger each step in the process, further helps align production with demand. Value stream mapping and process mapping are essential lean tools that allow organizations to visualize the flow of materials and information, identify bottlenecks, and pinpoint areas where inventory waste occurs. Conducting a waste walk can also reveal hidden inventory and inspire actionable improvements. By focusing on these strategies, organizations can reduce costs, free up valuable resources, and improve customer satisfaction through more responsive and efficient processes.

Extra Processing and Its Impact on Performance

Extra processing, or overprocessing, happens when more work is done on a product or service than is necessary to meet customer requirements. This form of waste often results from unnecessary steps, redundant approvals, or adding features that do not provide additional value to the end customer. The impact of extra processing is significant—it leads to wasted time, increased costs, and more complex production processes that can slow down delivery and reduce overall efficiency.

To eliminate waste from unnecessary processing, organizations should focus on simplifying their production processes and eliminating redundant steps. Streamlining workflows, standardizing procedures, and continuously reviewing processes for improvement are key lean principles that help reduce overprocessing. Lean management encourages teams to regularly assess their work, seek out opportunities for more efficient processes, and ensure that every action adds value. By embracing continuous improvement and eliminating unnecessary processing, companies can reduce costs, deliver products more quickly, and enhance customer satisfaction—all while fostering a culture of operational excellence.

Real-World Benefits from Eliminating the Eight Wastes

By addressing all eight forms of waste of reducing waste and eliminating manufacturing waste, companies gain:

- Cost savings and revenue protection from reduced inefficiencies

- Shorter and more predictable cycle time

- Better customer satisfaction through faster, higher-quality output

- A more substantial base for long-term, continuous improvement and innovation

These benefits help transform traditional operations into agile, value-driven organizations as part of the ongoing lean journey.

Take Action: Learn to Eliminate Waste Effectively

Understanding waste is only the start. To build deep lean capabilities, join this comprehensive training:

👉 Lean Management Course – Learn How to Eliminate Waste with Lean Tools

This certification program empowers you to:

- Master value stream mapping, process improvement, and lean tools, including the lean method for waste elimination

- Tackle all eight wastes in your organization

- Implement lean production systems with confidence

- Measure results via key performance indicators

Complement your learning with:

🎯 GET LEAN Simulation Game – practice eliminating waste in real-world scenarios, experiencing firsthand the impact of lean methodologies.

Final Thoughts: Your Path to a Lean Future

Eliminating the eight wastes of lean manufacturing isn’t just an operational improvement—it’s a strategic journey, often referred to as the lean journey, that involves ongoing improvement from initial waste identification to sustained gains. By focusing on value, reducing waste, and engaging employees, you can unlock transformative gains.

Equip yourself with the knowledge and skills to lead this transformation. Start today—enroll in the Lean Management Course and play the GET LEAN Simulation Game to bring lean thinking to life. Your organization, employees, and customers will appreciate your efforts.