Lean Certification: Your Practical Guide to Becoming Lean Certified and Driving Real Organizational Change

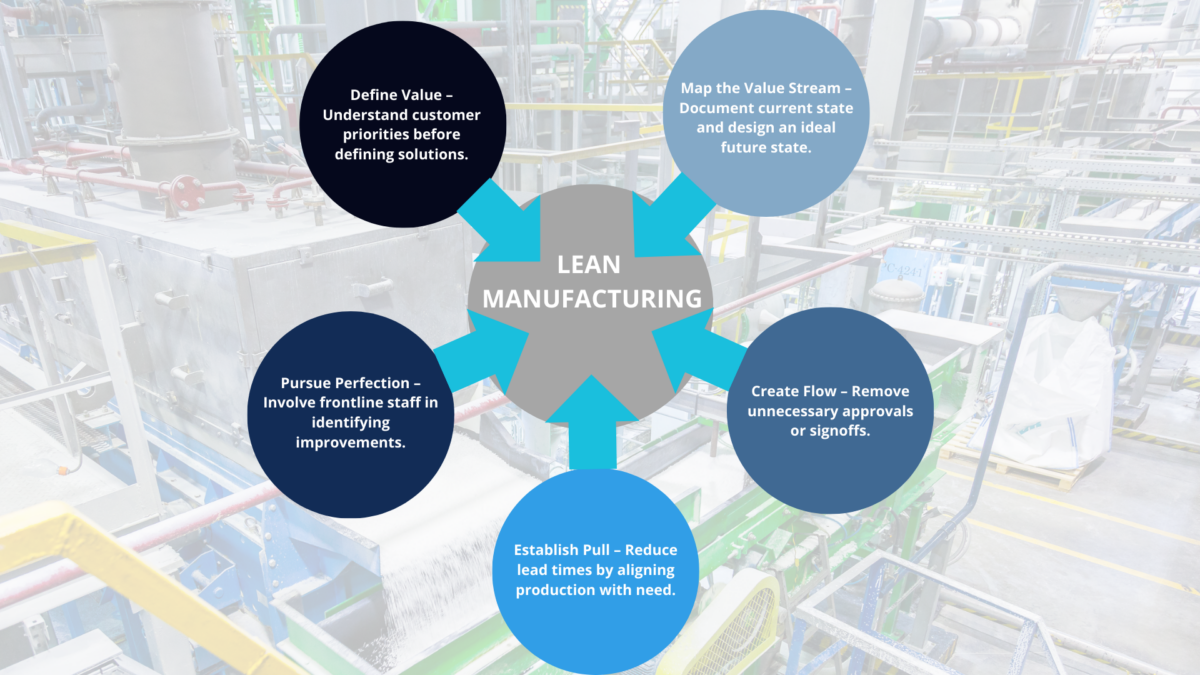

Lean has become a strategic must, not just a buzzword, in an economy driven by efficiency, quality, and adaptability. From small manufacturers to global enterprises, organizations and businesses are turning to Lean methodology to streamline operations, eliminate waste, and empower teams. Central to Lean principles is the focus on eliminating waste to improve process efficiency and quality control. However, implementing Lean isn’t just about tools and workshops. It’s about capability, where Lean certification makes all the difference.

Whether you’re an individual looking to upskill or a company investing in continuous improvement, a structured Lean training program helps ensure that your Lean efforts are effective and sustainable.

What Is a Lean Certification?

Lean certification formally acknowledges that you have gained the knowledge, skills, and practical experience necessary to apply Lean principles in real work environments. The certification process certifies an individual’s Lean skills and knowledge, validating their expertise to employers and peers. These programs are offered at multiple levels and formats, ranging from basic Lean awareness to advanced transformation leadership.

A certification is more than just a certificate—it’s proof of your ability to apply Lean tools to identify and eliminate waste, improve processes, and enhance customer value.

It answers the question: What is a Lean certification, and why does it matter in modern industry?

Why Lean Manufacturing Certifications Are in High Demand

The need for Lean manufacturing certifications has surged in recent years as companies across sectors look to:

- Improve quality while reducing costs

- Shorten lead times without compromising service

- Build a culture of structured problem-solving

- Scale efficiency across departments and sites

Achieving manufacturing excellence is a key goal of Lean certification, as it drives organizations to adopt advanced manufacturing practices and continuous improvement methodologies.

Certified professionals bring structured thinking, confidence, and a shared language to improvement work. And for companies, certification helps unify how Lean is practiced and understood across teams.

💡 Want a structured Lean program based on 25+ years of implementation in European industries? Explore this Lean Management course designed for practical, real-world outcomes.

The Benefits of Getting Lean Certified

Becoming Lean certified brings benefits at both the individual and organizational levels.

For Organizations

- Increased efficiency and reduced waste

- Improved customer satisfaction through better quality and efficiency

- Enhanced competitiveness in the market

- Better compliance with industry standards

- Stronger culture of continuous improvement

For Individuals:

- Increased career mobility and marketability

- Enhanced leadership and facilitation skills

- Hands-on understanding of tools like 5S, Value Stream Mapping, and Pull Systems

- New opportunities in quality, operations, and process improvement roles

For Organizations:

- Consistency in how Lean is taught and applied

- Stronger team engagement and ownership

- Faster and more reliable improvement outcomes

- Better communication across functions

Certification builds a common framework—so everyone from frontline operators to senior leaders is aligned in defining value, flow, and waste.

Types of Lean Certifications

There are multiple types of Lean certifications, often organized into Lean certification levels:

| Level | Target Group | Typical Focus |

|---|---|---|

| Foundation / Awareness | All employees | Lean principles, 5S, 8 wastes |

| Practitioner | Supervisors, engineers | Standard work, value stream mapping, metrics |

| Advanced / Black Belt | CI Managers, Lean leaders | Strategy deployment, coaching, facilitation |

| Executive / Champion | Senior leadership | Policy deployment, KPI design, cultural leadership |

Some programs also integrate Lean Six Sigma, blending statistical tools with Lean process improvement.

In addition to the above, Lean and Six Sigma certifications are structured into several recognized levels:

- White Belt: This entry-level certification provides foundational knowledge of Lean Six Sigma methodology and is suitable for beginners.

- Yellow Belt: An entry-level certification focused on basic Lean principles and process improvement, ideal for those new to Lean or Six Sigma.

- Green Belt: Intermediate certification for individuals managing small-scale projects and supporting larger initiatives, often held by team leaders or analysts.

- Lean Bronze / Lean Bronze Certification: Designed for practitioners working on tactical projects such as problem-solving and process improvements, supporting professional development and recertification.

- Lean Silver: Focuses on overseeing improvements across entire value streams, targeting professionals responsible for broader process enhancements.

- Lean Gold / Lean Gold Certification: Prestigious, enterprise-level credential for senior leaders and executives, emphasizing strategic influence, organizational improvement, and cultural change.

- Master Black Belt: The highest and most advanced level, signifying mastery of Lean and Six Sigma principles, leadership in process improvement, and the ability to drive transformational change within organizations.

Many certification programs, such as those offered by the Lean Six Sigma Institute and Sigma Institute, emphasize the importance of building a strong lean culture as a foundation for continuous improvement and organizational transformation. These programs are especially valuable for project managers, who play a key role in quality, operations, and business transformation initiatives.

Six Sigma, Six Sigma, and Six Sigma certifications are often integrated with Lean programs to provide a comprehensive approach to process improvement, quality management, and professional recognition. Leading organizations like the Sigma Institute and Lean Six Sigma Institute are recognized for delivering globally respected training and certification programs.

Obtaining a Lean Six Sigma certification is highly valuable for professional development, process improvement, and enhancing career prospects across industries.

Lean Manufacturing Certificate vs. Lean Production Certification

While the terms may seem interchangeable, a Lean manufacturing certificate typically focuses on factory environments—material flow, setup time reduction, line balancing, etc.. In contrast, Lean production certification may include production and support areas (planning, logistics, quality assurance, etc.).

Choose the correct option based on your industry and role:

- Manufacturing engineers may prefer hands-on certification focused on cycle time, OEE, and layout optimization.

- Office or healthcare teams might seek Lean programs that apply to transactional processes.

- Comprehensive Lean methodology certification benefits plant-wide initiatives, including leadership, coaching, and change management.

📦 Starting from the workplace level? Learn practical tools like red tagging and audits with our 5S Organization course.

What’s Included in a Lean Training Program?

A complete Lean training program is designed to train individuals in Lean principles to improve efficiency, reduce costs, and enhance quality. It usually includes:

- Instruction on Lean philosophy and principles

- Exercises on tools like 5S, PDCA, Kanban, and Visual Management

- Real-world case studies

- Simulations or improvement projects

- Quizzes, exams, and certification tasks

- Downloadable tools and templates

- Specialized modules such as sigma training, which may cover Six Sigma or Lean Six Sigma belt certifications

The best programs are application-driven, not just theory.

Formats of Lean Certification

You can pursue Lean process certification in several ways:

- Online Lean certification (self-paced, VoD)

- Hybrid programs (combining video lessons with live coaching)

- In-person workshops (at company sites or public seminars)

Online formats are ideal for distributed teams, internal capability building, and onboarding new employees.

🎓 Our Lean Management course includes downloadable tools, SOP templates, and unlimited lifetime access—perfect for training multiple employees across time zones and departments.

Key Topics in Lean Methodology Certification

Here are some core topics often included in Lean methodology certification:

- Value and Value Stream – Understanding the customer and mapping process flow

- Flow and Pull – Reducing WIP and making work move at customer demand

- Kaizen – Daily continuous improvement from the ground up

- Standard Work – Documenting best practices for consistency and training

- Problem Solving – Root cause analysis, A3 thinking, and countermeasures

- Visual Management – Clear, visible signals to drive daily decisions

- Quality Control – Ensuring process consistency, maintaining high standards, and reducing defects

- Operational Efficiency – Improving how work is done to maximize productivity and minimize waste

- Reducing Defects – Applying Lean and Six Sigma methodologies to minimize errors and improve process outcomes

- Improving Organization’s Processes – Fostering team unity and enhancing employee involvement to drive process improvements at every level

Certification programs may also cover leadership techniques, coaching, and how to sustain change over time.

What Makes a Lean Certification Program Credible?

Not all certifications are equal. A strong program includes:

- Proven instructional design (not just lectures)

- Practical application (not just tests)

- Trainers with field experience (not just academics)

- Real examples from manufacturing, services, or logistics

- Post-course resources for continued use

The best Lean principles certification programs prepare participants to do, not just to know.

The Lean Community: Networking and Support for Practitioners

The Lean community is a powerful resource for anyone committed to Lean principles and continuous improvement. Connecting with other Lean practitioners gives you access to a wealth of collective knowledge and practical experience. Whether you’re just starting your Lean journey or are an experienced Lean professional, being part of this community means you’re never alone in facing challenges or celebrating successes.

You’ll find various opportunities to expand your expertise within the Lean community. Regular webinars, interactive workshops, and industry conferences provide hands-on exposure to the latest Lean management tools and best practices. These events are not just about learning—they’re about sharing real-world stories, troubleshooting problems, and discovering new ways to apply Lean management in your organization.

Mentoring and coaching are also key benefits of joining the Lean community. Experienced Lean professionals are often eager to guide newcomers, offering insights on implementing Lean principles effectively and avoiding common pitfalls. This supportive environment encourages open discussion, feedback, and collaboration, helping you refine your approach and drive meaningful change.

Ultimately, the Lean community is about building relationships and fostering a culture of improvement. By engaging with peers who share your passion for Lean, you’ll stay motivated, informed, and equipped with the latest tools and knowledge to make a lasting impact in your organization.

Becoming a Lean Leader: Developing Leadership Skills Through Certification

Stepping into the role of a Lean leader goes beyond mastering Lean tools—it’s about inspiring teams, driving continuous improvement, and achieving operational excellence. Lean certification programs, such as those offered by the Lean Certification Alliance, are designed to develop technical knowledge and leadership capabilities.

These certification programs cover essential Lean management principles, practical Lean tools, and proven methodologies for continuous improvement. Through a blend of structured learning and real-world application, you’ll build the skills needed to lead Lean initiatives, solve complex problems, and foster a culture of improvement within your organization.

Completing a Lean certification program signals to employers and colleagues that you are committed to Lean principles and ready to take on leadership responsibilities. It’s a valuable asset that can set you apart in the job market and open doors to new career opportunities. But becoming a Lean leader also means developing strong communication, coaching, and problem-solving skills—qualities that enable you to guide teams, overcome resistance, and sustain long-term change.

Combining deep Lean knowledge with practical leadership skills will allow you to champion Lean management, optimize processes, and deliver measurable results for your organization.

Understanding Certification Fees and Additional Costs

When considering a Lean certification, it’s essential to understand the full scope of costs involved. Most certification programs require a fee for the certification exam, often separate from the cost of training courses and study materials. Some programs may also charge an additional fee for recertification or ongoing resource access.

While these costs can add up, viewing them as an investment in your career is worth it. Lean certification can enhance your skills, boost earning potential, and open new job opportunities. Many organizations recognize the value of Lean expertise and may offer financial support or reimbursement for employees who pursue certification.

Review all associated fees before enrolling in a certification program and consider the long-term benefits. By making an informed decision, you can ensure that your investment in Lean certification pays off for your professional growth and your organization’s success.

Maintaining Your Lean Certification: Recertification and Ongoing Requirements

Earning your Lean certification is significant, but maintaining it requires ongoing commitment. Most certification programs have recertification requirements, including completing a set number of continuing education hours, attending training sessions, or passing a recertification exam every few years.

Staying certified ensures that your Lean knowledge and skills remain current as new tools, principles, and best practices emerge. Many programs encourage certified professionals to participate in workshops, conferences, or online learning communities to keep up with the latest developments in Lean management.

By fulfilling these ongoing requirements, you demonstrate your dedication to continuous improvement and ability to apply Lean principles effectively in your organization. Recertification is not just a formality—it’s an opportunity to refresh your expertise, expand your toolkit, and continue delivering value as a Lean practitioner.

What to Expect After Certification

Earning a Lean certificate is just the beginning. Here’s how people typically apply what they learn:

- Leading improvement workshops or kaizen events

- Coaching teams in 5S or visual management

- Launching standard work audits or problem-solving boards

- Supporting cultural change as a Lean champion

- Using data and visuals to influence senior leadership

🔧 Want to go beyond the course and simulate Lean in real-time? Try the GET LEAN Simulation Game—a dynamic, competitive training tool for applying Lean under pressure.

How to Choose the Right Certification Lean Manufacturing Course

Here are five questions to help guide your choice:

- Is the content relevant to your industry and goals?

- Does it include templates, case studies, and simulations?

- Can you apply it immediately to your workplace?

- Is there support for follow-up learning and coaching?

- Will it prepare you for your next role or project?

Choosing the proper Lean certification can accelerate your impact—and your career.

Is a Lean Certification Worth It?

Absolutely. In today’s competitive world, Lean-certified professionals are seen as valuable assets. They bring discipline, consistency, and a toolkit for transformation.

For companies, Lean-certified employees drive measurable results like:

- 20–40% reductions in cycle time

- 30–70% improvements in on-time delivery

- Increased employee engagement and retention

- Lower operating costs and waste

The return on investment for individuals is clear: career growth, new roles, and the ability to lead meaningful change.

🧠 Develop Lean thinking that lasts

Join the course that delivers practical value 👉 Lean Management – Practical Course

♾️ Unlimited access

📂 Real tools for real impact

🏭 Trusted by European companies for over 25 years

🎲 Enhance your workshops with the GET LEAN Simulation Game

👓 You can preview a complete lesson for free – check the end of the course page!