Lean Management and Production: Aligning Strategy with Operational Excellence

Introduction to Lean Management and Production

Organizations must balance efficiency with quality to remain competitive in today’s fast-paced and cost-conscious market. Lean management and production provide a proven framework for achieving this balance. By eliminating waste, maximizing value, and delivering on customer demand, companies can achieve greater operational efficiency, drive innovation, and remain resilient in uncertain times.

Understanding lean manufacturing is essential for grasping its principles, significantly impacting streamlining operations, and improving overall performance.

This article explores the whole meaning of lean management and production, including its history, implementation strategies, tools, and real-world applications. Whether you’re seeking to understand the core principles of lean that underpin lean management and production, improve your manufacturing process, or transform your business through continuous improvement, this guide will serve as your comprehensive starting point.

Origins of Lean Philosophy

The Toyota Production System (TPS)

The origins of lean manufacturing and production lie in post-World War II Japan, particularly in the Toyota Production System (TPS). Led by Taiichi Ohno and Eiji Toyoda, TPS was developed to improve production efficiency by eliminating all forms of waste, known in Japanese as “muda.”

During its early automobile production, Toyota faced significant issues with poor quality castings, which prompted the company to form Kaizen improvement teams and ultimately led to the development of the Toyota Production System to address quality concerns and reduce waste.

Unlike mass production, which emphasized volume over flexibility, the TPS focused on:

- Just-in-time delivery

- Quality at the source

- Respect for people

These principles later formed the backbone of what we now call lean manufacturing systems and lean management systems.

What Is Lean Management and Production?

Lean management and production refer to a holistic business strategy and operating system that aims to:

- Eliminate waste in all areas (materials, time, effort)

- Streamline processes for more efficient flow

- Maximize value from the customer’s perspective

- Foster a culture of continuous improvement

Lean methodology is a strategy for enhancing quality and efficiency by identifying value from the customer’s perspective and using that insight to drive improvements.

Lean touches every part of the business, from the production line to supply chain management, product design, human resources, and inventory management. Adopting lean processes supports waste reduction, efficiency, and continuous organizational improvement.

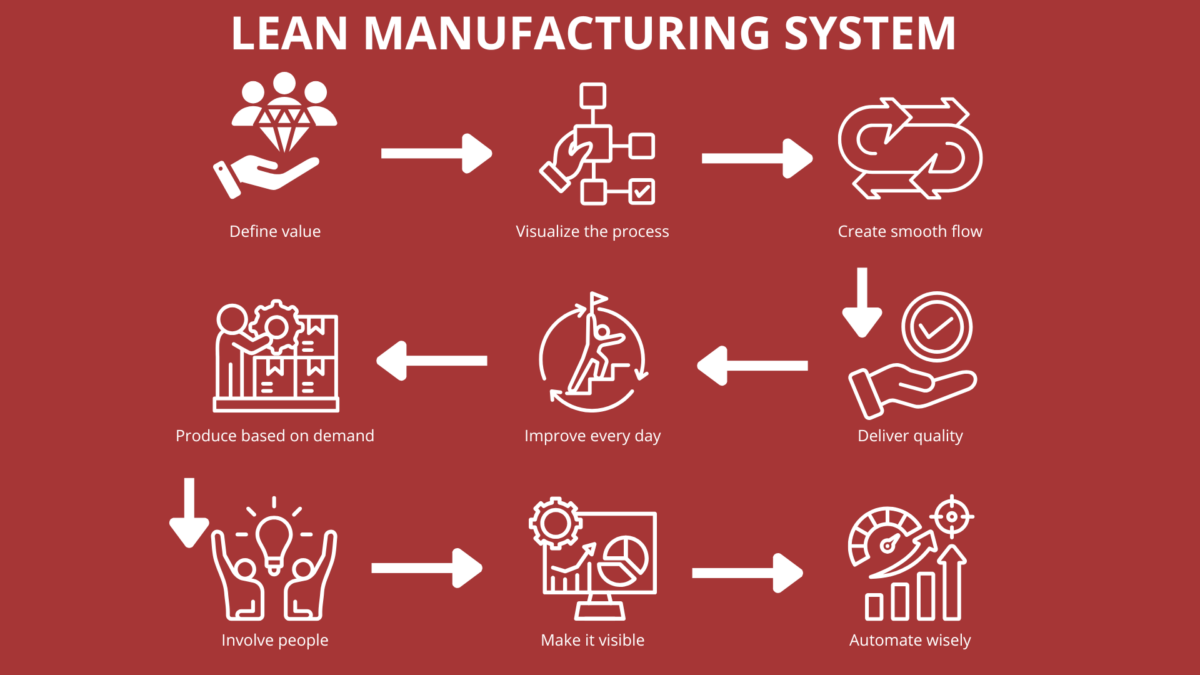

The Five Key Principles of Lean

The five key principles of lean manufacturing, as outlined by Womack and Jones in Lean Thinking, form the foundation for driving operational excellence. These principles of lean manufacturing are:

- Specify Value – Define what the customer values.

- Map the Value Stream – Visualize all steps in the production system.

- Create Flow – Eliminate interruptions and inefficiencies.

- Establish Pull – Respond only to actual customer demand.

- Pursue Perfection – Embrace continuous improvement at all levels.

These principles are designed to reduce waste by identifying and eliminating non-value-added activities throughout the organization.

Types of Waste in Lean Production

A cornerstone of lean manufacturing is the relentless pursuit of waste reduction across all manufacturing processes. Lean production identifies seven distinct types of waste—defined initially in the Toyota Production System—that can hinder operational efficiency and inflate costs:

- Transportation Waste is the unnecessary movement of materials or products between processes, which adds no value and increases handling risks.

- Inventory Waste: Excess raw materials, work-in-progress, or finished goods that tie up capital and space without immediate use.

- Motion Waste: Inefficient movement of people or equipment, often caused by poor workplace layout or unclear procedures.

- Waiting Waste: Idle time when people or machines are waiting for materials, information, or equipment, disrupting the production flow.

- Overproduction Waste: Producing more than what is needed or before it is needed, leading to surplus inventory and increased storage costs.

- Overprocessing Waste uses more resources, time, or technology than necessary to achieve the desired quality, often due to outdated standards or unnecessary steps.

- Defect Waste: Products or components that fail to meet quality standards, resulting in rework, scrap, or customer dissatisfaction.

By systematically identifying and eliminating these wastes through proven lean manufacturing techniques, organizations can streamline their production processes, boost operational efficiency, and foster a culture of continuous improvement. Implementing lean, especially following the Toyota Production System, enables companies to optimize their production system, reduce inventory waste, and achieve sustainable cost savings.

Core Lean Manufacturing Techniques and Tools

Value Stream Mapping (VSM)

Used to identify and remove non-value-adding steps in a manufacturing process.

5S Workplace Organization

A foundational method for organizing workspaces:

- Sort

- Set in Order

- Shine

- Standardize

- Sustain

Pull Systems & Kanban

Products are made only when needed, reducing inventory waste and aligning with just-in-time delivery models. Pull systems rely on accurately forecasting demand to prevent disruptions and maintain efficiency.

Standard Work & Production Leveling

Stabilizes processes and ensures efficient processes even under fluctuating demand.

Production leveling helps align production capacity with actual demand, preventing overproduction and inefficiencies arising from mismatched capacity and requirements.

Lean Manufacturing Tools

Includes SMED (Single-Minute Exchange of Die), Poka-Yoke (error-proofing), and Heijunka (production leveling).

Customer Focus in Lean Management

At the heart of lean management lies a deep commitment to understanding and delivering on customer demands. Lean manufacturing principles emphasize that the customer defines actual value, and every production process should be aligned to maximize customer satisfaction.

A key lean principle is the pull system, where actual customer demand rather than forecasts drives production. This approach minimizes excess inventory and ensures that resources are dedicated to creating products that customers truly want. By eliminating waste and creating flow throughout the production system, companies can respond quickly to changing customer needs and deliver higher-quality products.

The automotive industry, particularly through adopting lean production systems, has set the standard for customer-focused manufacturing. By streamlining production processes and optimizing supply chain management, automotive leaders have demonstrated how lean principles can lead to improved operational efficiency, reduced costs, and enhanced customer satisfaction. Ultimately, a lean production system is not just about efficiency—it’s about building a responsive, value-driven organization that consistently meets and exceeds customer expectations.

Key Benefits of Lean Management and Production

- Reducing waste and boosting operational efficiency

- Improved productivity through efficient flow

- Enhanced customer satisfaction

- Higher employee engagement and accountability

- Better alignment of strategy with production targets

Lean management and production are key in achieving operational excellence by driving continuous improvement and waste reduction throughout the organization. Building a high-performance supplier network supports lean initiatives and increases productivity.

Environmental Benefits of Lean Practices

Lean manufacturing is not only about improving productivity and reducing costs—it also delivers significant environmental benefits. Companies can dramatically reduce their environmental footprint by applying lean manufacturing techniques to eliminate waste and optimize resource use.

Practices such as just-in-time delivery minimize excess inventory and reduce the need for large storage spaces, lowering energy consumption and emissions. Lean principles encourage continuous improvement, prompting organizations to find new ways to conserve raw materials and reduce scrap. By streamlining production processes and focusing on operational efficiency, companies can reduce unnecessary transportation, decreasing their carbon footprint.

Toyota Motor Corporation is a leading example of how lean manufacturing can drive environmental sustainability. Toyota has set industry benchmarks for efficiency and environmental responsibility through a commitment to reducing waste and embracing just-in-time practices. By integrating lean principles into daily operations, businesses can achieve cost savings and enhance their reputation as environmentally conscious organizations.

Real-World Applications of Lean

Automotive Industry

The automotive industry pioneered lean, particularly through Toyota’s success. Today, most carmakers use lean methods to meet strict global standards.

Lean Manufacturing Plants

From aerospace to electronics, lean manufacturing plants achieve shorter production cycles, higher output, and better quality control.

In these environments, the level of plant technology often has less impact on operating performance than process efficiency and workforce flexibility.

Beyond Manufacturing

Lean has expanded into services, IT, and healthcare—anywhere production methods can be measured, improved, and standardized.

Digital Transformation and Lean Automation

The evolution of lean manufacturing in the digital age has unlocked new opportunities for efficiency and agility. Digital transformation—powered by artificial intelligence, IoT, and advanced data analytics—enables companies to automate production processes, monitor real-time performance, and respond swiftly to customer demands.

Lean automation helps eliminate waste by reducing manual errors, standardizing repetitive tasks, and ensuring consistent quality across production cycles. Organizations can create a more agile and responsive production management system by integrating digital tools with lean manufacturing principles. For example, value stream mapping—one of the essential lean manufacturing tools—can be enhanced with digital analytics to pinpoint bottlenecks and optimize the entire value stream.

Implementing lean manufacturing with digital transformation empowers companies to streamline their supply chain management, improve operational efficiency, and deliver greater customer satisfaction. As the term lean manufacturing continues to evolve, embracing digital innovation is key to sustaining continuous improvement and maintaining a competitive edge in today’s fast-paced market.

Implementing Lean: Best Practices

Implementing lean is not a plug-and-play activity. There is no standard lean production model; organizations must adapt lean principles to their unique context. Success comes from:

- Educating teams on the lean manufacturing principles

- Using metrics to track production process improvements

- Empowering teams to suggest and lead improvements

- Aligning Lean goals with business strategy

Learn how to apply Lean in any organization with our course on Lean Management.

Related Topics to Deepen Your Understanding

- 🎯 Problem Solving Course – Root Cause to Implementation

- 🚀 Continuous Improvement in Organizations

- 👥 Teamwork & Lean Leadership

- 🧹 5S Workplace Organization Course

Special Invitation to Practical Lean Training

🎓 Want to go beyond theory and implement lean manufacturing and production techniques? Join our Lean Management Course, built on over 25 years of direct implementation experience in large corporations and SMEs.

🎥 Preview a lesson and gain access to real-world case studies, implementation templates, and hands-on exercises.

🎮 For a more immersive experience, try the GET LEAN Simulation Game—a unique, interactive way to apply lean principles in simulated production scenarios.