Why Lean Management Was Born in Japan

Lean management, one of the most impactful operational philosophies in modern industry, traces its roots to post-war Japan. In the wake of World War II, Japanese companies faced severe resource shortages, low productivity, and intense global competition. Instead of mimicking Western mass production models, Japanese organizations—most notably Toyota Motor Corporation, a leader in the automotive industry—pioneered a more refined approach that prioritized efficiency, quality, and employee involvement.

This approach led to the creation of the Toyota Production System, a fundamental philosophy based on core principles that later became the foundation of what is now known as lean manufacturing. It introduced transformative practices such as the pull system, continuous flow, standardized work, and just-in-time production, fundamentally changing how products are made and how companies operate.

The Pillars of Japanese Lean Thinking

Japanese lean management is more than just a set of tools—it’s a mindset deeply embedded in the country’s work culture. This approach is guided by the lean philosophy, which serves as the overarching framework focused on continuous improvement, waste reduction, and maximizing value for customers. Lean is so effective in Japan because Japanese culture and organizational culture strongly influence and shape lean practices, embedding them into daily routines and business behaviors. It emphasizes continuous improvement, respect for people, and a relentless focus on customer value. The core lean principles include identifying value, mapping the value stream, creating flow, establishing pull, and pursuing perfection.

The Role of Culture and Visual Management

One of the reasons lean management in Japan is so effective is the cultural alignment with concepts like discipline, team orientation, and respect. Japanese workers are encouraged to contribute ideas for improvement, which fosters employee engagement and cultivates a culture of continuous improvement.

On the manufacturing floor, Japanese companies rely heavily on visual workplace tools, such as shadow boards, color-coded storage, and floor marking tape, as well as other visual cues, to ensure clarity and reduce waste. These elements support not only efficiency but also workplace safety and collaboration.

Visual communication tools facilitate the easy detection of abnormalities, tracking of progress, and enforcement of standard operating procedures, eliminating the need for verbal instruction. This creates a self-regulating and visually controlled production environment—an actual visual factory.

Lean Concepts and Tools: The Building Blocks of Excellence

Lean manufacturing is a transformative management approach, rooted in the Toyota Production System (TPS), developed by Toyota Motor Corporation in the aftermath of World War II. Facing resource scarcity and the need for rapid recovery, Japanese companies pioneered a system that would become the global benchmark for operational excellence. At the heart of TPS are two foundational pillars: Just-in-Time (JIT), which ensures that products are made to meet customer demand precisely when needed, and Jidoka, which empowers workers and machines to halt production at the first sign of a problem, thereby guaranteeing high-quality products and minimizing waste.

The lean manufacturing principles that emerged from TPS have since shaped industries far beyond automotive manufacturing. These lean principles—continuous improvement, a sharp focus on customer demands, and relentless waste reduction—are designed to foster a culture of continuous improvement within organizations. By implementing lean management principles, companies can streamline production processes, reduce inventory costs, and deliver greater customer satisfaction.

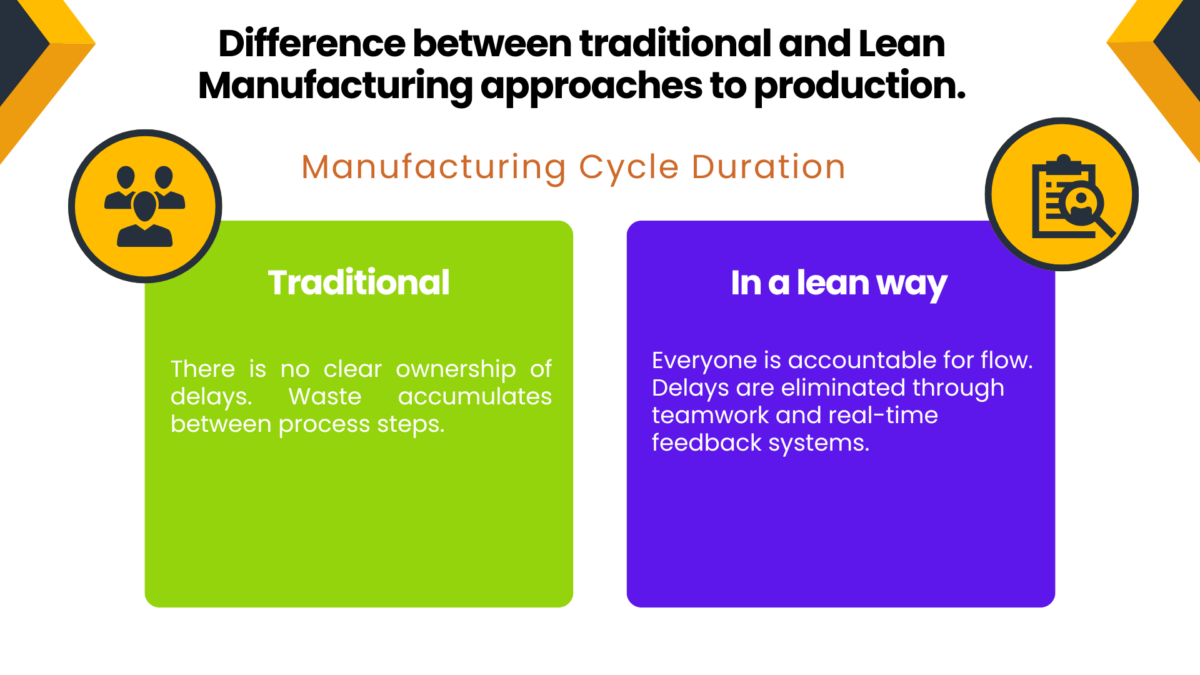

A central lean concept is the pull system, which produces goods only in response to actual customer demand. This approach contrasts with traditional production scheduling, which often leads to overproduction and excess inventory. By adopting a pull system, organizations can eliminate waste, reduce the burden of inventory management, and ensure that resources are used efficiently to meet real-time customer needs.

Visual management is another cornerstone of lean thinking. By using visual cues—such as color-coded storage, floor markings, and progress boards—teams can quickly identify issues, monitor production flow, and maintain efficient processes. This not only supports quality control and problem solving but also helps maximize productivity by making the status of work clear to everyone on the floor.

Japanese companies have also developed additional lean tools and methods to support operational excellence. Kaizen, the practice of continuous, incremental improvement, encourages every employee to contribute ideas for cutting waste and improving processes. The 5S methodology—Sort, Set in order, Shine, Standardize, and Sustain—creates a clean, organized, and efficient work environment, further supporting a lean culture that values both efficiency and employee engagement.

For those seeking firsthand experience, the Lean Japan Tour offers a unique opportunity to observe lean manufacturing and lean management principles in action. Participants visit leading Japanese companies, including Toyota Motor Corporation, engage in senior management discussions, and receive hands-on training in lean methods. This immersive experience provides invaluable insights into how Japanese organizations integrate lean concepts into their daily operations to achieve world-class operational excellence.

The influence of lean manufacturing now extends into various sectors, including healthcare and software development. For example, Osaka City University Hospital has established itself as a model for lean healthcare, utilizing lean tools to enhance patient care, streamline workflows, and improve operational efficiency. In software development, lean principles help teams reduce cycle times, enhance the quality of the product, and better align with customer demands.

Ultimately, lean manufacturing provides a robust management approach for any organization seeking to minimize waste, enhance production processes, and optimize productivity. By embracing lean principles and tools—whether through a Lean Japan Tour or targeted training—companies can build a culture of continuous improvement and achieve lasting operational excellence.

Lean in Practice: From Shop Floors to Healthcare

Although lean was initially developed for the manufacturing industry, Japan has successfully expanded its application to other sectors. Manufacturing organizations have played a crucial role in implementing lean practices, laying the groundwork for their adoption in various fields. For instance, Osaka City University Hospital implemented lean practices to streamline workflows and improve patient safety. Similarly, Japanese software development companies and logistics firms have adopted lean methods to reduce cycle time and boost product quality. Across these sectors, lean principles have demonstrated significant cost effectiveness and are instrumental in maximizing productivity.

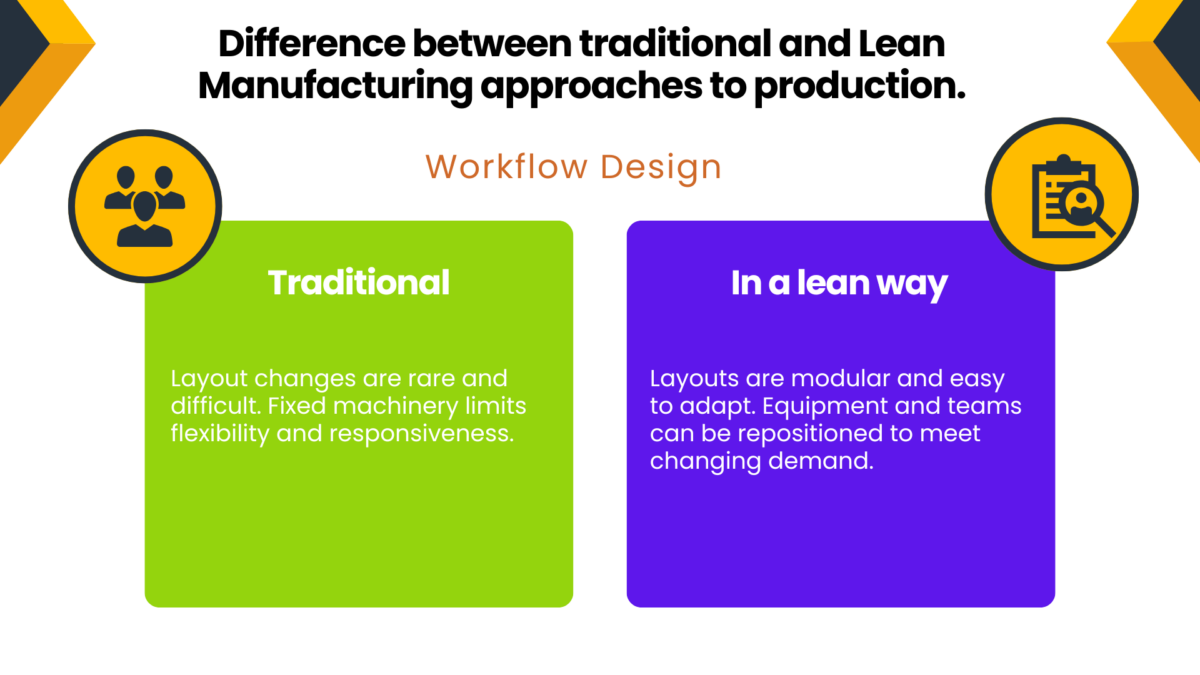

Japanese lean transformation efforts typically follow a structured model that begins with a deep understanding of lean manufacturing and the existing production process, followed by targeted interventions such as value stream mapping, problem-solving, and process improvement initiatives focused on eliminating waste and reducing it.

To see how lean principles work in action, explore this interactive Lean Simulation Game that allows teams to experience real-time problem solving and waste elimination.

Leadership and the Lean Journey

Senior management in Japan plays a crucial role in fostering a lean culture. Leaders not only set the strategic vision but also model desired behaviors on the shop floor. They focus on developing capability, promoting lean practices, and using key performance indicators to monitor the transformation process. Lean leadership is crucial for driving organizational transformation and cultural change, with Toyota leaders serving as exemplars of how leadership commitment and philosophy can shape lean management practices and drive organizational improvement.

Importantly, Japanese organizations view lean not as a one-time project but as a lifelong lean journey. Employees are continually trained, and lean principles are integrated into daily routines to ensure sustainable change, often by combining lean practices with digital transformation technologies and other organizational initiatives.

If you’re ready to lead your lean journey, our Lean Management Course offers hands-on training rooted in Japanese methodology and global best practices.

Why Lean Management from Japan Works So Well

The success of lean in Japan is closely tied to the nation’s cultural values: commitment, consistency, attention to detail, and collective responsibility. Unlike many Western implementations that treat lean as a toolbox, Japanese organizations embrace it as a philosophy that touches every part of the business—from the production lines to strategic planning. The lean production system, developed at Toyota, is foundational to this approach, focusing on efficiency, waste elimination, and responsiveness. Lean production principles have since influenced industries worldwide, integrating with technology and supply chain management to drive continuous improvement. Collaborative business arrangements, such as the joint venture between Omron and Japan Sun Industries (Omron Kyoto Taiyo), further exemplify how Japanese companies leverage partnerships for operational and strategic benefits.

Lean management Japan also places strong emphasis on minimizing waste across the board—be it excess inventory, unnecessary motion, or wasted talent—recognizing that every form of garbage consumes resources without adding value. This results in faster lead times, lower inventory costs, improved customer satisfaction, and higher levels of employee morale.

A Model for the World

From the original Toyota Production System to lean applications in healthcare, software development, and industrial engineering, Japan has set the global standard. Many Western countries now send their executives on lean Japan tours, which include organized company tours for participants to visit leading Japanese manufacturing sites, such as Gifu Auto Body. These tours provide invaluable insights into Japanese manufacturing excellence, allowing participants to observe key concepts, such as Japanese lean terminology and production leveling, in action. In addition to factory visits, the tours offer Japanese cultural experiences and opportunities to learn the Japanese language, helping attendees understand the cultural context and work practices that underpin lean management in Japan.

To implement lean thinking in your organization, it’s essential to go beyond tools and invest in cultural transformation, training, and leadership. Japan teaches us that lean is not just about cutting costs—it’s about creating long-term value for the customer.

Start your transformation with the Lean Management Course, designed to help leaders apply the timeless principles of Japanese lean thinking.

Check out a free sample lesson from our course:

Want a fun and practical way to teach lean? Try the GET LEAN Simulation Game—a proven tool for hands-on learning and team development.