Management Manufacturing: Streamlining Processes for Operational Excellence

In today’s competitive industrial landscape, lean management in manufacturing has become a cornerstone for organizations aiming to enhance efficiency, reduce waste, and deliver superior value to customers. The historical roots of lean management can be traced back to scientific management developed by Frederick Winslow Taylor, which laid the groundwork for modern efficiency methods. The evolution of lean manufacturing stems from these early principles and was further shaped by the development of the Toyota Production System (TPS).

Rooted in the Toyota Production System (TPS)—the foundation of the lean production system—lean management emphasizes eliminating non-value-adding activities, fostering a culture of continuous improvement, and optimizing the entire production process. Developed by Toyota Motor Corporation in the automotive industry, TPS introduced core principles such as Just-in-Time and Jidoka, profoundly influencing manufacturing practices worldwide.

Understanding Lean Manufacturing

Lean manufacturing is a systematic approach to identifying and eliminating waste within manufacturing systems. It utilizes lean methodology to streamline processes and improve efficiency across various industries. The goal is to achieve efficient processes that deliver maximum value to the customer with minimal resources. This lean philosophy, often called lean thinking, encourages organizations to view operations through the lens of customer value, ensuring every step in the production line contributes meaningfully. Waste elimination is the core and key lean principle of the lean philosophy, driving continuous improvement and value delivery.

Consider enrolling in the Lean Management Course for a deeper dive into the principles and applications of lean methodologies. This course offers comprehensive insights into effectively implementing lean strategies.

Core Principles of Lean Manufacturing

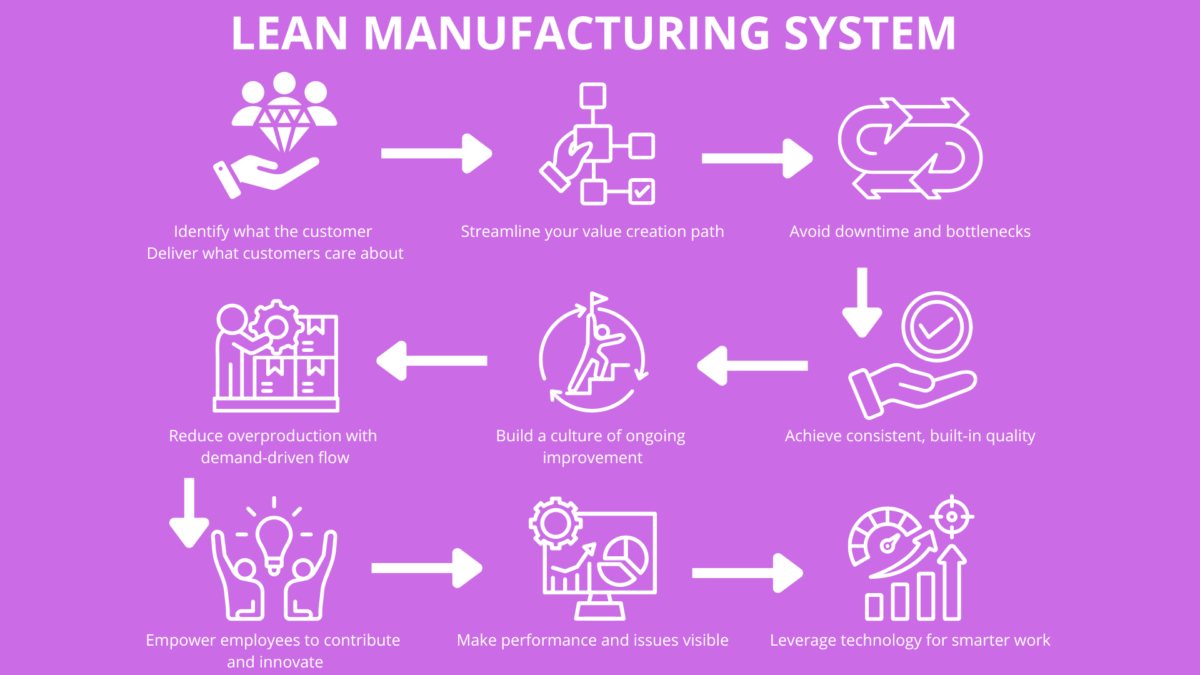

The foundation of lean manufacturing rests on the five lean principles, which serve as the foundational framework for implementing Lean methodologies:

- Define Value: Understand what the customer perceives as valuable.

- Map the Value Stream: Identify all steps in the value stream and eliminate those that do not add value.

- Create Flow: Ensure that the production process flows smoothly without interruptions.

- Establish Pull: Implement a pull system where production is based on actual customer demand.

- Pursue Perfection: Continuously seek ways to improve processes and eliminate waste.

While many organizations aim to implement a standard lean production model based on these five lean principles, it is essential to recognize that flexibility is often required. Different industries and company cultures may necessitate adaptations, making establishing a universal standard challenging.

These principles guide organizations in creating a lean enterprise that is responsive, efficient, and customer-focused.

Lean Culture and Leadership

A thriving lean culture is the backbone of any successful lean manufacturing journey. This culture is built on continuous improvement, where every employee is encouraged to seek better ways of working and contribute ideas that drive operational excellence. Leadership plays a pivotal role in shaping this environment by championing lean principles and demonstrating a genuine commitment to customer satisfaction.

Effective lean leaders set a clear vision, communicate organizational goals, and provide the resources necessary for teams to succeed. They empower employees at all levels to make decisions, solve problems, and take ownership of improvements. By fostering open communication and recognizing achievements, leaders help embed lean thinking into the organization’s daily routines. A strong lean culture—supported by dedicated leadership—ensures that lean initiatives are not just one-time projects, but an ongoing pursuit of excellence that delivers lasting value to the company and its customers.

Tools and Techniques in Lean Manufacturing

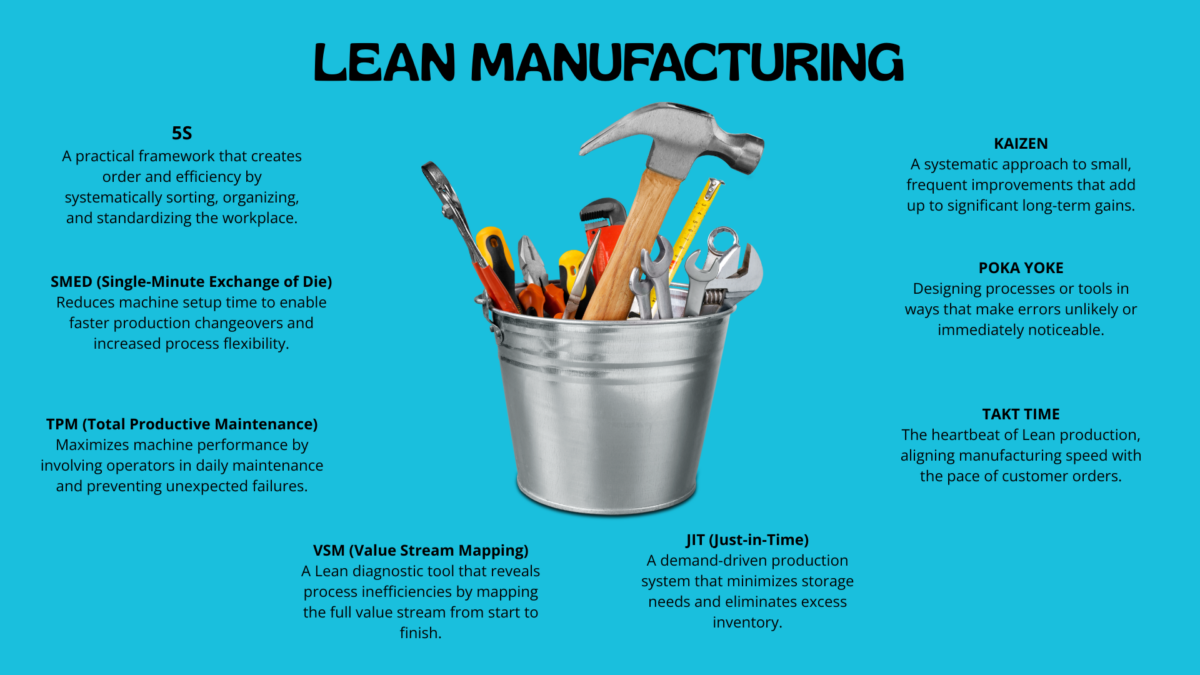

Implementing lean principles requires adopting specific tools and techniques to identify inefficiencies, streamline processes, and promote continuous improvement. Visual management is often used to support lean methods by making workflows and issues visible, which helps teams quickly identify problems and optimize operations.

- Value Stream Mapping: A visual tool to analyze the flow of materials and information within production processes, helping identify bottlenecks and waste areas.

- 5S Methodology: This methodology focuses on workplace organization to improve efficiency and safety. The five steps—sort, Set in order, Shine, Standardize, and sustain—create a foundation for a productive work environment.

- Lean Methods and Processes: These approaches optimize production processes by reducing waste, improving flow, and increasing value creation across various industries.

The Fundamentals of 5S Course provides practical guidance and implementation strategies for mastering the 5S methodology and enhancing workplace efficiency.

Creating Flow in Manufacturing Processes

One of the core principles of lean manufacturing is creating flow within the production process. Creating flow means ensuring materials and information move seamlessly through each production stage without unnecessary stops or delays. Achieving this requires a deep understanding of the value stream and a commitment to eliminating waste at every opportunity.

Manufacturers can use tools like value stream mapping to visualize the entire process, pinpoint bottlenecks, and identify areas where improvements can be made. Process mapping and spaghetti diagrams help refine the flow by highlighting inefficiencies and unnecessary movements. By focusing on creating flow, organizations can reduce lead times, improve quality, and respond more effectively to customer demand. The result is a more agile and productive operation that consistently delivers value to the customer.

The Role of Continuous Improvement

At the heart of lean manufacturing lies the commitment to continuous improvement. This involves regularly assessing processes, seeking feedback, and making incremental changes to enhance performance. Engaged and empowered teams play a crucial role in driving continuous improvement, as their involvement is essential for sustaining Lean initiatives and ongoing productivity enhancements. Cultivating a constant improvement culture ensures that organizations remain agile and responsive to changing demands.

For strategies on fostering a culture of ongoing enhancement, the Continuous Improvement Course offers valuable insights into building and sustaining improvement initiatives.

Implementing Lean in Manufacturing Operations

Implementing lean requires a structured approach:

- Assessment: Evaluate current processes to identify areas of waste and inefficiency.

- Planning: Develop a roadmap for lean implementation, setting clear goals and metrics. In lean, this often means shifting focus from traditional production targets to demand-driven approaches that better align with customer needs.

- Execution: Apply lean tools and principles to streamline operations, including implementing a lean management system to support process improvements and foster continuous improvement.

- Review: Monitor progress and make adjustments as necessary to ensure continuous improvement.

Some organizations combine lean with Six Sigma, known as Lean Six Sigma, to achieve comprehensive process improvement by reducing waste and minimizing process variation.

Effective implementation also hinges on strong leadership and teamwork. The Effective Teamwork and Leadership Course equips leaders with the skills to successfully guide teams through lean transformations.

Best Practices for Lean Implementation

Successful lean manufacturing implementation hinges on a structured approach and a dedication to continuous improvement. Start by clearly defining your organization’s objectives and aligning lean initiatives with these goals. Engage employees from the outset, as their insights and involvement are crucial for identifying opportunities to eliminate waste and streamline the value stream.

Invest in training and development to ensure everyone understands lean concepts and can effectively use lean tools such as value stream mapping, kaizen events, and root cause analysis. Foster a culture where employees are empowered to make decisions and held accountable for results. Regularly review progress, celebrate wins, and encourage ongoing feedback to sustain momentum. By following these best practices, organizations can maximize the benefits of implementing lean and drive lasting improvements.

Common Mistakes to Avoid

While implementing lean manufacturing offers significant benefits, common pitfalls can hinder success. One frequent mistake is neglecting to involve employees in the lean journey. Since frontline workers often have the best understanding of day-to-day challenges, their engagement is vital for generating effective solutions and minimizing resistance to change.

Another misstep is rushing the implementation process without adequate planning or preparation, leading to confusion and unsustainable results. Additionally, organizations sometimes focus too narrowly on cost-cutting, losing sight of the ultimate goal: creating value for the customer. To avoid these mistakes, prioritize thoughtful planning, inclusive participation, and a customer-centric mindset throughout your lean transformation.

Measuring Success in Lean Initiatives

Tracking the effectiveness of lean initiatives is essential for sustaining progress and reinforcing a culture of continuous improvement. Organizations should measure key performance indicators such as lead time, throughput, product quality, and customer satisfaction to gauge the impact of their efforts. Monitoring additional metrics like inventory levels, overtime, and absenteeism can provide further insights into operational health.

Regular assessments and audits help ensure that lean principles are consistently applied and that the organization remains on course to achieve its objectives. Celebrating milestones and recognizing employee contributions boosts morale and strengthens commitment to ongoing improvement. By systematically measuring success, organizations can identify new opportunities for enhancement and maintain the momentum needed for long-term operational excellence.

Benefits of Lean Manufacturing

Adopting lean manufacturing principles yields numerous advantages:

- Waste Reduction: By eliminating waste, organizations can minimize unnecessary costs and improve resource utilization, resulting in more productive processes.

- Enhanced Quality: Streamlined processes lead to more consistent and higher-quality outputs, improving quality.

- Improved Customer Satisfaction: Efficient operations enable faster delivery times and better responsiveness to customer needs.

- Increased Flexibility: Lean systems are more adaptable to changes in demand, enhancing the organization’s competitiveness.

These benefits contribute to better operating performance and help organizations achieve operational excellence.

Challenges and Considerations

While the benefits are substantial, organizations may face challenges in adopting lean practices:

- Cultural Resistance: Shifting to a lean mindset requires changes in organizational culture and employee attitudes.

- Sustaining Improvements: Maintaining momentum in continuous improvement efforts demands ongoing commitment and monitoring.

- Training and Development: Ensuring all team members understand lean principles is crucial for successful implementation.

- Supply Chain Integration and Supplier Networks: Integrating lean practices across the supply chain and building a high-performance supplier network are essential for eliminating waste, improving efficiency, and supporting just-in-time manufacturing.

Additionally, the level of plant technology often has less impact on lean success than workforce skills and strong supplier relationships.

To address these challenges, investing in comprehensive training programs, such as the Effective Problem-Solving Course, can empower employees to identify issues proactively and develop practical solutions.

Conclusion

Embracing lean management in manufacturing is a transformative journey that leads to more efficient, responsive, and customer-centric operations. Organizations can significantly enhance performance and competitiveness by understanding and applying lean principles—not only in the manufacturing process and production cycle, but also in areas like software development, inventory management, and just-in-time manufacturing and delivery. Lean manufacturing plants exemplify the benefits of efficient flow, smooth flow, and reducing waste, while waste elimination remains a core focus throughout the production cycle. Managing raw materials, addressing issues such as poor quality castings, and integrating lead management into broader business processes are also essential for success. Lean practitioners continue to identify new forms of waste, and ongoing lean arguments highlight both the positive impacts and challenges of lean approaches.

For a holistic understanding and practical application of lean methodologies, explore the range of courses offered by Sabat Consulting:

- Lean Management Course

- Fundamentals of 5S Course

- Continuous Improvement Course

- Effective Teamwork and Leadership Course

- Effective Problem-Solving Course

Embark on your lean transformation today and position your organization for sustained success in the dynamic manufacturing landscape.