Lean Manufacturing Certificate: Your Path to Operational Excellence

In today’s global market, achieving manufacturing excellence isn’t just a competitive edge—it’s essential for survival. Organizations are turning to Lean manufacturing to lead the way with increasing pressure to reduce waste, boost productivity, and enhance customer value. However, companies need certified professionals with the right mindset, tools, and strategies to ensure that Lean becomes more than a temporary initiative. Implementing Lean Six Sigma can significantly improve overall company performance, driving operational efficiency and fostering a culture of continuous improvement.

That’s where a Lean manufacturing certificate comes into play. Whether you are an individual aiming to upgrade your skillset or a business looking to upskill your team, Lean certification provides a structured path to implement practical process improvements and achieve operational excellence. Certified professionals become a valuable asset to any organization, contributing to high-impact projects and supporting long-term success in operational excellence.

What Is a Lean Manufacturing Certificate?

A Lean manufacturing certificate formally recognizes your knowledge and practical ability to apply Lean principles within a manufacturing process or operational environment. It validates your capability in areas such as:

- Waste elimination

- Process optimization

- Flow efficiency

- Quality enhancement

- Value delivery

It also demonstrates your understanding of lean methodologies and structured methods for process improvement.

Certification programs are available at various levels—from introductory to advanced—and often integrate with sigma certification paths such as Lean Six Sigma. The Lean Six Sigma certification hierarchy includes White Belt (introductory level), Green Belt (intermediate level focused on project management and process improvement), and Black Belt (advanced leadership level involving coaching, project management, and strategic influence), with Master Black Belt representing mastery and expertise.

Sigma and Six Sigma certifications are highly valued in the manufacturing industry for improving employee skills, increasing employability, and boosting salaries. The sigma and Six Sigma methodologies are data-driven approaches to process optimization and defect reduction, focusing on quality improvement and waste reduction through structured problem-solving.

🎓 Looking to implement Lean practically and effectively? Discover the Lean Management – Practical Course designed with real-world tools and strategies based on 25+ years of experience.

Why Earn a Lean Manufacturing Certificate?

For Individuals:

- Advance your career in operations, engineering, or supply chain

- Gain skills in lean tools like 5S, Kanban, and Value Stream Mapping

- Demonstrate your commitment to continuous improvement

- Prepare for higher-level roles or a Lean Six Sigma certification path

You’ll also benefit from learning directly from instructors with extensive expertise in Lean Six Sigma.

For Organizations:

- Build internal capacity for implementing lean principles

- Create a culture of problem-solving and ownership

- Align operations with strategic goals for manufacturing excellence

- Reduce cost and enhance agility across the supply chain

Lean certification programs are designed to improve an organization’s processes, improving efficiency and effectiveness at every level.

Who Should Consider a Lean Certificate?

This certification is ideal for professionals across various sectors, especially those in the manufacturing industry, where Lean certification can significantly enhance process efficiency, reduce defects, and boost overall productivity.

| Role | Benefit |

|---|---|

| Production Supervisors | Apply Lean to improve team performance and reduce downtime |

| Process Engineers | Lead process improvements and standardization |

| Quality Managers | Use Lean to reduce defects and enhance product consistency |

| Supply Chain Managers | Optimize logistics and inventory based on Lean principles |

| Project Managers | Coordinate Lean initiatives across teams and functions |

| Executives | Drive culture change and lead strategic Lean transformations |

💡 Want your team to work better together? Consider our Teamwork and Leadership course.

What You’ll Learn in a Lean Manufacturing Certification Program

While specific topics may vary, most Lean certification programs cover a standard set of principles and tools to improve production processes and business performance. These programs focus on enhancing manufacturing processes, operational efficiency, and product quality through structured training.

Core areas of study typically include:

- Lean methodologies and methods for process improvement, such as Kaizen and Six Sigma, are central to the curriculum.

- Techniques for optimizing manufacturing processes and streamlining workflows.

- Quality control and strategies to minimize defects, ensuring consistent product quality.

- Tools and practices to reduce costs and improve operational efficiency.

Many programs also integrate Six Sigma, and Six Sigma training is emphasized as essential for process improvement and cost reduction across manufacturing and business operations.

Core Areas of Study:

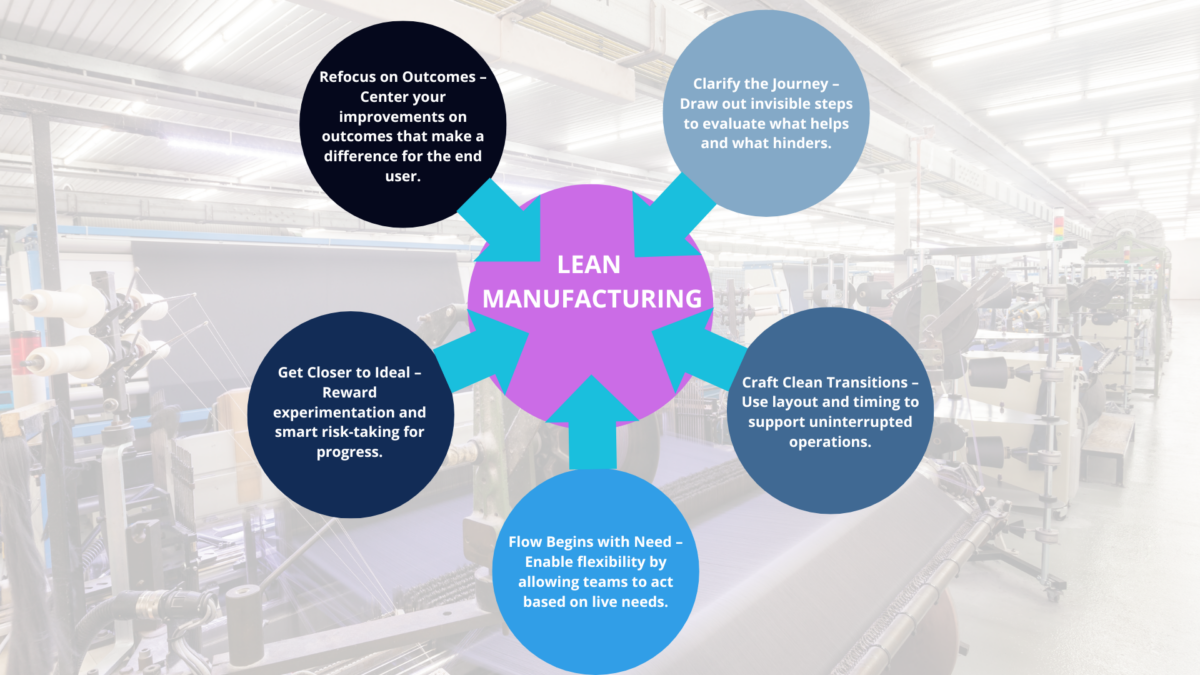

- Lean Principles – Value, Value Stream, Flow, Pull, and Perfection

- Lean Tools – 5S, Kanban, Andon, SMED, Poka-Yoke

- Manufacturing Processes – Analyzing, optimizing, and integrating efficient production workflows

- Process Improvement – Continuous improvement strategies to enhance operational efficiency and reduce waste

- Operational Efficiency – Techniques and practices to maximize productivity and resource utilization

- Product Quality – Ensuring high standards and consistency in outputs through quality management systems

- Quality Control – Implementing methods to monitor, assess, and maintain product quality and minimize defects

- Methods – Structured approaches such as Kaizen, Six Sigma, and Lean for process optimization

- Value Stream Mapping – Visualizing and optimizing entire workflows

- Root Cause Analysis – Solving Problems with A3 and 5 Whys

- Standardized Work – Documenting and improving daily tasks

- Visual Management – Making performance visible at all times

- Just-in-Time Production – Aligning output with real-time customer demand

- Total Productive Maintenance (TPM) – Minimizing downtime and maximizing equipment reliability

Some programs also integrate Six Sigma methodologies for statistical analysis and variation control, forming a hybrid Lean Six Sigma pathway.

Popular Lean Certification Levels

1. Introductory Certificate

Covers the fundamentals—ideal for those new to Lean. The White Belt is the foundational level of Lean Six Sigma certification, introducing Lean principles. Often a prerequisite for more advanced credentials.

2. Lean Bronze Certification

The Lean Certification Alliance offers this hands-on, project-based certification for professionals implementing Lean at the operational level. Many professionals pursue Green Belt certification after completing this introductory or Bronze level, as it represents the next step in Lean Six Sigma training and process improvement expertise.

3. Lean Silver Certification

Targeted at mid-level managers with experience leading Lean teams or projects across functions. After achieving Silver or Green Belt status, experienced professionals may advance to Black Belt certification, representing a leadership position focused on coaching, project management, and driving strategic process improvements.

4. Lean Gold Certification

Focused on organizational transformation. Candidates must show a track record of applying Lean at an enterprise level and leading sustainable cultural change. The Shingo Institute is widely recognized as a leading authority in Lean certification and organizational excellence, setting industry standards for best practices and evaluation.

🎯 Need a certification built on real experience? The Lean Management course gives you access to tools, templates, and simulations used by global manufacturers.

Online vs. In-Person Certification Programs

Modern learners value flexibility, and certification providers have responded with multiple formats.

| Format | Advantages |

|---|---|

| Online Courses | Online courses are self-paced, affordable, and ideal for remote learners. They also feature discussion forums, facilitating peer interaction and enabling targeted industry-specific discussions among participants. |

| Virtual Instructor-Led | Combines structure with interactivity |

| In-Person Workshops | Best for simulations and group activities |

| Blended Learning | Offers both structure and flexibility |

All formats typically include assessments and projects, and successful completion of real-world applications is required to earn the certificate.

How Lean Certification Enhances the Supply Chain

A Lean manufacturing certificate doesn’t just impact the shop floor. It also strengthens supply chain management by enhancing procurement, logistics, and operational efficiency. Specifically, it improves the supply chain by:

- Reducing inventory levels and lead times

- Improving supplier relationships through shared Lean practices

- Aligning production schedules with demand forecasts

- Enhancing responsiveness to changes in customer demand

- Lowering logistics and transport costs

🔍 Want to integrate Lean across departments? Our Continuous Improvement course connects operational tools to business strategy.

Certifications vs. Degrees: Which Should You Choose?

While a master’s degree in operations or industrial engineering provides deep theoretical knowledge, certification is:

- ✅ Shorter (weeks or months vs. years)

- ✅ Cheaper

- ✅ More practical and directly applicable

- ✅ Focused on real-world tools and case studies

- ✅ Often supported by companies for employee development

In many cases, professionals pursue both at different stages of their careers.

Return on Investment: Is It Worth It?

A Lean manufacturing certificate is not just a line on your resume. It’s a pathway to tangible business outcomes:

- 20–40% cost reduction through waste elimination

- 15–25% boost in throughput and productivity

- Shorter time-to-market for new products

- Enhanced employee engagement and accountability

- Increased customer satisfaction from higher quality and reliability

Achieving Lean certification is closely linked to long-term business performance and operational excellence success. It enables organizations to sustain high levels of efficiency and process improvement.

These outcomes translate to faster promotions, better job opportunities, and more robust business performance.

Final Thoughts: From Training to Transformation

Getting a Lean manufacturing certificate is more than checking a box—it starts a mindset shift. Whether you’re optimizing the manufacturing process, enhancing the supply chain, or supporting digital transformation, Lean skills are essential in today’s performance-driven economy. As part of digital transformation, artificial intelligence is increasingly used to advance Lean manufacturing, drive process optimization, and improve operational efficiency.

The most successful organizations don’t just send people to training—they build Lean capability from the inside out.

🎓 Ready to Start Your Lean Journey?

The Lean Management – Practical Course gives you the skills, tools, and real-life context to earn your Lean certificate and lead transformation.

✅ VoD format – Learn anytime, at your own pace

♾️ Lifetime access – Use it to train new hires and reinforce learning

🧰 Downloadable tools – SOPs, red-tag sheets, value stream maps

📘 Real experience – Built on 25+ years of global Lean consulting

👉 Preview a full lesson for free and discover how actionable Lean learning can be.

Explore the GET LEAN Simulation Game for immersive learning—perfect for engaging teams in Lean implementation through hands-on scenarios.