Lean Manufacturing Certificates: Your Path to Operational Excellence

In today’s fast-paced, globalized manufacturing environment, efficiency, precision, and adaptability are no longer optional—they are essential. Organizations across industries are adopting Lean manufacturing to streamline operations, reduce waste, and boost customer value. However, trained professionals must embed Lean into an organization’s DNA. That’s where Lean manufacturing certifications come into play.

A Lean Six Sigma certification is a key credential for professionals seeking to drive process improvement and operational efficiency in the manufacturing industry.

Whether you’re looking to advance your career, improve your organization’s manufacturing process, or lead a Lean transformation, this guide will help you understand the landscape of Lean certifications and how they enable individuals and businesses to achieve operational excellence. Lean manufacturing certifications are instrumental in achieving manufacturing excellence within the manufacturing industry by fostering innovation, high standards, and continuous improvement.

What Are Lean Manufacturing Certifications?

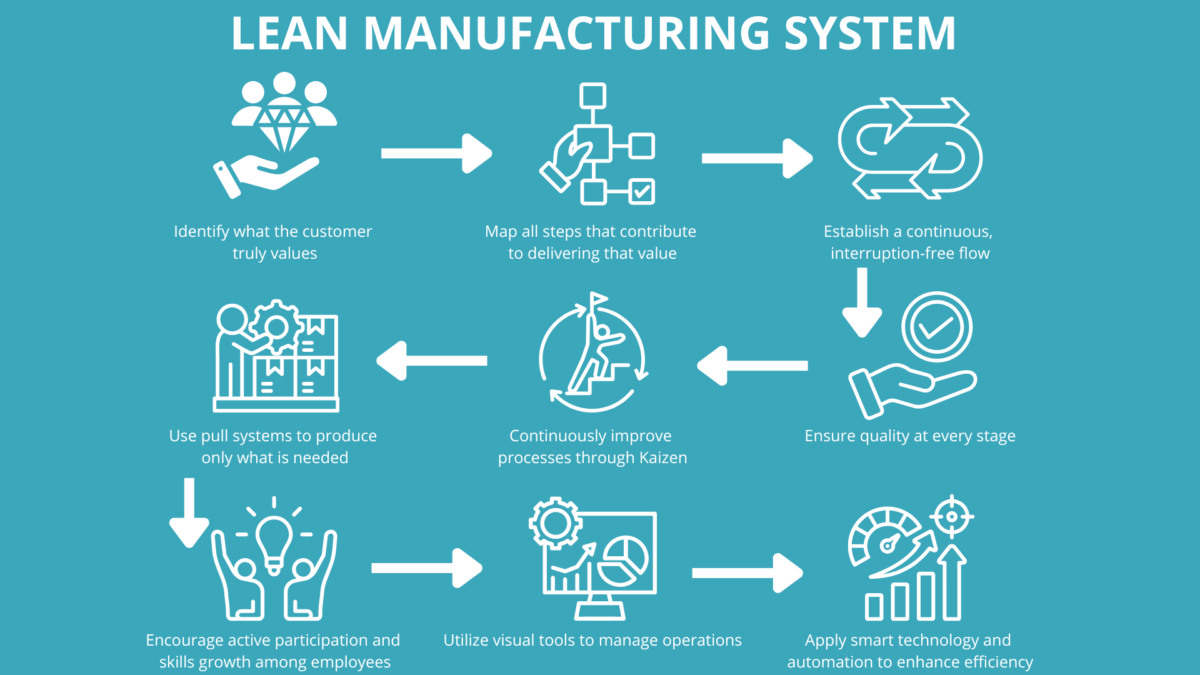

A Lean manufacturing certification validates your understanding and practical application of Lean principles, tools, and methodologies. These certifications are structured training programs covering Lean fundamentals, including value stream mapping, 5S, Kaizen, and root cause analysis. Many programs also offer sigma certification and cover the sigma methodology, focusing on process improvement and quality management within manufacturing.

Professionals who earn these certifications gain the skills needed to drive continuous improvement, enhance supply chain management, and lead change in production processes. Sigma training is often included as part of comprehensive Lean certification programs.

🎓 Want to begin or advance your journey in Lean? Explore our hands-on Lean Management – Practical Course designed to apply Lean tools across real operations with proven success.

Why Lean Certification Matters

Lean certifications aren’t just resume boosters. They’re signals—to employers, teams, and industries—that you have what it takes to improve efficiency, eliminate waste, and solve complex operational problems. Lean Six Sigma certification opens up new job opportunities and is considered a valuable asset for professionals seeking to advance their careers.

Benefits of Lean Manufacturing Certifications:

- ✅ Enhanced understanding of Lean tools and how to apply them

- ✅ Ability to identify and remove non-value-added activities

- ✅ Stronger cross-functional collaboration in supply chain and operations

- ✅ Opportunities to lead Lean transformation initiatives

- ✅ Increased job security and career advancement

Companies that support Lean training for their employees often see faster adoption of Lean methodologies, better team performance, and measurable cost savings.

Core Topics Covered in Lean Certification Programs

Most Lean manufacturing certification programs focus on these key areas: Lean certification programs emphasize process optimization and improving manufacturing processes to achieve higher product quality and reduce defects.

• Lean Principles

Understanding the five core principles—value, value stream, flow, pull, and perfection—is essential for identifying improvement opportunities in any manufacturing process.

• Lean Tools

Courses train participants in tools such as:

- 5S and red-tagging

- Standardized work

- Value stream mapping

- Kanban systems

- Error-proofing (Poka-Yoke)

These tools are foundational for streamlining production processes.

• Process Analysis

Participants learn to map and analyze production processes to find bottlenecks, delays, and redundancies that inhibit flow.

• Problem Solving

Training includes root cause analysis, A3 thinking, and PDCA (Plan-Do-Check-Act), allowing practitioners to lead focused process improvement efforts.

• Culture and Leadership

To sustain Lean, culture is key. Higher-level certifications emphasize leadership behaviors, coaching methods, and change management.

Who Should Pursue Lean Manufacturing Certifications?

While Lean began in manufacturing, its principles now apply to virtually every industry. The following roles benefit most from certification:

| Role | Value of Certification |

|---|---|

| Production Supervisors | Lead kaizen events and standardize work |

| Engineers | Optimize layouts and solve process issues |

| Supply Chain Managers | Improve flow and reduce inventory |

| Quality Managers | Eliminate root causes of defects |

| Executives | Align strategy with Lean culture |

Modern Lean programs’ flexibility makes them ideal for everyone, from floor workers to the C-suite. Lean certification can drive positive change in a company by improving the organization’s processes and fostering a culture of continuous improvement.

Industry Applications of Lean Certification

Lean certification is a powerful asset across many industries, not just traditional manufacturing. Organizations implement lean principles in everything from healthcare and finance to logistics and supply chain management to drive operational excellence, reduce costs, and boost customer satisfaction. By adopting lean methodologies, companies can optimize operations, eliminate waste, and minimize defects, leading to more efficient processes and higher-quality outcomes.

The Lean Certification Alliance offers a comprehensive certification program designed to help professionals gain knowledge and practical skills in lean. With this expertise, individuals can lead lean transformation initiatives, drive process improvement, and support continuous improvement efforts within their organizations. Whether you’re streamlining a manufacturing line, improving supply chain efficiency, or enhancing service delivery, lean certification empowers you to make informed decisions that contribute directly to organizational success.

Online vs. In-Person Lean Certification Programs

With digital platforms expanding rapidly, many Lean programs are now offered online. Some online Lean certification programs are beginning to incorporate artificial intelligence to personalize learning and simulate real-world manufacturing scenarios. Here’s how they compare:

Online Certification

- Self-paced or instructor-led

- Ideal for busy professionals or remote teams

- Includes videos, quizzes, and downloadable resources

- Available anywhere with internet access

In-Person Certification

- Hands-on workshops and group simulations

- Higher engagement through face-to-face collaboration

- Better for intensive team training

💻 Looking for flexibility? The Lean Management – Practical Course is 100% online, VoD format, with lifetime access and downloadable tools.

Time Commitment: What to Expect from Lean Certification

Pursuing a lean certification is a significant but rewarding investment in your professional development. The time required varies depending on the certification program, your prior experience, and the depth of the course. Most programs, such as the Lean Principles online course from Purdue University, recommend dedicating four to five hours per week over several weeks, often spanning two to three months.

In addition to scheduled learning, you’ll study course materials, complete assignments, and actively participate in discussion forums. These forums are invaluable for deepening your understanding of lean principles, exchanging ideas, and clarifying concepts with peers and instructors. Planning your schedule and engaging fully with the program will maximize your knowledge and ensure a successful certification experience.

Aligning Lean Certification with Organizational Goals

When organizations support Lean certification programs, they create a common language and methodology across teams. This accelerates:

- Operational excellence

- Faster adoption of process improvements

- Collaboration across departments and the supply chain

- Accountability and data-driven decision-making

Certified professionals become internal change agents—people who don’t just solve problems but build systems that prevent them.

📈 Looking to build a full improvement system? Pair Lean certification with Problem Solving training and Continuous Improvement programs.

Lean Certification Providers and Programs

Several globally recognized bodies offer Lean certifications. Many of these providers also provide Six Sigma certification, Lean Six Sigma certification, and training in the Six Sigma methodology for comprehensive process improvement.

1. Lean Certification Alliance

A partnership between SME, AME, and the Shingo Institute offering Bronze, Silver, and Gold certifications.

2. ASQ (American Society for Quality)

Offers Lean Six Sigma certifications, integrating statistical rigor with Lean philosophy.

3. University Programs and Private Academies

Many business schools and consultancies provide custom or sector-specific Lean certifications.

Each provider has its exam process, project requirements, and continuing education standards. Be sure to choose a program that aligns with your professional goals and industry context.

The Lean Certification Exam: What You Need to Know

The lean certification exam validates your mastery of lean principles and methodologies. Typically, the exam features a mix of multiple-choice questions and real-world case studies, challenging you to apply your knowledge to practical scenarios. To prepare, it’s essential to thoroughly review all course materials, practice with sample questions, and participate in discussion forums to address any uncertainties.

The Lean Certification Alliance provides various exam preparation resources, including study guides and practice tests, to help you build confidence and expertise. Successfully passing the exam demonstrates your proficiency in lean methodologies and earns you a respected certification, enhancing your credibility and opening new career opportunities in process improvement and operational excellence.

Building Your Network: The Value of the Lean Online Community

Joining the lean online community is a strategic move for anyone pursuing lean certification. This vibrant network connects you with professionals from diverse industries who share a passion for lean principles and continuous improvement. Through discussion forums, webinars, and shared resources, you can exchange knowledge, ask questions, and learn from the experiences of others on their lean journey.

The community is an excellent place to stay updated on the latest trends in lean methodologies, discover best practices, and receive feedback on your ideas and projects. By actively participating, you expand your knowledge and skills and build relationships that can support your career growth and help you drive meaningful process improvements within your organization. The collective expertise and support found in the lean online community make it an invaluable resource for ongoing professional development and organizational success.

Practical Outcomes from Lean Certification

Certified Lean professionals report a wide range of measurable improvements, including:

- 15–25% increase in productivity

- 30–50% reduction in inventory waste

- Improved quality control

- Enhanced employee engagement and morale

- Better alignment between operations and strategy

These aren’t just numbers—they represent cultural and structural shifts that strengthen competitive advantage.

Final Thoughts: Certifications That Drive Real Change

A structured, proven improvement approach is necessary in an age of complexity. Lean manufacturing certifications provide a framework for thinking, acting, and leading that delivers consistent results.

They turn talent into capability—and capability into sustainable performance.

🎓 Build Your Expertise with Practical Certification

If you’re ready to bring Lean to life in your organization, the Lean Management – Practical Course offers:

🎥 Study Lean anytime with convenient video modules

♾️ Never expires – great for refreshing knowledge

🧰 Red tags, SOPs, audits – download and go

🏭 Over two decades of hands-on experience

👉 You can preview a complete video lesson for free and see how practical and actionable this training is.