Lean Manufacturing Certification: Mastering Efficiency, Quality, and Performance

In today’s fast-paced and increasingly complex industrial world, organizations are constantly pressured to improve quality, reduce costs, and respond to customer demands with agility. One of the most effective ways to meet these challenges is through a Lean Manufacturing Certification. This credential validates your understanding of lean principles and equips you with practical tools and techniques to optimize operations and lead meaningful change.

What Is Lean Manufacturing Certification?

Lean manufacturing certification is a structured and recognized credentialing program that confirms an individual’s expertise in applying lean principles, lean tools, and continuous improvement techniques within manufacturing and service environments. Unlike general education in business or engineering, a lean certification program focuses on eliminating waste, enhancing process improvement, and building a lean culture that supports long-term operational excellence.

Certified professionals gain hands-on skills in process optimization, quality control, and operations management, learning to apply strategies that increase productivity, improve customer satisfaction, and drive measurable value. Whether you’re involved in supply chain management, production processes, or project management, a lean certification prepares you to optimize your organization’s processes from the ground up.

Why Lean Principles Matter

The core principles derived from the Toyota Production System are at the core of any lean transformation, shaping modern manufacturing excellence. These principles emphasize:

- Delivering maximum value to the customer

- Eliminating all forms of waste

- Creating efficient processes through continuous improvement

- Building flexible systems for responsive operations

- Developing lean leadership to sustain change

When you apply lean principles, you don’t just change how work is done—you transform the entire organization’s culture. Through lean methodologies, companies learn to question every step in the manufacturing process, seeking ways to increase flow, reduce errors, and foster collaboration.

Benefits of Lean Manufacturing Certification

Completing a lean certification offers tangible benefits for both individuals and organizations:

- Learn to identify and eliminate waste across departments

- Drive process improvement projects that increase ROI

- Use practical tools to make informed decisions

- Enhance product quality and reduce variability using statistical methods

- Improve operational efficiency and workflow across systems

- Support project managers with better problem-solving frameworks

- Build credibility with an industry-recognized credential

- Become a valuable asset within your company or to potential employers

Graduates of a certification program often see expanded job opportunities, increased responsibility, and even higher compensation. Verifying lean knowledge and skills can be a key differentiator in a competitive job market.

Flexible Learning: Self-Paced and Online Courses

For busy professionals and learners worldwide, the ability to pursue online courses at their own pace is essential. Today’s best lean training platforms offer VOD (video on demand), interactive discussion forums, downloadable resources, and real-life case studies.

Whether in manufacturing, healthcare, logistics, or services, these online training solutions allow you to gain valuable knowledge without disrupting your work schedule. You can access material anytime, revisit complex topics, and progress based on availability.

🎓 Ready to earn your certification? Start with the Lean Management Course—a powerful, experience-based program trusted by industry professionals.

Curriculum Overview: What You’ll Learn

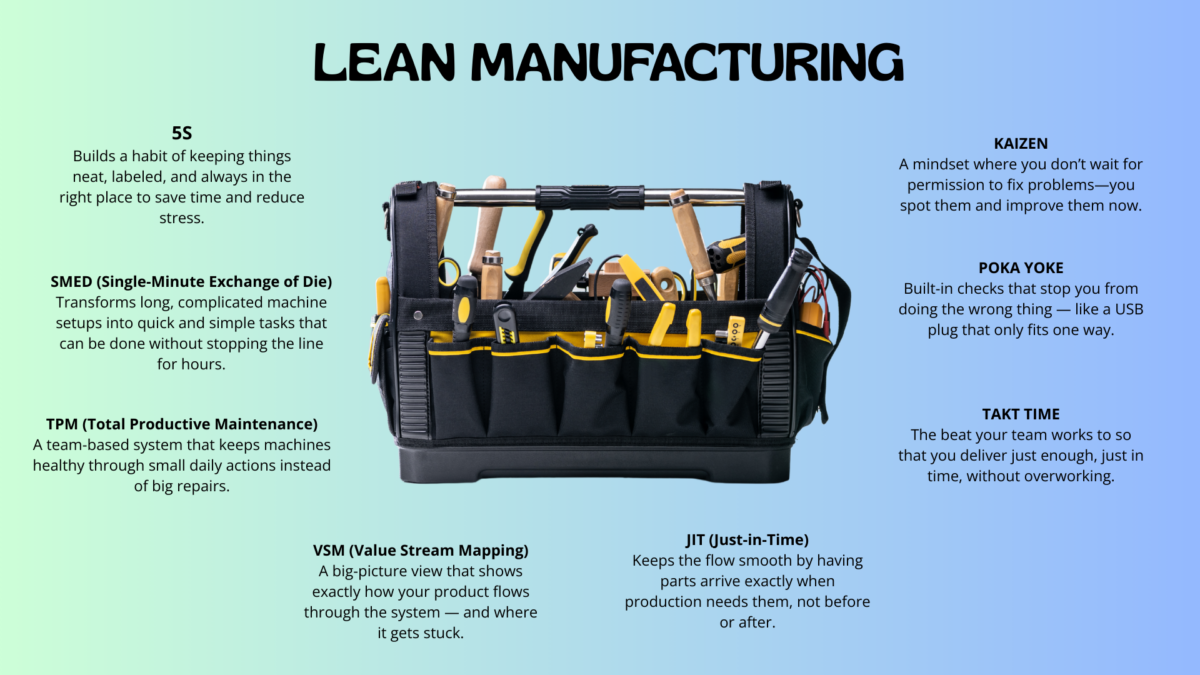

The lean manufacturing certification curriculum typically covers:

- Lean principles and the foundation of the Toyota Production System

- Value stream mapping and process analysis

- Identification and removal of the eight wastes (muda)

- Tools such as 5S, Kanban, SMED, and Andon

- Lean tools for daily problem solving

- Project management for improvement initiatives

- Quality control and minimizing defects

- Strategies for creating and sustaining a lean culture

These modules are designed to develop theoretical understanding and practical ability, enabling learners to lead and execute improvements from day one.

📘 For a deeper dive into core principles and techniques, explore our Continuous Improvement Course, which pairs perfectly with the lean certification path.

Career Opportunities and Industry Applications

A lean certification opens doors across various sectors, including automotive, aerospace, electronics, healthcare, logistics, food production, and more. It’s especially valuable in roles involving processes, such as:

- Production Supervisors and Plant Managers

- Quality Engineers and Project Managers

- Continuous Improvement Specialists

- Supply Chain Coordinators

- Lean Coaches and Trainers

Certification allows you to contribute effectively to cross-functional teams and organization-wide transformation efforts, whether at the beginning of your lean journey or advancing to senior leadership.

💡 Want to develop stronger problem-solving frameworks? Check out our Effective Problem-Solving Course to complement your lean training.

How Certification Programs Work

Most certification programs involve self-paced study, practical assignments, and a final assessment. Some offer tiered certifications (e.g., Yellow Belt, Green Belt, Black Belt), while others are project-based and focus on real-world implementation.

Upon successful completion, learners receive a certificate that can be added to resumes, LinkedIn profiles, and professional portfolios. Many programs also provide lifetime access to learning materials, case libraries, and discussion forums to foster continuous learning.

🧰 To experience lean in action, explore the GET LEAN Simulation Game, a hands-on tool for individuals and teams.

Final Thoughts: Lean as a Long-Term Strategy

Lean manufacturing is not just a set of tools—it’s a strategic framework for sustainable excellence. A strong foundation in lean principles allows professionals to design, lead, and execute transformation in any setting. With the proper training, support, and commitment to continuous improvement, certified individuals become the cornerstone of innovation.

Take your first step toward lean manufacturing certification and reshape how your company approaches efficiency, quality, and performance.

🎓 Begin today with the Lean Management Course—a self-paced, internationally respected training that puts theory into practice.

Explore Additional Lean Training Options:

- 🔧 5S Workplace Organization Course

- 💡 Continuous Improvement Course

- 🧠 Effective Problem-Solving Course

- 🌐 GET LEAN Simulation Game

Stay tuned. Next, we can expand further by adding expert quotes, mini case studies, or infographics to reinforce key learning points visually.