Lean MFG Principles: A Practical Guide to Applying Lean Thinking in Modern Manufacturing

Introduction: Why Lean Matters More Than Ever

In today’s fast-paced industrial landscape, companies are constantly challenged to reduce costs, enhance quality, streamline production, and respond quickly to changing customer demand. As global competition intensifies and operational efficiency becomes a necessity rather than a differentiator, manufacturers increasingly turn to Lean Manufacturing. Also known as lean thinking, this structured methodology offers a proven way to maximize customer value while minimizing waste. The historical roots of the term lean manufacturing can be traced back to early 20th-century scientific management, pioneered by Frederick Winslow Taylor, and later evolved through the Toyota Production System, emphasizing waste reduction and continuous improvement.

Lean is not just a set of tools or isolated practices; it is a comprehensive philosophy that shapes how organizations think, act, and improve. At its core, Lean is about creating more value for customers with fewer resources by aligning every activity to deliver value and eliminate waste. In this comprehensive article, we will explore how lean manufacturing has evolved from earlier management theories such as scientific management, examine lean mfg principles in depth, and explain how they support operational excellence and can be applied effectively in real-world settings.

This guide is intended for professionals across all industries, especially those in manufacturing operations, supply chain management, and continuous improvement roles. Whether you’re an executive, lean leader, process engineer, or production manager, you will find actionable insights here to support your Lean journey.

What Are Lean MFG Principles?

Lean Manufacturing is centered around five lean principles that are the foundation for improvement efforts. These principles, known as the five principles, are core lean concepts derived from the lean production system. They provide a structured framework for analyzing and optimizing business processes, especially in manufacturing environments:

- Define Value

- Map the Value Stream

- Create Flow

- Establish Pull

- Seek Perfection

These five lean principles, often called the five key principles of lean manufacturing, form the core of lean thinking and apply across the production process, from sourcing raw materials to delivering finished goods. The framework originates from the lean production system, which emphasizes waste reduction, efficiency, and continuous improvement.

1. Define Value: Customer-Centric Thinking

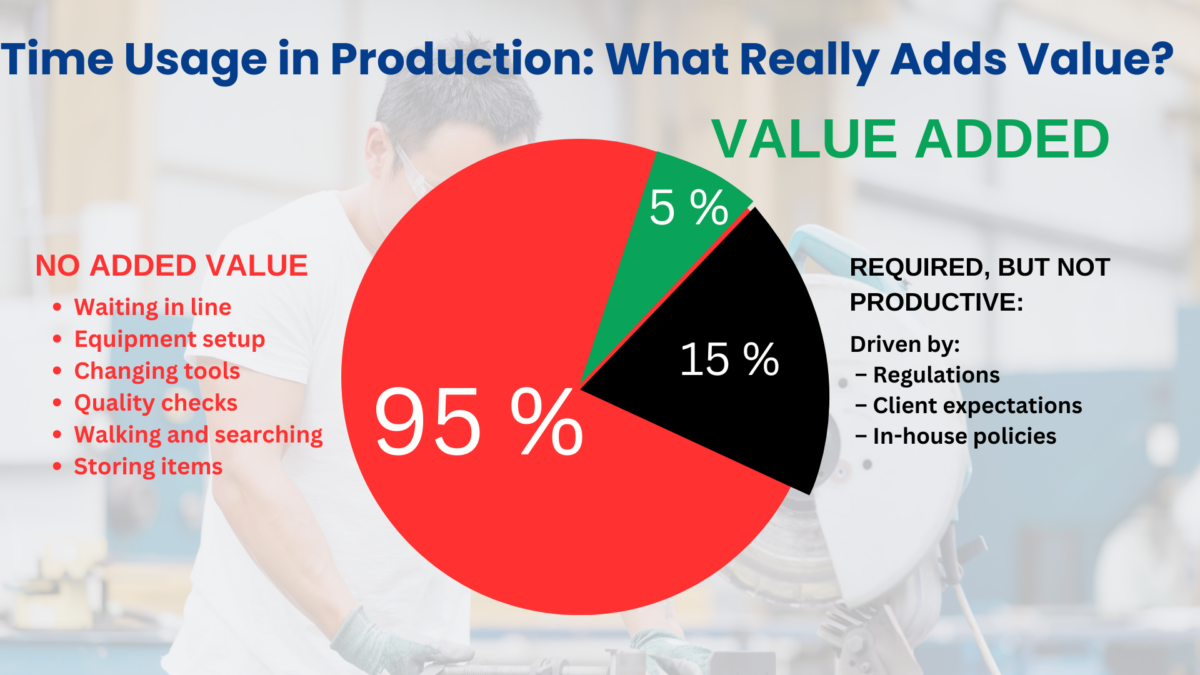

Every lean journey begins by defining what constitutes value from the customer’s perspective. This means identifying the features, functions, and services the customer will pay for. In lean terminology, any activity that doesn’t directly contribute to this value is classified as waste.

Common types of waste include overproduction, waiting, unnecessary transportation, excess inventory, unnecessary movement, over-processing, defects, and underutilized talent. Lean methods focus on identifying waste and eliminating it throughout the system.

Understanding value allows organizations to align their efforts with customer expectations and focus on delivering what truly matters. By defining value and concentrating resources on activities that drive value and profitability, organizations can create wealth and cut waste.

Want to see how these principles work in real organizations? Enroll in our Lean Management Course.

2. Map the Value Stream: Visualizing the Production Process

The next step is value stream mapping, which involves documenting every step in the manufacturing process. Mapping the value stream is a crucial step in Lean methodology, as it visually represents the entire product or service lifecycle to identify waste and opportunities for process improvements. This technique helps teams understand the flow of materials and information, from raw materials to the finished product.

When teams map the value stream, they analyze it and identify value-adding and non-value-adding activities. Mapping should cover the entire supply chain, from sourcing materials to delivery, ensuring a holistic view of all stages. This provides clarity on where improvements can be made and supports better decision-making. Stream mapping is also a foundation for lean tools, such as standard work, visual management, and takt time analysis.

For a more structured approach to analyzing processes, we recommend our Effective Problem-Solving Course, which guides teams through root cause analysis and solution implementation.

3. Create Flow: Ensuring Smooth Transitions

Once waste is identified, the goal is to create flow in the production process. This means achieving smooth flow, where products move seamlessly from one process step to the next without delays or interruptions.

Continuous flow requires careful layout planning, work balancing, and task standardization. It also involves reducing batch sizes and setting up work cells to eliminate bottlenecks. Optimizing flow focuses on developing productive processes and removing unnecessary processes, which are key to achieving smooth flow. When flow is optimized, the production process becomes faster, more flexible, and less prone to errors.

Tools like 5S, just in time, and visual management are critical to creating flow. Our 5S Course offers actionable strategies for implementing flow-friendly work environments.

4. Establish Pull: Producing Based on Demand

The fourth principle of Lean is to establish a pull system, where work is driven by actual customer demand, not forecasts. Pull systems align production with real consumer demand, rather than fixed production targets. This reduces excess inventory, improves cash flow, and ensures that only necessary products are produced. In contrast, push systems rely on forecasts and predetermined schedules, which can lead to inefficiencies such as overproduction or shortages.

In pull systems, downstream processes signal upstream processes when to produce or replenish. This is commonly managed through Kanban cards, FIFO lanes, and real-time monitoring.

Systems designed to flow smoothly and react quickly to customer needs are more agile and responsive to market changes. Pull systems are critical when customer requirements are unpredictable or highly variable.

5. Seek Perfection: Building a Culture of Continuous Improvement

The final lean principle is to seek perfection through continuous improvement. Lean organizations never settle for the status quo. They are committed to improving efficiency, reducing errors, and optimizing every aspect of the business.

This cultural shift is driven by lean leadership, which encourages employees to take ownership, suggest improvements, and participate in structured activities like Kaizen events. By fostering a lean philosophy throughout the organization, companies drive continuous improvement and embed the core values that support ongoing enhancement. Tools such as A3 thinking, PDCA (Plan-Do-Check-Act), and Hoshin Kanri support this principle.

To fully embrace this mindset, check out our Continuous Improvement Course. It provides real examples, templates, and techniques for driving sustainable change.

Lean Management and Leadership: Guiding Change from the Top

Successful implementation of lean manufacturing principles starts with strong lean management and leadership. Leaders play a pivotal role in setting the vision for continuous improvement and fostering a culture that embraces lean thinking at every level of the organization. By championing lean manufacturing, leaders demonstrate a commitment to reducing costs, improving efficiency, and responding swiftly to customer demand.

Lean management is more than overseeing processes—it’s about empowering employees to take ownership of improvements and providing them with the training and resources needed to succeed. When leaders encourage open communication and support employee involvement, they create an environment where continuous improvement becomes second nature.

A high-performance supplier network is also essential for effectively implementing lean manufacturing. By collaborating closely with suppliers, companies can ensure that materials and components are delivered just in time, supporting a smooth production process and enabling rapid response to shifts in customer demand. This integrated approach reduces costs and enhances customer satisfaction by delivering value more efficiently.

Ultimately, lean management drives a successful lean transformation, guiding teams to adopt lean manufacturing principles and achieve lasting results.

Lean Manufacturing Tools That Support the Principles

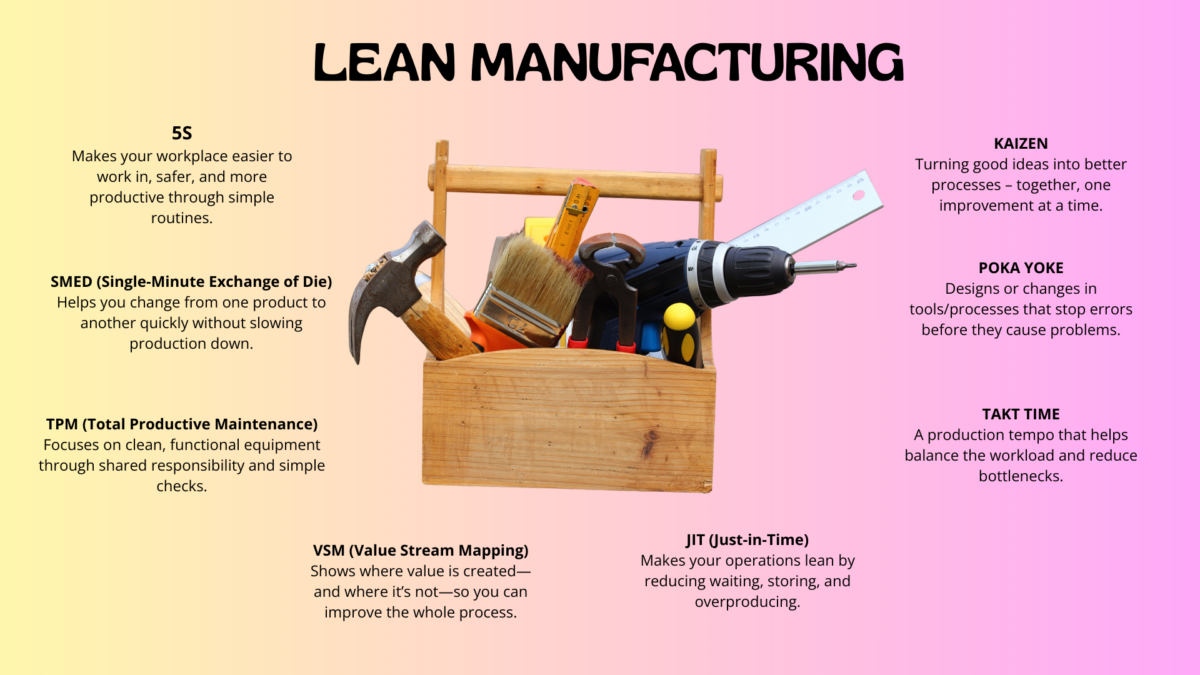

While the five lean principles provide a strategic direction, Lean Manufacturing also involves practical tools that help operationalize these concepts. Some essential lean manufacturing tools include:

- 5S System

- Kanban

- Poka-Yoke (error proofing)

- Standard Work

- Takt Time

- Value Stream Mapping

- Visual Management

- Just-In-Time Delivery

These tools support lean processes across various functions, including optimizing lead management, by streamlining workflows and improving efficiency.

Implementing Lean isn’t about using every tool at once but selecting the right ones based on the current maturity level and specific process needs.

Reducing Excess Inventory: Strategies for Lean Stock Management

One of the core objectives of lean manufacturing is to minimize excess inventory, which often represents hidden waste within the production process. Effective lean stock management relies on aligning inventory levels with actual sales and customer demand, rather than relying on forecasts that can lead to overproduction.

Implementing a pull system is a proven strategy for reducing excess inventory. By producing only what is needed, when it is required, companies can prevent the buildup of unnecessary stock and ensure that resources are used efficiently. Value stream mapping is another powerful tool, allowing organizations to visualize the entire value stream and pinpoint areas where inventory tends to accumulate. Stream mapping will enable teams to identify bottlenecks, reduce lead times, and create a more responsive and efficient manufacturing process.

Companies can streamline operations by continuously monitoring inventory levels and making data-driven adjustments. This frees up working capital and boosts manufacturing efficiency. These lean practices cut waste and support a more agile and customer-focused production system.

Best Practices for Lean Implementation

Implementing lean manufacturing requires a structured approach and a commitment to continuous improvement. Start by clearly defining your organization’s goals and objectives, ensuring everyone understands the purpose behind adopting lean manufacturing principles. Next, identify key areas where waste can be eliminated and value can be enhanced across the value stream.

Forming a cross-functional team is essential for driving the lean implementation effort. This team should have the necessary training and resources to lead change and engage employees at all levels. Utilizing lean tools such as value stream mapping and root cause analysis helps teams visualize processes, identify inefficiencies, and develop targeted solutions for eliminating waste.

Creating a culture of continuous improvement is equally important. Encourage employees to actively participate in problem-solving and empower them to suggest and implement improvements. By following these best practices and leveraging proven lean tools, organizations can implement lean effectively, drive sustainable change, and achieve significant gains in efficiency and productivity.

Measuring Success in Lean: Metrics and KPIs

To ensure the effectiveness of lean initiatives, organizations must establish clear metrics and KPIs that align with their goals. Tracking progress with the correct measurements allows companies to evaluate the impact of lean manufacturing on their value stream and make informed decisions for further improvement.

Key metrics for lean include lead time, inventory turns, defect rates, on-time delivery, customer satisfaction, and employee engagement indicators. Value stream mapping is crucial in this process, helping teams identify waste areas and monitor improvements over time. By regularly reviewing these metrics, organizations can assess the success of their lean implementation, identify new opportunities for stream mapping, and ensure that continuous improvement remains a central focus.

Using data-driven insights, companies can refine their lean strategies, enhance customer satisfaction, and sustain high performance levels across the entire value stream.

Common Challenges in Implementing Lean

Many companies struggle to implement lean manufacturing successfully because they underestimate the cultural and organizational change required. Some of the most frequent challenges include:

- Resistance to change from staff or leadership

- Lack of understanding of lean principles

- Inconsistent management support

- Poor communication or training

Some critics of lean argue that if not managed carefully, these challenges can impact employee well-being or lead to unintended consequences.

Overcoming these challenges requires strong leadership, a clear roadmap, and continuous communication. It also helps to create small wins that build momentum and prove the value of Lean.

Cross-Functional Collaboration and Lean Teams

Lean thrives in environments where cross-functional teams collaborate across departments. Siloed thinking undermines improvement efforts, whereas aligned teams that understand the end-to-end process can drive better outcomes.

See our Teamwork and Leadership Course for tips on aligning your teams and fostering leadership.

The Role of the Standard Lean Production Model

The standard lean production model includes predictable routines, clear goals, and measurable performance indicators. It guides behavior and allows organizations to benchmark their performance against best practices.

Lean organizations standardize processes not to limit flexibility but to enable consistent performance, reduce variation, and support training. Once standards are in place, teams are encouraged to improve them incrementally. In lean organizations, operating performance is often driven more by workforce practices and supplier networks than by investments in advanced plant technology.

Industry Applications of Lean MFG Principles

Although lean principles originated in the automotive industry with the Toyota Production System, they are widely used in various sectors today:

- Healthcare: Improving patient flow and reducing medical errors

- Food production: Ensuring freshness and reducing spoilage

- Construction: Utilizing lean construction methods to improve productivity, minimize rework, and reduce material waste

- Manufacturing: Lean manufacturing plants exemplify lean principles by reducing waste, developing flexible workforces, and utilizing efficient supply chains

- Logistics: Streamlining supply chains and inventory management

Every sector has the opportunity to benefit from lean practices tailored to its unique challenges, and these practices have been adopted by other industrial nations beyond the automotive industry.

Benefits of Lean for Your Organization

Some of the most compelling benefits of lean manufacturing include:

- Reduced waste and lower operating costs, leading to significant waste reduction

- Improved manufacturing processes through continuous improvement and process optimization

- Improved customer satisfaction through timely delivery and quality

- Increased employee engagement

- Greater agility and responsiveness to change

- Stronger competitive advantage

Companies implementing lean principles often see double-digit improvements in key metrics within the first year.

Sustaining Lean Improvements: Keeping Momentum Alive

Achieving initial success with lean manufacturing is only the beginning—sustaining those improvements requires ongoing dedication to continuous improvement. Building a culture where employees are encouraged to identify and solve problems is key to maintaining momentum. Regular training and development programs help maintain engagement and ensure that teams have the skills to support lean initiatives.

Using lean tools like value stream mapping and root cause analysis enables organizations to systematically eliminate waste and adapt to changing business conditions. By making continuous improvement a core value, companies can drive ongoing efficiency, productivity, and competitiveness gains.

Sustaining lean improvements means never settling for the status quo. By fostering a proactive mindset and leveraging stream mapping to uncover new opportunities, organizations can ensure that lean principles remain deeply embedded in their operations for the long term.

Final Thoughts: The Future of Lean Manufacturing

Lean manufacturing continues to be a transformative approach for organizations seeking to improve efficiency, reduce waste, and enhance customer satisfaction. As lean thinking evolves, companies leverage new technologies like artificial intelligence and the Internet of Things to collect real-time data and make smarter decisions throughout production.

Lean manufacturing principles will play an even greater role in driving sustainability and environmental responsibility. By minimizing waste and optimizing resource use, companies can reduce their environmental footprint while maintaining high performance and customer satisfaction.

Embracing lean principles and fostering a culture of continuous improvement will be essential for organizations to stay competitive in a rapidly changing world. By committing to lean manufacturing, companies can unlock new levels of efficiency, innovation, and long-term success.

Final CTA Section

If you’re looking to apply Lean Manufacturing principles in a practical, hands-on way, the Lean Management Course is the ideal resource. This course is based on over 25 years of direct experience implementing Lean and 5S in real European manufacturing environments. You’ll gain access to practical tools, real-world case studies, and actionable strategies to implement Lean successfully in your organization.

🎓 You can preview a whole lesson to experience the depth and clarity of our training before enrolling.

In addition, we invite you to explore the GET LEAN Simulation Game, a unique interactive training tool that allows teams to practice Lean principles in a realistic, risk-free environment. It is perfect for leaders and teams that want to build Lean competencies through simulation-based learning.

Now is the time to turn Lean theory into measurable results. Join us on this journey toward excellence.