Lean Mgmt: The Ultimate Guide to Streamlining Processes and Maximizing Customer Value

Introduction

In an age where market conditions shift rapidly and customer expectations evolve faster than ever, organizations must continuously adapt to survive and thrive. Enter lean mgmt—a strategic and operational approach that empowers businesses to maximize customer value, minimize waste, and enhance efficiency. Understanding the customer’s perspective and responding to customer demands are central to lean management, ensuring that processes are aligned with what customers truly value.

Derived from the renowned Toyota Production System, lean management (or lean mgmt) has become a universal tool applicable far beyond manufacturing. The lean concept serves as the foundation for these practices, providing a guiding philosophy, management method, and cultural shift.

🎓 Want to turn lean theory into practical, repeatable action? Enroll now in our expert-led Lean Management course packed with actionable strategies built on 25+ years of implementation experience.

The History and Evolution of Lean Management

The story of lean management begins with the groundbreaking Toyota Production System (TPS), developed in post-war Japan during the late 1940s. Facing resource constraints, Toyota’s leaders—notably Taiichi Ohno and Shigeo Shingo—pioneered a production system that focused on eliminating waste, streamlining processes, and delivering maximum value to the customer. This approach significantly improved productivity, cost efficiency, and cycle times, setting a new standard for manufacturing excellence.

As lean management principles evolved, they were distilled into the Five Lean Principles, which guide organizations in defining value, mapping the value stream, creating flow, establishing pull, and pursuing perfection. Tools like value stream mapping and the pull system became central to identifying inefficiencies and aligning production with customer demand.

Over the decades, the lean philosophy has expanded far beyond its automotive roots. Today, industries ranging from healthcare to software development and engineering leverage lean principles to drive continuous improvement and eliminate waste in their key processes. Influential thinkers such as W. Edwards Deming further shaped the lean management system, emphasizing quality, learning, and the relentless pursuit of better ways to work.

The evolution of lean management is a testament to its adaptability and effectiveness. By focusing on continuous improvement, value stream mapping, and the core principles of lean management, organizations worldwide have achieved significant improvements in efficiency, quality, and customer satisfaction, proving that the lean production system is as relevant today as ever.

What Is Lean Mgmt?

Lean mgmt—short for lean management—is a structured methodology aimed at streamlining processes, eliminating waste, and delivering the highest possible value for the customer. It integrates both philosophy and tools to achieve a continuous improvement process across the entire organization. Lean methodology is a management approach focused on delivering value and optimizing workflows, utilizing specific lean methods to implement improvements. These efforts are guided by lean management principles, which provide the framework for optimizing processes and enhancing organizational performance. The lean principle of focusing on value and eliminating waste is central to this approach.

While lean mgmt originated in manufacturing, particularly within the automotive industry, its core principles are relevant to sectors as diverse as healthcare, software development, logistics, and service industries.

The Five Lean Principles

At the heart of lean mgmt are the five principles of lean:

- Define Value – Understand what the customer truly values.

- Map the Value Stream—Identify and remove waste across the production and work processes, analyzing each step to optimize efficiency.

- Create Flow – Ensure a smooth flow of materials and information.

- Establish Pull—Respond to actual customer demands, not forecasts, to better align production with customer needs.

- Pursue Perfection – Foster a culture of continuous improvement.

These principles are the bedrock of all lean initiatives, forming the core of any lean management system.

🛠️ Explore these concepts in depth in our Lean Management course, tailored to leaders and frontline managers.

Lean Mgmt in Practice: From Concept to Execution

Value Stream Mapping

A central technique in lean management is value stream mapping, which analyzes the current and future states of production systems to expose and eliminate pure waste. By visualizing all actions and personnel involved in the process, value stream mapping offers visibility into the company’s workflow, from raw materials to the finished product. This comprehensive view of the company’s workflow helps identify inefficiencies and eliminate non-value-adding steps, supporting the lean principle of continuous improvement.

Pull System Implementation

In contrast to traditional push production, lean mgmt relies on a pull system based on customer demand. Demand-driven production is central to this approach, supporting just-in-time practices by reducing inventory and ensuring production responds directly to actual customer needs. This just-in-time approach limits inventory, reduces lead times, and boosts flexibility.

Want to understand how pull systems improve responsiveness and productivity? It’s all inside our Lean Management course.

Creating Continuous Flow

A continuous workflow ensures that tasks proceed seamlessly from one stage to the next, reducing bottlenecks and improving throughput. By minimizing delays and optimizing each step, continuous flow helps enhance efficiency in both production and knowledge work environments. This is particularly vital in both the production line and knowledge work environments.

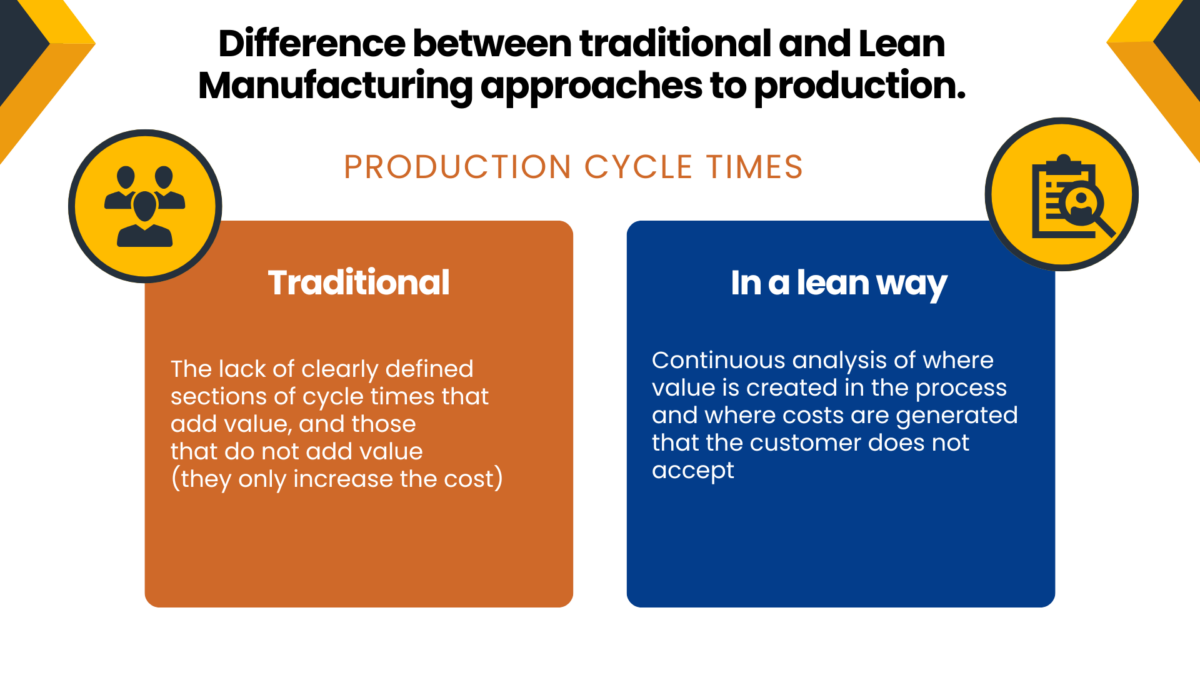

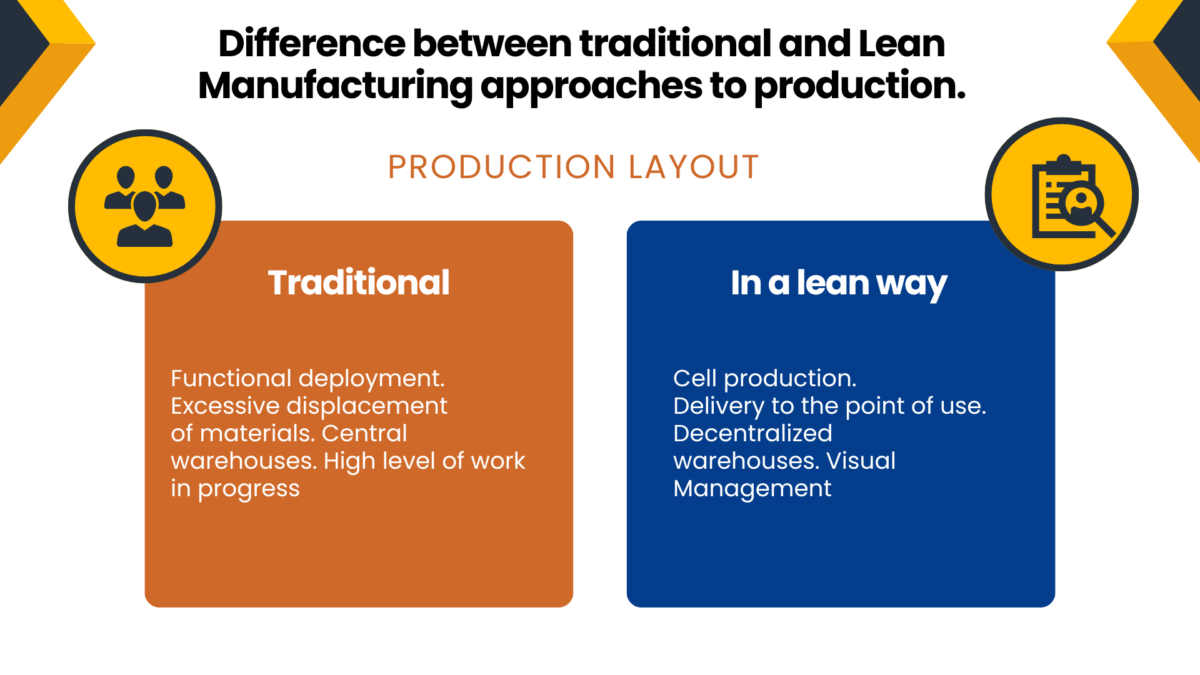

Lean Mgmt vs. Traditional Management

| Traditional Management | Lean Mgmt |

|---|---|

| Focuses on output volume | Focuses on value creation |

| Uses top-down decision-making | Encourages team-based ownership |

| Operates in silos | Promotes cross-functional collaboration |

| Reactive to problems | Proactively eliminates waste |

Break away from outdated management approaches. Get practical, modern training in our Teamwork and Leadership course.

Key Benefits of Lean Mgmt

Implementing lean mgmt results in:

- Cost efficiency, cost reduction, and improved cost effectiveness

- Shortened product development cycles

- Reduced excess inventory and unnecessary movement

- Enhanced productivity and better service quality

- Higher customer satisfaction, increased customer satisfaction through value creation and continuous improvement, and increased employee engagement

These benefits help organizations remain competitive by improving quality, reducing costs, and better meeting customer needs.

Lean Mgmt Tools and Techniques

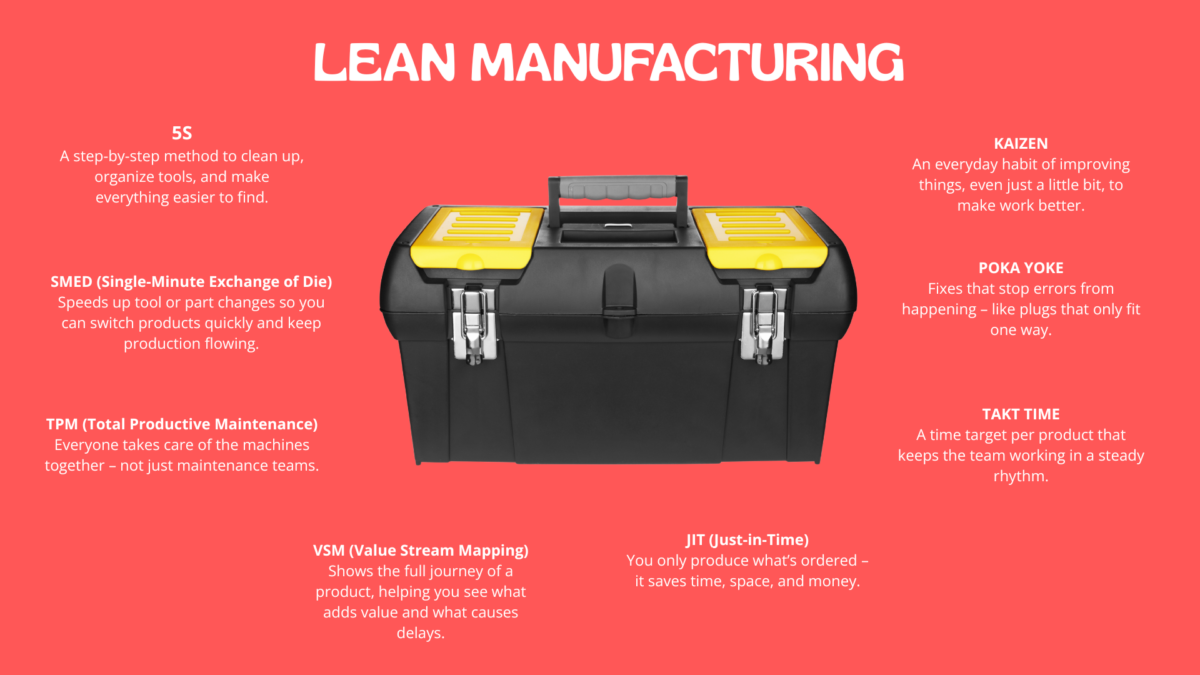

Lean mgmt utilizes a toolbox of proven methods to drive performance improvement—these are known as lean methods:

- 5S (Sort, Set in Order, Shine, Standardize, Sustain) for workplace organization

- Kanban boards for visualizing tasks

- Standard Work to reduce variation in internal processes

- Root Cause Analysis for problem-solving

- Kaizen for minor, daily improvements

- Stream mapping and just-in-time production

Master practical lean tools in our detailed 5S Workplace Organization course.

The Role of Lean Thinking in Lean Mgmt

Lean thinking emphasizes minimizing waste, maximizing value, and adopting a lean philosophy at every organizational level. It encourages decision-making from the customer’s perspective, focusing on value creation rather than just efficiency.

🎯 Strengthen your lean mindset with our Continuous Improvement course.

Building a Lean Culture

Creating a sustainable lean culture goes beyond implementing tools and techniques—it requires embedding the lean philosophy into the very fabric of your organization. At its core, a lean culture empowers every employee to contribute to continuous improvement and focus relentlessly on delivering customer value.

To build a lean culture, organizations must foster an environment where questioning the status quo is encouraged and where employees feel safe identifying problems and proposing solutions. This means celebrating small wins, rewarding innovative thinking, and making continuous improvement a shared responsibility across all levels.

Leadership plays a pivotal role in shaping lean culture. Leaders must model the behaviors they wish to see, communicate a clear vision, and provide the resources and support needed for teams to succeed. Open communication, transparency, and a commitment to ongoing learning are essential.

By investing in training, setting clear goals, and nurturing a spirit of collaboration, organizations can create a culture that drives significant improvements in efficiency and productivity and enhances customer value and employee engagement. A strong lean culture ultimately becomes a powerful engine for sustained competitive advantage.

Real-World Applications of Lean Mgmt

Manufacturing

Organizations apply lean principles to improve the manufacturing process, minimize waste, and align production with demand in lean manufacturing.

Healthcare

Hospitals use lean management to reduce patient wait times, optimize staff workflows, and increase the quality of care while improving cost effectiveness in healthcare settings.

Software Development

Tech companies incorporate lean principles to shorten product development cycles and deliver faster iterations using lean startup methodologies.

Logistics & Supply Chain

Lean improves routing, warehousing, and inventory efficiency by reducing delays and aligning with actual demand.

🎮 Experience how lean management works across departments in our Lean Simulation Game. It’s hands-on learning at its best.

Lean Mgmt Metrics: Measuring What Matters

Lean mgmt encourages the use of key metrics to track progress:

- Lead time

- On-time delivery

- Inventory turnover

- First-time quality rate

- Customer satisfaction index

- Cycle time

Solve operational problems with data-driven methods in our Problem Solving course.

Training and Development for Lean Success

Achieving lean success hinges on equipping your workforce with the right skills and mindset. Comprehensive training and development programs are essential for embedding lean principles and ensuring employees can confidently apply lean tools such as value stream mapping, root cause analysis, and stream mapping.

Practical lean training goes beyond technical know-how. It should also develop soft skills like communication, teamwork, and leadership, which are critical for driving lean initiatives and fostering a culture of continuous improvement. Hands-on learning opportunities—such as real-world projects and cross-functional improvement teams—allow employees to practice what they’ve learned and see the impact of their efforts firsthand.

Coaching and mentoring further support the continuous improvement, providing guidance and encouragement as employees tackle new challenges. By investing in ongoing development, organizations build a knowledgeable, agile workforce capable of delivering significant improvements in performance and sustaining lean initiatives over the long term.

Challenges in Implementing Lean Mgmt

While lean mgmt is highly effective, it’s not without hurdles:

- Resistance to cultural change

- Misunderstanding lean as a cost-cutting tool only

- Inconsistent leadership commitment

- Poor training and communication

Overcoming these requires:

- Leadership alignment

- Transparent communication

- Ongoing coaching and education

- Demonstrating quick wins

Common Mistakes in Lean Mgmt (and How to Avoid Them)

While lean management offers a proven path to significant improvements, many organizations stumble by making avoidable mistakes. One common pitfall is failing to engage employees at all levels, which can lead to resistance and missed opportunities for improvement. Another is neglecting to set clear, measurable goals and objectives, making tracking progress or celebrating success difficult.

Insufficient training and development can also undermine lean efforts, leaving teams ill-equipped to implement lean principles or use tools like value stream mapping effectively. Rushing into lean initiatives without adequate planning or treating lean as a one-time project rather than an ongoing journey often results in disappointing outcomes.

Organizations should adopt a structured, systematic approach to lean management to avoid these mistakes. Start by thoroughly understanding your current state, define a compelling vision for the future, and establish strong governance with clear roles and responsibilities. Provide continuous support, celebrate quick wins, and ensure that lean becomes an integral part of your management system. By steering clear of these common missteps, you’ll set your organization up for lasting success and unlock the full potential of lean management.

Sustaining Lean Mgmt Long-Term

Long-term lean success depends on embedding its principles into your management system:

- Make lean part of the strategy, not a side project

- Establish standard operating procedures

- Empower frontline teams

- Celebrate improvements

Build sustainable systems with our expert-designed Lean Management course, based on decades of field experience.

Conclusion: Why Lean Mgmt Matters

Lean mgmt offers a robust framework for businesses aiming to become more competitive, agile, and customer-focused. Its five lean principles, value-based thinking, and strong tools provide an enduring strategy for maximizing customer value while reducing costs and inefficiencies.

Whether in manufacturing, services, healthcare, or IT, the lean management concept will empower your teams, streamline operations, and help you consistently deliver what your customers value most.

🎓 Ready to master Lean Mgmt in real-world settings?

Join our Lean Management course with practical insights from over 25 years of experience implementing lean across industries.

👉 Preview a lesson today and see why it’s one of the most actionable and experience-based lean training programs available.

And if you’re more of a hands-on learner, check out our Lean Simulation Game—a fun and immersive way to experience lean in action.

Also, explore these expert courses:

Lean mgmt isn’t just a strategy—it’s a culture. Start building yours today.