Lean Operations Principles: Mastering Efficiency Through Lean Thinking

Why Lean Manufacturing Still Matters

Lean manufacturing is more than a set of tools—it’s a comprehensive management philosophy focused on delivering maximum customer value while minimizing waste. It shapes how organizations think, make decisions, and optimize their operations. Lean manufacturing principles are especially relevant today as companies seek to navigate global competition, volatile customer demand, and pressure to innovate.

This article explores the core principles of lean manufacturing, highlights practical applications, and introduces supporting systems that drive continuous improvement across the entire supply chain. Whether you’re a plant manager, operations director, or improvement specialist, this guide will give you a structured framework for understanding and effectively implementing lean thinking.

Understanding the Principles of Lean Manufacturing

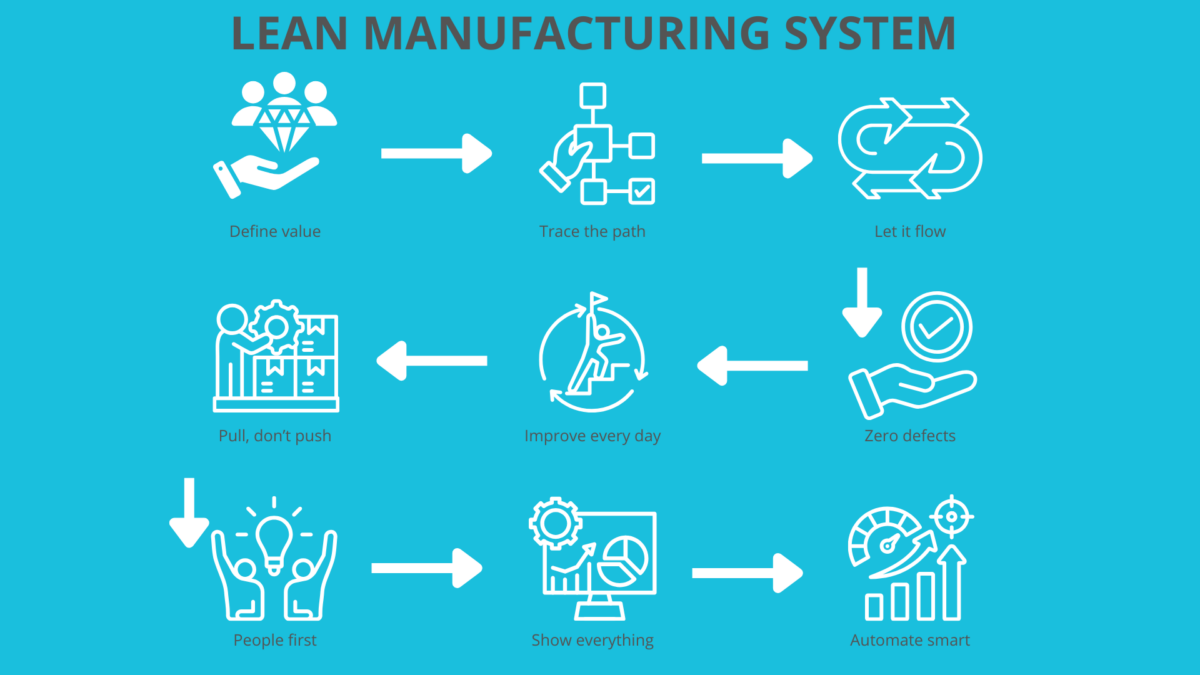

At the core of lean manufacturing are five guiding principles that serve as the foundation for operational transformation:

- Define Value – from the customer’s perspective.

- Map the Value Stream – to identify and eliminate waste.

- Create Flow – by ensuring smooth transitions in the production process.

- Establish Pull – to produce only what is needed, when needed.

- Seek Perfection – through a culture of continuous improvement.

Originally derived from the Toyota Production System, these principles are universal across industries, from automotive manufacturing to healthcare and logistics. When properly implemented, they promote efficient processes, reduce costs, and improve customer satisfaction.

For a structured introduction, check out our Lean Management Course that explains how to build a lean enterprise using these principles.

Define Value: The Voice of the Customer

The journey toward lean manufacturing begins with defining value from the customer’s perspective. Value refers to any activity or process the customer is willing to pay for—everything else is considered waste.

Companies must focus on what truly matters: delivering products or services that meet customer expectations regarding functionality, cost, and delivery time. This principle of lean urges organizations to align every task, role, and decision with customer value.

Example

In a packaging line, value might be defined as consistent output without damage or defects. Extra handling, redundant checks, or unnecessary movement of goods adds no value and should be eliminated.

To understand value better, explore our Effective Problem Solving Course, which helps identify root causes that undermine value creation.

Map the Value Stream: Visualizing the Process

Value stream mapping documents every step in the production process, from handling raw materials to delivering the finished product. This allows organizations to:

- Identify non-value-adding steps

- Detect process inefficiencies

- Improve the flow of materials and information

This tool is essential for understanding lean manufacturing as it exposes bottlenecks, rework loops, and waiting times.

Value stream mapping can help manufacturers visualize waste and effectively determine where to apply lean tools. It also forms the foundation for systematically implementing lean manufacturing.

Create Flow: Achieving Smooth Production

Once waste is removed, the following principle creates a flow. This involves designing a production process where tasks move seamlessly from one step to another without interruptions.

A smooth flow reduces lead time, lowers excess inventory, and increases responsiveness to customer demand. Techniques such as work cells, just-in-time delivery, and layout optimization foster continuous flow.

Creating flow also requires cross-training employees and establishing standard lean production models that promote predictable, repeatable outcomes.

A well-organized workplace is key to this. Our 5S Workplace Organization Course offers practical strategies for creating environments that support flow.

Establish Pull: Producing Based on Demand

In traditional manufacturing, companies push products through the system based on forecasts. Lean turns this model on its head with the pull system, where production is driven by actual customer demand.

Instead of building extensive inventories, lean systems only produce what’s needed. This:

- Reduces inventory holding costs

- Avoids overproduction

- Enhances agility

Tools like Kanban cards and visual cues allow for timely replenishment, ensuring that materials and products flow smoothly through the system.

Seek Perfection: The Culture of Continuous Improvement

The final principle is about driving continuous improvement. Lean organizations never stop looking to improve efficiency, quality, and customer satisfaction. This requires a cultural commitment known as kaizen—small, incremental changes that lead to significant results over time.

It also involves empowering employees, encouraging feedback, and measuring performance through KPIs.

To build this mindset, we recommend our Continuous Improvement Course, which includes templates, frameworks, and exercises for building a continuous improvement culture.

The 8 Wastes of Lean Manufacturing

Understanding the principles of lean manufacturing also means knowing what to eliminate. Lean identifies eight types of waste (muda) that add no value to the customer:

- Overproduction – making more than what is needed

- Waiting – idle time in workers or machines

- Transport – unnecessary movement of goods

- Overprocessing – doing more than required

- Inventory – holding excess raw materials or finished goods

- Motion – unnecessary movements by employees

- Defects – errors that require rework or scrap

- Underutilized Talent – not leveraging people’s skills and ideas

These wastes exist across the manufacturing process; eliminating them is a key step in improving operating performance.

Supporting Tools for Lean Implementation

To make lean principles actionable, organizations deploy various lean manufacturing tools, such as:

- Standard Work – for repeatable best practices

- Poka-Yoke – error-proofing mechanisms

- Takt Time – aligning production speed with demand

- Visual Management – using signs and symbols to guide work

- 5S – for clean, organized workspaces

These tools help streamline the production line and support consistent, high-quality outputs.

Looking for hands-on experience? Try our GET LEAN Simulation Game, an interactive learning tool that brings lean methods to life.

Benefits of Lean for Manufacturing Plants

By applying the principles of lean manufacturing, companies can:

- Reduce costs through waste elimination

- Improve efficiency across the production systems

- Enhance customer satisfaction through consistent delivery

- Shorten lead times and increase throughput

- Create a more engaged and motivated workforce

These benefits are not limited to large corporations. Small and medium-sized manufacturing plants can also implement lean to drive sustainable growth and competitiveness.

Industry Applications Beyond Automotive

Though lean originated in the automotive industry, notably the Toyota Motor Corporation, its application spans many sectors:

- Healthcare – streamline patient flow

- Logistics – optimize the entire supply chain

- Construction – reduce rework and delays

- Pharma – ensure quality and compliance

Regardless of the field, the key principles remain the same: eliminate waste, deliver customer value, and pursue operational excellence.

Common Challenges in Implementing Lean

Despite its advantages, implementing lean isn’t without challenges:

- Cultural resistance

- Lack of training or lean leadership

- Poor understanding of lean philosophy

- Misalignment between departments

Success requires not only technical tools but also a change in mindset. Leaders must communicate the “why” behind lean and engage employees at all levels.

To build team alignment, explore our Teamwork and Leadership Course.

Final Thoughts: Transforming with Lean Principles

Lean manufacturing principles offer a robust framework for rethinking how value is created, waste is eliminated, and organizations can adapt to changing demands. They are not just techniques for the shop floor—they are strategic enablers that influence your entire business model.

🎓 Ready to go beyond theory and build fundamental skills? Start your journey with the Lean Management Course.

🧰 Want to practice lean tools in action? Experience our GET LEAN Simulation Game.

📘 Need practical guidance on organizing your workspace for better flow? Enroll in our 5S Workplace Organization Course.

Let lean thinking become your competitive advantage. With the correct principles, tools, and mindset, you can transform your manufacturing operations and build a culture of excellence.