Lean Principles in Manufacturing: Building Efficiency, Quality, and Value in the Modern Factory

Understanding the Core of Lean Thinking

In today’s competitive manufacturing landscape, businesses are under continuous pressure to deliver high-quality products faster, at lower cost, and with greater adaptability. At the heart of meeting these demands is adopting Lean principles in manufacturing. Lean is more than just a methodology—it is a lean philosophy, a comprehensive management approach rooted in efficiency, waste reduction, and delivering customer value at every stage of the manufacturing process. Understanding lean manufacturing is essential for grasping its core principles, origins, and the significant benefits it brings to operational efficiency and continuous improvement.

Originally derived from the Toyota Production System, Lean has evolved into a globally recognized lean production system that revolutionizes the delivery of goods and services. Early efficiency techniques such as scientific management influenced Lean principles, notably Frederick Winslow Taylor’s 1911 work, ‘Principles of Scientific Management,’ which laid the groundwork for later developments by figures like Shigeo Shingo and Taiichi Ohno. The term lean manufacturing was adopted to distinguish these modern practices from earlier concepts such as JIT, highlighting its strategic significance and widespread adoption in manufacturing efficiency. This article offers an in-depth guide to Lean principles in manufacturing, their implementation, and how they drive measurable performance improvements.

What Are Lean Principles in Manufacturing?

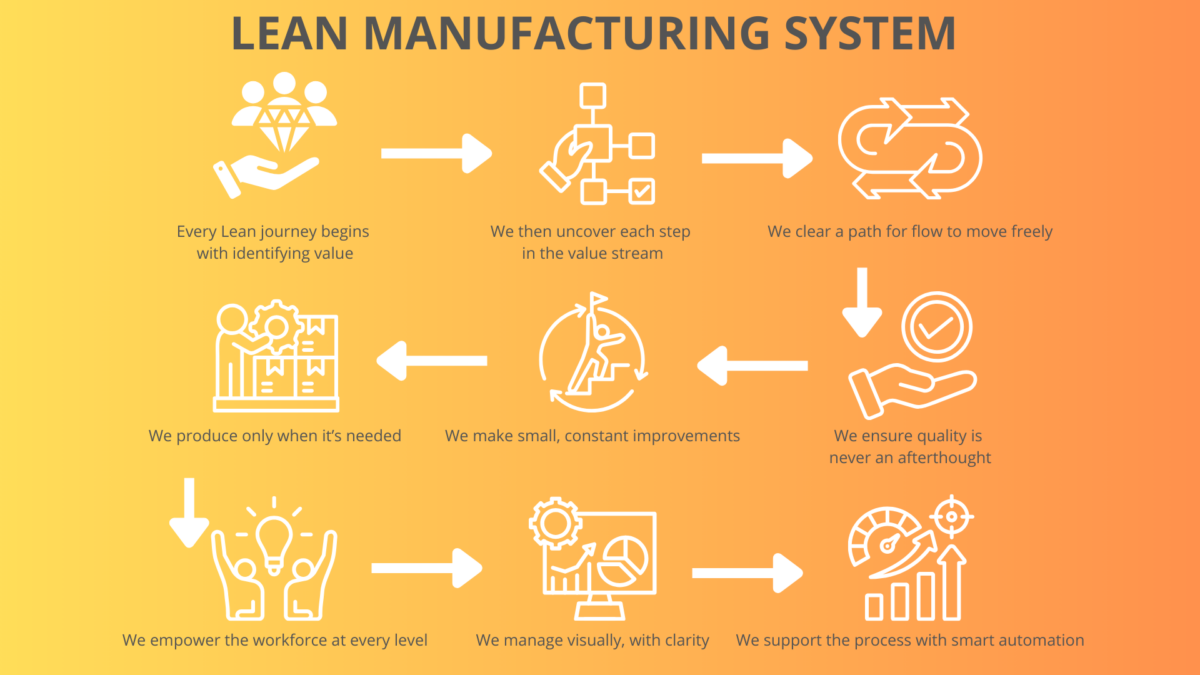

Lean principles in manufacturing are built upon the five principles of lean manufacturing: defining value from the customer’s perspective, mapping the value stream, creating flow, establishing pull, and pursuing perfection. These five principles are underpinned by core lean concepts, which focus on improving efficiency, streamlining production processes, and enhancing customer value and satisfaction.

- Define Value from the Customer’s Perspective

- Map the Value Stream

- Create Flow

- Establish Pull

- Pursue Perfection

While these five principles provide a strong foundation, no standard lean production model exists. Instead, organizations adapt lean concepts and principles to fit their unique needs, recognizing that lean is more a culture and set of guiding ideas than a rigid methodology.

These principles guide companies in implementing lean strategies, supporting process optimization, and continuous improvement across the supply chain.

Define Value: Start with the Customer

Defining value requires businesses to shift their focus to what the customer wants. In Lean thinking, value is defined as any activity that transforms raw materials into a product the customer is willing to pay for.

Anything that doesn’t add value is considered waste and should be eliminated. By banishing waste from production processes, companies can maximize value delivery and create wealth through improved efficiency and profitability. This includes overproduction, waiting, unnecessary movement, excess inventory, and more.

Understanding value from the customer’s perspective is the first step toward building efficient processes that support customer satisfaction.

🎓 Want to learn how to identify what your customer truly values? Enroll in our Lean Management Course to master real-world Lean implementation.

Map the Value Stream: Visualize the Whole Process

Value stream mapping is a critical Lean tool used to analyze the current state of the production process and design a more efficient future state. This method reveals where unnecessary processes, bottlenecks, or delays occur. Value stream mapping can be applied to assess the complete life cycle of a product, from design to disposal, by examining all production processes involved at each stage.

Mapping the value stream helps teams understand how each step contributes (or doesn’t) to the end goal. Understanding the value chain is essential for identifying improvement opportunities across all stages of production and delivery. It is the foundation for identifying improvement opportunities and making informed decisions about where to apply Lean methods.

Learn how to diagnose and resolve bottlenecks in our Problem-Solving Course.

Create Flow: Removing Barriers and Delays

After mapping the process, the following principle is creating a flow. This means organizing the manufacturing operations so that products can move smoothly from one value-adding activity to another without interruption. Achieving a smooth flow helps identify existing quality problems and naturally reduces waste by providing a system-wide perspective, which enhances overall process efficiency.

Key tactics include:

- Reorganizing layouts for cellular manufacturing

- Implementing standard lean production models

- Reducing batch sizes

- Ensuring equipment availability and worker readiness

The goal is to optimize productive processes to organize manufacturing operations for maximum efficiency and minimal waste.

Creating a continuous flow reduces lead time and enhances manufacturing efficiency and responsiveness to changes in customer demand.

To build a workplace that supports flow, check out our 5S Workplace Organization Course.

Establish Pull: Responding to Real Demand

In traditional push systems, production is based on forecasts, often leading to overproduction and excess inventory. This approach relies on predetermined production targets rather than actual demand. Lean, in contrast, advocates for a pull system where each step in the process signals when the next is needed, based on actual customer orders.

Implementing a pull system reduces waste, cuts down storage costs, and aligns production with real-time demand by synchronizing manufacturing with actual sales data instead of forecasts. This focus on cutting waste helps avoid inefficiencies and unnecessary inventory, making production more responsive and efficient. Techniques like just-in-time delivery and Kanban cards manage inventory and production levels efficiently.

Explore how to develop responsive systems in our Continuous Improvement Course.

Seek Perfection: Continuous Improvement Culture

The final Lean principle is to seek perfection. This is not a one-time effort but a continuous journey of refining processes, engaging employees, and pursuing innovation.

Organizations must foster a continuous improvement culture where employees can suggest improvements. This includes applying tools like:

- Kaizen

- A3 problem-solving

- Root cause analysis

- PDCA cycles

Leadership plays a crucial role in creating this culture by modeling Lean behaviors, recognizing contributions, and ensuring consistency.

💡 Want to drive long-term excellence in your organization? Discover the practical side of Lean leadership in our Teamwork and Leadership Course.

The Role of the Toyota Production System

The Toyota Production System (TPS) is the original model from which Lean was developed. TPS was created by Toyota Motor Corporation, which began as a textile company before transitioning into automobile manufacturing. TPS focused on eliminating waste, standardizing work, and empowering employees.

Two pillars of TPS are:

- Just-in-Time: Producing only what is needed, when, and in the required amount.

- Jidoka: Building quality into the process by stopping production when a defect is found.

In its early years, Toyota Motor Corporation faced significant challenges with poor quality castings in engine production. Addressing these issues led to key process improvements and the evolution of TPS.

TPS is a powerful demonstration of lean principles in manufacturing that have been applied consistently over decades. Research shows that plant technology has less impact on lean manufacturing success than factors like workforce training and supply chain support. It serves as a benchmark for implementing lean manufacturing successfully.

Lean Tools that Enable the Principles

While principles provide the framework, Lean tools operationalize the philosophy. Some of the most common and effective lean manufacturing tools include:

- 5S: Workplace organization

- Kanban: Inventory control and scheduling

- Value Stream Mapping: Process analysis

- Poka-Yoke: Error proofing

- Takt Time: Production rhythm

- Standard Work: Documented best practices

- Inventory Management: Optimizing stock levels and reducing waste

These tools must be applied in alignment with the five key principles and adapted to your specific production systems.

Real-World Benefits of Lean Implementation

Manufacturers that embrace Lean report dramatic performance improvements across multiple dimensions:

- 30-50% reduction in lead times

- 20-40% inventory reduction

- 30-60% improvement in productivity

- Higher employee morale and customer satisfaction

Lean manufacturing plants consistently achieve higher productivity and quality levels than traditional facilities, thanks to their focus on continuous improvement and workforce flexibility. Superior operating performance in these plants is driven not only by lean practices but also by the limited influence of plant technology, the critical role of a skilled workforce, and high-quality product designs. A high-performance supplier network supports lean implementation, reduces risks, and ensures efficient, high-quality production.

The ultimate goal is not just to reduce costs, but to build systems that can flow smoothly, respond to market changes, and create sustainable value.

Common Challenges and How to Overcome Them

While Lean offers transformative benefits, companies often face hurdles in their Lean transformation:

- Inadequate training

- Resistance to change

- Lack of leadership support

- Misaligned metrics

Addressing these challenges requires:

- Leadership commitment

- Clear communication

- Ongoing education and coaching

- Aligning Lean with business goals

Sector Applications of Lean Manufacturing

Lean isn’t just for automotive industry giants. Other industrial nations have adopted lean principles beyond Japan, spreading across various countries and industries to drive efficiency and global competitiveness. It has been successfully applied in:

- Healthcare: Improving patient flow

- Aerospace: Reducing rework

- Pharmaceuticals: Ensuring compliance

- Food and Beverage: Enhancing freshness and reducing waste

- Construction: Scheduling and resource management

Each sector adapts Lean based on its unique needs, but Lean manufacturing principles remain consistent.

Case Example: Applying Lean in a Mid-Sized Manufacturing Plant

A European manufacturer of industrial components faced long lead times, high scrap rates, and low on-time delivery. By applying lean principles in manufacturing, including:

- Mapping the production process

- Introducing pull systems

- Training frontline supervisors in Lean

…they reduced lead times by 45%, improved delivery reliability by 30%, and boosted employee engagement.

One-of-a-Kind Learning Opportunity

🎓 Ready to implement Lean principles in your plant the right way? Lean Management Course offers a practical blueprint based on over 25 years of experience. It combines proven strategies with real-world insights tailored for European manufacturers.

📽️ Preview a whole lesson to see the clarity and practicality before enrolling.

🎮 Looking for an experiential Lean training? Don’t miss our GET LEAN Simulation Game – a fun and effective way to build Lean competencies with your team.