Top Lean Production Benefits: Boost Efficiency and Reduce Waste

Curious about lean production benefits? Lean production helps businesses cut costs, eliminate waste, and improve efficiency. Read on to learn the key benefits.

Key Takeaways

- Lean production focuses on eliminating waste and optimizing processes, significantly improving efficiency and reducing production costs.

- Implementing lean methodologies enhances quality control, resulting in higher quality products and improved customer satisfaction.

- A culture of continuous improvement and employee engagement in lean practices fosters innovation, responsiveness, and a competitive advantage in the market.

Streamlined Production Processes

One of the most compelling benefits of lean manufacturing is its focus on eliminating waste in production processes. Lean production targets common types of waste, such as:

- overproduction

- waiting

- Defects thereby improve overall efficiency. This waste reduction strategy is at the heart of lean processes, enabling businesses to optimize every aspect of their production line.

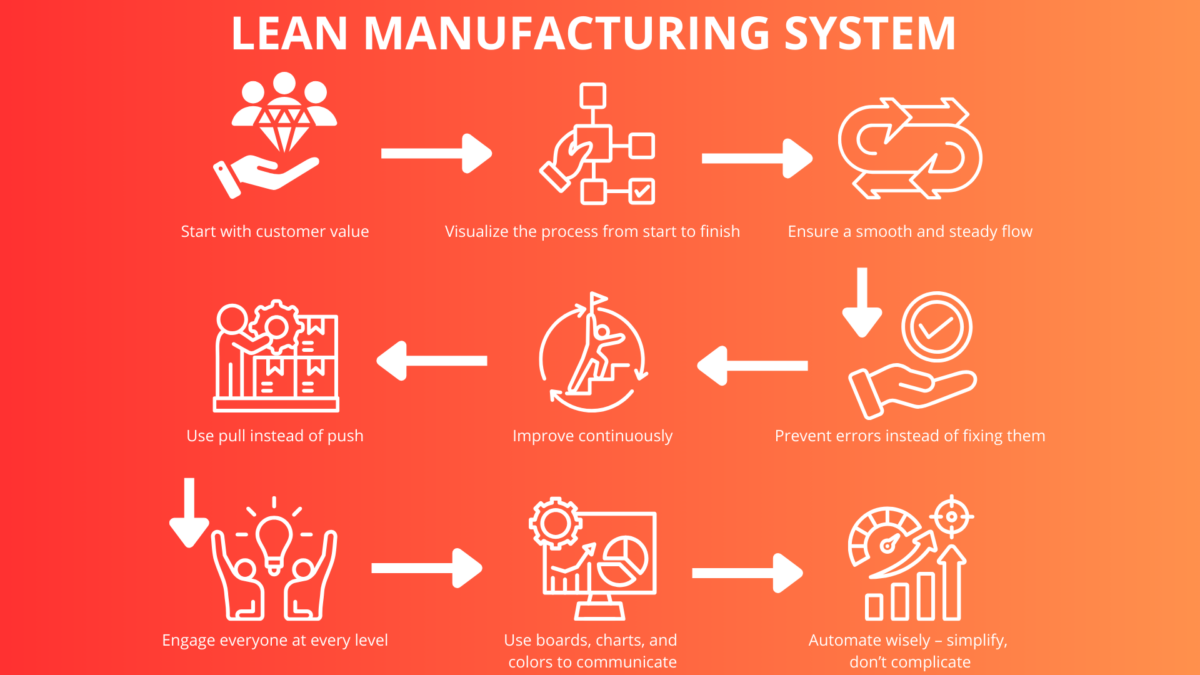

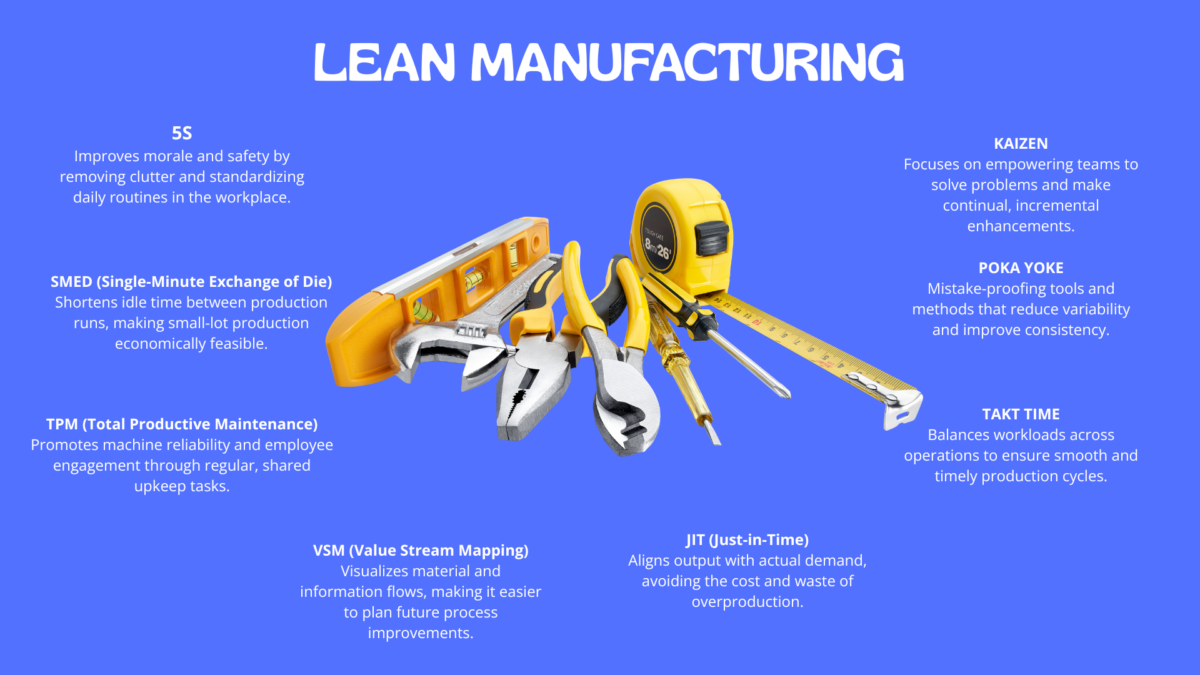

Value Stream Mapping (VSM) is a powerful tool used in lean manufacturing to identify inefficiencies and opportunities for improvement. Mapping the entire production process, from raw materials to finished products, allows businesses to identify waste areas and take corrective actions. This method not only helps eliminate waste but also continuously improves processes.

Creating a continuous flow and establishing a pull system are fundamental lean production principles. A pull system, activated by customer orders, ensures that production processes align with customer demand, thereby avoiding overproduction and improving workflow. This alignment with customer demand is crucial for minimizing waste and enhancing operational efficiency, as demonstrated by the Toyota production system. Adhering to these principles is essential to creating flow.

Lean production seeks to foster a culture of continuous improvement, where employees are encouraged to regularly assess and adjust their workflows to enhance efficiency. This culture helps optimize processes and discover new ways to streamline production and reduce waste. Focusing on continuous improvement keeps businesses competitive and responsive to market changes under lean manufacturing processes, contributing to a lean enterprise that embraces lean thinking.

If you’re eager to explore these methodologies in greater depth, the Lean Management course provides in-depth guidance on applying lean principles in practice.

Reduced Production Costs

Implementing lean manufacturing techniques can significantly reduce costs by minimizing waste and enhancing productivity. Lean production emphasizes the creation of efficient systems that reduce unnecessary expenses, leading to lower production costs. Cellular manufacturing eliminates non-value-added activities, helping businesses achieve substantial savings on operating costs while also aiming to minimize expenses.

One key strategy in lean manufacturing is the use of just-in-time (JIT) techniques, which help reduce costs tied to excess inventory and unnecessary transport. When required, producing only what is needed allows businesses to lower inventory holding costs and minimize waste. This approach reduces production costs and improves cash flow and operational efficiency.

Lean methodologies also contribute to cost savings by enhancing product quality and reducing the costs associated with defects and rework. Focusing on quality improvement and eliminating waste enables businesses to deliver high-quality products at competitive prices. This dual focus on quality and cost efficiency is a hallmark of lean manufacturing and lean techniques, allowing enterprises to achieve manufacturing excellence and maintain a competitive edge.

Enhanced Quality Control

Quality control is a cornerstone of lean manufacturing, emphasizing addressing defects early in production. Focusing on reducing defects in lean manufacturing helps:

- Maintain consistent product quality, which is crucial for customer trust and satisfaction.

- Ensure early detection of defects so issues are resolved before they escalate.

- This results in higher quality products and lower production costs.

Kaizen, a key component of lean manufacturing, encourages continuous improvement and early detection of defects by engaging all employees in the improvement process. This collaborative approach fosters a culture of quality and accountability, where everyone is responsible for maintaining high standards. Visual management tools further enhance the ability to detect quality issues swiftly, ensuring that problems are addressed promptly.

Poka-Yoke techniques are designed to prevent manufacturing defects. They achieve this by eliminating the root causes of human error. These error-proofing methods are intended to avoid mistakes before they occur, ensuring the production process runs smoothly and efficiently. Integrating real-time quality monitoring and frequent testing in lean manufacturing maintains product standards more effectively, resulting in higher quality products and improved customer satisfaction.

Faster Lead Times

Lean principles can significantly reduce lead times, with some companies achieving up to 50% reductions. Creating a continuous flow in production and optimizing material flow under lean production enhances responsiveness to customer demands. This reduction in lead times is crucial for businesses aiming to meet customer expectations and stay competitive.

A continuous flow and pull system are essential components of lean management that contribute to faster lead times. Aligning production processes with actual customer demand ensures products are produced only when needed, reducing waiting times and improving workflow under lean practices. This alignment enhances operational efficiency and leads to streamlined processes for quicker order processing.

Implementing a Just-In-Time inventory strategy further reduces lead times by improving delivery accuracy and minimizing excess inventory levels. This approach ensures that materials and products are available exactly when needed, reducing delays and enhancing customer satisfaction. Faster response times to customer demands contribute to a positive customer experience, making lean production a valuable business strategy.

For individuals seeking to deepen their understanding of these approaches, the Lean Management course thoroughly explores lean principles and how to apply them effectively.

Increased Employee Engagement

Lean management transforms traditional roles, enabling employees to become active problem-solvers rather than task executors. Implementing suggestion systems and Kaizen workshops empowers employees to identify and resolve issues directly affecting their work. This employee empowerment fosters a commitment to continuous improvement and enhances employee motivation and satisfaction.

Kaizen promotes a culture where employees actively identify and solve problems. Involving employees in the improvement process increases their investment and motivation in lean production. This higher level of engagement leads to greater accountability and a more positive workplace culture, which attracts skilled employees and strengthens the company’s overall market position.

Recognizing and celebrating employee contributions further enhances morale and satisfaction in the workplace. Successful lean transformations require aligning HR practices with lean behaviors to cultivate a supportive environment for employees. This alignment ensures employees are motivated to continuously improve processes and contribute ideas, leading to better performance and quality products.

Improved Customer Satisfaction

Lean management focuses on creating value for the customer by increasing quality, which is essential for customer satisfaction. Higher-quality products delivered faster result in improved customer satisfaction and loyalty. Enhancing customer service and reducing waiting times under lean management fosters positive customer experiences and strengthens the business’s competitive position.

A continuous flow in lean production helps improve response time to customer demands, ensuring that products are delivered promptly. This improved responsiveness to customer needs enhances satisfaction and increases customer loyalty and recommendations. Lean production techniques lead to faster product delivery, a key customer benefit.

Focusing on actual demand and continuously improving processes ensures businesses can meet and exceed customer expectations under lean production. This customer-focused approach is central to lean manufacturing, enabling companies to deliver high-quality products and services that drive customer satisfaction and competitive advantage.

Competitive Advantage

Lean practices enable businesses to improve their processes, making them more effective and efficient, which helps them gain market share. Reducing costs through efficient systems under lean production significantly contributes to a strong competitive advantage. Continuous improvement of processes under lean management positions businesses to innovate effectively and respond to market demands.

Lean management increases agility and responsiveness to market changes, allowing companies to adapt quickly and maintain a competitive edge. Enhancing operational efficiency, reducing costs, and improving overall quality enable companies to adopt lean practices and an approach to achieve a strong competitive edge. This improved competitiveness enables businesses to meet customer demands better and stay ahead of the competition.

Cost reduction and quality improvement achieved through lean practices make businesses more attractive to customers and investors. Delivering high-quality products at competitive prices helps companies build a loyal customer base and secure a dominant market position.

Safer Work Environment

Lean production organizes the workspace and eliminates hazards, contributing to a safer work environment. Implementing lean principles can reduce workplace hazards by streamlining processes and removing unnecessary items. A clutter-free workspace enhances productivity and minimizes the risk of accidents.

Employee involvement in decision-making fosters a safety culture and encourages prompt identification and reporting of safety issues. Engaging employees in safety protocols and improvement initiatives ensures safety is a shared responsibility under lean production. This collaborative approach leads to a more vigilant and proactive workforce, further enhancing workplace safety.

Standardizing safety protocols within lean processes helps create a consistent risk management approach. This standardization ensures that all employees are aware of and adhere to safety guidelines, reducing the likelihood of accidents and injuries. A safer work environment protects employees and improves overall operational efficiency and performance.

Environmental Benefits

Lean practices contribute to environmental sustainability, giving companies a competitive edge as consumers increasingly favor green businesses. Lean principles enhance environmental management by identifying waste streams, which helps reduce material and energy waste. The Just-In-Time (JIT) production method significantly curtails resource consumption and waste generation, aligning with sustainable manufacturing goals.

Implementing lean methodologies can significantly reduce greenhouse gas emissions through optimized energy management. A well-structured workspace under the 5S Lean principle enhances resource efficiency and reduces environmental footprints. Continuous improvement strategies, known as Kaizen, are crucial in minimizing energy use and fostering eco-friendly practices to improve efficiency.

Focusing on waste reduction and resource efficiency benefits the environment while enhancing operational efficiency and reducing costs under lean production. This dual focus on sustainability and efficiency makes lean manufacturing an attractive option for businesses aiming to achieve economic and environmental goals, including cutting waste and utilizing fewer resources.

Continuous Improvement Culture

Lean manufacturing fosters a culture of continuous improvement, which is essential for sustaining high-quality outputs. Kaizen focuses on manageable, small changes rather than drastic overhauls, facilitating sustainable improvements. This approach encourages businesses to continually assess and enhance their operations from the customer’s viewpoint.

Key elements for effective Kaizen initiatives include:

- Setting clear, measurable goals to track progress.

- Develop a continuous improvement committee to maintain momentum.

- Using Lean tools, like Value Stream Mapping, to identify process inefficiencies.

Incorporating Kaizen into Lean practices ensures that process optimization is continually reinforced. This continuous improvement culture enhances operational efficiency and drives innovation and responsiveness to market changes. Fostering a culture of continuous improvement and incremental improvements helps businesses achieve sustained success and remain competitive in the ever-evolving market.

If you want to master the practical application of these methodologies, the Lean Management course offers a complete overview of implementing lean principles in real-world scenarios.

Summary

The benefits of lean production are vast and impactful, ranging from reduced production costs to improved customer satisfaction and environmental sustainability. By focusing on eliminating waste, enhancing quality, and fostering a culture of continuous improvement, lean manufacturing transforms businesses into efficient, competitive, and customer-focused entities.

Embracing lean production is a strategic advantage and a commitment to excellence and innovation. As businesses continue to navigate the challenges of the modern market, lean principles offer a proven path to sustained success and operational excellence. The journey towards lean production is continuous learning and improvement, paving the way for a brighter, more efficient future.

Frequently Asked Questions

What is lean manufacturing?

Lean manufacturing is a production methodology that reduces waste and enhances productivity by targeting inefficiencies and non-value-adding activities. Ultimately, it seeks to optimize production processes for greater efficiency.

How does lean production reduce costs?

Lean production effectively reduces costs by eliminating waste, improving workflow efficiency, and employing Just-In-Time techniques to decrease inventory expenses. This approach enhances productivity, leading to significant savings on operating costs.

What is Value Stream Mapping?

Value Stream Mapping (VSM) is an essential lean management tool that visualizes the flow of materials and information needed to deliver a product to the customer. It effectively highlights inefficiencies and waste in the production process, enabling organizations to implement targeted improvements for enhanced efficiency.

How does lean manufacturing improve quality control?

Lean manufacturing enhances quality control by prioritizing early defect detection and involving employees in continual improvement efforts. It utilizes tools like Kaizen and Poka-Yoke to minimize errors, improve product quality, and increase customer satisfaction.

What are the environmental benefits of lean production?

Lean production significantly enhances environmental sustainability by minimizing waste and resource consumption and promoting eco-friendly practices through continuous improvement. This approach leads to a more efficient and environmentally responsible production process.