Mastering the Lean Production Process: Boosting Efficiency and Reducing Waste

The lean production process improves efficiency and reduces waste in manufacturing. Aligning production with customer value helps companies streamline operations and adapt quickly to market changes. This article covers the core principles of the lean output and practical steps for implementation.

Key Takeaways

- Lean manufacturing aims to enhance efficiency and reduce waste through defining customer value, employing continuous improvement, and integrating comprehensive production systems.

- The five fundamental principles of lean manufacturing—value, value stream, flow, pull, and perfection—guide companies in achieving operational excellence.

- Identifying and eliminating eight types of waste—defects, overproduction, waiting, non-utilized talent, transportation, inventory, motion, and excessive processing—is crucial for improving manufacturing efficiency.

Ready to advance your Lean skills? The Lean Management course provides a comprehensive guide to mastering Lean principles, tools, and strategies for process optimization and waste elimination.

Understanding Lean Production Process

Lean manufacturing aims to enhance efficiency and reduce waste within production processes. The primary goal is to identify and implement lean manufacturing to eliminate waste while improving quality and production times. This methodology, rooted in lean manufacturing, the Toyota Production System (TPS), has revolutionized manufacturing across the globe, helping companies stay competitive by improving operational efficiency and attracting customers.

Central to lean manufacturing is the definition of value. This value is determined from the customer’s perspective based on their willingness to pay for a product or service. Identifying customer value is the first critical step for successful lean implementation. Understanding what the customer truly values allows companies to streamline their processes and deliver that value efficiently.

Kaizen, a fundamental aspect of lean production, emphasizes continuous improvement and waste elimination. It involves all employees, from top management to the shop floor, in the ongoing effort to make incremental improvements. This constant improvement mindset is crucial for competitiveness in a rapidly changing market.

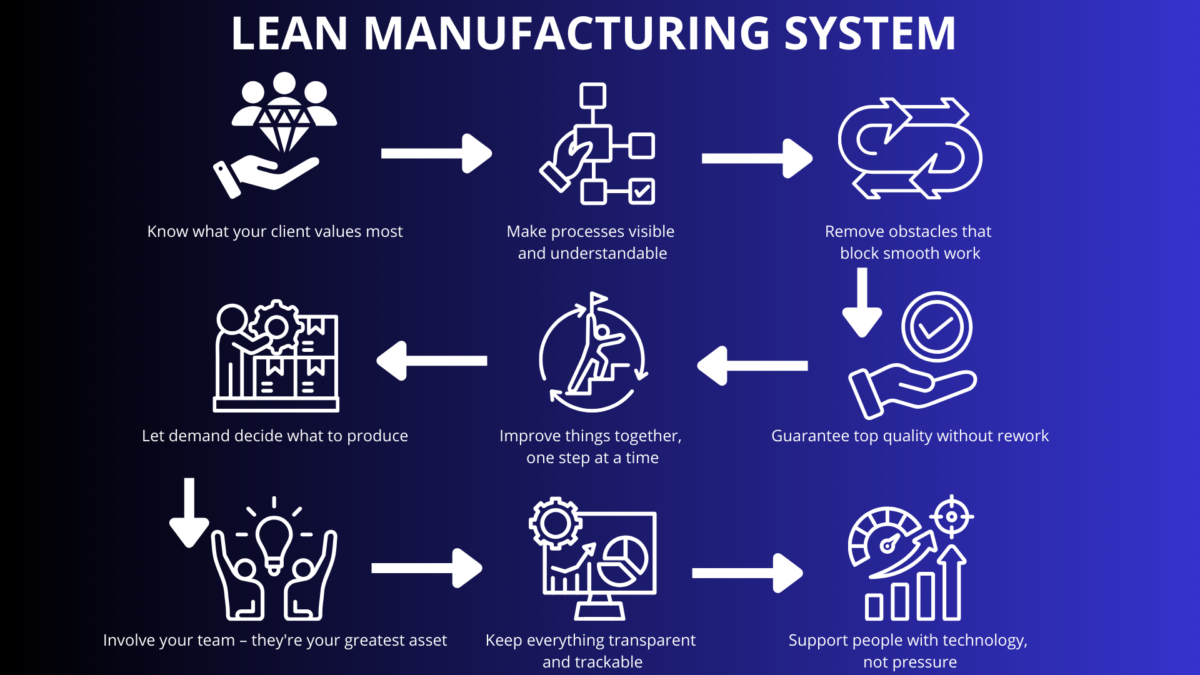

Lean manufacturing is not just a set of tools or techniques; it’s a comprehensive lean manufacturing system that integrates various aspects of production and management, including lean manufacturing systems and lean methods. It encompasses everything from inventory management and production scheduling to quality control and employee engagement. Adopting lean principles enables companies to create a cohesive, efficient, and adaptable production system that responds swiftly to customer demands and market changes, all within a lean manufacturing process, highlighting the benefits of lean manufacturing techniques.

In essence, lean manufacturing creates more value for customers with fewer resources. Lean manufacturing systematically identifies and eliminates waste, optimizes processes, and continually improves operations. As we delve deeper into the key principles of lean manufacturing, you’ll see how this methodology can transform your production processes, reduce costs, and enhance overall efficiency.

Key Principles of Lean Manufacturing

Lean manufacturing is built around five fundamental principles:

- Value

- Value stream

- Flow

- Pull

- Perfection

Following the lean principle, these core principles guide the lean production system and are essential for achieving operational excellence.

The first principle, value, is defined from the customer’s perspective. It’s based on what the customer is willing to pay for a product or service. Understanding and prioritizing customer value allows companies to direct their efforts toward activities that provide this value.

The second principle, the value stream, encompasses all actions required to design, create, and deliver a product or service to customers. Value stream mapping is a crucial tool in this process, enabling companies to visualize and analyze the flow of materials and information across their production processes. Identifying and eliminating waste within the value stream enables companies to optimize production processes and improve efficiency.

The third principle, creating flow, involves removing functional barriers to ensure a smooth and uninterrupted production process. This means optimizing process steps to perform only value-adding activities at each stage. A continuous flow reduces lead times, minimizes inventory, and improves overall efficiency.

The fourth principle, pull, means that actual customer demand rather than forecasts drives production. In a pull system:

- Work is commenced only when there is demand from the following process or customer.

- This approach helps in reducing inventory and waste.

- It improves responsiveness to customer needs.

The final principle, perfection, is about striving for continuous improvement in all aspects of the production process. It involves regularly assessing and refining methods to eliminate waste and continually enhance value. This relentless pursuit of perfection ensures that companies remain competitive and responsive to market changes.

Together, these five principles form the foundation of lean manufacturing. Companies can apply lean principles to create more efficient and effective production systems, delivering greater value to customers while minimizing waste and improving quality.

Explore the Lean Management course for a step-by-step framework on applying Lean Manufacturing principles across your business. It’s packed with actionable insights and real-world case studies to help you make Lean a reality in your organization.

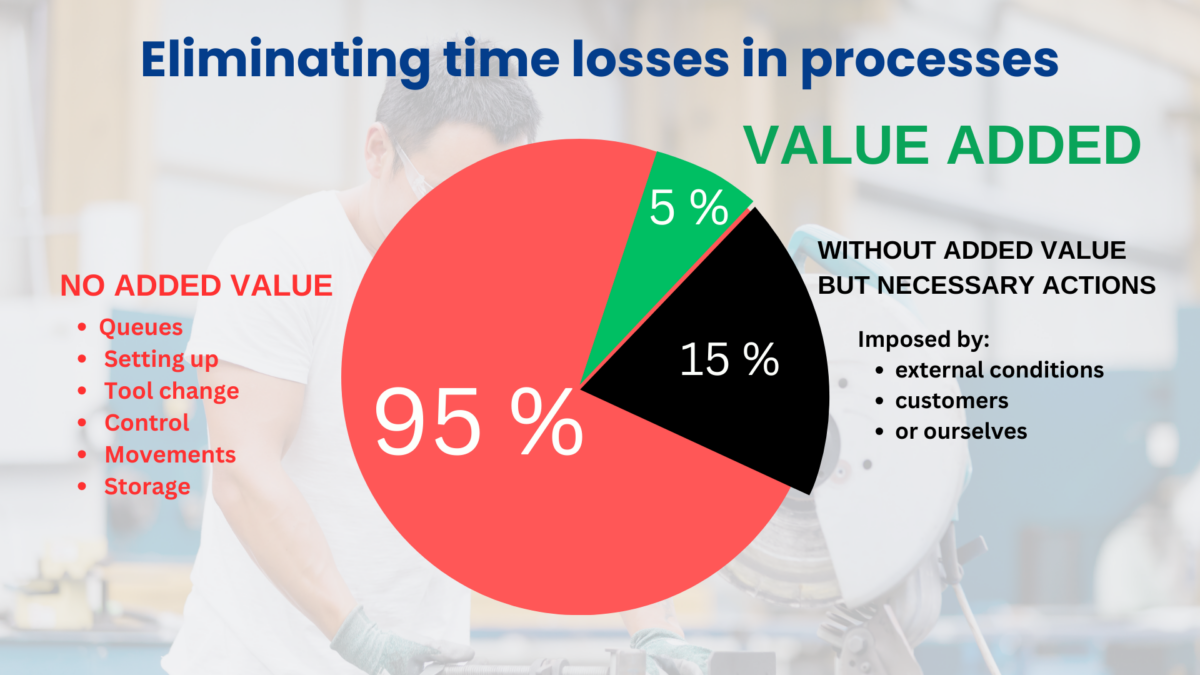

Identifying and Eliminating Waste

Lean manufacturing identifies eight distinct types of waste:

- Defects

- Overproduction

- Waiting

- Non-utilized talent

- Transportation

- Inventory

- Motion

- Excessive processing

Identifying waste is crucial for improving efficiency.

These wastes are any expenses or efforts that do not contribute to transforming raw materials into a sellable product.

Defects and wastes in production include:

- Defects: Errors in production that lead to rework and scrap, which are costly and time-consuming.

- Overproduction: Results in excess inventory that ties up resources and space.

- Waiting: Delays caused by waiting for materials, information, or equipment, leading to inefficiencies.

- Unused talent: Underutilization of employees’ skills and potential, which could otherwise contribute to production improvement.

Types of waste include:

- Transportation waste is the unnecessary transportation of materials between processes, which adds no value and increases the risk of damage or loss.

- Excess inventory is a common waste that incurs holding costs and may arise from overproduction or inadequate forecasting.

- Motion waste is unnecessary motion by people, such as searching for tools or materials, that does not add value to the product.

- Excessive processing: doing more work than necessary, often resulting from poor process design or inadequate training.

Eliminating waste in the supply chain is crucial to supporting continuous flow and just-in-time deliveries. By reducing waste, companies can enhance efficiency, improve quality, and reduce costs. Visual tools like value stream mapping can help highlight delays and excess inventory, making identifying and addressing waste easier.

In lean manufacturing, the goal is to create a production process where every step adds value and waste is minimized. By reducing waste, companies can improve efficiency, reduce costs, and enhance customer satisfaction. As we move forward, we will explore how manufacturing resource planning, value stream mapping, and creating flow in production processes can further support these goals.

Value Stream Mapping

Value stream mapping is a powerful tool for visualizing and analyzing the flow of materials and information across production processes. Originating from the Toyota Production System, it helps companies identify and eliminate waste, optimize the value stream, reduce lead times, and improve quality and flexibility.

Creating a value stream map involves:

- Using software or a whiteboard, you can create flowcharts of all necessary processes, information, and inventory.

- This visual representation shows the entire production process, from raw materials to finished products.

- Identifying areas where waste occurs.

Value stream mapping has significant benefits. A clear visual of the production process helps companies identify bottlenecks, redundancies, and inefficiencies. This, in turn, allows for targeted improvements that enhance flow, reduce lead times, and improve overall efficiency.

General Electric is a prime example of a company that has successfully used value stream mapping to identify process value and potential waste areas in its operations. By applying this tool, GE was able to streamline its production processes, reduce waste, and improve overall performance.

Value stream mapping is an essential component of lean manufacturing. It provides the insights needed to optimize production processes and ensure that every step adds value. As we continue our exploration of lean manufacturing, we’ll delve into the importance of creating flow in production processes and how it supports lean principles.

Creating Flow in Production Processes

Continuous flow in manufacturing systems is a production approach that ensures products are produced continuously and uninterrupted. This principle is fundamental to the lean production system, as it minimizes inventory, reduces lead times, improves efficiency, and eliminates waiting times.

Creating flow in the value stream involves removing barriers and ensuring that production steps proceed without interruptions or delays. This seamless movement of materials and information is essential for a smooth production process, reducing cycle times and enhancing overall efficiency.

One-piece flow is a key concept in creating flow. It allows each item to proceed to the next stage immediately upon completion, reducing cycle times and improving responsiveness to customer demand. Visual management tools, such as Kanban boards, help maintain flow by ensuring that necessary information and resources are easily accessible.

To create flow, it’s essential to:

- Analyze and rearrange production processes for optimal order.

- Reorganize the production line.

- Standardize work processes.

- Implement visual management tools.

By doing so, companies can ensure a continuous and efficient flow of production lines, enhance overall performance within a high-performance supplier network in the automotive industry, and reduce costs.

Creating flow in production processes is essential for reducing lead times and enhancing efficiency. Focusing on continuous flow allows companies to optimize the production cycle, minimize waste, and improve performance.

Next, we will explore the implementation of a pull system and its benefits in lean manufacturing.

Implementing a Pull System

In lean manufacturing, the pull system minimizes inventory and goods production based on customer demand. This approach ensures that production is driven by customer demand rather than forecasts, reducing the risk of overproduction and excess inventory.

To implement a pull system, lean systems often employ tools like Takt time and Kanban to better align production with actual demand. Takt time helps determine the pace at which products must be produced to meet customer demand. At the same time, Kanban boards provide a visual representation of the production process, ensuring that work only commences when there is demand from the following process or customer.

The benefits of a pull system are significant. Producing only what is needed, when it is required, significantly reduces inventory costs and waste. This approach enhances flow efficiency and optimizes resource use, ensuring production processes align with customer needs.

A well-functioning pull system improves responsiveness to changes in customer demand, allowing for more agile production capabilities. By implementing a pull system, companies can enhance efficiency, reduce waste, and improve customer satisfaction.

As we move forward, we will explore the various tools used in lean manufacturing and how they support the implementation of lean principles.

If you’re looking for a practical and proven way to implement Lean Manufacturing in your daily work, the Lean Management course has you covered. Learn how to apply Lean tools, improve processes, and drive long-term success.

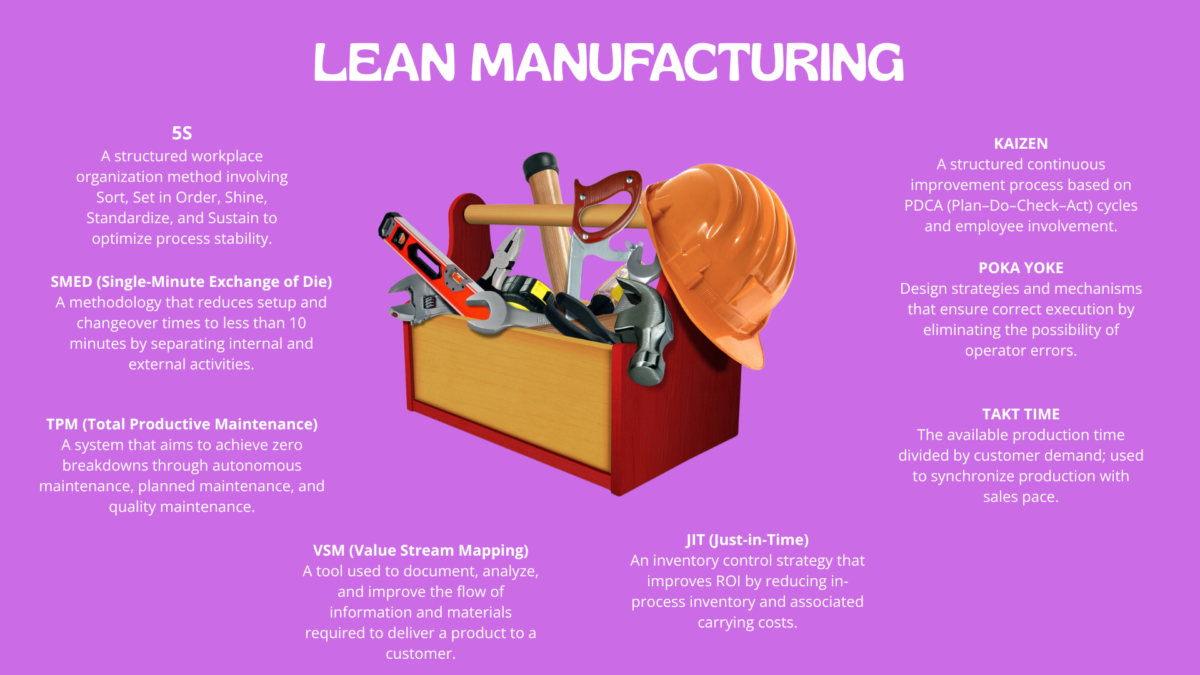

Lean Manufacturing Tools

Lean manufacturing employs various tools and techniques to optimize production processes and eliminate waste. These tools are essential for implementing lean principles and achieving operational excellence.

Kanban is one of the most widely used tools in lean manufacturing. It manages inventory and production, ensuring that materials and products are only produced or moved when needed. This visual management tool helps maintain a smooth production flow and reduce excess inventory.

The 5S methodology is another key tool in lean manufacturing and scientific management. It fosters an organized workplace by establishing standards for:

- Sorting

- Organizing

- Cleaning

- Maintaining order by implementing 5S, companies can create a more efficient and productive work environment, reduce waste, and improve overall performance.

The Single-Minute Exchange of Die (SMED) approach aims to minimize setup times to enhance flexibility and responsiveness in production. By reducing the time to switch from one production run to another, companies can improve their agility and reduce downtime.

Total Productive Maintenance (TPM) emphasizes proactive maintenance to maximize equipment uptime and involves operators in maintenance. Ensuring well-maintained and efficiently operating equipment helps companies reduce downtime and improve productivity.

These lean manufacturing tools are essential for implementing lean principles and achieving operational excellence. By utilizing these lean tools, companies can optimize their production processes, reduce waste, and improve efficiency.

Continuous Improvement (Kaizen)

Continuous improvement, or Kaizen, is a fundamental aspect of lean manufacturing. It involves the ongoing assessment and refinement of processes to enhance operational efficiency. This principle encourages every employee to strive for better performance and quality, fostering a culture of continuous improvement.

Kaizen focuses on involving all employees in incremental improvements. Encouraging staff to find ways to improve processes enhances flow and efficiency. This involvement also fosters a sense of ownership and accountability among employees, further driving the continuous improvement process.

In lean manufacturing:

- Small incremental changes are preferred over large sweeping ones.

- These small changes are easier to implement.

- They can quickly lead to significant improvements in the production process, including just-in-time manufacturing.

- Improvements from Kaizen initiatives are often implemented quickly, frequently within 72 hours.

Improvements must be implemented through specific designs, procedures, and processes to be effective. This ensures that the changes are integrated into the production process and contribute to long-term efficiency, quality, and manufacturing improvements.

Continuous improvement is an ongoing process that requires regular assessment and refinement. Fostering a culture of constant improvement enhances production processes, reduces waste, and improves performance.

Next, we will explore real-world case studies that showcase the successful implementation of lean production.

Case Studies: Lean Production in Action

Many companies have successfully implemented lean production processes, significantly improving efficiency and cost savings. These case studies highlight the transformative power of lean manufacturing and provide valuable insights into its practical application, including various manufacturing processes.

Herman Miller, a renowned furniture manufacturer, is a prime example of a company that has reaped the benefits of lean manufacturing. Adopting lean initiatives allowed Herman Miller to improve productivity and enhance its resilience against economic downturns. The company’s commitment to continuous improvement and waste reduction has resulted in a more efficient and resilient production system.

SunPower, a leading solar technology company, redefined its mission and operations by combining lean principles with circular economy concepts. This innovative approach allowed SunPower to optimize its production processes, reduce waste, and improve efficiency. The company’s lean journey underscores the importance of integrating lean principles with sustainability initiatives.

Canada Post applied lean techniques to its postal operations, improving efficiency in traditional batch-processing tasks. Streamlining processes and eliminating waste enabled Canada Post to enhance operational efficiency and deliver better service. This case study demonstrates the versatility of lean manufacturing principles across different industries.

Thrustmaster of Texas, a manufacturer of marine propulsion products, successfully utilized lean practices to achieve sustainable improvements in a short timeframe. Focusing on waste reduction and process optimization allowed Thrustmaster of Texas to enhance production efficiency and improve product quality.

FedEx also experienced significant benefits from lean practices. A major check at FedEx was reduced from over 32,000 man-hours to about 21,500 through lean practices, saving millions. This case study highlights the potential for substantial cost savings and efficiency improvements by implementing lean principles.

These real-world examples illustrate the power of lean manufacturing to transform production processes, reduce waste, and enhance overall efficiency. As we move forward, we will explore how to implement lean production in your organization, drawing on the insights and lessons from these case studies.

Implementing Lean Production in Your Organization

Implementing lean production in your organization requires careful planning and execution. One key factor for success is staff buy-in, as it ensures support for the methodology and helps address actual problems. Successful lean organizations understand lean principles and actively engage employees in lean thinking.

Continuous monitoring and follow-up activities are essential to maintaining the improvements from Kaizen events over time. This regular assessment helps apply continual improvements with employee support, ensuring the changes are sustained and refined over time.

Technologies such as:

- Production monitoring

- Machine monitoring

- IoT

- Cloud computing can support the implementation of lean manufacturing principles. These tools facilitate better communication, coordination, and real-time data analysis, enabling companies to optimize their production processes and reduce waste.

Value stream mapping and the Kanban system are crucial for effective lean implementation. Value stream mapping facilitates better communication and collaboration among team members, while the Kanban system improves communication and coordination, reducing lead times and minimizing waste. Companies must consider the lean production tools and desired goals for effective implementation.

However, challenges such as employee pushback and a lack of management understanding can hinder the success of lean management. Addressing these challenges requires strong leadership, clear communication, and a commitment to fostering a culture of continuous improvement. Following these steps and leveraging the right tools enables companies to successfully implement lean production and achieve significant efficiency and quality improvements.

Summary

Lean manufacturing offers a comprehensive approach to optimizing production processes, reducing waste, and improving overall efficiency. By understanding and applying the core principles of lean manufacturing—value, value stream, flow, pull, and perfection—companies can create more efficient and effective production systems. Tools like value stream mapping, Kanban, 5S, SMED, and TPM are essential for implementing lean principles and achieving operational excellence.

The journey towards lean production is continuous, requiring ongoing assessment, refinement, and employee engagement. Real-world case studies from companies like Herman Miller, SunPower, Canada Post, Thrustmaster of Texas, and FedEx demonstrate the transformative power of lean manufacturing. By adopting lean principles and fostering a culture of continuous improvement, companies can enhance their competitiveness, reduce costs, and deliver greater value to customers.

If you want to learn to apply Lean principles effectively in your organization, the Lean Management course is the ideal place to start. This course offers clear guidance, practical examples, and tools to help you implement Lean Manufacturing in a structured and impactful way.

Watch a sample Lean Manufacturing implementation course lesson and see what it offers.

Try the GET LEAN Simulation Game for a hands-on, interactive learning experience. This game-based training helps teams understand and apply Lean Manufacturing tools in real-world scenarios, making Lean concepts fun and practical.

Frequently Asked Questions

What is lean manufacturing?

Lean manufacturing is a methodology focused on improving efficiency and minimizing waste by eliminating non-value-adding activities. It ultimately enhances customer value and promotes continuous improvement.

What are the key principles of lean manufacturing?

The key principles of lean manufacturing are value, value stream, flow, pull, and perfection. These principles are vital for enhancing operational efficiency and ensuring optimal production processes.

How can value stream mapping help in lean manufacturing?

Value stream mapping is essential in lean manufacturing. It enables organizations to visualize and analyze the flow of materials and information, helping to identify and eliminate waste. This ultimately leads to optimized processes, reduced lead times, and enhanced quality and flexibility.

What are the benefits of implementing a pull system in lean manufacturing?

Implementing a pull system in lean manufacturing significantly reduces inventory and waste by aligning production with customer demand. This enhances flow efficiency and responsiveness, ultimately optimizing resource utilization.

What are some standard tools used in lean manufacturing?

Standard tools utilized in lean manufacturing are Kanban, 5S methodology, Single-Minute Exchange of Die (SMED), and Total Productive Maintenance (TPM). These tools streamline inventory management, enhance workplace organization, reduce setup times, and optimize equipment efficiency.