Lean Production Training: Empowering Excellence Across Every Manufacturing Process

In a global economy of rapid change, rising customer expectations, and intense competition, lean production training has become a critical foundation for any organization committed to operational excellence. Lean production training is also key to achieving manufacturing excellence, enabling organizations to implement advanced and innovative practices. Increasingly, artificial intelligence is being integrated into lean production training to drive innovation, automation, and operational efficiency. Whether you’re in automotive, electronics, pharmaceuticals, or food manufacturing, Lean offers a universal framework for eliminating waste, optimizing flow, and delivering superior value.

This comprehensive guide examines how lean production training fosters continuous improvement, enhances customer satisfaction, and cultivates future-ready teams equipped to lead transformation throughout the entire value stream. Embarking on lean production training marks the beginning of your lean journey, focused on continuous improvement and sustained organizational growth.

What Is Lean Production Training?

Lean production training refers to structured educational programs that teach employees to apply lean principles to improve manufacturing processes’ efficiency, quality, and responsiveness. These programs encompass various methodologies, including Lean, Six Sigma, and Kaizen, offering a comprehensive approach to operational excellence. Training emphasizes implementing lean principles to eliminate waste and improve productivity. These programs combine theory with practice, empowering individuals and teams to eliminate waste, reduce variability, and build standardized, repeatable workflows.

Training can be delivered online, on-site, or hybrid, and it can include simulations, case studies, hands-on exercises, and certification assessments. Participants also have the opportunity to engage in real-world projects, applying their learning and demonstrating practical skills.

Key learning outcomes include:

- Understanding the 5 Lean principles

- Applying process analysis to identify inefficiencies

- Using lean tools like 5S, SMED, Kanban, and value stream mapping

- Focusing on waste reduction and process flow to enhance efficiency

- Improving flow across production processes

- Strengthening quality control and customer value delivery

🎓 Want to equip your team with practical Lean capabilities? Explore our Lean Management – Practical Course, designed for real-world application and long-term results.

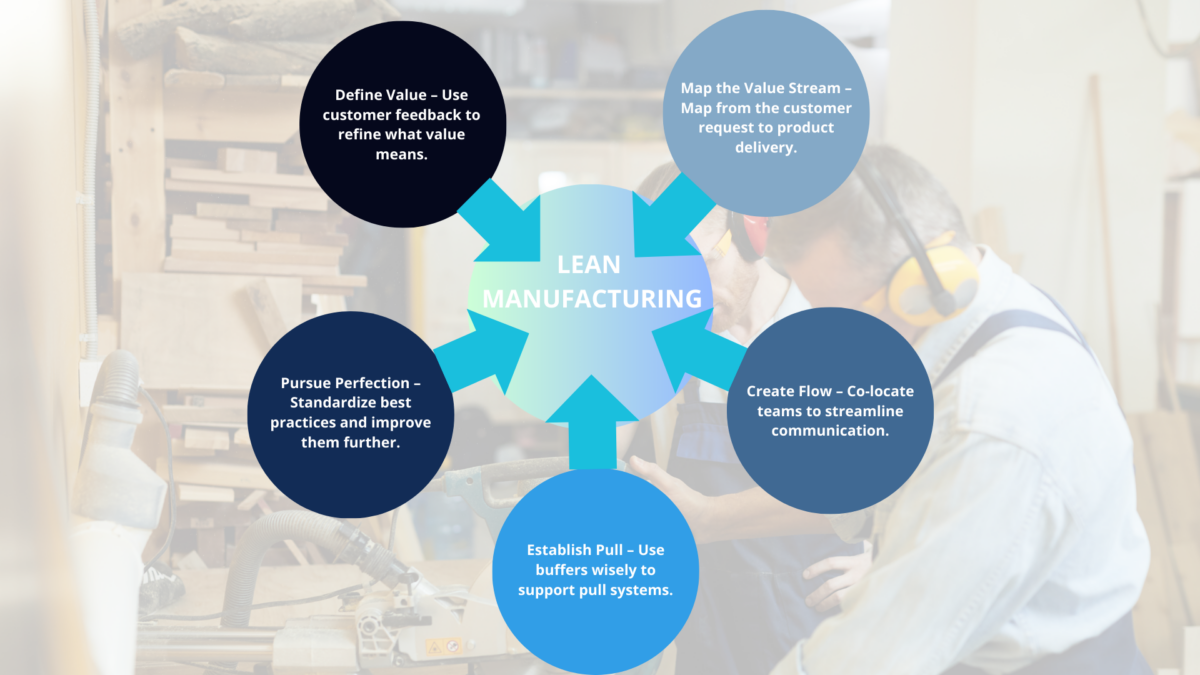

The 5 Core Lean Principles Covered in Training

At the heart of every effective lean production training program are the five core principles developed by Toyota and later adopted globally:

- Define Value – Understand what the customer truly values.

- Map the Value Stream – Identify every step in the production process, distinguishing between value-added and non-value-added activities.

- Create Flow – Ensure smooth progress of materials and information without delays or interruptions.

- Establish Pull—Make only what is needed, when it’s needed, based on actual demand. This principle is closely tied to just-in-time production, which aligns output with customer demand and reduces inventory.

- Pursue Perfection – Continuously refine processes to achieve the ideal state.

These principles are the compass for implementing lean across simple tasks and complex manufacturing processes. Reducing waste is a central goal of applying these principles, leading to greater efficiency, improved flow, and higher productivity.

Why Lean Production Training Is Essential

Lean isn’t just about learning tools and building a mindset. When training is done right, it develops internal capability that drives change long after the course ends. Companies benefit from lean production training through enhanced performance, improved operational efficiency, and a positive workplace culture. Organizations across industries can achieve proven results by implementing lean production training programs.

Benefits of lean production training include:

- Enhanced process optimization

- Improved operational efficiency throughout the company

- Increased productivity in manufacturing and organizational processes

- Training helps improve quality by standardizing processes and reducing errors

- Lean production training can reduce costs by eliminating waste and streamlining operations

- Reduced downtime and inventory

- Greater process improvement ownership by employees

- Measurable improvements in quality, cost, and delivery

- Increased customer satisfaction

- Stronger collaboration across departments and the supply chain

💡 Participants don’t just gain knowledge—they gain the confidence to lead change and deliver sustainable results.

What Does Lean Production Training Cover?

A well-designed training program touches every part of operational life, from the production floor to strategic supply chain decisions. By focusing on lean production training, organizations can drive significant improvements in product quality through enhanced process control, quality management systems, and continuous improvement initiatives.

1. Lean Manufacturing Basics

Participants gain a foundational understanding of lean manufacturing concepts, history, and impact. They learn how Toyota revolutionized production and Lean evolved into a global standard. Mastering these lean manufacturing basics sets the stage for achieving manufacturing excellence.

2. Process Analysis and Value Stream Mapping

Through process analysis, trainees learn to visualize workflows and identify bottlenecks, redundant tasks, and waste areas. Methods such as value stream mapping and root cause analysis are commonly used to identify and address process inefficiencies systematically. This builds the basis for targeted process improvements.

3. Standard Work and Flow

Learners explore how to document and standardize best practices to increase predictability and reduce variability in the production process.

4. Lean Tools

Hands-on use of lean tools like:

- 5S – Workplace organization

- Kanban – Visual inventory control

- SMED – Quick changeover techniques

- Andon Systems – Visual alerts for abnormal conditions

- Poka-Yoke – Mistake-proofing devices

These tools are not just taught but applied through simulations and workshops.

5. Quality Control and Root Cause Analysis

Effective Lean systems build quality control into every process. Training includes tools like the 5 Whys, Ishikawa diagrams, and error-proofing to address the root cause of issues.

🧠 Want to train your team in structured problem-solving? See our Problem Solving course for a hands-on approach to root cause resolution.

6. Leadership and Culture Building

Leading a Lean transformation requires more than technical skills—it demands vision, communication, and coaching.

Lean production training includes modules on lean leadership, showing managers how to:

- Conduct daily Gemba walks

- Set up visual management systems

- Empower teams through kaizen

- Lead continuous improvement efforts

🧭 Build stronger leaders with our Teamwork and Leadership course.

From Manufacturing to Supply Chain: The Broader Impact

While Lean started in manufacturing, its influence extends deep into the supply chain. Organizations benefit by extending lean principles beyond manufacturing, achieving improved processes, reduced costs, and greater efficiency throughout their supply chains. Through lean training, teams learn to:

- Reduce procurement lead times

- Align suppliers with pull systems

- Minimize inventory and logistics waste

- Improve visibility and communication

Lean promotes a culture of collaboration—internally and externally—creating a seamless link between production processes and delivery systems.

🌐 Looking to implement Lean across your supply chain? The Continuous Improvement course is ideal for integrating Lean thinking across departments and partners.

Who Should Attend Lean Production Training?

Lean is for everyone. A common mistake is limiting Lean to process engineers or managers, but real results happen when everyone participates.

| Role | Benefit |

|---|---|

| Operators | Improve workstations and eliminate frustrations |

| Supervisors | Manage flow and enable standardization |

| Engineers | Redesign layouts and implement process optimization |

| Quality Teams | Apply root cause tools and reduce variation |

| Supply Chain Staff | Reduce delivery lead times and errors |

| Executives | Align operations with business strategy |

Cross-functional training ensures alignment and momentum across the entire value stream.

Lean production training and certification can also open up new job opportunities for professionals by enhancing their career prospects and making them more competitive in the job market.

Formats: Flexibility That Fits

Lean production training is available in multiple formats to suit your team’s availability and learning style:

- Self-paced online courses

- Live virtual classes

- In-person workshops

- On-site coaching

- Simulation-based training

📦 Prefer on-demand access? The Lean Management – Practical Course is a VoD program with lifetime access—ideal for onboarding, refreshers, or full team training.

Lean Certification and Career Growth

Certification adds credibility and demonstrates commitment to excellence. Many lean production training programs offer:

- Certificates of Completion

- Lean Practitioner or Lean Leader badges

- Integration with Lean Six Sigma programs (e.g., Green Belt)

- Opportunities to participate in or lead real-world projects as part of the certification process

Certified professionals gain a competitive edge in lean management, process improvement, and supply chain management roles.

Real Outcomes from Lean Production Training

Companies that invest in lean training see measurable results:

- 20–30% improvement in OEE

- 15% reduction in inventory levels

- 50% fewer quality defects

- 30–70% reduction in setup times

- Increased employee engagement and retention

These improvements are not one-time wins—they compound as Lean becomes embedded in the culture.

Learn by Doing: Lean Simulation Game

For many learners, the best way to understand Lean is to experience it firsthand.

🎮 Try the GET LEAN Simulation Game, a fun and interactive way to apply lean tools and lead real-time production improvements in a simulated environment.

Perfect for kaizen events, onboarding programs, and cross-functional alignment.

Final Thoughts: Lean Training Builds Stronger Operations

Lean isn’t a destination—it’s a journey. And every journey starts with education. Lean production training gives your team the tools and mindset to question the status quo, improve what matters, and build sustainable systems for excellence.

If you’re serious about creating a culture of continuous improvement, delivering lasting value, and aligning operations with strategic goals, start with training.

🎓 Practical Lean Training That Delivers Results

If you’re ready to embed Lean into your team’s DNA, the Lean Management – Practical Course is your starting point.

Here’s what you’ll get:

🎥 On-demand video format for ultimate flexibility

♾️ Revisit lessons anytime with lifetime access

🧰 Download useful Lean templates and checklists

🏭 Built on 25 years of European industry know-how

👉 Scroll down to preview a free lesson

🔁 Bonus: Learn Lean by Playing

Experience Lean in action with the GET LEAN Simulation Game. Solve real problems, reduce waste, and build teamwork—perfect for any training initiative.