Lean Training Manufacturing: A Strategic Approach to Process Excellence

In the fast-paced world of modern industry, lean training in manufacturing has become essential for operational success. As organizations strive for greater efficiency, reduced costs, and improved product quality, equipping teams with lean knowledge through structured training programs is no longer optional—it’s a competitive necessity.

This article explores how lean training in manufacturing empowers professionals and companies alike to achieve excellence in production, optimize operations, and implement continuous improvement strategies that lead to long-term value.

The Importance of Lean Training in Modern Manufacturing

Lean training is not just about learning tools—it’s about transforming mindsets and embedding a culture of continuous improvement throughout the organization. Companies that invest in lean manufacturing training programs cultivate a workforce capable of identifying waste, solving problems systematically, and driving performance across every stage of the manufacturing process.

From production operators to supply chain managers and engineers, lean training enhances individual capabilities while aligning team efforts with organizational goals. With a strong emphasis on process improvement, problem solving, and value stream mapping, it equips employees with the skills and confidence needed to innovate and lead.

✅ If you’re ready to begin your lean journey, enroll in the Lean Management Course—a comprehensive, VOD-based certification program designed to help you implement real change.

What Lean Training Manufacturing Covers

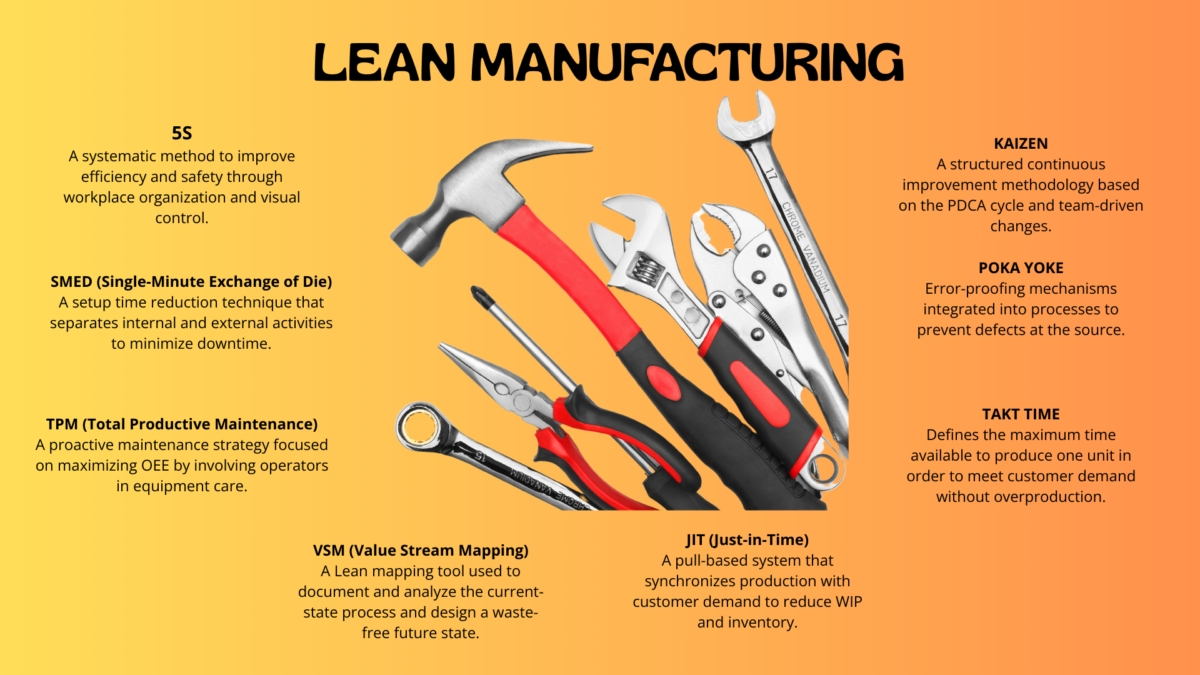

Practical lean manufacturing training includes a broad spectrum of learning content tailored to the realities of the manufacturing industry. The training covers:

- Lean principles and their practical application in real-world settings

- Mapping and analyzing production processes using value stream mapping techniques

- Identifying and eliminating waste to improve operational efficiency

- Using lean tools such as 5S, Kanban, Poka-Yoke, SMED, and visual management

- Applying lean to quality control, inventory management, and scheduling

- Learning how to reduce defects, improve lead times, and enhance product quality

At the heart of this training is the emphasis on lean manufacturing as a holistic methodology that integrates strategy, operations, people, and culture.

The Benefits of Lean Training in Manufacturing Environments

Organizations that invest in lean training experience benefits far beyond isolated cost savings. They witness improvements in multiple areas:

- Process optimization: Training improves analytical skills needed to identify bottlenecks and streamline operations

- Employee engagement: Workers become active participants in change, motivated by new skills and opportunities

- Customer satisfaction: Reduced lead times and better product quality lead to higher satisfaction and loyalty

- Reduced costs: Waste elimination lowers production costs and increases margins

- Increased productivity: Employees work smarter with standardized processes and clearly defined goals

🎓 Ready to gain knowledge and apply it to real projects? The Lean Management Course offers lifetime access and team-sharing features to benefit your organization.

Real-World Application: From Theory to Implementation

Lean training is most effective when it moves beyond the classroom. Our certification program emphasizes direct application through exercises, simulations, and workplace improvement projects.

For example, after learning about 5S and workplace organization, participants are encouraged to analyze their workspace, identify inefficiencies, and propose solutions. Similarly, modules on takt time and flow lead to hands-on simulations where trainees must redesign an unbalanced production line.

🎮 Want a practical way to apply lean principles? The GET LEAN Simulation Game helps teams experience lean concepts through an engaging and realistic business scenario. Every license includes a free access code to the Lean Management Course and other learning materials.

Building a Culture of Continuous Improvement

Training is not a one-time event. It’s the foundation for a culture where continuous improvement becomes part of the daily work routine. Organizations can ensure that lean thinking becomes deeply embedded in their DNA through structured certification programs.

Key components of building this culture include:

- Developing internal coaches and lean champions

- Regular reflection and process analysis

- Integration of lean into leadership behavior

- Alignment between lean goals and business strategy

- Ongoing support through mentorship and discussion forums

📈 The Continuous Improvement Course is an ideal next step for teams looking to deepen their commitment to lean culture and agility.

Achieving Certification and Advancing Careers

Certification in lean manufacturing is a significant professional achievement. It demonstrates knowledge and the ability to implement solutions, measure results, and contribute meaningfully to organizational success.

- It opens up job opportunities across multiple industries

- It enhances your profile as a certified change agent

- It validates your competence in lean manufacturing training methods

- It positions you for leadership roles in lean transformation projects

- It gives you confidence to mentor others on the lean journey

Many professionals use this credential to transition into operations management, process engineering, or continuous improvement leadership roles.

🎯 Interested in growing your career? Learn more in the Effective Problem Solving Course—a practical companion to lean certification.

Lean Training as a Competitive Advantage

Today, companies that embrace lean training in manufacturing are building the capability to adapt and thrive. With lean-certified teams, organizations are better positioned to:

- Respond quickly to market changes

- Launch new products more effectively

- Improve customer response times

- Maintain quality and consistency across operations

- Achieve manufacturing excellence and operational excellence

Lean is not just about cutting costs—it’s about increasing value. Whether looking to optimize operations, improve quality, or innovate your production systems, lean training provides the tools and mindset to move forward.

🛠️ You can also explore the 5S Workplace Organization Course to gain hands-on techniques for organizing, standardizing, and sustaining improvements.

Final Thoughts: Invest in Lean Training Today

Lean training in manufacturing is a powerful driver of performance, engagement, and results. It helps individuals gain clarity, companies gain agility, and industries gain competitiveness.

Start with a proven program like the Lean Management Course—and discover how a structured approach to learning can lead to measurable, lasting change.

More Learning Opportunities:

- 🎯 Lean Management Course

- 🔍 Effective Problem-Solving Course

- ♻️ Continuous Improvement Course

- 🧹 5S Workplace Organization Course

- 👥 Teamwork and Leadership Course

- 🎮 GET LEAN Simulation Game