Principles of Lean Manufacturing: Mastering the Core of Operational Excellence

Why Understanding Lean Principles Matters

In today’s highly competitive global marketplace, manufacturers are constantly pressured to increase efficiency, reduce costs, and deliver greater customer value. Lean manufacturing offers a systematic approach to achieving these goals through the elimination of waste, the optimization of production processes, and the enhancement of customer satisfaction. Understanding lean manufacturing principles is essential for any organization to build a culture of continuous improvement, sustainable growth, and operational excellence.

This article explores the core lean manufacturing principles, explains their application across various industries, and highlights best practices for effective implementation. Whether you’re a production manager, quality engineer, or business leader, mastering these principles will transform your operations and position your organization for long-term success.

Defining the Principles of Lean Manufacturing

Lean manufacturing principles are guiding philosophies inspired initially by the Toyota Production System (TPS). Womack and Jones established the five key principles as the foundational concepts of lean manufacturing, providing the core guidelines for implementing lean processes. They focus on maximizing customer value while minimizing waste and inefficiency. These principles help organizations streamline operations, reduce variability, and foster a proactive culture of continuous improvement.

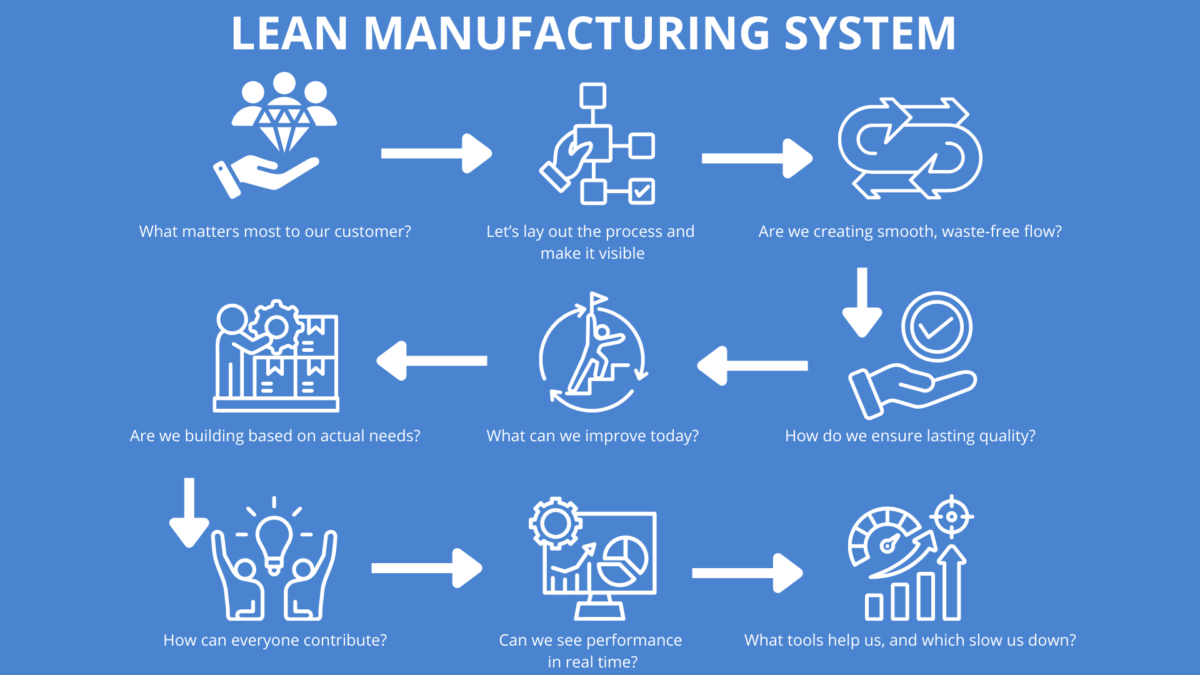

The five principles, which are central elements of the methodology, include:

- Value Definition: As a lean principle, identify value from the customer’s perspective to guide waste reduction and value creation.

- Value Stream Mapping: This lean principle analyzes and visualizes the complete production process, helping to eliminate inefficiencies and enhance value.

- Creating Flow: As a lean principle, ensure processes move smoothly without interruption, supporting waste reduction and continuous value delivery.

- Establishing a Pull System: This lean principle aligns production with actual customer demand, minimizing overproduction and maximizing value.

- Pursuing Perfection: As a lean principle, strive for continuous, incremental improvements to drive ongoing waste reduction and value creation.

Let’s explore each principle in detail.

Identifying Customer Value

The first and most critical step in implementing lean manufacturing is clearly defining customer value. This means understanding what your customer truly needs and is willing to pay for. Everything that does not contribute to this value is considered waste and should be eliminated.

For example, in the manufacturing process, value might come from precision machining, timely delivery, or the product’s durability. Activities that lead to unnecessary movement, excess inventory, or poor-quality castings detract from that value.

By starting with the customer’s perspective, businesses can align their operations to produce only what is necessary and valuable.

Mapping the Value Stream

Once the value is defined, the next step is value stream mapping. This involves identifying every step in the production process, from sourcing raw materials to delivering the finished product. To effectively map the value stream, analyze each stage to uncover waste and improvement opportunities.

Mapping the value stream allows teams to visualize the entire supply chain, pinpoint inefficiencies, and develop action plans to reduce waste. It is essential to consider the complete life cycle of a product—from the design phase, through customer usage, to end-of-life—when mapping the value stream. Typical forms of waste include:

- Overproduction

- Waiting

- Transport

- Overprocessing

- Inventory

- Motion

- Defects

By using this tool, organizations can better understand how lean tools such as 5S, Kanban, or standard work support a lean environment.

Explore practical value stream analysis techniques in our Problem-Solving Course.

Eliminating Waste at Every Step

Eliminating waste is at the heart of lean manufacturing, driving organizations to scrutinize every aspect of the manufacturing process for activities that do not add value. Inspired by the Toyota Production System, Lean manufacturing principles identify seven primary types of waste: transportation, inventory, motion, waiting, overproduction, overprocessing, and defects. Each of these wastes can hinder the efficiency of the production process and inflate costs.

By leveraging value stream mapping, manufacturers can visualize the entire value stream and pinpoint where waste occurs. This detailed analysis enables teams to systematically eliminate waste at every step, ensuring that resources are focused on activities that directly contribute to customer value. Implementing lean manufacturing means embedding a culture of continuous improvement, where every employee is empowered to identify and remove inefficiencies.

The result is a streamlined production system that reduces costs, improves efficiency, and enhances customer satisfaction. Organizations can create a more agile and responsive manufacturing process that delivers superior customer value by continuously applying lean manufacturing principles and tools.

Creating Smooth Flow in the Production Line

After waste has been identified, the focus shifts to creating flow. The goal is explicitly creating flow by removing functional barriers and ensuring the efficient, uninterrupted movement of products or processes through production.

A smooth flow reduces lead times, improves flexibility, and minimizes the chances of errors. Flow is significant in lean manufacturing plants where efficiency is paramount.

Tools like just-in-time delivery, visual management, and takt time analysis help achieve continuous flow. Implementing small batch production and reorganizing the workplace using the 5S methodology can make a significant difference.

To dive deeper into flow optimization, look at our comprehensive 5S Workplace Organization Course.

Inventory Management and Tackling Excess Inventory

Effective inventory management is a cornerstone of lean manufacturing. It ensures that raw materials, work-in-progress, and finished goods flow smoothly through the production system. Excess inventory is a common waste that can tie up capital, increase storage costs, and reduce overall efficiency. If products are not aligned with actual customer demand, they can also lead to obsolescence and negatively impact customer satisfaction.

To address these challenges, lean manufacturing advocates for just-in-time (JIT) production systems, which synchronize production and delivery with real-time customer demand. By producing only what is needed, when it is required, manufacturers can significantly reduce inventory levels and improve efficiency. Lean tools such as kanban and pull systems support this approach by providing visual signals that help manage inventory and trigger replenishment only when necessary.

By implementing these lean tools and principles, manufacturers can optimize inventory management, reduce excess inventory, and ensure that the production system is responsive to customer needs. This cuts costs and enhances customer satisfaction by delivering products promptly and efficiently.

Establishing a Pull System

Traditional manufacturing often relies on push systems, which lead to excess inventory, poor forecasting, and inefficient resource allocation. Lean advocates a pull system, which aligns production with customer demand.

A pull system only initiates work when there is a signal of actual demand, avoiding the buildup of unused goods. This system enhances responsiveness and reduces lead times, making it a powerful concept in lean production systems.

Kanban boards and FIFO lanes are standard tools for effectively implementing pull systems.

Pursuing Perfection Through Continuous Improvement

The final principle of lean is to seek perfection. This is not a destination, but a journey. It involves embedding a continuous improvement culture in which everyone is empowered to contribute to better processes.

Kaizen events, PDCA cycles, and A3 reports are structured approaches to implementing incremental changes and improving organizational efficiency.

The concept of perfection also supports developing lean leadership that champions problem-solving, employee engagement, and innovation.

Learn how to build a culture of continuous improvement in our Continuous Improvement Course.

Integrating Lean Tools and Techniques

Successfully implementing lean manufacturing requires more than philosophy—it demands action. Across industries, applying lean methods and concepts helps organizations improve efficiency and reduce waste. Essential lean manufacturing tools include:

- 5S Workplace Organization

- Kanban Scheduling

- Poka-Yoke (Error Proofing)

- Andon Systems

- Standard Work

- Value Stream Mapping

Selecting and applying the right tools for your production systems can reduce waste, cut costs, and increase customer satisfaction. Adopting a lean manufacturing system also delivers significant operational improvements and cost savings.

Overcoming Implementation Challenges

Despite its many benefits, implementing lean is not without obstacles. Organizations may face:

- Resistance from employees

- Lack of proper training

- Weak leadership commitment

- Ineffective change management

Companies need tailored training, strong communication, and visible leadership to overcome these issues. Effective lead management is also crucial for streamlining workflows and supporting strategic growth across all areas of the organization. Developing a high-performance supplier network also plays a key role in reducing risks and supporting lean objectives. Combining these elements helps build a resilient, lean enterprise capable of adapting to market changes.

Check out our Teamwork & Leadership Course for support in navigating organizational transformation.

Measuring Success in Lean Manufacturing

Measuring success using relevant key performance indicators (KPIs) is essential to ensure that lean manufacturing initiatives deliver the desired results. Common KPIs in lean manufacturing include lead time, which tracks the time from order to delivery; throughput, which measures the production rate; inventory turns, which indicate how often inventory is cycled through; and defect rate, which reflects product quality.

In addition to these metrics, manufacturers often use overall equipment effectiveness (OEE) and total productive maintenance (TPM) to assess the performance and reliability of their equipment and processes. By regularly tracking these KPIs, organizations can identify areas for improvement, evaluate the impact of their lean initiatives, and make informed, data-driven decisions to drive continuous improvement.

Consistent measurement and analysis are vital for sustaining a culture of continuous improvement and ensuring that lean manufacturing efforts translate into tangible operational gains.

Sustaining Lean Manufacturing for Long-Term Results

Achieving long-term success with lean manufacturing requires more than initial implementation—it demands an ongoing commitment to continuous improvement and lean thinking. Organizations must foster a culture where every employee is engaged in identifying opportunities for improvement and where lean leadership sets the tone for sustained excellence.

Establishing a dedicated lean leadership team helps maintain focus on lean objectives and ensures accountability. Regular training and development opportunities empower employees with the skills and knowledge to contribute to lean initiatives. Lean tools such as value stream mapping and root cause analysis are invaluable for uncovering inefficiencies and driving ongoing improvements across the value stream.

By embedding lean thinking into the organizational culture and consistently applying lean tools, manufacturers can sustain their lean manufacturing gains, adapt to changing market conditions, and deliver exceptional value to customers.

Best Practices for Lean Manufacturing

Adopting best practices is essential for maximizing the benefits of lean manufacturing. Key strategies include cultivating a continuous improvement culture, where employees at all levels are encouraged to contribute ideas and drive change. Value stream mapping helps identify and eliminate waste, while establishing a pull system ensures that production is closely aligned with customer demand.

Fostering lean thinking through ongoing training and employee involvement is critical for sustaining momentum. Lean tools such as kanban and total productive maintenance (TPM) support efficient inventory management, waste reduction, and process optimization. By integrating these best practices, manufacturers can significantly improve efficiency, reduce waste, and enhance customer satisfaction, positioning themselves for long-term success in a competitive marketplace.

Common Mistakes to Avoid in Lean Initiatives

While implementing lean manufacturing principles offers significant benefits, common pitfalls can undermine success. One frequent mistake is failing to establish a clear vision and strategy for lean initiatives, leading to confusion and a lack of direction. Insufficient employee training and development opportunities and a lack of employee involvement in lean efforts can also hinder progress.

Another standard error is implementing lean without a thorough understanding of current operations or a structured plan. Overemphasizing cost reduction at the expense of driving continuous improvement and increasing customer value can also limit the effectiveness of lean initiatives.

Organizations should build a strong foundation of lean manufacturing principles to avoid these mistakes, prioritize continuous improvement, and ensure all employees are engaged and aligned with the organization’s lean vision. This approach will help improve sustainable efficiency, quality, and customer satisfaction.

Applying Lean Principles Across Industries

Although lean began in the automotive industry, its principles are widely applicable. Optimizing manufacturing processes is central to lean’s success across industries, enabling organizations to streamline production and drive continuous improvement. Today, lean is driving improvements in:

- Healthcare: Reducing patient wait times and improving care delivery

- Logistics: Enhancing inventory management and transportation flow

- Food processing: Minimizing spoilage and improving compliance

- Construction: Increasing labor productivity and resource coordination

Improving productive processes is key to enhancing efficiency and reducing waste, regardless of the industry. The universality of lean manufacturing principles makes them adaptable to any sector where efficient processes and customer value are priorities. Notably, the level of plant technology is often less important than factors like workforce training, product design, and supplier networks in achieving lean success.

Real Benefits of Lean Manufacturing

Organizations that embrace the key principles of lean often see measurable outcomes, such as:

- 20–40% increase in productivity

- 25–50% reduction in cycle times

- 30%+ improvement in operating performance

- Enhanced customer satisfaction and quality

- More substantial alignment across the entire supply chain

- Cutting waste to improve efficiency and reduce costs

Lean also shifts the focus from predetermined production targets to demand-driven systems, ensuring production is closely aligned with customer demand and increasing overall efficiency.

With the right strategies and tools, lean becomes a pathway to creating wealth, building a high-performance culture, and sustaining competitive advantage.

Final Thoughts and Next Steps

Mastering lean manufacturing principles is a strategic move for any organization aiming for agility, efficiency, and growth. From mapping the value stream to cultivating a culture of continuous improvement, these principles provide a foundation for long-term operational success.

Lean manufacturing originated from the study of Toyota Motor Corporation and its pioneering Toyota Production System (TPS), which was heavily influenced by earlier concepts of scientific management developed by Frederick Winslow Taylor. Over time, the lean production system evolved to emphasize waste reduction, efficient workflows, and continuous improvement, guided by the broader lean philosophy that shapes organizational culture and management practices. Despite its widespread adoption, there is no standard lean production model, and ongoing lean production debates highlight criticisms regarding its implementation, standardization, and impact on employee well-being.

If you’re ready to bring these concepts to life in your organization, start with our in-depth Lean Management Course. You’ll gain access to proven techniques and frameworks used in world-class lean manufacturing plants.

🎓 Plus, enhance your team’s hands-on skills with the GET LEAN Simulation Game – a dynamic, interactive learning experience that makes Lean principles tangible.

The journey to excellence starts now. Apply Lean, eliminate waste, and transform your production for the future.