What Is Lean in Manufacturing? A Comprehensive Guide to Lean Principles and Practices

In today’s competitive industrial landscape, understanding lean manufacturing is crucial for organizations aiming to enhance efficiency, reduce waste, and deliver superior value to customers. Lean manufacturing originated from studying the Toyota Production System (TPS) and its groundbreaking application in the automotive industry.

Rooted in the Toyota Production System (TPS), lean manufacturing emphasizes eliminating non-value-adding activities, fostering a culture of continuous improvement, and optimizing the entire production process. Lean manufacturing evolved from earlier approaches such as scientific management, pioneered by Frederick Taylor, and mass production methods that dominated the early 20th century. The shift from mass production to lean practices marked a move from push-based, scale-driven manufacturing to more efficient, demand-driven systems. The lean production system established by Toyota became the foundation for modern lean practices, influencing the automotive industry and the broader manufacturing industry worldwide.

Understanding Lean Manufacturing

Lean manufacturing is a systematic approach to identifying and eliminating waste within manufacturing systems. The goal is to achieve efficient processes that deliver maximum value to the customer with minimal resources. This philosophy, often called lean thinking, encourages organizations to view operations through the lens of customer value, ensuring every step in the production line contributes meaningfully. Designing processes from the customer’s perspective is essential, as the customer ultimately defines value, and processes should be aligned to meet their needs and expectations. Over time, the evolution of manufacturing concepts has been significantly influenced by lean philosophy, which emphasizes continuous improvement, waste elimination, and a strategic cultural shift toward operational excellence.

Consider enrolling in the Lean Management Course for a deeper dive into the principles and applications of lean methodologies. This course offers comprehensive insights into implementing lean strategies effectively. Lean methods and philosophy have also been adapted in industries beyond manufacturing, such as healthcare, IT, and services.

Core Principles of Lean Manufacturing

A core principle of lean manufacturing is to eliminate waste and maximize value for the customer. The foundation of lean manufacturing rests on five key principles:

- Define Value: Understand what the customer perceives as valuable.

- Map the Value Stream: Identify all steps in the value stream and eliminate those that do not add value.

- Create Flow: Focus on creating flow by removing barriers and ensuring smooth, uninterrupted production flow throughout the process.

- Establish Pull: Implement a pull system where production is based on actual customer demand.

- Pursue Perfection: Continuously seek ways to improve processes and eliminate waste.

Identifying waste is a fundamental lean principle that underpins all other principles. It enables organizations to optimize production flow and drive continuous improvement.

These principles guide organizations in creating a lean enterprise that is responsive, efficient, and customer-focused.

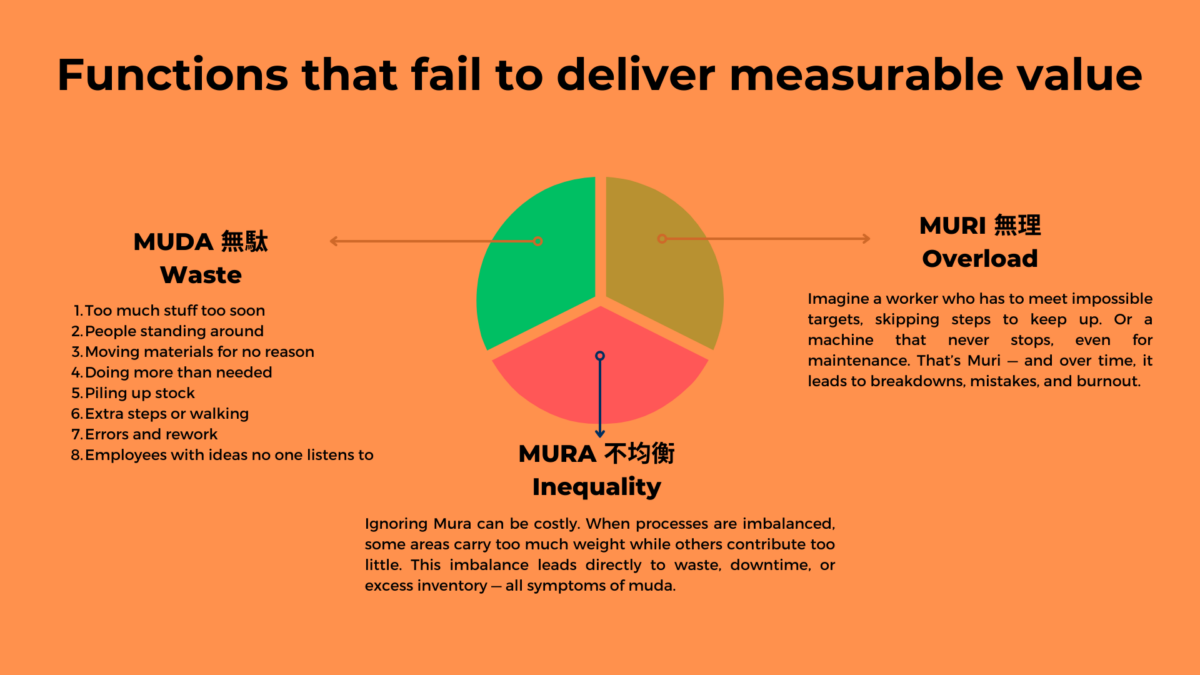

Types of Waste in Lean Manufacturing

In lean manufacturing, waste is defined as any activity or process that consumes resources but does not add value from the customer’s perspective. The Toyota Production System (TPS) famously identified seven types of waste that can hinder efficiency and increase costs within a production system. Understanding and eliminating these wastes is central to lean thinking and the pursuit of continuous improvement.

The seven classic types of waste in lean manufacturing are:

- Transportation: Unnecessary movement of products or materials between processes or locations. This can be minimized by optimizing supply chain logistics and streamlining the production line layout.

- Inventory: Excess inventory, whether raw materials, work-in-progress, or finished goods, ties up capital and can hide underlying problems in the production process. Effective inventory management and just-in-time strategies help reduce this waste.

- Motion: Unnecessary movement of people or equipment, such as reaching, walking, or searching for tools, can be reduced through efficient production line design and standardized work practices.

- Waiting: Idle time when materials, information, or equipment are not available, causing delays in the production process. This waste can be addressed by improving production scheduling and resource allocation.

- Overproduction: Producing more than or before it is needed leads to excess inventory and increased storage costs. Lean practitioners use demand forecasting and production planning to align output with customer demand.

- Overprocessing: Performing more work or using more expensive processes than necessary to meet customer requirements. Streamlining processes and focusing on value-added activities can help eliminate this waste.

- Defects are errors or mistakes that require rework or result in scrap, directly impacting quality and customer satisfaction. Implementing quality improvement initiatives and root cause analysis can reduce defects.

Many lean practitioners also recognize an eighth waste: the waste of unused talent and ingenuity. This occurs when employees’ skills, ideas, and problem-solving abilities are not fully utilized. Encouraging team involvement and leveraging workers’ expertise can unlock new opportunities for improvement and innovation.

Organizations can create a more efficient, responsive, and competitive production system by systematically identifying and addressing these types of waste.

Tools and Techniques in Lean Manufacturing

Implementing lean principles requires specific tools and techniques to identify inefficiencies and promote continuous improvement. Lean manufacturing techniques such as lean six sigma, just in time manufacturing, and total productive maintenance are widely used to eliminate waste, improve quality, and enhance efficiency in manufacturing environments:

- Value Stream Mapping: A visual tool to analyze the flow of materials and information, helping to identify bottlenecks and areas of waste.

- 5S Methodology: This methodology focuses on workplace organization to improve efficiency and safety. The five steps—sort, Set in order, Shine, Standardize, and sustain—create a foundation for a productive work environment.

These techniques help improve manufacturing processes by reducing waste, improving quality, and ensuring efficient and continuous flow in production operations.

The Fundamentals of 5S Course provides practical guidance and implementation strategies for mastering the 5S methodology and enhancing workplace efficiency.

The Role of Continuous Improvement

At the heart of lean manufacturing lies the commitment to continuous improvement. This involves regularly assessing processes, seeking feedback, and making incremental changes to enhance performance. Cultivating a constant improvement culture ensures that organizations remain agile and responsive to changing demands.

For strategies on fostering a culture of ongoing enhancement, the Continuous Improvement Course offers valuable insights into building and sustaining improvement initiatives.

Implementing Lean in Manufacturing Operations

Implementing lean requires a structured approach:

- Assessment: Evaluate the manufacturing process and identify waste, inefficiency, and functional barriers.

- Planning: Develop a roadmap for lean implementation, setting clear production targets and considering production leveling to balance workload, along with clear goals and metrics.

- Execution: Apply lean tools and principles to streamline operations by implementing a lean manufacturing system and lean manufacturing methodology, while leveraging a high-performance supplier network and plant technology.

- Review: Monitor progress and make adjustments as necessary to ensure continuous improvement.

Manufacturing resource planning (MRP) systems are often contrasted with lean approaches, as MRP relies on forecasts and push-based inventories, which can hinder productive processes. Optimizing the production cycle and manufacturing process is essential, but establishing a standard lean production model can be challenging due to the adaptable and cultural nature of lean practices.

Ultimately, these approaches aim to reduce waste and drive efficiency throughout manufacturing operations.

Effective implementation also hinges on strong leadership and teamwork. The Effective Teamwork and Leadership Course equips leaders with the skills to successfully guide teams through lean transformations.

Technology and Lean Manufacturing

Technology has become an essential enabler of lean manufacturing, helping organizations streamline production processes, eliminate waste, and drive continuous improvement. By integrating advanced tools and systems, companies can enhance every aspect of their manufacturing operations.

Enterprise Resource Planning (ERP) systems are a cornerstone of modern lean manufacturing. They provide real-time visibility into inventory, production, and supply chain activities. These systems support effective inventory management, production scheduling, and resource allocation, which are critical for reducing excess inventory and aligning output with customer demand.

Lean manufacturing tools such as value stream mapping and root cause analysis are even more powerful when combined with technology. Digital platforms allow teams to visualize the value stream, identify bottlenecks, and track progress toward eliminating waste. Automation and robotics further enhance efficiency by reducing manual labor, minimizing errors, and ensuring consistent quality throughout the production process.

Real-time monitoring and data analytics empower organizations to make informed, data-driven decisions. By continuously collecting and analyzing production data, companies can quickly identify issues, implement corrective actions, and sustain improvements. This approach supports lean manufacturing principles but also helps improve customer satisfaction by delivering higher-quality products faster and more reliably.

Industry leaders like Toyota Motor Corporation have demonstrated the benefits of integrating technology with lean manufacturing systems. Their use of advanced manufacturing systems and digital tools has significantly improved production efficiency, quality, and environmental sustainability.

Ultimately, the synergy between technology and lean manufacturing enables organizations to build more agile, efficient, and environmentally responsible production systems, positioning them for long-term success in a competitive marketplace.

Benefits of Lean Manufacturing

Adopting lean manufacturing principles yields numerous advantages:

- Waste Reduction: Organizations can minimize unnecessary costs and improve resource utilization by eliminating waste.

- Enhanced Quality: Streamlined processes lead to more consistent and higher-quality outputs.

- Improved Customer Satisfaction: Efficient operations enable faster delivery times and better responsiveness to customer needs.

- Increased Flexibility: Lean systems are more adaptable to changes in demand, enhancing the organization’s competitiveness.

- Create Wealth: Lean manufacturing helps organizations create wealth by maximizing value and minimizing waste, leading to greater profitability and long-term success.

Challenges and Considerations

While the benefits are substantial, organizations may face challenges in adopting lean practices:

- Cultural Resistance: Shifting to a lean mindset requires changes in organizational culture and employee attitudes.

- Sustaining Improvements: Maintaining momentum in continuous improvement efforts demands ongoing commitment and monitoring.

- Training and Development: Ensuring all team members understand lean principles is crucial for successful implementation.

Some critics of lean argue that it may overlook employee well-being or introduce new challenges, and these ongoing debates are essential considerations for organizations.

To address these challenges, investing in comprehensive training programs, such as the Effective Problem-Solving Course, can empower employees to identify issues proactively and develop practical solutions.

Conclusion

Understanding what is lean in manufacturing is essential for organizations striving for operational excellence. Businesses can significantly enhance performance and competitiveness by embracing lean principles, utilizing practical tools, and fostering a continuous improvement culture.

For a holistic understanding and practical application of lean methodologies, explore the range of courses offered by Sabat Consulting:

- Lean Management Course

- Fundamentals of 5S Course

- Continuous Improvement Course

- Effective Teamwork and Leadership Course

- Effective Problem-Solving Course

Embark on your lean transformation today and position your organization for sustained success in the dynamic manufacturing landscape.