What Is a Lean Manufacturing System? Principles, Tools, and Benefits Explained

In today’s competitive industrial landscape, understanding the lean manufacturing system is crucial for organizations aiming to enhance efficiency, reduce waste, and deliver superior value to customers. The lean production system originated from the Toyota Production System and evolved from earlier management theories, shaping modern approaches to manufacturing efficiency.

Rooted in the Toyota Production System (TPS) and influenced by early concepts such as scientific management, lean manufacturing emphasizes eliminating non-value-adding activities, fostering a culture of continuous improvement, and optimizing the entire production process.

The term lean manufacturing, developed through the historical evolution of these management philosophies, represents a strategic and cultural approach to improving efficiency and reducing waste in manufacturing.

Understanding Lean Manufacturing System

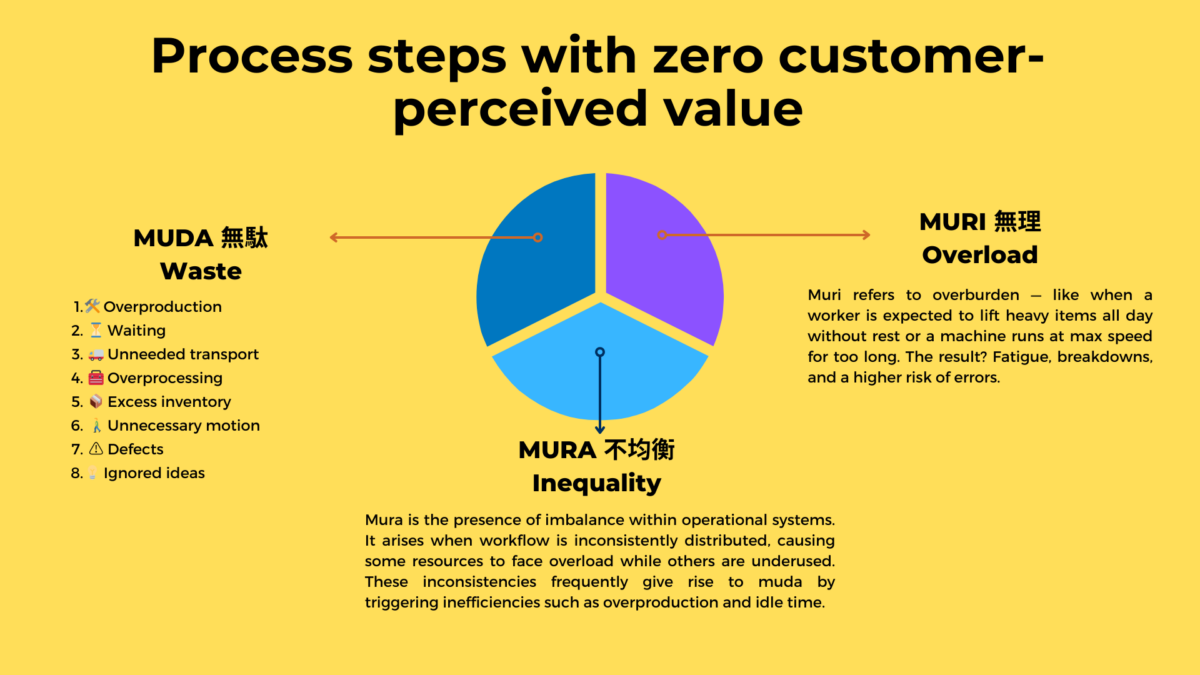

Lean manufacturing is a systematic approach to identifying and eliminating waste within manufacturing systems. The goal is to achieve efficient processes that deliver maximum value to the customer with minimal resources. Value should always be defined from the customer’s perspective, ensuring that improvements align with what the customer perceives as beneficial. The core principle of lean is to eliminate waste and optimize processes, focusing on improving the manufacturing process to enhance operational efficiency. This philosophy, often called lean thinking, encourages organizations to view operations through the lens of customer value, ensuring every step in the production line contributes meaningfully by optimizing processes to maximize value.

Consider enrolling in the Lean Management Course for a deeper dive into the principles and applications of lean methodologies. This course offers comprehensive insights into implementing lean strategies effectively. The underlying principles of lean manufacturing guide organizations in shaping productive processes that continuously improve efficiency and value delivery.

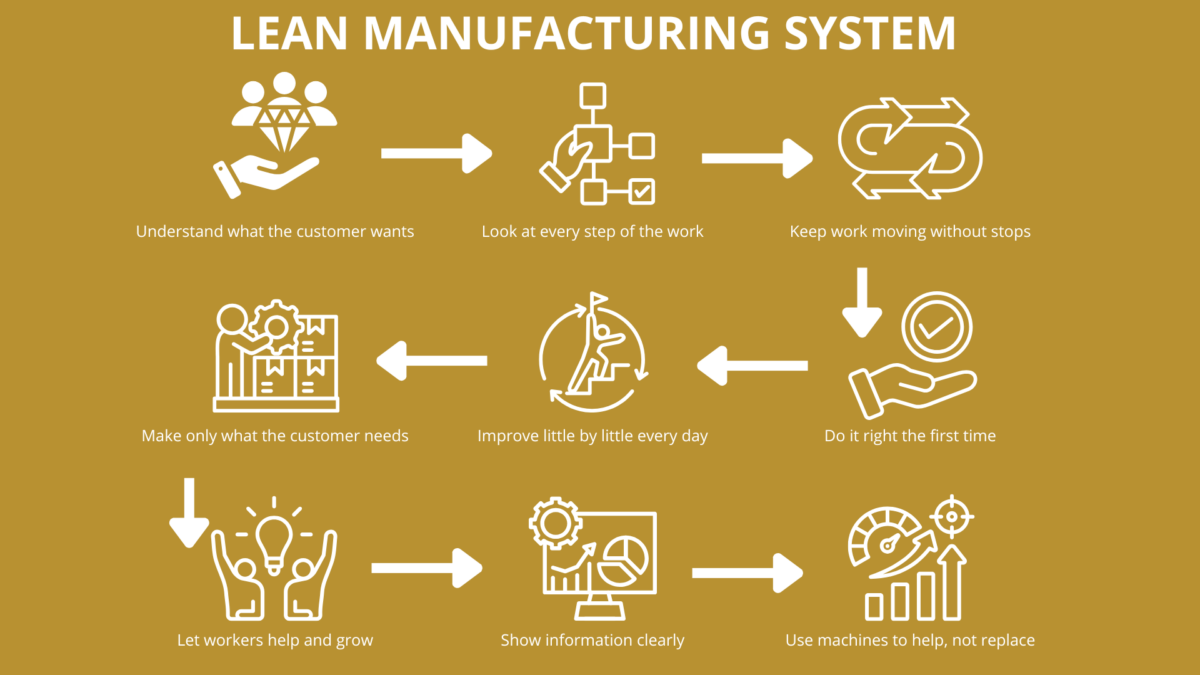

Core Principles of Lean Manufacturing

The foundation of lean manufacturing rests on five key principles. Each lean principle is designed to maximize productivity and minimize waste:

- Define Value: Understand what the customer perceives as valuable.

- Map the Value Stream: Identify all steps in the value stream and eliminate those that do not add value.

- Create Flow: Ensure that the production process flows smoothly without interruptions, focusing on optimizing and achieving continuous flow.

- Establish Pull: Implement a pull system where production is based on actual customer demand.

- Pursue Perfection: Continuously seek ways to improve processes and eliminate waste.

Production leveling is also crucial for maintaining a consistent output rate and reducing fluctuations in the manufacturing process.

Identifying waste is a foundational step in lean, enabling organizations to streamline operations and focus on value-added activities.

There is no standard lean production model; organizations must adapt lean principles to their unique circumstances.

Creating Flow in Lean Manufacturing

Creating flow is a fundamental aspect of lean manufacturing, aimed at eliminating waste and boosting efficiency throughout production. In a lean manufacturing system, flow refers to the seamless and uninterrupted movement of materials, products, and information from one stage to the next. Achieving this requires manufacturers to break down functional barriers, such as poorly designed production lines or inefficient material handling systems, that can cause delays, bottlenecks, or idle equipment.

One of the most effective ways to create flow is by implementing a pull system, where actual customer demand rather than forecasts directly drives production. This approach helps reduce excess inventory and ensures that resources are only used when needed. Value stream mapping is a potent lean manufacturing tool that enables organizations to visualize the entire value stream, identify inefficiencies, and target areas for improvement.

The Toyota Production System (TPS) is a prime example of a lean manufacturing system that prioritizes creating flow and eliminating waste. By continuously monitoring and refining the production process, manufacturers can reduce lead times, enhance product quality, and increase overall productivity. Creating flow is not a one-time effort but an ongoing process that requires a commitment to continuous improvement and regular value stream assessment.

Just in Time Manufacturing

Just-in-time (JIT) manufacturing is a cornerstone of lean manufacturing, designed to align production closely with customer demand. In a JIT system, products are manufactured and delivered precisely when they are needed, minimizing inventory and reducing waste throughout the production process. Unlike traditional push systems, where production is based on forecasts, JIT relies on a pull system—actual customer orders trigger production.

Implementing JIT manufacturing requires strong collaboration with suppliers and real-time visibility into the production process to ensure that raw materials and components arrive just in time for use. This approach reduces inventory costs and improves quality and responsiveness to changing customer needs. The automotive industry, particularly companies like Toyota, has successfully leveraged JIT manufacturing to streamline operations and achieve high levels of efficiency.

However, JIT manufacturing can present challenges, especially in industries with unpredictable demand or supply chain disruptions. To address these challenges, manufacturers often combine JIT with other lean manufacturing techniques, such as total productive maintenance (TPM) and continuous improvement (Kaizen), to maintain smooth operations and drive ongoing process optimization.

Inventory Management in Lean Manufacturing

Effective inventory management is a critical element of lean manufacturing, as excess inventory represents a significant source of waste and ties up valuable resources. The lean manufacturing approach focuses on minimizing inventory levels and maximizing inventory turnover, ensuring that materials and products move efficiently through the supply chain.

Techniques such as just-in-time (JIT) manufacturing help manufacturers align production schedules with actual customer demand, reducing the need for large stockpiles of raw materials or finished goods. By closely monitoring inventory levels and adjusting production in real time, organizations can maintain the optimal balance, having enough inventory to meet demand without incurring unnecessary costs.

Inventory management in lean manufacturing is closely linked to supply chain management, requiring strong partnerships with suppliers to ensure timely materials delivery. Advanced inventory management software and analytical tools further support optimizing inventory levels, helping manufacturers reduce waste, lower costs, and improve quality. Ultimately, streamlined inventory management enhances the organization’s ability to respond quickly to customer needs and market changes.

Tools and Techniques in Lean Manufacturing

Implementing lean principles requires specific tools and techniques to identify inefficiencies and promote continuous improvement. Lean manufacturing tools and methods, such as value stream mapping, 5S, and kanban, are essential for implementing lean and are widely used to cut waste and improve manufacturing processes across various sectors.

- Value Stream Mapping: A visual tool to analyze the flow of materials and information, helping to identify bottlenecks and areas of waste. As one of the key lean manufacturing tools, it plays a crucial role in cutting waste and improving manufacturing processes.

- 5S Methodology: This methodology focuses on workplace organization to improve efficiency and safety. The five steps—sort, Set in order, Shine, Standardize, and sustain—create a foundation for a productive work environment.

Lean Six Sigma combines lean and Six Sigma principles to improve manufacturing processes. It targets waste reduction and variation control, driving continuous improvement and operational efficiency.

The Fundamentals of 5S Course provides practical guidance and implementation strategies for mastering the 5S methodology and enhancing workplace efficiency.

The Role of Continuous Improvement

At the heart of lean manufacturing lies the commitment to continuous improvement. Continuous improvement aims to create a meaningful and lasting difference in organizational performance. This involves regularly assessing processes, seeking feedback, and making incremental changes to enhance performance. Cultivating a continuous improvement culture ensures that organizations remain agile and responsive to changing demands. Lean practitioners play a key role in fostering a culture of continuous improvement by identifying opportunities for waste reduction and encouraging collective responsibility at all levels.

For strategies on fostering a culture of ongoing enhancement, the Continuous Improvement Course offers valuable insights into building and sustaining improvement initiatives.

Customer Satisfaction in Lean Manufacturing

Customer satisfaction is at the heart of lean manufacturing, guiding every decision and process improvement. Lean manufacturing principles emphasize understanding the customer’s perspective and defining value based on the customer’s needs. Manufacturers can deliver high-quality products that meet or exceed customer expectations by eliminating waste and driving continuous improvement.

Tools like value stream mapping and root cause analysis enable organizations to identify inefficiencies and optimize production processes, leading to better quality and fewer defects. Supported by regular customer feedback and performance metrics, quality improvement initiatives help manufacturers measure satisfaction and pinpoint areas for further enhancement.

Prioritizing customer satisfaction not only builds loyalty and drives repeat business but also supports the broader goals of lean manufacturing—reducing waste, improving efficiency, and creating value throughout the entire value stream. Lean manufacturing principles can also be extended beyond the production floor, benefiting areas such as sales, marketing, and service to deliver a seamless and satisfying customer experience.

Implementing Lean in Manufacturing Operations

Implementing lean requires a structured approach:

- Assessment: Evaluate current processes and each stage of the production cycle to identify areas of waste and inefficiency.

- Planning: Develop a roadmap for lean implementation, setting clear goals and metrics. Unlike traditional manufacturing resource planning approaches that rely on forecast-based push systems, lean focuses on demand-driven, pull-based production and waste elimination.

- Execution: Apply lean tools and principles to streamline operations.

- Review: Monitor progress and make adjustments as necessary to ensure continuous improvement.

Effective implementation also hinges on strong leadership and teamwork. Building a high-performance supplier network supports lean implementation and enhances operational excellence. The Effective Teamwork and Leadership Course equips leaders with the skills to successfully guide teams through lean transformations.

Benefits of Lean Manufacturing

Adopting lean manufacturing principles yields numerous advantages:

- Waste Reduction: By focusing on eliminating and minimizing waste, organizations can improve resource utilization, reduce costs, and enhance efficiency in lean manufacturing plants.

- Enhanced Quality: Streamlined processes lead to more consistent and higher-quality outputs.

- Improved Customer Satisfaction: Efficient operations enable faster delivery times and better responsiveness to customer needs.

- Increased Flexibility: Lean systems are more adaptable to changes in demand, enhancing the organization’s competitiveness.

Lean manufacturing plants can achieve high performance with minimal reliance on advanced plant technology, as other factors such as workforce training and supplier networks play a more significant role.

By optimizing processes and eliminating non-value-added activities, lean principles help organizations create wealth.

Minimizing waste across the entire supply chain maximizes efficiency and overall operational performance.

Challenges and Considerations

While the benefits are substantial, organizations may face challenges in adopting lean practices:

- Cultural Resistance: Shifting to a lean mindset requires changes in organizational culture and employee attitudes. Some critics of lean argue that it can negatively impact employee well-being, raising concerns about safety and the effects of lean practices on workers.

- Sustaining Improvements: Maintaining momentum in continuous improvement efforts demands ongoing commitment and monitoring. Additionally, the concept of the eighth waste highlights the risk of not utilizing employees’ skills and creativity, which can hinder process improvement.

- Training and Development: It is crucial for successful implementation that all team members understand lean principles. Planning and implementation should also involve a shift from traditional production targets to demand-driven systems, reducing overproduction and aligning with lean principles.

To address these challenges, investing in comprehensive training programs, such as the Effective Problem-Solving Course, can empower employees to identify issues proactively and develop practical solutions. Embracing lean philosophy is essential for overcoming these obstacles and fostering a culture of continuous improvement.

Conclusion

Understanding the lean manufacturing system is essential for organizations striving for operational excellence. Originating from the pioneering efforts of Toyota Motor Corporation through the development of the Toyota Production System, lean production has become a global benchmark for eliminating waste and improving process flow. Its impact on modern manufacturing is profound, with principles now adapted across various industries. A key takeaway is optimizing production flow to ensure continuous, efficient operations and support overall lean objectives. By embracing lean principles, utilizing practical tools, and fostering a culture of constant improvement, businesses can significantly enhance performance and competitiveness.

For a holistic understanding and practical application of lean methodologies, explore the range of courses offered by Sabat Consulting:

- Lean Management Course

- Fundamentals of 5S Course

- Continuous Improvement Course

- Effective Teamwork and Leadership Course

- Effective Problem-Solving Course

Embark on your lean transformation today and position your organization for sustained success in the dynamic manufacturing landscape.