Spis treści

Introduction to Lean Manufacturing

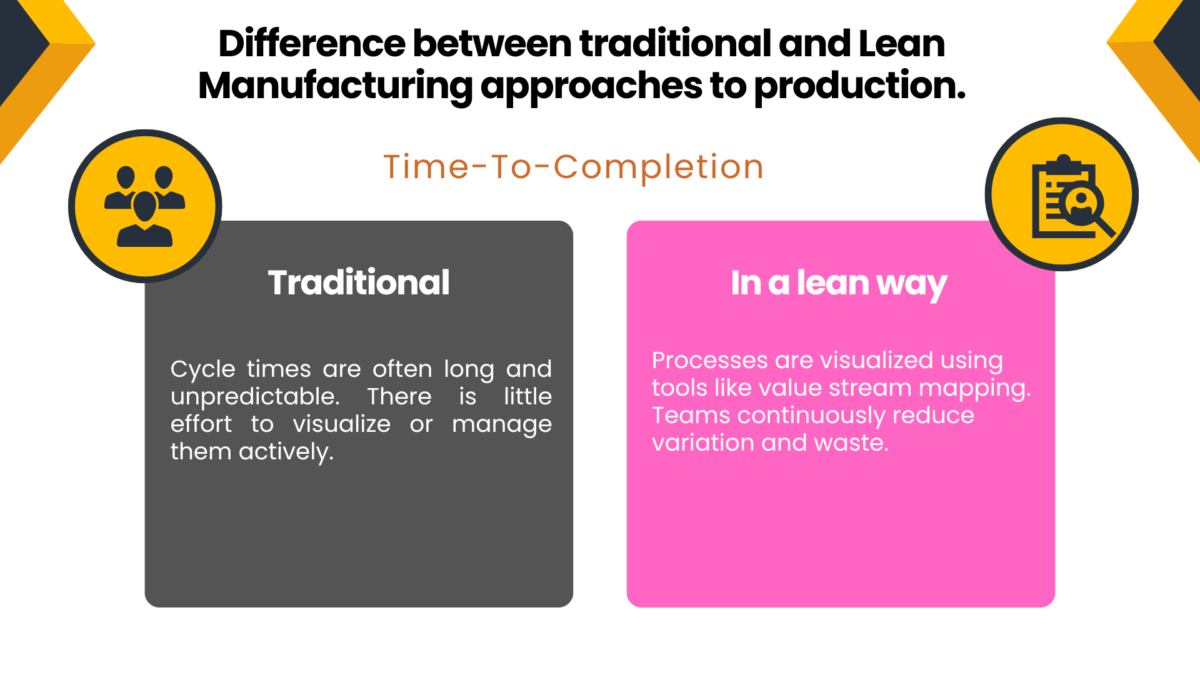

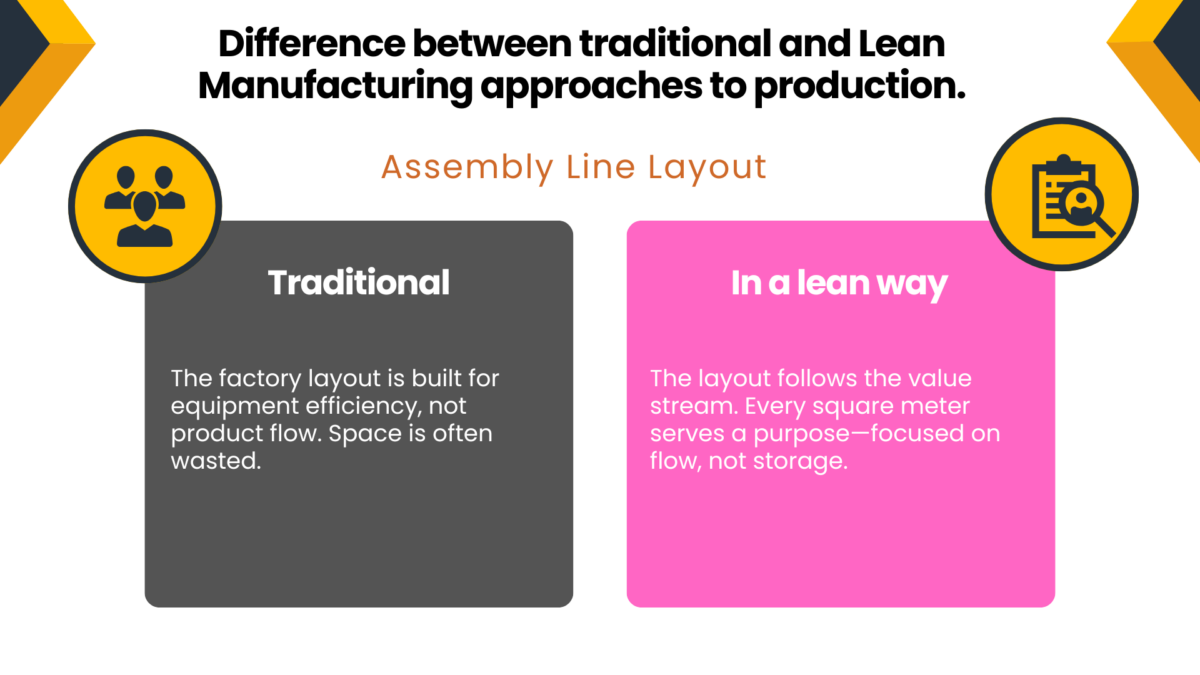

Lean manufacturing is a crucial production methodology that empowers organizations to streamline their manufacturing processes by focusing on reducing costs, minimizing defects, and maximizing efficiency. At its core, lean manufacturing is about identifying and eliminating non-value-added activities, allowing companies to deliver high-quality products in less time and at a lower cost. By applying essential lean concepts and tools—such as value stream mapping, root cause analysis, and just-in-time production—organizations can systematically reduce waste and errors throughout the production stream. This approach is particularly valuable for organizations seeking to enhance operational performance, improve customer satisfaction, and maintain a competitive edge in today’s fast-paced manufacturing environment.

Why Enroll in a Lean Manufacturing Course?

A lean manufacturing course equips students and learners with the principles, tools, and methodologies of lean manufacturing that transform entire production processes. Learners engage deeply with course content, participating in virtual lectures and discussion forums tailored to their needs. The course teaches an integrated system of frameworks and tools essential for management, quality control, and production efficiency. Working collaboratively in teams is emphasized, allowing students to develop their teamwork skills and manage their workflow for greater success.

Participants gain:

- A certification program to validate lean expertise

- Practical skills in process improvement, quality control, and problem solving

- Tools to eliminate waste, minimize defects, and make informed decisions

- Competitive edge—boosting product quality, reducing costs, and expanding job opportunities

Students can choose industry-specific specialization tracks within the course, ensuring a tailored learning experience that aligns with their professional goals.

The instructor leads live sessions, provides personalized support, and facilitates interactive learning through discussions and Q&A.

Learners benefit from hands-on experience and real-world experiences through projects, simulations, and site visits, which are critical for building confidence and maintaining certification relevance.

What You’ll Learn: Key Topics & Outcomes

1. Core Lean Principles & Methodologies

– Understand fundamental concepts: value, flow, pull, perfection

– Apply lean tools like Kaizen, 5S, value stream mapping, and root cause analysis

2. Process Optimization Techniques

– Analyze manufacturing processes and supply chain management

– Enhance throughput, reduce cycle time, and improve process flow

3. Data-Driven Problem Solving

– Use metrics and quality control tools to identify inefficiencies

– Drive continuous improvement and minimize defects

4. Leading Lean Transformation

– Build a lean culture and drive organizational change

– Engage teams, develop lead lean transformation strategies, and sustain benefits

5. Metrics & Results

– Achieve measurable gains: operational efficiency, reducing costs, and manufacturing excellence

– Learn from case studies across diverse industries

Advanced Lean Concepts

Building on foundational lean principles, advanced lean concepts introduce robust methodologies, such as Lean Six Sigma, Total Productive Maintenance, and sophisticated supply chain management strategies. These topics are designed to help organizations achieve perfection by systematically reducing defects, waste, and process variability. Emphasizing the importance of a strong lean culture and effective leadership, advanced lean concepts encourage continuous learning and improvement at every level. By mastering these principles, organizations can drive lean transformation across their manufacturing processes, unlocking new opportunities for growth, operational excellence, and increased customer satisfaction. The integration of Lean Six Sigma and other advanced techniques ensures that organizations remain agile, innovative, and positioned for long-term success.

Overcoming Challenges in Lean Implementation

Successfully implementing lean manufacturing often requires organizations to overcome significant challenges, such as resistance to change, limited resources, and a lack of leadership commitment. To address these obstacles, it is essential to develop a clear strategy and provide ongoing support and training for employees at all levels. Establishing a culture of continuous improvement and commitment to lean principles is key to ensuring lasting results. Organizations should utilize tools such as Lean Six Sigma and root cause analysis to identify and eliminate errors and defects in their production processes. By systematically addressing these challenges and providing the necessary resources, organizations can ensure a smooth transition to lean manufacturing, resulting in improved efficiency, higher quality, and greater customer satisfaction.

Best Practices for Lean Success

Achieving lean success requires organizations to focus on continuous improvement, empower employees, and foster a culture of collaboration and problem-solving. Prioritizing the development of lean practitioners and leaders is crucial, as it provides them with the necessary resources and training to lead lean transformation initiatives. Organizations should emphasize the importance of teamwork, open communication, and data-driven decision making to drive process optimization and reduce costs. By implementing these best practices, companies can significantly decrease waste and defects, enhance operational performance, and support sustainable business growth. A strong commitment to lean culture and the ongoing development of practitioners ensures that organizations remain agile and competitive in a rapidly evolving marketplace.

Who Should Take This Course?

This course is ideal for:

- Manufacturing and supply chain professionals

- Engineers and operations managers

- Quality control and continuous improvement leaders

- Project managers and change agents looking to enhance their skillset

- Anyone aiming to gain knowledge in lean strategies, earn certification, and demonstrate successful completion

Job Opportunities in Lean Manufacturing

The field of lean manufacturing offers a wide range of job opportunities for individuals passionate about process improvement, innovation, and operational excellence. From hands-on roles in production and quality control to leadership positions in operations and supply chain management, there is a growing demand for skilled lean practitioners across industries. Organizations are actively seeking professionals who can help reduce costs, drive process improvement, and enhance customer satisfaction. Careers in lean manufacturing offer opportunities for professional growth, continuous learning, and the chance to work on challenging projects that have a tangible impact. Whether you are just starting or looking to advance your career, lean manufacturing offers dynamic opportunities for individuals committed to driving change and achieving success in the manufacturing sector.

Benefits of Certification

Achieving certification means you can:

- Showcase your understanding of lean manufacturing methods

- Promote increases in customer satisfaction, reduce waste, and optimize processes

- Take on leadership roles and drive continuous improvement

- Gain credibility and better job opportunities in lean-driven organizations

How It Works – Your Lean Journey

- Self-paced training modules covering lean principles and tools

- Real-life manufacturing scenarios and group problem-solving

- Quizzes, simulations, and projects to reinforce learning

- Final assessment and certification for those who complete successfully

Resource Spotlight

🎓 Lean Manufacturing Course – Become a Certified Lean Expert

- Comprehensive coverage: lean principles, value stream mapping, 5S, Kaizen

- Tools for optimization, waste reduction, and quality control

- Insight from experienced practitioners and lean transforms

- Lifetime access, certificate upon completion, shareable with your team

💡 GET LEAN Simulation Game

- An interactive simulation focused on lean tools in production

- Engages participants in problem-solving and operational enhancement

- Supports real-world application of course learnings

Real-World Impact

Case Study Outcomes:

- 30–50% reduction in unplanned downtime

- 20–40% increase in production throughput

- 15–30% cost savings while improving quality

- Enhancement of customer loyalty and internal collaboration

These results stem from the implementation of lean practices taught in the course across global manufacturing sites and supply chains.

Take the Next Step!

Deliver real change in your organization—from process optimization and quality improvement to cost reduction and sustainable lean culture.

👉 Ready to lead lean transformation?

Enroll in our Lean Manufacturing Course today and gain the skills, methods, and certification to make a measurable difference.

Join the lean journey—become a valuable asset, drive higher performance, and steer your organization toward success in continuous improvement.