Spis treści

Lean Manufacturing Industry: Driving Efficiency and Excellence in Modern Production

In today’s rapidly evolving industrial landscape, lean manufacturing has emerged as a cornerstone for organizations seeking to enhance efficiency, reduce waste, and deliver superior value to customers. Rooted in the Toyota Production System, the lean production system originated from the need to improve efficiency in automobile manufacturing, particularly at Toyota. Lean manufacturing principles have transcended their automotive origins to revolutionize sectors ranging from healthcare to software development.

The assembly line, pioneered by Henry Ford, played a significant role in shaping lean manufacturing by demonstrating that simple, repetitive steps could reduce waste and increase efficiency. While mass production methods dominated Western industries, Japanese manufacturers like Toyota contrasted these approaches by developing the lean production system, which focused on demand-driven processes rather than economies of scale.

Understanding Lean Manufacturing

At its core, lean manufacturing is a systematic approach focused on minimizing waste without compromising productivity. Through systematic process improvement, lean manufacturing aims to reduce waste, increase efficiency, and deliver greater customer value. Organizations can streamline their production processes, improve quality, and respond more effectively to customer demand by identifying and eliminating non-value-adding activities.

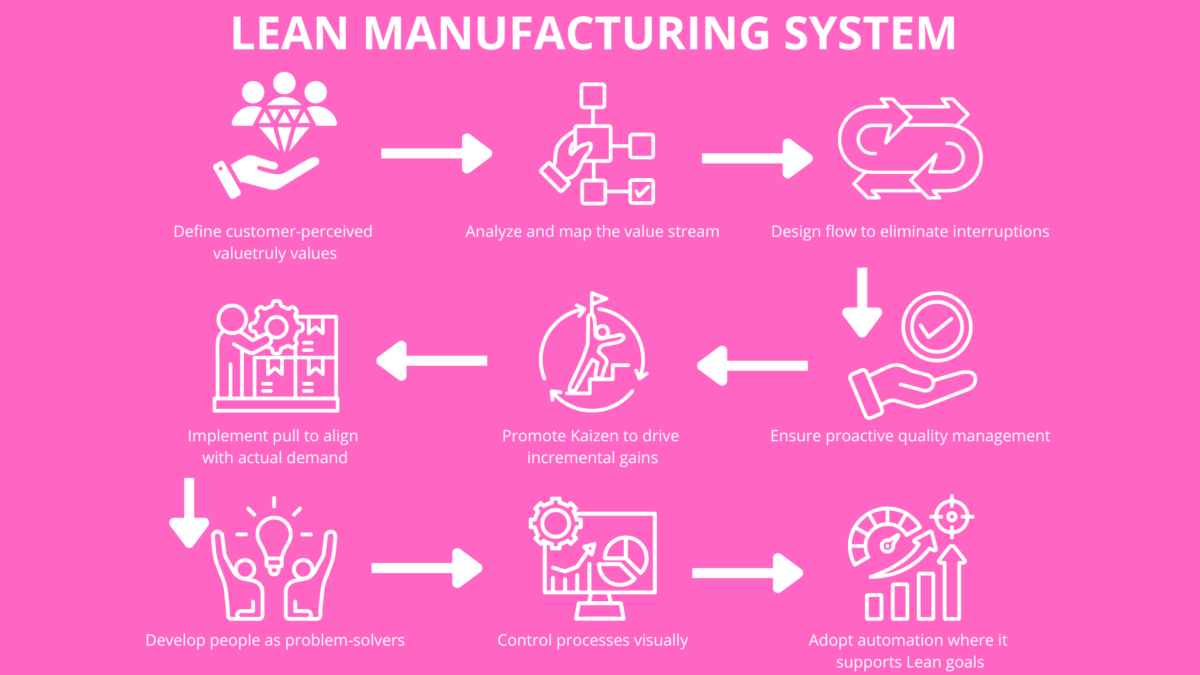

The principles of lean manufacturing revolve around:

- Identifying Value: Understanding what the customer perceives as value.

- Mapping the Value Stream: Analyzing the flow of materials and information to pinpoint waste.

- Creating Flow: Ensuring smooth progression of products through the manufacturing process by removing barriers and creating flow throughout the value stream.

- Establishing Pull: Producing based on actual customer demand rather than forecasts.

- Pursuing Perfection: Continuously seeking perfection by improving processes and eliminating waste.

These key principles and underlying principles of lean manufacturing serve as the foundation for lean practices, guiding organizations to eliminate waste and optimize value streams.

These principles guide organizations in implementing lean manufacturing techniques that enhance efficiency and reduce costs. Organizations adopt lean processes to streamline processes, drive process improvement, and foster a culture of continuous improvement throughout their operations.

Consider enrolling in our Lean Management Course to understand these principles and their application comprehensively. It offers practical insights into implementing lean methodologies effectively.

History and Evolution of Lean Production

Lean manufacturing began in the 1950s with the development of the Toyota Production System (TPS) by visionaries Taiichi Ohno and Shigeo Shingo. Drawing inspiration from scientific management and just-in-time production, TPS set out to revolutionize product production by eliminating waste, improving flow, and delivering maximum value to customers.

Lean manufacturing was introduced in the 1990s to describe an innovative approach that sought to minimize waste and optimize every step of the production process. Over time, lean production has evolved, incorporating powerful new tools and techniques such as value stream mapping and total productive maintenance to further enhance efficiency and quality.

While its roots are firmly planted in the automotive industry, the influence of lean production has spread far and wide. Today, organizations across sectors—from aerospace and healthcare to software development and beyond — leverage the core principles of lean: eliminate waste, reduce variability, and create seamless flow throughout the value stream.

Guided by management philosophies like the Toyota Way and the teachings of the Lean Enterprise Institute, the history of lean production is a testament to continuous improvement and relentless innovation. At its heart, lean manufacturing remains dedicated to creating customer value and driving excellence by systematically removing all forms of waste.

Key Components of Lean Manufacturing Systems

Implementing a successful lean manufacturing system involves several critical components:

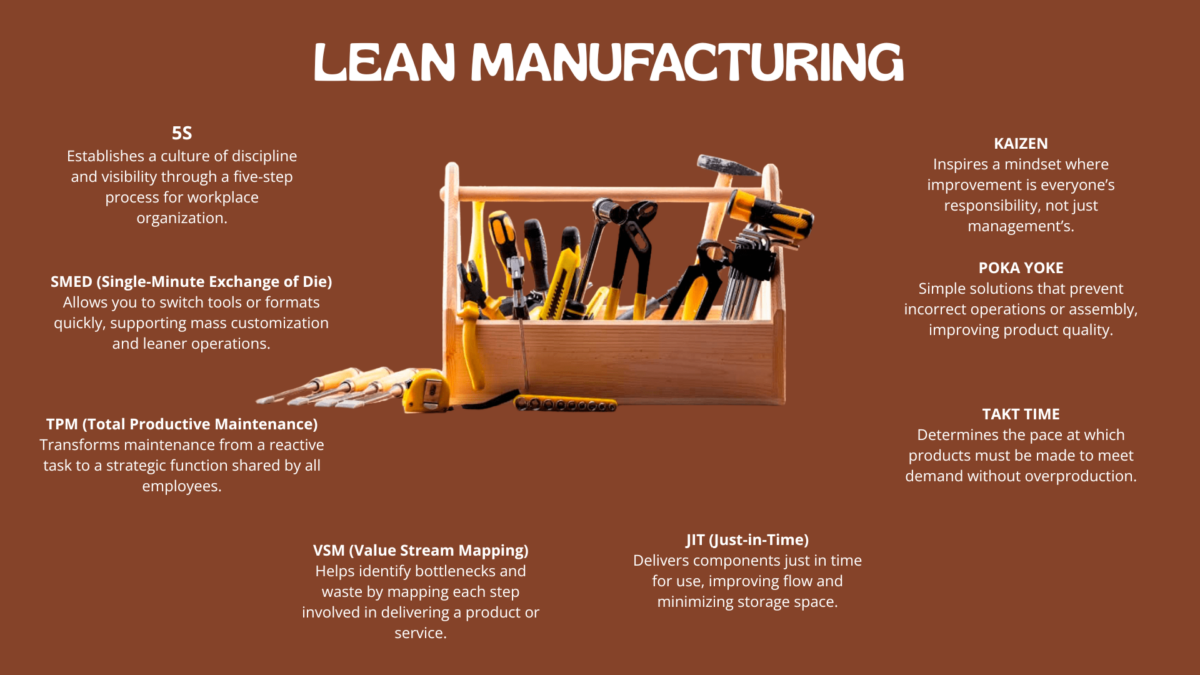

- Just-In-Time (JIT) Manufacturing: Also known as just-in-time manufacturing, this approach aligns production schedules with demand, reducing excess inventory and storage costs.

- Value Stream Mapping: Visualizes the flow of materials and information, identifying waste areas and opportunities for improvement.

- 5S Methodology: Focuses on workplace organization to enhance efficiency and safety.

- Total Productive Maintenance (TPM): Aims to improve equipment reliability and reduce downtime.

- Pull Systems: A pull system ensures production is based on actual demand rather than forecasts. Establishing a pull system minimizes waste and improves efficiency throughout the production line.

Lean manufacturing methodologies and methods are widely applied across manufacturing facilities to improve processes, streamline operations, and reduce waste.

By integrating these lean tools, manufacturing companies can significantly improve productivity and quality. Manufacturing resource planning (MRP) has traditionally been used for production scheduling and inventory management. Still, lean manufacturing contrasts with MRP by emphasizing demand-driven processes, such as the pull system and just-in-time manufacturing, to reduce waste. Streamlining processes and optimizing the production cycle in production lines and manufacturing facilities are essential for eliminating inefficiencies and maximizing output.

Enhance your ability to identify and solve production inefficiencies with our Effective Problem-Solving Process Course, designed to equip professionals with practical tools for root-cause analysis and solution implementation.

Lean Manufacturing Tools

Organizations rely on specialized tools and methodologies to streamline production and eliminate waste to implement lean manufacturing principles. These tools are the foundation for implementing lean thinking and driving meaningful process improvements.

One of the most impactful tools is value stream mapping, which provides a visual overview of the entire value stream, highlighting inefficiencies and pinpointing opportunities for improvement. Root cause analysis is another essential technique that enables teams to dig deep and uncover the underlying causes of recurring issues in the production process.

Total productive maintenance maximizes equipment effectiveness and minimizes downtime, ensuring that machinery operates at peak performance. Various lean manufacturing techniques—from standardized work to visual management—help organizations reduce variability, improve flow, and foster a culture of continuous improvement.

By integrating these lean manufacturing tools into daily operations, companies can achieve significant gains in productivity, quality, and customer satisfaction while supporting the goal of eliminating waste and creating lasting value.

Value Stream Mapping

Value stream mapping is a cornerstone of lean manufacturing. It offers a powerful way to visualize and analyze the entire production process —from the arrival of raw materials to the delivery of finished products to customers. This tool enables organizations to map the flow of materials and information, making it easier to spot bottlenecks, redundancies, and sources of waste.

The process begins by identifying the value stream for a specific product or service, then creating a detailed map of the current state. This map highlights every step in the process, revealing where delays, excess inventory, or unnecessary movements occur. The next step is to design a future-state map that represents the ideal, waste-free production process.

Value stream mapping is not limited to manufacturing; it can be applied to any workflow, including service and software development. By using this tool, organizations can eliminate waste, streamline operations, and ultimately deliver greater customer value. The benefits are clear: improved productivity, shorter lead times, and higher customer satisfaction.

Benefits of Lean Manufacturing

Adopting lean manufacturing offers numerous advantages:

- Waste Reduction: Eliminates non-value-adding activities considered waste, such as unused materials, leading to cost savings.

- Improved Quality: Focuses on defect prevention and continuous improvement.

- Enhanced Flexibility: Allows for quicker responses to changes in customer demand.

- Increased Employee Engagement: Empowers workers to contribute to process improvements.

- Better Inventory Management: Reduces excess inventory, wasted resources, and associated production costs.

Lean manufacturing helps organizations create wealth by reducing wasted resources and production costs.

These benefits contribute to a more efficient production process and higher customer satisfaction. Such improvements make a meaningful and lasting difference in operational efficiency and customer value.

Lean Manufacturing Across Industries

While initially developed for the automotive industry, the principles of lean manufacturing have been successfully applied across various sectors:

- Healthcare: Streamlining patient care processes to reduce wait times and improve outcomes.

- Software Development: Implementing agile methodologies to enhance product delivery.

- Construction: Optimizing project workflows to minimize delays and cost overruns.

- Retail: Managing inventory and the supply chain to meet customer demand efficiently.

Lean manufacturing principles also optimize the entire supply chain —from production to distribution —reducing waste and improving efficiency at every stage.

A high-performance supplier network supports lean manufacturing across industries by providing reliable, flexible, high-quality supply sources that enhance operational excellence.

These examples demonstrate the versatility and effectiveness of lean principles beyond traditional manufacturing settings.

Challenges in Implementing Lean Manufacturing

Despite its benefits, implementing lean manufacturing can present challenges:

- Cultural Resistance: Employees may be hesitant to adopt new processes. Additionally, functional barriers in the work environment, such as poorly planned facility layouts or departmental silos, can hinder lean implementation by obstructing process flow and waste elimination.

- Resource Constraints: Limited time and budget can hinder implementation efforts.

- Sustaining Momentum: Maintaining focus on continuous improvement requires ongoing commitment.

Addressing these challenges involves strong leadership, clear communication, and a structured approach to change management. Successful lean manufacturers overcome these obstacles by fostering a supportive work environment and a lean culture that encourages open communication, employee engagement, and continuous improvement.

Measuring Success in Lean Manufacturing

Achieving excellence in lean manufacturing requires more than just implementing new processes—it demands a commitment to measuring and sustaining progress. Organizations track key performance indicators (KPIs) such as lead time, cycle time, and inventory levels to gauge the effectiveness of their lean manufacturing system.

Beyond operational metrics, monitoring customer satisfaction, product quality, and overall productivity is essential. The true goal of lean manufacturing is to foster a culture of continuous improvement, where every employee is empowered to identify and address challenges.

A balanced measurement approach combines financial and non-financial metrics, using data and analytics to inform decisions and drive ongoing improvement. Tools such as value stream mapping and root cause analysis help organizations pinpoint areas for further improvement.

Regular monitoring and evaluation ensure that improvements are sustained, leading to reduced waste, increased efficiency, and consistently high levels of customer satisfaction. In this way, measuring success becomes an integral part of the lean journey, supporting the pursuit of operational excellence.

The Role of Continuous Improvement

At the heart of lean manufacturing is the concept of continuous improvement, or Kaizen. This philosophy encourages ongoing, incremental enhancements to processes, fostering a culture in which employees at all levels actively identify and implement improvements. Unlike a standard lean production model, which does not exist due to lean’s adaptability, continuous improvement is tailored to each organization’s unique needs and circumstances.

By embracing continuous improvement, organizations can:

- Adapt to changing market conditions.

- Enhance operational efficiency.

- Foster innovation and employee development.

Consider our Continuous Improvement Course to delve deeper into the principles of continuous improvement and learn how to drive efficiency across your organization.

Sustaining a Lean Culture

Building and maintaining a lean manufacturing culture is a long-term endeavor that hinges on a steadfast commitment to continuous improvement and a relentless focus on creating customer value. Empowering employees at every level to identify and solve problems is crucial, as is providing ongoing training and development in lean manufacturing principles.

Lean manufacturing tools—such as value stream mapping and total productive maintenance—help organizations embed lean thinking into their daily routines. Strong leadership sets the tone for a culture that prioritizes eliminating waste, reducing variability, and striving for the perfect production process.

Sustaining a lean culture also means regularly assessing progress, using metrics like employee engagement and customer satisfaction to ensure the organization remains on track. This ongoing commitment to excellence delivers lasting benefits: improved productivity, reduced waste, and a reputation for providing exceptional value.

Ultimately, sustaining a lean culture is not a one-time effort but a continuous journey that requires dedication, adaptability, and a shared vision for operational excellence across the entire organization.

Conclusion

Embracing the lean manufacturing industry enables organizations to enhance efficiency, reduce waste, and deliver greater customer value. By understanding and applying lean manufacturing principles, businesses can create more efficient processes, foster a culture of continuous improvement, and achieve sustainable success in today’s competitive environment.

To gain practical knowledge on organizing your workspace for maximum efficiency and safety, explore our Fundamentals of 5S Course, which delves into the 5S methodology—a cornerstone of lean manufacturing.

If you want to deepen your understanding of lean principles and their practical application, consider enrolling in our Lean Management Course. This course offers comprehensive insights and hands-on strategies for effectively implementing lean methodologies.

Additionally, explore our Get Lean Simulation Game for an interactive learning experience that brings lean concepts to life through real-world scenarios.

Enhance your skills further with our specialized courses:

- Effective Problem-Solving Process: Master techniques to identify root causes and implement sustainable solutions.

- Continuous Improvement: Drive efficiency and agility across your organization.

- Effective Teamwork and Leadership: Build strong teams and leadership skills for lean success.

- The Fundamentals of 5S: Learn to organize your workspace for maximum efficiency and safety.

Embark on your lean journey today and improve your organization’s operations.