Spis treści

Lean Production Principles: How to Rethink Manufacturing for Maximum Impact

Lean production principles are the foundation of efficient, customer-focused manufacturing. Originating from the Toyota Production System, they offer a structured approach to reducing waste, enhancing flow, and aligning operations with real customer needs. This approach is often referred to as the lean production system, which was developed and refined by Toyota to achieve world-class manufacturing performance. These principles serve as a strategic blueprint for manufacturers seeking to increase competitiveness and long-term sustainability. The development of lean production principles was also influenced by early 20th-century scientific management, which emphasized process optimization and efficiency.

More than just tools or practices, lean principles are a mindset—one that promotes operational excellence, employee involvement, and relentless improvement. At its core, lean philosophy provides the cultural foundation for these principles, emphasizing the importance of shared values and beliefs in driving continuous improvement. Fostering a constant improvement culture is essential, as it encourages organizations to eliminate waste, enhance quality, and engage employees at all levels. Organizations must understand lean as a philosophy and follow a structured process that embeds its principles into daily operations to implement lean effectively. A key to success is understanding lean manufacturing, its origins, and its impact on modern production practices. In this article, we dive deep into lean manufacturing principles, explore how they’re applied across industries, and provide practical recommendations for sustainable lean implementation.

The Five Core Principles of Lean Production

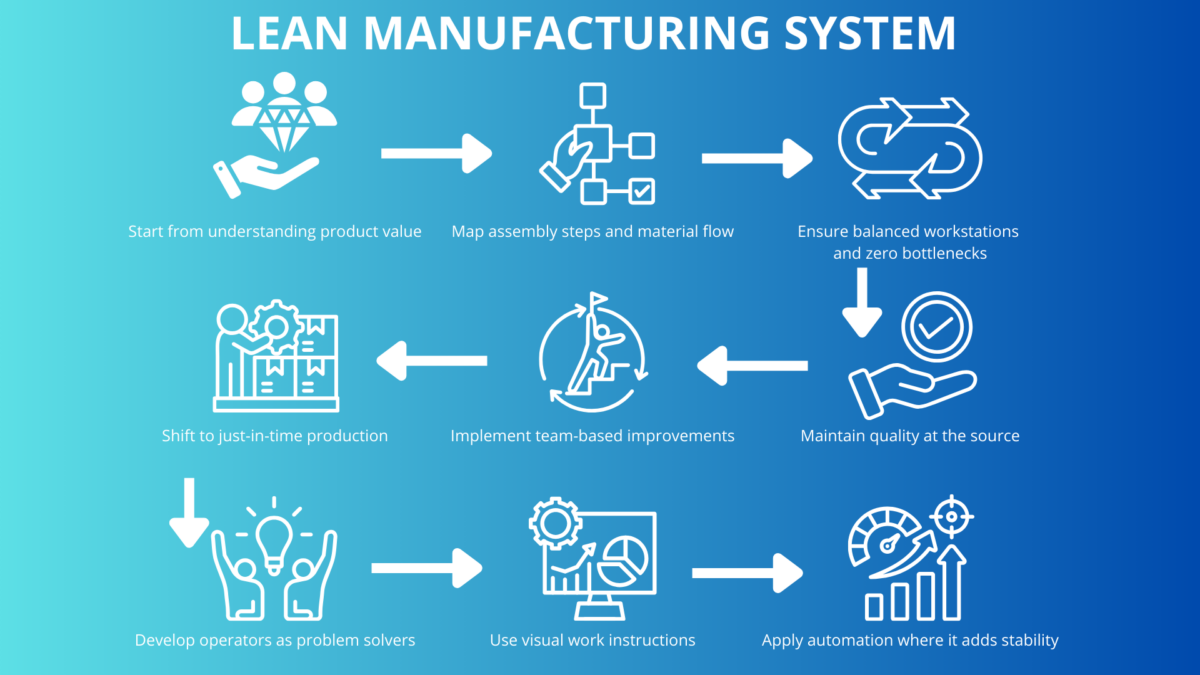

The fundamental framework behind lean manufacturing rests on five interrelated principles (often referred to as the five principles or five lean principles), which serve as the foundation for continuous process improvement and waste elimination, with each lean principle guiding organizations to enhance efficiency and reduce waste:

1. Focus on Customer Value

The customer is the ultimate judge of value. In lean manufacturing, everything begins with understanding customer value—what the customer truly wants and is willing to pay for. This principle forces organizations to think externally and consider the customer’s perspective when designing, producing, and delivering products or services.

Practically, this may involve speaking directly with customers, conducting surveys, and evaluating how your product fits into their workflows. The goal is to eliminate anything that does not contribute to customer value, cutting waste and freeing up resources to invest in improvements that matter. By focusing on customer value and eliminating waste, organizations can create wealth by maximizing value and reducing costs.

This foundational mindset helps reduce complexity and shift focus toward the outcomes customers expect. It also underpins all subsequent steps in the lean methodology.

2. Map the Entire Value Stream

Once customer value is clearly defined, the next step is to analyze and visualize every process involved in delivering that value. This is achieved through value stream mapping—a powerful tool that allows organizations to document their production process, including both value-added and non-value-added steps. To do this, teams map the value stream to create a detailed visualization of all steps, helping to identify waste and optimize efficiency.

This mapping helps identify redundancies, bottlenecks, and points where unnecessary movement, inventory, or waiting time accumulates. Teams use this information to plan changes that remove barriers to efficiency and enhance the flow of materials and information. Mapping the value stream can extend across the entire supply chain, allowing organizations to spot waste from sourcing raw materials to final delivery.

By actively involving cross-functional teams in the mapping process, companies gain deeper insight into how different departments contribute (or fail to contribute) to value creation. Mapping can also include the production line, helping to optimize workflow and improve efficiency. It also serves as a training tool for identifying lean waste and enables better collaboration.

🧠 Learn how to analyze and improve your processes with the Problem-Solving Course.

3. Create a Smooth and Continuous Flow

The goal of lean is not only to eliminate waste but also to ensure that production flows smoothly and continuously through all stages of the operation, so that materials and information flow smoothly without interruptions. A well-designed flow enables products to move through manufacturing without interruptions, delays, or unnecessary backtracking. Creating flow is essential for minimizing delays and bottlenecks, ensuring a seamless and efficient value stream.

This often requires reducing batch sizes, balancing workloads, and investing in equipment that supports flexibility and quick changeovers. Tools such as 5S, takt time, and standard work are frequently used to improve flow and reduce variability. These tools help create flow and support efficient processes by eliminating waste and streamlining operations.

A smooth flow boosts quality, reduces lead times, and minimizes the need for excess inventory, allowing businesses to respond faster to changes in customer demand. Efficient processes are foundational to lean, supporting sustainability and reducing costs.

📘 Want to set up your operations for optimal flow? Take the 5S Course.

4. Establish a Pull System

Companies often rely on forecasts to plan production in traditional production systems, setting production targets as a key feature of these conventional push systems. Lean manufacturing, however, employs a pull system where production is triggered by actual customer demand, not predictions. This ensures that companies produce only what is needed, when, and in the quantity required.

Pull systems reduce the risks associated with overproduction, such as wasted materials, increased storage costs, and inefficient processes. Tools like Kanban, supermarkets, and visual signals help coordinate inventory and production in real-time.

A pull system enhances flexibility and responsiveness while encouraging tighter coordination between suppliers and internal processes. It also creates transparency throughout the supply chain.

5. Pursue Continuous Improvement

The fifth principle—often called kaizen—is the engine that drives Lean’s long-term success. Driving continuous improvement is a systematic, ongoing effort to enhance productivity and reduce waste throughout the organization. It encourages everyone, from frontline operators to senior executives, to reflect regularly and experiment. The aim is to make small, incremental changes that gradually lead to significant improvements.

This continuous improvement mindset also requires lean leadership, structured problem-solving, and supportive systems that track progress and celebrate success. The PDCA cycle (Plan, Do, Check, Act) is one common framework for implementing and sustaining change. In Lean, cutting excess inventory is more than a cost-saving measure—it’s a strategic move that supports long-term growth, customer satisfaction, and the pursuit of perfection in every aspect of the production process. The seek perfection principle encourages organizations to continually optimize quality and efficiency, recognizing that perfection is an ongoing journey rather than a final goal.

🧩 Build your improvement strategy with our Continuous Improvement Course.

Key Concepts Supporting Lean Production

Lean Thinking Beyond Manufacturing

While rooted in manufacturing, lean thinking extends into service industries, logistics, healthcare, and education. The principles of flow, pull, and customer focus are universal and applicable to any process that delivers value. This broader application is often called a lean enterprise, which goes beyond lean manufacturing by integrating lean management practices across the entire organization, including areas like accounting and supply chain, to drive strategic business improvement.

Standard Lean Production Models

Standardization does not mean rigidity—it means clarity and consistency. Standard lean production models ensure that tasks are completed the same way every time, allowing teams to detect abnormalities, improve quality, and train new workers more effectively.

Just-in-Time vs. Just-in-Case

The Lean preference for just-in-time inventory systems contrasts with traditional “just-in-case” stockpiling. Just-in-time delivery is crucial for minimizing inventory costs and ensuring the timely and efficient distribution of goods. While JIT reduces storage costs and increases responsiveness, it must be implemented with care to avoid shortages or disruptions.

Managing Inventory for Lean Success

Effective inventory management is at the heart of lean manufacturing success. Lean manufacturing principles emphasize keeping inventory levels as low as possible to eliminate waste and ensure that resources are used efficiently throughout production. By minimizing excess inventory, manufacturers can reduce costs, improve cash flow, and create a more agile operation that responds quickly to customer demand.

A key strategy in lean inventory management is implementing a pull system. Instead of producing goods based on forecasts, production is triggered by actual customer demand, ensuring that only what is needed is made, when it’s needed. This approach reduces the risk of overproduction and helps streamline the entire value stream, from raw materials to finished goods.

Value stream mapping is an essential lean tool for optimizing inventory management. By mapping the value stream, manufacturers can pinpoint areas where inventory accumulates unnecessarily, identify bottlenecks, and uncover opportunities to improve the flow of materials and information. Streamlining inventory management in this way leads to greater manufacturing efficiency, lower storage costs, and higher customer satisfaction.

Effective inventory management guided by lean manufacturing principles ultimately gives companies a competitive edge. It allows them to deliver value to customers faster and more reliably while reducing waste.

Lean Tools and Techniques That Drive Results

Lean manufacturing offers a powerful toolkit for driving real results in production environments. The most impactful lean tools are value stream mapping, root cause analysis, and total productive maintenance. These techniques help organizations identify and eliminate waste, improve flow, and boost efficiency across all production processes.

Value stream mapping provides a clear visual of the entire production process, making it easier to spot inefficiencies and areas for improvement. Root cause analysis digs deep into problems to uncover their underlying causes, ensuring that solutions address the source rather than just the symptoms. Total productive maintenance maximizes equipment reliability, reduces downtime, and supports a smooth, continuous flow.

Implementing lean manufacturing principles such as continuous improvement and a relentless focus on customer value transforms these tools from one-off projects into ongoing habits. Lean thinking encourages teams to assess their processes regularly, seek new ways to eliminate waste, and strive for operational excellence.

These lean tools and techniques are not limited to manufacturing—they have proven effective in the automotive industry and beyond, helping organizations in diverse sectors improve efficiency, reduce waste, and create a culture of continuous improvement. Manufacturers can achieve sustainable, long-term success by embracing lean production systems and integrating these tools into daily operations.

Reducing Excess Inventory: The Hidden Opportunity

Excess inventory is often an overlooked barrier to lean manufacturing success. It ties up valuable resources, increases storage costs, and can mask underlying inefficiencies in production processes. Lean manufacturing principles offer a clear path to tackling this challenge and unlocking hidden opportunities for improvement.

By adopting just-in-time production and a pull system, manufacturers can align production more closely with actual customer demand, significantly reducing the risk of accumulating excess inventory. Understanding and applying the five key principles of lean manufacturing—value, value stream, flow, pull, and perfection—enables organizations to identify where inventory builds up unnecessarily and take targeted action to address it.

Reducing excess inventory frees up working capital, improves cash flow, and enhances a company’s ability to respond quickly to market changes. Effective inventory management, guided by lean manufacturing principles, is essential for achieving operational excellence and maintaining a competitive edge.

For manufacturers committed to continuous improvement, cutting excess inventory is more than a cost-saving measure—it’s a strategic move that supports long-term growth, customer satisfaction, and the pursuit of perfection in every production process.

Real-World Applications of Lean Production Principles

Automotive Industry

Lean originated in the Toyota Motor Corporation, where its application led to faster assembly lines, reduced waste, and improved quality. Toyota also addressed issues such as poor quality castings through process improvements and the Toyota Production System.

Healthcare

Hospitals use Lean to streamline patient flow, minimize waiting times, and reduce unnecessary movement in treatment areas.

Food and Beverage

Lean methods reduce spoilage and enhance safety by aligning production more closely with consumer demand.

Software Development

In Agile and DevOps, Lean informs value delivery, flow efficiency, and minimizing rework.

Common Pitfalls in Implementing Lean

- Misaligned KPIs: Focusing on local rather than system-wide metrics may reinforce siloed behavior.

- Tool Overload: Overusing tools without a clear purpose dilutes Lean’s impact.

- Lack of Engagement: Employees need to be empowered, not micromanaged.

- Weak Leadership Commitment: Without ongoing leadership support, lean initiatives stall.

Some critics of lean management argue that lean approaches may overlook employee safety and well-being, and there are ongoing debates about their overall effectiveness.

💡 Explore strategies for effective leadership in the Teamwork and Leadership Course.

Expanding Capabilities Through Practical Learning

The Importance of Hands-On Training

Theory without practice is a missed opportunity. Our Lean Management Course bridges the gap between conceptual understanding and implementation. It is based on 25 years of consulting across industries—from lean manufacturing plants to service providers. The hands-on training directly improves operating performance by enhancing productivity and quality.

It offers:

- Actionable case studies

- Templates and checklists

- Instructor feedback

- Flexible, on-demand content

🎓 Curious? You can preview a sample lesson before enrolling.

Simulate Before You Implement

Want a safe space to test ideas? The GET LEAN Simulation Game is a unique tool for teams to learn Lean principles through interactive challenges, process redesigns, and decision-making simulations. Simulation games like this also allow teams to practice integrating lean principles with emerging technologies and digital tools.

This gamified experience improves:

- Collaboration

- Systems thinking

- Real-time adaptation

Additional Resources to Accelerate Your Lean Journey

- 🛠️ 5S Workplace Organization Course

- 🔍 Problem-Solving Course

- 📈 Continuous Improvement Course

- 🤝 Teamwork and Leadership Course

Additional Resources to Accelerate Your Lean Journey

Mastering lean manufacturing tools is essential for supporting ongoing improvement and implementing lean principles across various industries.

Conclusion: Make Lean a Strategic Pillar

The future belongs to organizations that can adapt quickly, respond to customer needs, and do more with less. Lean production principles offer a path to building such organizations by aligning people, processes, and priorities around continuous learning and value creation. By focusing on lean production, organizations can develop productive processes that drive long-term success.

Take action today. Invest in your team. Build a culture of excellence.

👉 Start learning now with our practical, expert-led Lean Management course.

And don’t miss the opportunity to explore the GET LEAN Simulation Game for an unforgettable hands-on experience of Lean in action.