Lean Activity: Transforming Teams Through Hands-On Lean Learning

What is a Lean Activity?

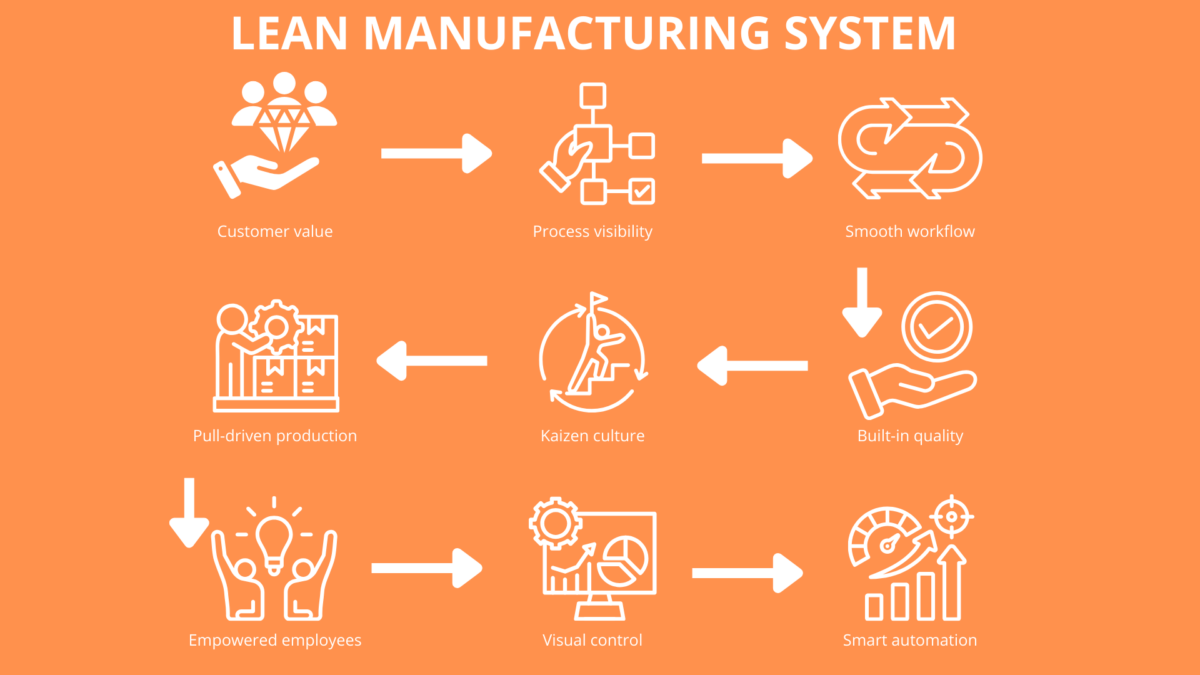

A lean activity is a hands-on, interactive method that allows teams to understand and apply Lean principles practically and engagingly. It can take many forms, such as a lean game, a short game focused on a specific process, or a full-scale value stream mapping exercise. These activities are widely used in business settings, with companies across industries adopting them to drive improvement. Regardless of the format, the goal of a Lean activity is to help teams eliminate waste, improve flow, and optimize their processes using proven Lean tools. Lean activities demonstrate the value of 5S and workplace organization, measuring success in creating more organized and efficient environments. Lean is rooted in the Toyota Production System, which laid the foundation for its principles and widespread adoption.

By participating in a Lean activity, teams learn how to identify and remove bottlenecks, implement one-piece flow, apply the pull system, and create a lean culture focused on continuous improvement. Whether it’s a plastic bricks exercise, a software development simulation, a practical work cell task, or an office scenario, Lean activities offer a fun, easy-to-understand way to internalize complex Lean concepts. These activities help make processes more efficient and support the elimination of waste throughout the organization.

Why Lean Activities Matter

Lean activities go beyond theory by allowing employees to see Lean principles. They:

- Teach problem-solving skills to improve quality and deliver value to customers.

- Show how to eliminate waste in the real world, focusing on activities that create direct customer value.

- Demonstrate pull systems and standardized work in practice to enhance quality.

- Help teams and groups understand lean manufacturing and lean six sigma principles.

- Build group collaboration and communication across roles.

Looking to boost your Lean expertise? Enroll in our Lean Management course, where you’ll gain practical knowledge from over 25 years of Lean implementation experience.

Popular Lean Activity Examples

The Get Lean Simulation Game

The Get Lean Simulation Game is a prime example of a Lean activity. Developed from nearly 25 years of Lean consulting across diverse industries, this game challenges teams to deliver products efficiently while meeting customer expectations. Using plastic bricks and a structured approach with six rounds, players simulate a real company environment, learning to manage process flow, optimize batch sizes, and reduce waste. Participants work around a table in this lean lego game and may be tasked with building houses using one set of bricks per round. Some rounds may ask participants to draw a specific item, such as a fish, to illustrate variation and process understanding. Each round or task must be fully completed before moving to the next, emphasizing the importance of thorough execution and documentation.

With each purchase of the Get Lean Simulation Game, participants receive an email code unlocks access to all of Sabat Consulting’s Lean courses—an incredible opportunity to deepen their knowledge and practical skills.

Value Stream Mapping Workshop

Value Stream Mapping is a classic lean activity and a form of continuous improvement that helps teams identify waste in their processes, improve the flow of information and materials, and create a roadmap for constant improvement. Value stream mapping refers to a Lean tool used to visualize and analyze the steps involved in delivering a product or service, highlighting areas for improvement. It’s a fundamental tool for lean implementation in manufacturing, software development, and service organizations. The outcome of a value stream mapping workshop often includes a plan for designing or implementing a new process to enhance efficiency and reduce waste.

Explore our Continuous Improvement course to learn how to lead impactful Lean activities like VSM sessions.

One Piece Flow and Pull System Simulations

Activities like one-piece flow games demonstrate how reducing batch sizes and using pull systems can improve efficiency, reduce inventory, and increase customer satisfaction by producing items more efficiently. Teams often changed their approach or process during the simulation to optimize results. Participants experience how Lean concepts apply across various industries, from manufacturing to software development, including developing new workflows and creating continuous workflows that add value.

For a comprehensive guide to implementing Lean in your workplace, check out our Effective Problem Solving course.

Team Roles and Debriefing in Lean Activities

In any Lean activity, clearly defined team roles and structured debriefing sessions are essential for driving real improvement. Assigning specific roles within the team, such as operator, observer, or facilitator, ensures that everyone actively eliminates waste and enhances efficiency. These roles help teams focus on different aspects of the process, making it easier to spot areas where waste occurs and where Lean principles can be applied for better results.

During Lean games or simulations, each team member’s responsibilities are aligned to streamline processes and support continuous improvement. For example, operators might focus on completing tasks efficiently, while observers track where delays or bottlenecks happen. Facilitators guide the team, ensuring that Lean tools and techniques are used effectively throughout the activity.

After the activity, debriefing sessions provide a structured opportunity for teams to reflect on their experiences. This is where the real learning happens: teams discuss what worked, what didn’t, and where waste was identified. By sharing observations and insights, teams can pinpoint improvements to implement in their work processes. Debriefing is not just a recap—it’s an essential step in the Lean journey, turning hands-on practice into actionable improvement.

By emphasizing team roles and debriefing, Lean activities empower teams to take ownership of their processes, collaborate more effectively, and make continuous improvement a natural part of their daily work. This focus on teamwork and reflection makes Lean a powerful method for eliminating waste and achieving lasting results.

Lean Activity Benefits

Participating in Lean activities helps teams:

- Understand Lean principles, including kaizen (continuous improvement), and Japanese words used in Lean.

- Develop practical skills in waste elimination.

- Learn how to create a Lean culture through standard work and visual management.

- Practice real-world problem-solving techniques.

- Build team cohesion through collaborative learning.

These activities are designed to make Lean easy to understand. While they may sound simple, they are highly effective in driving improvement. The main point is that Lean activities empower teams to improve and sustain results continuously. They provide a safe space for experimentation, allowing teams to learn from mistakes and improve their processes.

Ready to Implement Lean Activities in Your Organization?

Lean activities are an excellent way to introduce lean thinking to any organization. They help teams grasp Lean concepts like flow, identify waste, and understand the Lean model, while developing a continuous improvement mindset. Sign up for our Lean Management course today to learn more about applying these activities and developing Lean skills in your workplace. This practical program includes insights from 25 years of Lean consulting experience and a free preview of one lesson.

Additionally, explore our full range of Lean training courses:

- Lean Management course

- Effective Problem-Solving Course

- Continuous Improvement course

- Effective Teamwork and Leadership course

- 5S Workplace Organization course

Let Lean activities transform how your teams learn, play, and work together—creating a Lean mindset and culture, one Lean step at a time!