Transform Your Organization with an Innovative Lean Course: Mastering Lean Manufacturing Through Simulation

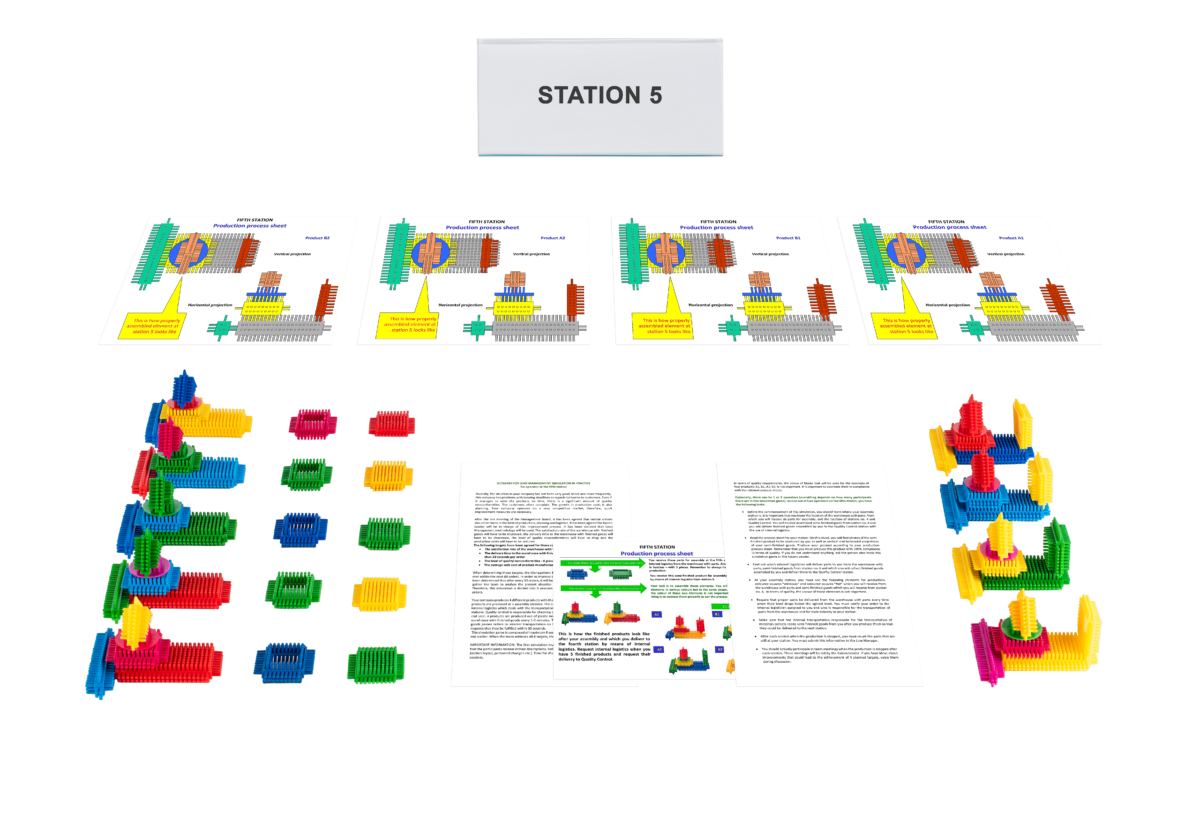

This detailed training station is part of a Lean Course. It provides hands-on experience with process flow, standardized work, and visual instructions.

In today’s fast-paced industrial landscape, effective training methods are essential for any company that strives for excellence in efficiency, quality, and competitiveness. One of the most transformative approaches is a lean course based on simulation-driven learning. Simulation-based training creates a laboratory environment where employees experience real-life challenges in a risk-free setting, understand the impact of their decisions, and learn how to implement lean principles that drive operational excellence.

Additionally, numerous online lean resources and community support options are available for continuous learning and networking. These virtual training and certification programs provide expertise in Lean Six Sigma, enhancing the overall learning experience.

I have developed an innovative simulation game based on my 25 years of hands-on experience in Lean Manufacturing – refined at respected companies such as General Motors, Gillette, Timken, and ABB. Over many years, I have designed this training tool to demystify the principles of a streamlined production process. This article delves into the essence of Lean Manufacturing, reveals the inner workings of our simulation game, and explains how a robust Lean course can drive lasting change across global enterprises.

The Impact of Simulation-Based Training on Employee Performance

Training methods based on simulation games have repeatedly proven effective in engaging employees and transforming behaviors. Unlike traditional classroom settings, simulation-based training immerses participants in realistic scenarios where they can safely experience challenges without risking actual operations. Lean methods and tools used in these simulations drive efficiency by enhancing continuous improvement and solving critical problems within the organization.

Why Simulation Works

- Immersive Learning Environment: Employees experience an environment that mimics real production conditions. They face challenges such as bottlenecks, quality issues, and supply delays. This “safe space” enables them to explore solutions without the pressure of real-world consequences.

- Hands-on Experience: The simulation lets participants test, fail, and iterate on process changes. It teaches them how to overcome obstacles, thereby increasing their problem-solving skills.

- Team Collaboration: Working in groups on a simulation game fosters communication and teamwork. Cross-functional collaboration becomes second nature, and solutions are developed through collective brainstorming.

- Real-Time Feedback: As participants execute tasks, they receive immediate feedback on their decisions. This rapid response loop accelerates learning and helps individuals understand the cause-and-effect relationships in production.

By participating in such a simulation, employees develop the critical thinking and operational expertise that are the cornerstones of any successful lean course. In turn, companies see improvements in productivity, waste reduction, and customer satisfaction.

Understanding Lean Manufacturing: The Foundation of a Lean Course

Lean Manufacturing is a systematic approach focused on minimizing waste and maximizing customer value. It transforms production systems through continuous improvement, waste elimination, and employee empowerment. A lean course structured around these principles provides actionable insights and practical training to help your organization excel. The lean journey involves education, certification, and a commitment to continuous improvement, which are essential for successfully adopting and integrating lean principles.

Core Principles of Lean Manufacturing

- Waste Reduction (Muda):

Lean Manufacturing targets non-value-added processes. Waste can be overproduction, waiting time, excess inventory, unnecessary transportation, over-processing, extra motion, and defects. The goal is to create a process where every step adds value to the final product. - Continuous Improvement (Kaizen):

At the heart of lean thinking is Kaizen – the commitment to continuous, incremental improvements. A successful lean course instills a mindset where small changes lead to significant long-term benefits. - Just-In-Time (JIT):

Companies reduce excess inventory and cut costs by producing only what is needed when it is required. JIT production is a fundamental component of lean practices. - Employee Empowerment:

Lean Manufacturing empowers frontline workers to identify problems and propose solutions immediately. A well-designed lean course underscores the importance of empowering teams to make decisions that improve the production process. - Value Stream Mapping:

This involves visualizing every step in the production process to identify inefficiencies and opportunities for improvement. A detailed mapping of the process is essential for any practical lean course.

These principles are not just theoretical; they are the building blocks of our simulation game, a practical tool that allows teams to live these concepts through real-world scenarios. Please see our detailed description of our simulation game to see how our tool operates.

How the Simulation Game Works as a Powerful Lean Course

Our simulation game is the practical implementation of a comprehensive lean course designed to teach Lean Manufacturing through interactive play. This tool breaks down complex production processes into manageable, engaging, educational, and transformational sessions.

Pre-Game Preparation: Setting the Stage

Before the simulation begins, the facilitator (typically the instructor) prepares the environment meticulously:

- Role Assignment:

Every participant receives a detailed role: operators, quality controllers, warehouse managers, and planners. Each role is pivotal and mirrors real-world responsibilities. - Workspace Arrangement:

The training area has multiple “stations,” like a production line. Each station has components (colorful blocks representing parts) that participants will use to assemble products according to specific instructions. - Pre-Session Briefing:

An introductory presentation explains Lean Manufacturing concepts, outlines the simulation’s objectives, and sets performance expectations. This briefing ensures that all participants understand the rules and goals of the simulation.

Running the Simulation: The Heart of the Lean Course

During the simulation, participants experience several rounds of production, each designed to replicate real manufacturing challenges:

- Order Fulfillment and Production Flow:

- The simulation starts with a client placing an order. Participants must collaborate to process the order, produce the required components, and assemble the final product within a strict timeframe.

- Each workstation follows a detailed playbook. Operators produce products, while quality controllers verify the integrity of the output. All actions are monitored to ensure adherence to lean principles.

- Each simulation round must be completed to gain the full benefits of the training.

- Performance Evaluation and Feedback:

- After each session, performance metrics such as on-time delivery, product quality, and overall production costs are analyzed. This performance evaluation is integral to the lean course, reinforcing continuous improvement.

- A debrief session follows each round, where challenges are discussed and strategies for process optimization are developed. The feedback loops enable participants to recalibrate their approach and improve in subsequent sessions.

- Iterative Process Improvements:

- The game is designed to be dynamic; adjustments are made based on real-time feedback. Teams experiment with changes, such as reorganizing workstations, optimizing resource allocation, or adjusting production schedules.

- Over multiple sessions, these iterative improvements reinforce lean methodologies and illustrate the long-term benefits of continuous improvement.

Real-World Applications

The mechanics of the simulation game closely mirror the complexities of real-life production systems:

- Waste Identification:

Players learn how bottlenecks occur and identify non-value-added activities, enabling them to target areas for waste reduction. - Cost Efficiency:

The simulation tracks production costs in real time. Managers learn to balance quality, speed, and cost-effectiveness, a key lesson of any lean course. - Enhanced Teamwork:

The game’s collaborative nature boosts communication among team members, leading to higher coordination and more effective problem-solving.

Many industry studies confirm that immersive approaches remarkably impact operational efficiency and employee engagement, authoritatively revealing the benefits of simulation-based training.

The Role of 25 Years of Experience in Shaping Our Lean Course

With a quarter-century of experience implementing Lean Manufacturing across Europe and beyond, I have witnessed firsthand the critical challenges organizations face when transitioning to lean processes. This extensive experience has informed every facet of our simulation game development. Our lean course is considered the gold standard in lean training and certification, recognized for its comprehensive approach to training, assessment, and practical application.

My Journey in Lean Manufacturing

- Foundational Training:

My academic and professional background in Production Economics provided the basis for an in-depth understanding of manufacturing challenges. I then expanded this foundation with practical experience in the United States, where I learned advanced methods such as Six Sigma and Kaizen. - Hands-On Implementation:

Working with industry giants like General Motors, Gillette, Timken, and ABB allowed me to refine my understanding of lean processes and develop strategies that yield real-world results. These experiences have been instrumental in creating a practical and highly effective simulation game. - Continuous Development:

Over many years, I have iterated on our simulation tools to create a methodology that makes lean principles accessible and relevant. This lean course educates and transforms operations by embedding lean thinking into daily routines.

The blend of academic knowledge and extensive practical experience ensures that our training is grounded in real-world applications. Companies worldwide have recognized the value of these strategies, and numerous global references attest to the success of our lean training simulation.

Global References: Proven Success Across Diverse Industries

Our simulation game has earned accolades from organizations around the world. Companies across various sectors have implemented this lean course and observed measurable efficiency, quality, and cost management improvements.

Success Stories and References

- Automotive Industry: A leading automobile manufacturer reported reduced production downtime and waste significantly after incorporating our simulation training.

- Consumer Goods: A major global brand leveraged our lean course to streamline production processes, improving product quality and customer satisfaction.

- Electronics Manufacturing: A renowned electronics firm used the simulation game to detect and eliminate bottlenecks in production, yielding substantial cost savings.

- Healthcare: Organizations in the healthcare sector have successfully used our simulation tool to optimize operations and enhance quality control, proving that lean principles can be universally applied regardless of industry.

These success stories from around the globe underscore the reliability and effectiveness of our simulation-based lean training and reinforce the importance of a comprehensive lean course in today’s competitive market. Additionally, this certification provides a significant competitive advantage, distinguishing candidates in the job market.

The Benefits of a Lean Course Delivered Through Simulation

Investing in a simulation-based lean course is a training expense and a strategic initiative that substantially benefits your organization. Below, we highlight some of the key advantages that your company can expect by adopting this approach:

1. Operational Efficiency

A central tenet of Lean Manufacturing is reducing waste and optimizing resources. The involvement of trained professionals in the lean course ensures that participants gain insights from experts with extensive industry experience. The simulation game replicates the entire production chain, forcing participants to identify and eliminate unnecessary steps, streamline processes, and achieve smooth production flows. Such insights translate into real-world improvements such as reduced downtime, minimized errors, and lower operational costs.

2. Quality Assurance and Control

During the simulation, every production error or defect is tracked meticulously. Employees learn to meet quality standards consistently. Improved quality control results in fewer defects on the production floor, boosting customer satisfaction and reinforcing the company’s reputation for excellence.

3. Enhanced Employee Engagement and Communication

The interactive nature of the simulation fosters a collaborative work culture. Employees engage actively with the training material and learn through doing rather than passively listening. This hands-on approach breaks down silos and promotes an environment in which employees are empowered to communicate, share insights, and collaborate toward shared goals.

4. Cost Reduction

Our simulation tracks every aspect of the production process—from the cost of individual components to the total cost per production cycle. By understanding how various elements affect overall expenses, managers can make data-driven decisions to optimize spending and achieve a better return on investment. The practical lessons from the simulation help organizations significantly reduce unit costs over time.

5. Continuous Improvement Culture

The debriefing and feedback sessions integrated into the simulation are designed to nurture a culture of continuous improvement (Kaizen). After each session, teams analyze their performance, discuss what worked, identify areas for change, and implement new strategies. This iterative learning process is fundamental to any successful lean course and ensures that your organization remains agile and responsive to change.

For more insights into the benefits of gamification in training environments, additional industry experts have highlighted that integrating game-based elements into professional learning experiences can dramatically enhance motivation and long-term learning retention.

Detailed Walkthrough: How Our Simulation Game Operates

A comprehensive lean course delivered through our simulation game goes beyond theory. The game is engineered to mirror the intricacies of modern production environments, from role assignment to detailed process management. Here’s a detailed walkthrough of how the simulation works:

Stage 1: Setup and Role Distribution

- Workspace Arrangement:

The training area is divided into multiple stations, each representing a different segment of the production line. Workstations are arranged with sufficient space, chairs, and materials like colored blocks. - Material Distribution:

Each station is stocked with the appropriate types and quantities of parts. For instance, station one might have a set number of colored strips and rectangles, while station two features squares or other shapes. The focus is on building products that meet strict quality and structural standards. - Role Allocation:

Participants are assigned roles such as operator, quality controller, planner, warehouse manager, and more. Each participant receives a role description along with a detailed set of responsibilities. The general director’s role is crucial as they oversee the simulation and lead debrief sessions. - Pre-Simulation Briefing:

The facilitator delivers a presentation covering Lean Manufacturing principles, the objectives of the simulation, and an explanation of each role’s duties. This initial briefing establishes clear expectations and prepares participants for the challenges ahead.

Stage 2: Simulation Execution

The simulation is divided into several sessions, each designed to represent a production cycle. In every session:

- Order Initiation: The client (a designated role in the simulation) places an order with specific product demands. Orders are time-sensitive (for example, a 20-second window for delivery), closely replicating real-world pressures.

- Production Activities: Operators begin production by assembling products according to given technological cards. Quality controllers inspect the work, ensuring that every unit meets the required standards.

- Data Capture: Throughout the session, data on production time, quality checks, and costs are meticulously recorded. These metrics provide a clear picture of the process efficiency and serve as the basis for subsequent feedback sessions.

- Issue Identification: Any deviations, such as delays or quality defects, are noted. For example, if the production exceeds the 20-second delivery time, the session is marked as unsuccessful, and the reasons for failure are discussed.

- Feedback Loop: At the end of each session, all participants come together to analyze the results, propose process improvements, and discuss strategies for overcoming identified obstacles. This debrief is pivotal in turning theoretical lean principles into actionable improvements.

It is crucial to complete each simulation session to gain the full benefits of the training.

Stage 3: Post-Simulation Evaluation and Continuous Improvement

After completing all simulation sessions, the collective data is thoroughly analyzed:

- Performance Metrics Analysis:

Customer satisfaction, defect rates, employee productivity, and overall production costs are measured and reviewed. - Strategic Discussions:

The general director leads a brainstorming session to identify systemic issues and potential improvements. Inspired by Kaizen, this collaborative process is the driving force behind long-term operational transformation. - Actionable Insights:

Recommendations from the debrief sessions are consolidated and implemented in real production processes. Thus, the simulation bridges theoretical knowledge and practical application, making it a cornerstone of any effective lean course.

For more on the benefits of simulation-based training, industry experts consistently highlight that immersive, interactive training methods produce superior learning outcomes compared to traditional classroom settings.

The Advantages of Integrating a Lean Course into Your Business

A simulation-based lean course does more than train employees; it transforms production cultures. Let’s explore how this innovative approach benefits your organization:

Streamlining Processes

- Process Visualization:

The game makes invisible inefficiencies visible. Team members learn to detect and eliminate waste from their processes by mapping the entire production chain. - Optimized Workflow:

A hands-on simulation encourages teams to experiment with various strategies until they find the most efficient workflow. This results in faster production times and a significant reduction in overall waste.

Enhancing Product Quality

- Real-Time Quality Control:

Integrated quality checks during the simulation help employees understand the importance of adhering to stringent quality standards. This focus on quality ensures that the final products always meet customer expectations. - Cost Efficiency and Waste Reduction:

By reducing defects and streamlining production, companies can achieve cost savings that boost profit margins. The simulation’s emphasis on continuous improvement means that these benefits compound over time.

Boosting Employee Morale and Collaboration

- Interactive Learning:

The engaging nature of the simulation transforms learning into an enjoyable experience that employees look forward to. This added motivation enhances overall participation and reinforces learning. - Team Cohesion:

The simulation game fosters collaboration where employees are encouraged to collaborate, share ideas, and support each other in solving production problems.

Driving Measurable Business Outcomes

- Tangible ROI: Data from simulation sessions provides clear, actionable insights that can be directly applied to improve business processes. Companies that have adopted this lean course have reported reductions in production downtime, improved delivery times, and enhanced overall operational efficiency. Additionally, obtaining lean certification can further improve these outcomes by validating expertise and ensuring structured pathways for continuous improvement.

- Global Competitiveness: Our simulation tool has helped businesses improve significantly worldwide, with proven success stories from diverse industries. Whether in automotive manufacturing, consumer goods, electronics, or healthcare, the benefits of a simulation-based lean training course are both tangible and transformative.

For further insights into the benefits of gamification, you can explore various case studies online that detail how game-based approaches lead to higher engagement and long-term learning success.

How Our Simulation Game Helps Your Enterprise

Our simulation game is an integrated component of the lean course, designed to help your company overcome production challenges by putting lean theory into practice. Here’s how our tool aids enterprise-wide transformation:

- On-the-Job Training and Real-Time Learning: The simulation replicates everyday production challenges. Employees learn by doing and experience the consequences of inefficiencies. This approach facilitates immediate corrections and long-term learning. Additionally, we offer online courses for continuous learning and improvement.

- Systematic Process Improvement: Every session highlights critical areas for improvement. Teams learn to analyze their workflows, identify bottlenecks, and implement strategies for continuous improvement – all key components of a successful lean transformation.

- Customizable Learning Experience: Our simulation game is adaptable to various industries and company sizes. Whether your organization is small or multinational, this lean course can be tailored to meet your specific needs.

- Empowering Leadership: The general director’s role in the simulation is pivotal. By guiding the team through challenges and leading debrief sessions, leaders gain insights into effective management practices that can be replicated in real-world settings.

- Global Credibility and References: Organizations from different regions and sectors have integrated our simulation game into their continuous improvement programs. These global references attest to the superior effectiveness of this lean training approach.

For those ready to experience the full benefits of our simulation tool, please check our detailed simulation game description for comprehensive information about its features and proven results.

Real-Life Case Studies: Success Stories from Global Enterprises

Our simulation-based lean course has been implemented in numerous companies worldwide, and their success stories speak volumes about its effectiveness:

- Automotive Sector: An international automotive manufacturer integrated the simulation into their training program and noted a 20% reduction in production downtime. The interactive learning environment helped employees quickly identify inefficiencies and implement effective solutions. Additionally, obtaining the sigma certification has further enhanced their quality and productivity, leading to worldwide recognition and better career opportunities.

- Consumer Goods: A major global consumer goods company used our simulation tool to revamp its supply chain. The result significantly boosted product quality and customer satisfaction as teams learned to fine-tune their processes through hands-on experience.

- Electronics: By adopting our simulation-based training, an electronics manufacturer was able to streamline its production process and reduce waste, ultimately cutting production costs by over 15%.

- Healthcare: A leading company in the healthcare sector reported that the simulation improved operational efficiencies and enhanced the skills and confidence of its frontline workers, ensuring consistent delivery of high-quality products.

These case studies emphasize that when organizations invest in a well-structured lean course, they see measurable improvements in efficiency, quality, and cost management.

Implementing a Lean Course: A Step-by-Step Guide

For companies interested in adopting this transformative training method, here is a step-by-step guide to implementing a simulation-based lean course:

Step 1: Preliminary Assessment

- Identify Needs: Conduct an internal assessment to identify current inefficiencies and areas where lean improvements could yield significant benefits. A Six Sigma certification can be crucial in this preliminary assessment to enhance operational efficiency and productivity.

- Consultation: Engage with experts to understand which aspects of Lean Manufacturing are most relevant. Our team provides guidance based on 25 years of industry experience.

Step 2: Customize the Simulation Setup

- Role Assignment: Tailor role descriptions to align with your company’s operational structure.

- Station Setup: Arrange workstations to mirror your production environment. Ensure that each station is stocked with the appropriate components. Integrate Lean Six Sigma principles to enhance efficiency and productivity.

- Briefing Sessions: Conduct pre-simulation briefings where lean principles and session objectives are communicated.

Step 3: Execute the Simulation

- Run Multiple Sessions: Organize several simulation rounds to give employees multiple opportunities to learn and apply lean principles. Each session should end with a thorough debrief. Innovation plays a crucial role in these simulations by integrating advanced technologies to enhance learning and operational excellence.

- Monitor and Record: Use performance metrics to track efficiency, quality, and production costs. This data will guide future improvements.

Step 4: Analyze and Act on Feedback

- Post-Simulation Analysis: Review session data collaboratively. Identify patterns, successes, and areas for improvement. Utilize lean methods to enhance the efficiency and effectiveness of the feedback analysis.

- Implement Changes: Develop an improvement plan and implement the necessary changes. Continuous monitoring ensures that improvements are sustained.

Step 5: Integrate into Daily Operations

- Continuous Learning: Ensure that lean practices learned during the simulation are integrated into daily operations through routine training and follow-up sessions. Gaining lean knowledge through certification is crucial for professionals in various management roles to enhance their career potential in quality management, project management, and business transformation.

- Long-Term Strategy: Embed the culture of continuous improvement within the organization for lasting benefits.

For those interested in taking the next step, consider purchasing our simulation game and experience firsthand how a simulation-based lean course can transform your operations.

The Future of Lean Training and Continuous Improvement

As industries evolve, agile and efficient processes become increasingly essential. A simulation-based lean course offers not only immediate training benefits but also fosters a mindset of continual learning and process optimization. The future of lean training lies in immersive, interactive experiences that empower employees to make informed decisions and drive operational success. This vision for the future of lean training aligns with pursuing manufacturing excellence, where methodologies like Lean Six Sigma and advanced technologies revolutionize industry practices.

Embracing Change Through Simulation

- Dynamic Adjustments: A simulation allows teams to experiment with process modifications and immediately see the effects of those changes. This dynamic approach equips them with the skills to adapt quickly in a rapidly changing market.

- Employee Empowerment: Participating in a simulation, every employee develops a deeper understanding of their role in achieving efficiency. This empowerment translates to faster decision-making and a proactive approach to problem-solving.

- Measurable Outcomes: The performance metrics collected during the simulation provide concrete data to refine processes continually. These quantifiable outcomes are essential for realizing long-term improvements. A certification program can enhance continuous improvement by incorporating various learning resources and encouraging self-improvement.

As companies increasingly turn to simulation-based training methods, they benefit from a clear roadmap for continuous improvement—a hallmark of successful lean transformations.

Special Offer: An Exclusive Bonus When You Invest in a Lean Course

We have a special surprise for every organization that invests in our innovative simulation game as part of their lean course. All buyers will receive an email containing a unique code that provides free access to all the courses available on our website. This bonus enriches your lean training journey by ensuring continuous access to the latest materials and expert insights. Additionally, it includes resources to help you achieve lean certification, a respected credential that validates your expertise in lean principles.

Conclusion

Integrating a simulation-based lean course into your company’s training program is not merely a method of instruction—it is a strategic initiative that transforms your operational processes, boosts employee engagement, and drives measurable improvements in quality and efficiency. Through immersive learning, real-time feedback, and a culture of continuous improvement, our simulation game equips your team to navigate the complexities of Lean Manufacturing successfully.

Drawing on my 25 years of practical experience in implementing Lean Manufacturing and the evolution of our simulation tool, this training method has been proven across global enterprises. After implementing this approach, companies from various industries have reported significant enhancements in production efficiency, waste reduction, and overall operational excellence.

The right lean course is essential for building a robust, agile organization prepared to tackle challenges and seize opportunities in today’s competitive landscape. Our simulation game teaches lean principles and inspires teams to collaborate, innovate continuously, and adopt strategic improvements that drive lasting success. Additionally, acquiring a Lean Six Sigma certification can further enhance your team’s ability to achieve operational excellence by improving efficiency, quality, and productivity.

If you are ready to transform your organization through simulation-based training and experience the tangible benefits of a comprehensive lean course, seize the opportunity today. For more detailed insights into our simulation tool, visit our detailed description of our simulation game. Moreover, take the crucial step toward operational excellence by purchasing our simulation game.

Embrace the future of Lean Manufacturing with our innovative training method and join a growing community of global enterprises that have harnessed the power of simulation to drive continuous improvement.