Lean Games and Simulations: The Best Way to Learn Lean in Action

Introduction to Lean Principles

Lean principles form the foundation for creating efficient, value-driven processes in any organization. At their core, these principles focus on maximizing value for the customer by eliminating waste and streamlining every step of a process. Key lean concepts, such as one-piece flow, standard work, and pull systems, are essential for achieving these goals. By applying these concepts, companies can reduce unnecessary costs, improve process flow, and deliver higher levels of customer satisfaction.

Lean games and simulations are among the best ways to teach and reinforce these principles. They aim to demonstrate the value of Lean concepts and achieve specific learning objectives by providing hands-on experience with process improvement. Through interactive learning, participants gain a deeper understanding of how lean concepts are applied in practice, making it easier to identify and eliminate waste, create value, and optimize processes for both the organization and its customers.

What Are Lean Games and Simulations?

Lean games and simulations are powerful teaching methods that make learning Lean principles practical, interactive, and fun. Unlike traditional lectures, these activities engage participants in hands-on training sessions where they can apply, experiment with, and demonstrate their understanding of lean concepts. These activities are typically done in a group setting, and clear instructions are provided to guide participants through each game or simulation. Whether you’re a team member new to Lean or an experienced practitioner looking to refine your skills, these tools provide a practical method for improving processes and driving customer satisfaction.

In a typical lean game, teams assume roles within a simulated company, collaborating to enhance flow, minimize waste, and fulfill customer needs. They explore concepts like one-piece flow, pull systems, and batch sizes in a collaborative setting. Each session encourages problem-solving, critical thinking, and teamwork, helping learners build real-world skills they can apply immediately. Lean games and simulations are also widely used by consultants to facilitate workshops and training sessions.

If you want to deepen your understanding of Lean, consider joining our Lean Management course—a complete guide to Lean principles, tools, and techniques. These games are suitable for groups of various sizes and training objectives.

Types of Interactive Tools for Lean Learning

Various interactive tools are designed to make lean learning engaging and effective. Lean games, such as the 5S Challenge and the Lean Office Game, offer participants a fun way to experience lean concepts firsthand. These games are ideal for teaching the basics of lean, from organizing the workplace to streamlining office processes.

Simulations, such as the SMED Lean Simulation Kit and the Lean Six Sigma Catapult Kit, offer a more immersive experience. They enable participants to experiment with lean techniques and observe the results in real-time. These simulation tools are often used in training sessions and workshops to help teams gain a practical understanding of complex lean concepts and sigma methodologies.

Workshops and structured training sessions complement the learning experience, providing opportunities for in-depth discussion, hands-on practice, and collaborative problem-solving. By combining games, simulations, and workshops, organizations can create a comprehensive approach to teaching and understanding lean principles.

The Get Lean Simulation Game: A Hands-On Lean Experience

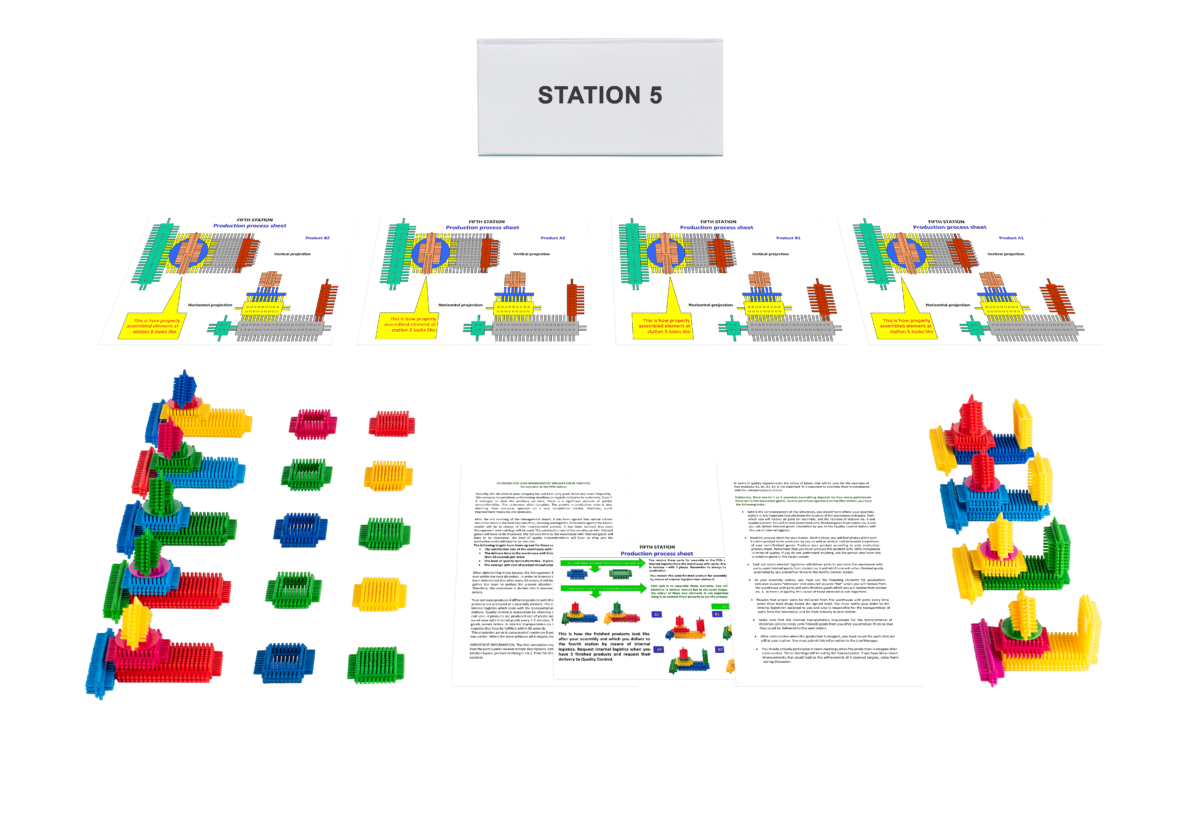

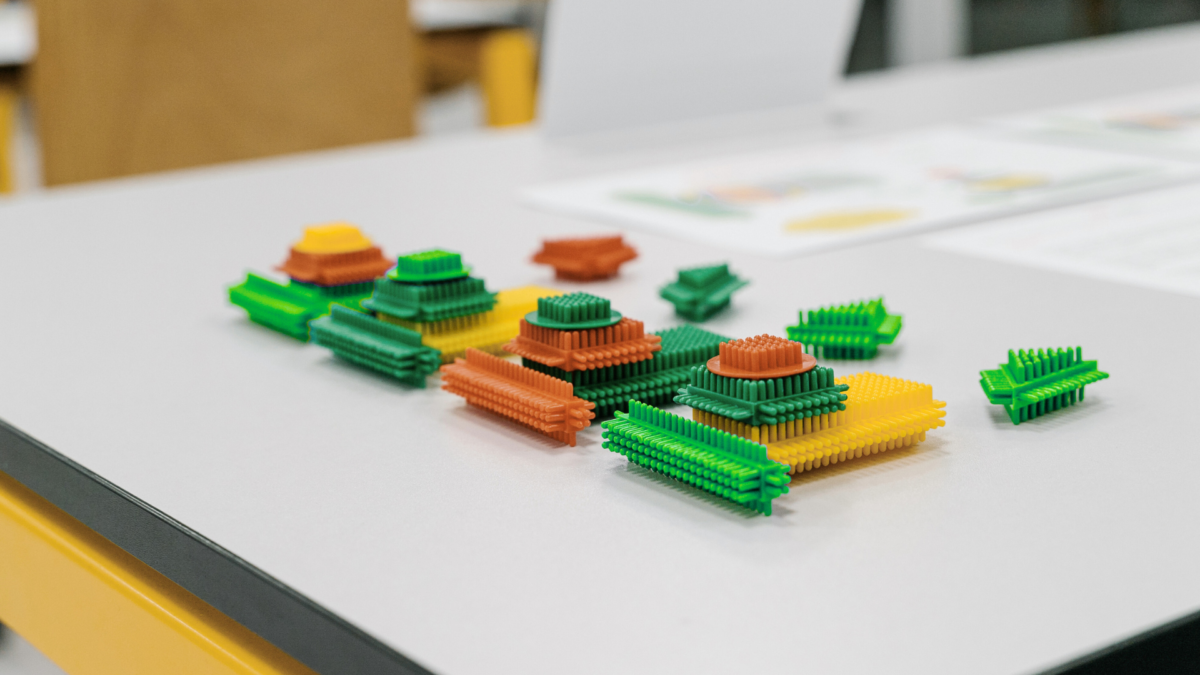

The Get Lean Simulation Game is a Lean simulation designed for practical learning. Developed from 25 years of Lean consulting experience, this game immerses participants in a realistic production environment using hedgehog blocks and various paper materials. Teams are seated around a table to facilitate collaboration, and only the necessary resources for each task are provided, emphasizing the importance of focusing on what is essential. Each team member, such as a middle person or quality checker, ensures a precise distribution of roles. Facilitators simulate to mimic real production environments. The Get Lean Simulation Game offers adaptability to various group sizes and customizable scenarios, enabling tailored experiences and enhanced learning.

Each session is played over multiple rounds, representing 10 customer orders and offering opportunities for improvement. After every round, teams pause to reflect, analyze data, and decide on improvements, just like in real-world Lean workshops. Teams compare their performance data between rounds to identify areas for improvement and track their progress. The game emphasizes standard work, effective communication, and the importance of continuous improvement. Teams plan their next steps using the Plan-Do-Check-Act approach to efficiently trial new ideas. The game also helps participants identify and reduce variation in their processes, reinforcing key Lean concepts through successive rounds of activity.

Understanding One Piece Flow

One-piece flow is a core lean concept transforming how work moves through a process. Instead of producing items in large batches, one-piece flow focuses on driving a single item from start to finish. This approach helps reduce waste, minimize delays, and ensure a smooth, continuous workflow.

Implementing one-piece flow enables organizations to reduce batch sizes, respond promptly to customer needs, and enhance overall customer satisfaction. Lean games and simulations, such as the Paper Airplane Lean Game and the Lean Dice Game, are excellent tools for demonstrating the advantages of one-piece flow. By participating in these games, teams can witness firsthand how one-piece flow reduces waste, enhances process efficiency, and delivers better results for their customers.

Managing Batch Sizes in Lean Simulations

Managing batch sizes is a fundamental aspect of lean games and simulations, as it directly influences the efficiency and flow of any process. In a lean match, participants experiment with different batch sizes—processing items in groups versus one at a time—to see firsthand how these choices impact waste, lead times, and customer satisfaction. By adjusting batch sizes during the simulation, teams quickly learn that smaller batches, or even one-piece flow, often result in less waiting, reduced inventory, and faster response to customer needs.

Through these interactive sessions, participants gain a deeper understanding of how batch sizes impact the entire process. They gain valuable problem-solving skills by analyzing the trade-offs between processing efficiency and inventory costs. Lean games make it easy to visualize how reducing batch sizes can minimize waste and improve flow, helping teams apply these lean concepts in real-world scenarios. Ultimately, mastering batch size management in simulations enables teams to implement lean principles that reduce costs and enhance customer satisfaction.

Benefits of Lean Games and Simulations

Lean games and simulations offer:

- Hands-on experience applying Lean tools and techniques.

- A safe space to experiment, learn, and improve without risks.

- Real-time feedback on decisions made during the game.

- A fun, engaging format that builds teamwork and communication skills.

- The ability to demonstrate the impact of Lean on processes and customer satisfaction.

- A quick way to grasp Lean concepts and see results through fast-paced simulations.

- Opportunities for various departments, including sales teams, to improve their processes and customer interactions.

These activities help teams understand the importance of Lean principles, such as reducing waste, optimizing flow, and aligning operations with customer needs.

Why Lean Games and Simulations Work

- They make Lean easy to understand by breaking down complex concepts into simple, actionable steps.

- Many lean games involve activities where participants draw process maps or diagrams to visualize standard work and identify areas for improvement.

- They promote collaboration and foster a strong sense of shared responsibility among team members.

- These games help ensure that each process step matches customer requirements.

- They allow learners to explore variations, try different techniques, and see how their choices affect overall process performance.

- Games can reveal inefficiencies such as unnecessary crossing of materials or people, and optimizing these can improve flow.

- Kanban systems can be simulated in these games to teach pull-based workflow management.

- Production line concepts are often demonstrated through these simulations.

- Lean games can be adapted for use on-site in construction or manufacturing environments.

- They create an engaging learning environment that encourages active participation.

- Post-game analysis, such as using post-it notes to gather feedback and reflect on learning, is essential for continuous improvement.

- The end of the game is just the beginning of the real learning process, as teams analyze and apply what they’ve learned.

- Lean games and simulations are valuable for organisations of all sizes and industries.

- Universities use lean games as educational tools for students and faculty. A university may offer Lean courses, training programs, or certification, using lean games and simulations to facilitate learning and practical application.

If you’re ready to see Lean in action, sign up for our Effective Problem Solving and Continuous Improvement courses for deeper insights.

Experiential Learning: The Power Behind Lean Games

Experiential learning is at the heart of what makes lean games so effective. Rather than simply reading about lean concepts or listening to lectures, participants are immersed in hands-on activities that bring these ideas to life. By actively engaging in lean games, teams experience the challenges and rewards of reducing waste, improving flow, and solving problems together.

This approach transforms abstract concepts into practical skills. As participants work through each game, they gain an understanding of how lean principles apply to everyday processes. The interactive nature of these games encourages teamwork and communication, allowing everyone to contribute ideas and learn from one another. This deepens their understanding of lean and builds essential skills, such as problem-solving and collaboration, which are vital for driving process improvements and achieving higher levels of customer satisfaction in any organization.

Implementing Lean Games and Simulations

Successfully implementing lean games and simulations starts with thoughtful planning and clear objectives. Begin by identifying your team’s learning goals— such as mastering lean concepts, improving problem-solving skills, or strengthening teamwork. Then, choose a game or simulation that aligns with these objectives and is suitable for your group.

Before the session, the facilitator should clearly explain the rules, objectives, and expected outcomes to all participants. During the game, the facilitator must observe, guide, and provide feedback to ensure that everyone stays engaged and on track. After the simulation, hold a debriefing session to review what was learned, discuss any challenges that arose, and explore how the lessons can be applied to real-world processes. This structured approach to implementing lean games and simulations ensures that participants gain a meaningful understanding of lean while fostering teamwork and continuous learning.

Real-World Applications: Lean Games in Action

Lean games and simulations are not just training tools—they have a tangible impact in the real world across various industries. Companies use lean games to demonstrate key lean concepts, such as standard work, pull systems, and one-piece flow, helping teams understand how these principles can be applied to improve efficiency and reduce waste. For example, a manufacturing team might use a lean game to simulate a production line, discovering how one-piece flow can speed delivery and enhance customer satisfaction.

In healthcare, simulations can teach staff the importance of teamwork, communication, and problem-solving in delivering high-quality patient care. Service organizations utilize lean games to streamline processes, reduce costs, and enhance customer satisfaction. By applying the lessons learned from these games, companies can foster a culture of continuous improvement, resulting in measurable gains in productivity, quality, and customer value. The versatility of lean games makes them a powerful method for demonstrating and embedding lean concepts in any organization.

Best Practices for Lean Games

Following a few best practices is essential to maximizing the impact of lean games and simulations. First, choose games and simulations that are relevant to your participants’ roles and challenges. Each game should have clear learning objectives, such as understanding lean concepts, improving problem-solving skills, or building teamwork skills.

An experienced facilitator is crucial in guiding participants through the simulation, addressing questions, and ensuring everyone remains engaged. After the game, hold a debriefing session to review what was learned, discuss how the concepts apply to real processes, and identify areas for improvement. By following these best practices, organizations can ensure that their lean games and simulations are effective teaching tools that drive real understanding and skill development.

Overcoming Challenges in Lean Game-Based Learning

While lean games and simulations offer powerful learning opportunities, they can also present challenges that must be addressed for maximum effectiveness. One common hurdle is resistance to change—some participants may be skeptical about new approaches or unsure how the game relates to their daily work. Facilitators can overcome this by clearly explaining the relevance of the simulation and encouraging open discussion about its real-world applications.

Another challenge is ensuring that all participants understand the game’s objectives and rules. Clear instructions and ongoing feedback help keep everyone engaged and focused on the learning process. Technical issues, such as equipment malfunctions or unexpected disruptions, can also arise, so it’s essential to have a backup plan and remain flexible. By proactively addressing these challenges, organizations can create a supportive environment where participants feel comfortable experimenting, learning, and applying lean concepts to drive real process improvements.

Measuring Success in Lean Game-Based Learning

Evaluating the effectiveness of lean game-based learning is crucial for continuous improvement. Success can be measured in several ways, including participant engagement, knowledge retention, and the practical application of lean concepts in the workplace. Surveys and feedback forms help gauge how well participants understood the concepts and how engaged they were during the game.

Observing changes in workplace processes, tracking performance metrics such as cycle time and lead time, and monitoring customer satisfaction can all provide valuable insights into the impact of lean game-based learning. By regularly reviewing these metrics, organizations can refine their training sessions, ensure that learning objectives are met, and maximize the value delivered to both the team and the customer.

Final Thoughts

Lean games and simulations are more than just activities—they are the best way to learn, teach, and implement Lean in any organization. They help teams build problem-solving skills, improve communication, and align their actions with Lean principles.

Explore the Get Lean Simulation Game to experience Lean learning in a practical, team-based format.

Special Offer

When you purchase the Get Lean Simulation Game, you’ll receive a unique code via email that grants you free access to all of Sabat Consulting’s Lean training courses, including:

- Lean Management course

- Effective Problem-Solving Course

- Continuous Improvement course

- Effective Teamwork and Leadership course

- 5S Workplace Organization course

This is an exceptional opportunity to expand your knowledge of Lean and acquire practical skills across various Lean topics.

Ready to get started? Explore the Get Lean Simulation Game today and unlock the full suite of Lean training resources to take your team’s Lean learning to the next level!